UGIMA 4305HM - Ugitech

UGIMA 4305HM - Ugitech

UGIMA 4305HM - Ugitech

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

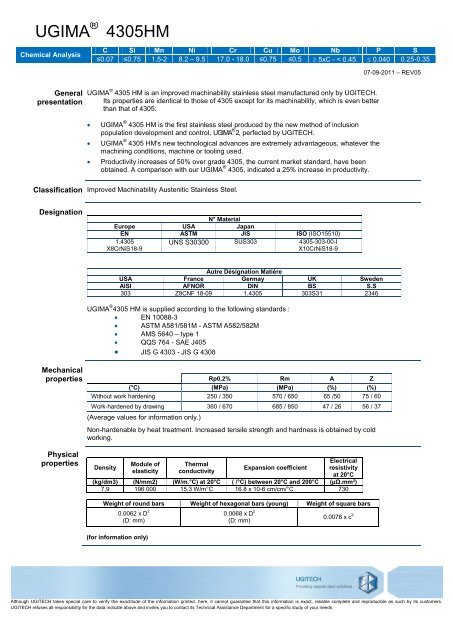

<strong>UGIMA</strong> ® <strong>4305HM</strong><br />

Chemical Analysis<br />

General<br />

presentation<br />

C Si Mn Ni Cr Cu Mo Nb P S<br />

≤0.07 ≤0.75 1,5-2 8.2 – 9.5 17.0 - 18.0 ≤0.75 ≤0,5 5xC - < 0.45. 0.040 0.25-0.35<br />

<strong>UGIMA</strong> ® 4305 HM is an improved machinability stainless steel manufactured only by UGITECH.<br />

Its properties are identical to those of 4305 except for its machinability, which is even better<br />

than that of 4305:<br />

<strong>UGIMA</strong> ® 4305 HM is the first stainless steel produced by the new method of inclusion<br />

population development and control, <strong>UGIMA</strong> ® 2, perfected by UGITECH.<br />

<strong>UGIMA</strong> ® 4305 HM's new technological advances are extremely advantageous, whatever the<br />

machining conditions, machine or tooling used.<br />

Productivity increases of 50% over grade 4305, the current market standard, have been<br />

obtained. A comparison with our <strong>UGIMA</strong> ® 4305, indicated a 25% increase in productivity.<br />

Classification Improved Machinability Austenitic Stainless Steel.<br />

Designation<br />

Mechanical<br />

properties<br />

Physical<br />

properties<br />

N° Material<br />

Europe USA Japan<br />

EN ASTM JIS ISO (ISO15510)<br />

1.4305<br />

X8CrNiS18-9<br />

UNS S30300 SUS303 4305-303-00-I<br />

X10CrNiS18-9<br />

Autre Désignation Matière<br />

USA France Germay UK Sweden<br />

AISI AFNOR DIN BS S.S<br />

303 Z8CNF 18-09 1.4305 303S31 2346<br />

<strong>UGIMA</strong> ® 4305 HM is supplied according to the following standards :<br />

EN 10088-3<br />

ASTM A581/581M - ASTM A582/582M<br />

AMS 5640 – type 1<br />

QQS 764 - SAE J405<br />

JIS G 4303 - JIS G 4308<br />

Rp0,2% Rm A Z<br />

(°C) (MPa) (MPa) (%) (%)<br />

Without work hardening 250 / 350 570 / 650 65 /50 75 / 60<br />

Work-hardened by drawing 360 / 670 685 / 850 47 / 26 56 / 37<br />

(Average values for information only.)<br />

Non-hardenable by heat treatment. Increased tensile strength and hardness is obtained by cold<br />

working.<br />

Density<br />

Module of<br />

elasticity<br />

Thermal<br />

conductivity<br />

Expansion coefficient<br />

Electrical<br />

resistivity<br />

at 20°C<br />

(kg/dm3) (N/mm2) (W/m.°C) at 20°C ( /°C) between 20°C and 200°C (µΩ.mm²)<br />

7,9 196 000 15.3 W/m°C 16.8 x 10-6 cm/cm/°C 730<br />

Weight of round bars Weight of hexagonal bars (young) Weight of square bars<br />

0.0062 x D 2<br />

(D: mm)<br />

(for information only)<br />

0.0068 x D 2<br />

(D: mm)<br />

0.0078 x c 2<br />

07-09-2011 – REV05<br />

Although UGITECH takes special care to verify the exactitude of the information printed. here, it cannot guarantee that this information is exact, reliable complete and reproducible as such by its customers.<br />

UGITECH refuses all responsibility for the data indicate above and invites you to contact its Technical Assistance Department for a specific study of your needs.

