SAIA-BURGESS-PRODUKTÜBERSICHT - Wagner GmbH

SAIA-BURGESS-PRODUKTÜBERSICHT - Wagner GmbH

SAIA-BURGESS-PRODUKTÜBERSICHT - Wagner GmbH

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

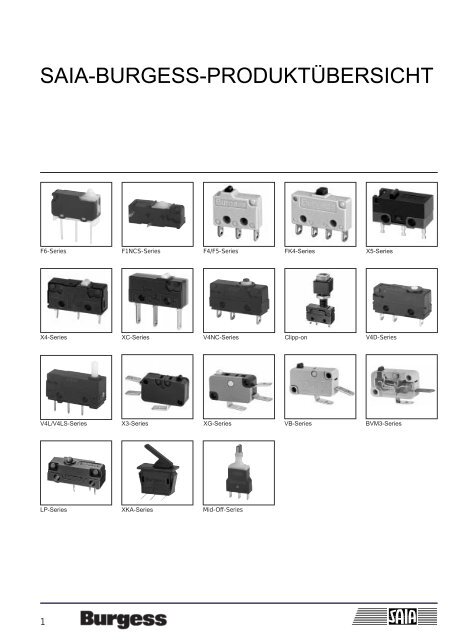

<strong>SAIA</strong>-<strong>BURGESS</strong>-<strong>PRODUKTÜBERSICHT</strong><br />

