UGIMA® 4307 HM / UGIMA® 304L XL - Ugitech

UGIMA® 4307 HM / UGIMA® 304L XL - Ugitech

UGIMA® 4307 HM / UGIMA® 304L XL - Ugitech

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

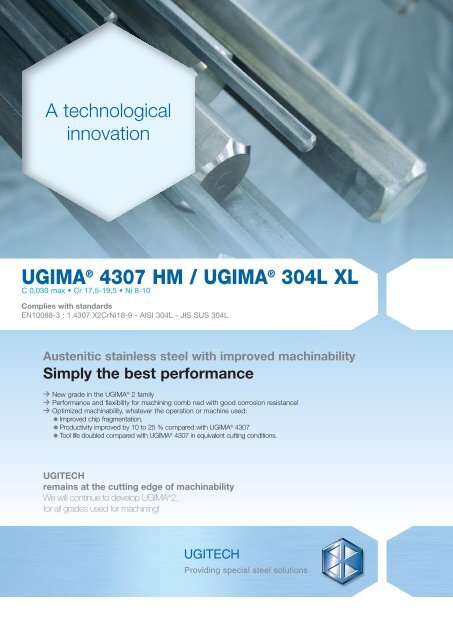

A technological<br />

innovation<br />

UGIMA ® <strong>4307</strong> <strong>HM</strong> / UGIMA ® <strong>304L</strong> <strong>XL</strong><br />

C 0,030 max • Cr 17,5-19,5 • Ni 8-10<br />

Complies with standards<br />

EN10088-3 : 1.<strong>4307</strong> X2CrNi18-9 - AISI <strong>304L</strong> - JIS SUS <strong>304L</strong><br />

Austenitic stainless steel with improved machinability<br />

Simply the best performance<br />

> New grade in the UGIMA ® 2 family<br />

> Performance and flexibility for machining comb ned with good corrosion resistance!<br />

> Optimized machinability, whatever the operation or machine used:<br />

Improved chip fragmentation,<br />

Productivity improved by 10 to 25 % compared with UGIMA ® <strong>4307</strong><br />

Tool life doubled compared with UGIMA ® <strong>4307</strong> in equivalent cutting conditions.<br />

UGITECH<br />

remains at the cutting edge of machinability<br />

We will continue to develop UGIMA ® 2,<br />

for all grades used for machining!

Turning<br />

Chip flow (cm 3 /mm)<br />

360<br />

350<br />

340<br />

330<br />

320<br />

310<br />

300<br />

290<br />

280<br />

UGIMA ® <strong>4307</strong><br />

UGITECH<br />

Avenue Paul Girod<br />

73403 UGINE Cedex<br />

FRANCE<br />

Tel. +33 (0)4 79 89 30 30<br />

Fax: +33 (0)4 79 89 34 34<br />

www.ugitech.com<br />

GB_Fiche format A4 recto verso adresse au verso<br />

UGIMA ® <strong>4307</strong> <strong>HM</strong><br />

UGIMA ® <strong>304L</strong> <strong>XL</strong><br />

For a series of 10,000 parts of the type below, the improved productivity saves<br />

1.05 € per part, i.e. 10,500 € in total.<br />

UGIMA ® <strong>4307</strong><strong>HM</strong><br />

Productivity increase calculation method<br />

Diameter (mm) 40<br />

Component length (mm) 25<br />

Material weight (kg/m) 9,865<br />

Material weight per component (g) 247<br />

Hourly machine cost (€/hr) 40<br />

No. of components per production run 10000<br />

Drilling<br />

HSS ø4 mm<br />

Chip flow (cm 3 /mm)<br />

2<br />

1,8<br />

1,6<br />

1,4<br />

1,2<br />

1<br />

0,8<br />

0,6<br />

0,4<br />

0,2<br />

0<br />

UGIMA ® <strong>4307</strong> UGIMA ® <strong>4307</strong><strong>HM</strong><br />

Productivity* (components per production run) 9 11,8<br />

Machining cost (€/component) 4,44 3,39<br />

Machining increase per component (€) 1.05**<br />

Production run increase (€) 10500<br />

Material cost per component (€) 0,37**<br />

*with 83% efficiency<br />

**Nota Bene : In this example, the productivity saving<br />

is higher than the material cost<br />

UGIMA ® <strong>4307</strong><br />

UGIMA ® <strong>4307</strong><strong>HM</strong><br />

13<br />

Imprimeurs : Dumas & Titoulet - www.thuria.com - Photo credits : <strong>Ugitech</strong> - Non-contractual document 01/2009 - D7595