<strong>UGIMA</strong> ® <strong>4305HM</strong><br />

Chemical Analysis<br />

Magnetic<br />

properties<br />

Corrosion<br />

resistance<br />

Avenue Paul Girod<br />

73403 UGINE Cedex - France<br />

www.ugitech.com<br />

C Si Mn Ni Cr Cu Mo Nb P S<br />

≤0.07 ≤0.75 1,5-2 8.2 – 9.5 17.0 - 18.0 ≤0.75 ≤0,5 5xC - < 0.45. 0.040 0.25-0.35<br />

Non-magnetic in annealed condition.<br />

Slight magnetism is produced by cold-working operations.<br />

environment behaviour<br />

Nitric acid Good<br />

Phosphoric acid Average<br />

Sulphuric acid Average<br />

Acetic acid Average<br />

Sodium carbonate Average<br />

NaCl (Saline mist) Average<br />

Humidity Good<br />

Sea water Restricted use<br />

07-09-2011 – REV05<br />

<strong>UGIMA</strong> ® 4305 HM has excellent ability to withstand corrosion in many environments. Its corrosion resistance<br />

is typical of an austenitic steel and is similar to that of the 4305 / 303 in every respect.<br />

The use of <strong>UGIMA</strong> ® 4305 HM is compatible with all the fluids, lubricants, oils and greases used in the<br />

machining industry.<br />

However, <strong>UGIMA</strong> ® 4305 HM is not recommended for use in marine environments and highly<br />

oxidising chemical environments.<br />

In addition, as with all resulphurised steels, special care must be taken when using <strong>UGIMA</strong> ® 4305<br />

HM in acid or chloride environments that are liable to pitting and crevice corrosion, it should not be used<br />

where components are shaped in such a way as to have areas where corrosive products might collect and<br />

corrode.<br />

Optimum corrosion resistance is obtained where a surface is free from all traces of machining oil or<br />

foreign particles (of iron for example).<br />

<strong>UGIMA</strong> ® 4305 HM is pickled in the same way as 304 grade steel.<br />

Decontamination of steels with a high sulphur content is not recommended owing to the complexity and cost<br />

of this operation; however, if it is necessary, the recommended decontamination / passivation process is as<br />

follows:<br />

1 volume 52% nitric acid (36° Baumé)<br />

1 volume water<br />

ambient temperature<br />

short duration<br />

wash carefully when the process is completed<br />

The corrosion resistance of a stainless steel depends on many factors related to the composition of<br />

the corrosive atmosphere (chloride concentration, presence or absence of oxidising agents, temperature, pH,<br />

agitation or no agitation, and so on), as well as to the preparation of the material (surfaces free from metal<br />

particles, surface finish, such as hardening, polishing, and so on). Precautionary measures should be taken<br />

for certain tests such as the saline mist test (French standard NFX 41002): for example marking labels (that<br />

might cause corrosion run-outs and reduce the test resistance time) should not be used on the sample.<br />

Although UGITECH takes special care to verify the exactitude of the information printed. here, it cannot guarantee that this information is exact, reliable complete and reproducible as such by its customers.<br />

UGITECH refuses all responsibility for the data indicate above and invites you to contact its Technical Assistance Department for a specific study of your needs.<br />

2

<strong>UGIMA</strong> ® <strong>4305HM</strong><br />

Chemical Analysis<br />

Avenue Paul Girod<br />

73403 UGINE Cedex - France<br />

www.ugitech.com<br />

C Si Mn Ni Cr Cu Mo Nb P S<br />

≤0.07 ≤0.75 1,5-2 8.2 – 9.5 17.0 - 18.0 ≤0.75 ≤0,5 5xC - < 0.45. 0.040 0.25-0.35<br />

Machinability The performance of <strong>UGIMA</strong> ® 4305 HM in machining is exceptionally good as a result of the<br />

optimisation of the inclusion population. This is true for very high speeds and severe cutting<br />

conditions, as a result of the <strong>UGIMA</strong> ® process, but also for low speeds and less severe cutting<br />

conditions, because of the new improvements achieved through this latest development. <strong>UGIMA</strong> ®<br />

4305 HM is therefore particularly appropriate for screw machining, as its improved machinability is<br />

effective through an extensive range of cutting conditions and machining operations. Its<br />

performance is based on extremely good chip breakability, extended tool life and excellent surface<br />

finish.<br />

If you would like to use the grade to best advantage for your components and working<br />

environment, contact our Technical Service.<br />

Welding Like all stainless steels with a high sulphur content, <strong>UGIMA</strong> ® 4305 HM is very difficult to weld, due<br />

to the almost inevitable phenomenon of thermal weld cracking. This is particularly true in the case<br />

of welding without the use of filler material.<br />

If a weld is required, it is recommended that ER312 welding wire be used as the filler metal to<br />

minimise thermal cracking problems. Heat treatment must not be performed after welding with<br />

ER312 wire.<br />

Heat treatment The annealing treatment that gives <strong>UGIMA</strong> ® 4305 HM its lowest properties includes heating to<br />

1000 - 1100°C, followed by rapid air or water cooling.<br />

In this case, the properties obtained will be:<br />

Products<br />

available<br />

Rm 575 - 650 Mpa<br />

> 250/350 Mpa<br />

Rp 0.2<br />

A% > 65/50<br />

Forging<br />

The forging of <strong>UGIMA</strong> ® 4305 HM is not recommended. However, if this operation is indispensable,<br />

the material should be heated to 1175 - 1205° C, and the work should be finished at a<br />

temperature higher than 955°C<br />

Produit Forme Finition Tolérance<br />

Bars Rolled 13<br />

Bars Descaled 13<br />

Turned bars 6 to 11<br />

Ground bars 6 to 11<br />

Other presentations: please consult us<br />

07-09-2011 – REV05<br />

Although UGITECH takes special care to verify the exactitude of the information printed. here, it cannot guarantee that this information is exact, reliable complete and reproducible as such by its customers.<br />

UGITECH refuses all responsibility for the data indicate above and invites you to contact its Technical Assistance Department for a specific study of your needs.<br />

3