F6-Series F1NCS-Series F4/F5-Series<br />

X4-Series<br />

V4L/V4LS-Series<br />

1<br />

XC-Series<br />

X3-Series<br />

LP-Series XKA-Series<br />

V4NC-Series Clipp-on V4D-Series<br />

XG-Series VB-Series<br />

Mid-Off-Series<br />

FK4-Series X5-Series<br />

BVM3-Series

Terminology<br />

OPERATING CHARACTERISTICS<br />

Free Position<br />

the position of the actuator when no external<br />

force is applied.<br />

Pretravel<br />

movement of the switch actuator between<br />

free and operating position.<br />

Operating Position<br />

the position of the actuator when contact<br />

changeover takes place.<br />

Release Position<br />

the position of the actuator when the switch<br />

mechanism resets.<br />

Movement Differential<br />

the distance between operating and release<br />

position.<br />

Overtravel<br />

movement of the switch actuator beyond the<br />

operating position.<br />

Total Travel<br />

the sum of pre-travel and overtravel.<br />

Actuating Force<br />

the force required to move the actuator from<br />

the free to the operating position.<br />

Release Force<br />

the value to which the applied force must be<br />

reduced to allow the mechanism to reset after<br />

operation<br />

Force Differential<br />

The difference between the values of actuating<br />

and release forces.<br />

Please see drawings on this page.<br />

2<br />

Force required to operate actuator or auxiliary actuator<br />

Maximum Force<br />

Actuating Force<br />

Force<br />

Differential<br />

Release<br />

Force<br />

Free Position<br />

Post-release travel<br />

Position of actuator or auxiliary actuator<br />

Description of switch positions and micro switch forces<br />

Actuator or<br />

auxiliary actuator<br />

Guide<br />

Pretravel<br />

Operating Position<br />

Release Position<br />

Free position Operating Position<br />

Operation of actuator or auxiliary actuator<br />

Movement<br />

Differential<br />

Pretravel Overtravel<br />

Overtravel<br />

Total Travel<br />

Release Travel<br />

Movement<br />

Differential<br />

Release Travel<br />

Final Position<br />

Post-release<br />

Travel<br />

Final position Release Force<br />

Total Travel

SWITCH TECHNOLOGY<br />

TECHNICAL TERMS<br />

Butt Contacts<br />

Contacts which make at one point and maintain<br />

their initial relationship without further<br />

movement until they are opened.<br />

Wiping Contact<br />

A moving contact mechanically arranged to<br />

slide across the fixed contact during pretravel<br />

and overtravel.<br />

Clearance Distance<br />

The distance in air between current carrying<br />

parts of opposite polarity or between any current<br />

carrying part and an earthed (grounded)<br />

metal plate to which the switch is attached.<br />

Creepage Distance<br />

The path along the surface of insulating material<br />

between current carrying parts of opposite<br />

polarity or between any current carrying part<br />

and an earthed (grounded) metal plate to<br />

which the switch is attached.<br />

Insulation Resistance<br />

Resistance as measured between the<br />

normally-open and normally-closed terminals,<br />

3<br />

or between all terminals connected together<br />

and a metal plate to which the switch is<br />

mounted. In dry condition the value would be<br />

expected to be greater than 5000 megohms.<br />

Single Throw<br />

A switch which provides an ON-OFF or OFF-<br />

ON function but does not change over from<br />

one conductor to another. Such switches are<br />

usualIy referred to as being «normalIy-closed<br />

only» or «normally-open only». C2 signifies<br />

«Normally-closed only»; C4 signifies «normally-open<br />

only».<br />

Switching Cycle<br />

One complete switching operation, from free<br />

position into overtravel and back through<br />

release position to free position. Mechanical<br />

life estimates reflect the number of switching<br />

cycles expected to be accomplished before<br />

operating characteristics become impaired.<br />

Switch Resistance<br />

The total resistance offered by a switch in<br />

a circuit, as measured from terminal, through<br />

mating contacts, to terminal.<br />

Transit Time<br />

The time taken by the moving contact in<br />

snap-action switch mechanism to move from<br />

one stable position to another.<br />

ELECTRICAL RATINGS<br />

Recommended maximum electrical ratings<br />

are quoted for each product group.<br />

These ratings are based on the results of controlled,<br />

accelerated, laboratory-type tests and<br />

are regarded as safe working maxima for<br />

most applications.<br />

The performance of switches is, however, influenced<br />

by conditions pertaining on site e.g.<br />

frequency of operation, type of load, amount<br />

of actuator travel used, temperature and humidity,<br />

etc.<br />

The characteristics of micro switches rely<br />

upon mechanisms having small contact<br />

separation. Because of this, it is always<br />

desirable to check on the arcing potential of<br />

your circuit and to suppress those elements<br />

which could cause excessive arcing.<br />

SWITCH LIFE<br />

The electrical life of a switch is dependent<br />

upon frequency of operation, the on-off ratio<br />

of operation, the nature of the load, arc suppression<br />

and other circuit details, the amount<br />

of actuator travel used, ambient humidity and<br />

temperature and many other site factors, none<br />

of which is within the switch manufacturers<br />

competence to control. Electrical life test information<br />

relates to laboratory controlled<br />

tests.<br />

Individual assessments, for specific applications<br />

where all relevant data is available, are<br />

possible and can be undertaken by <strong>SAIA</strong>-<br />

Burgess Electronics upon request.<br />

For details of the mechanical life of individual<br />

switches, please refer to the appropriate<br />

specification sheet.

APPLICATION TECHNOLOGY<br />

Shock and Vibration<br />

If switches are likely to be subjected to shock<br />

or vibration, select models with the highest<br />

available actuating force. Switches in this<br />

Catalogue possess low mass mechanisms<br />

which are inherently resistant to shock and<br />

vibration.<br />

If practicable, the switches should be<br />

mounted in such a position that the line of<br />

acceleration is at right angles to the travel of<br />

the plunger. The maximum available overtravel<br />

should be used.<br />

Capacitive Loads<br />

These can generate very high inrush peaks<br />

and care should therefore be exercised to<br />

avoid contact welding.<br />

Direct Current<br />

Direct Current (DC) ratings are provided for<br />

each product group listed in this Catalogue.<br />

The values stated should not be exceeded if<br />

destructive arcing and contact welding are to<br />

be avoided.<br />

Some form of arc suppression is recommended<br />

when switches are used in DC circuits<br />

containing inductive devices wired in series<br />

with the switch and the supply. Five common<br />

arc suppression circuits which may be used to<br />

alleviate the effects of arcing on the switch<br />

contacts are shown here. The values of the<br />

components used depend on circuit<br />

conditions.<br />

4<br />

Inductive Loads<br />

Electrical Ratings Tables included in this<br />

Catalogue provide data for switches used to<br />

control inductive circuits at a power factor of<br />

0.5<br />

Lamp Loads<br />

Because of the very high inrush currents<br />

associated with incandescent lamps, applications<br />

should be subject to individual assessment.<br />

Logic Circuits<br />

To provide reliable switching, the use of gold<br />

plated contacts is recommended. Three types<br />

of construction are used:<br />

AU: signifies gold plating on nickel underlay<br />

GP: indicates gold-plated silver contacts<br />

GPX: relates to gold-plated cross point<br />

contacts<br />

Installation recommendations<br />

The following notes are intended merely to<br />

stress the most important and general<br />

aspects of good switch installation procedure<br />

and to provide some helpful additional information.<br />

Safety Considerations<br />

Installation should only be carried out by competent<br />

personnel.<br />

Position and Operation<br />

Operating position is the significant factor to<br />

consider when positioning any snap-action<br />

switch. The actuating medium must be able to<br />

operate the switch through this position into<br />

overtravel and then to retract far enough to<br />

allow the switch to regain its free position.<br />

Mounting<br />

Side mounting switches should be mounted<br />

on smooth, firm, flat surfaces using the recommended<br />

size of screw. Avoid over-tightening<br />

the screws. For added security, they<br />

should be locked using epoxy resin. Do not<br />

attempt to enlarge switch mounting holes and<br />

avoid over stressing the switch. Use insulating<br />

material between switch and metallic plates to<br />

increase clearance on switches with open<br />

terminals.<br />

Mounting holes and Screw sizes<br />

Nominal hole Metric Unified Thread<br />

Diameter Screw Screw<br />

(mm) (in)<br />

2.25 0.09 M 2 #2<br />

2.9 0.11 M 2.5 #4<br />

Mounting-Screw Torque<br />

The following provides guidance when using<br />

mild steel screws<br />

M 2 or # 2 screws 0.12 Nm<br />

M 2.5, M3 or # 4 screws 0.5 Nm<br />

Connections<br />

When soldering, avoid over-heating any part<br />

of the switch insulation. In certain circumstances,<br />

it may be advisable to use a heat shunt.<br />

For optimum mechanical strength, the conductor<br />

should be wrapped round the tip of the<br />

terminal taking care to avoid loose strands of<br />

wire. The soldering iron bit should be applied<br />

to the end of the terminal while simultaneously<br />

applying solder. Remove the iron as soon as<br />

the solder has wetted the conductor and terminal<br />

end. A soldering iron bit temperature of<br />

370°C applied for a maximum of 2-3 seconds<br />

should be adequate.

CONTACT MATERIALS<br />

Gold<br />

Gold plated contacts are recommended for<br />

switches to be used in low voltage control or<br />

logic circuits, especially when long periods of<br />

inactivity are envisaged. Gold flash, a thinner<br />

deposit, is applied to certain switch terminals<br />

to ensure good solderability even after prolonged<br />

storage.<br />

How to determine the contact material<br />

for <strong>SAIA</strong> XG/XC-series only<br />

The selection of the appropriate contact<br />

material will depend on a number of factors:<br />

• current and voltage<br />

• resistive or inductive load<br />

• inrush current peak<br />

• frequency of switching operations<br />

• atmospheric conditions<br />

• required switching reliability<br />

Pure silver contacts (standard)<br />

<strong>SAIA</strong>-Burgess Snap-Action Switches are<br />

normally equipped with pure silver contacts<br />

(Ag999). These are suitable for most<br />

applications and have satisfactory electrical<br />

and thermal properties.<br />

Gold-plated contacts<br />

Gold-plated contacts (4 µm) are used for low<br />

currents of a few mA and voltages below<br />

about 20 V (for DC and AC) and for<br />

sulphurous atmospheres. They are unsuitable<br />

for higher breaking capacities.<br />

5<br />

Silver-cadmium oxide contacts<br />

Silver-cadmium oxide (AgCdO 90/10) contacts<br />

should be used where high inrush current<br />

peaks (30A or more) are switched on as they<br />

tend to weld less at high current loads. They<br />

can resist peaks of 80A or more for several<br />

ms provided that they are used with a <strong>SAIA</strong>-<br />

Burgess Snap-Action Switch with high operating<br />

and contact force (80cN in the free<br />

position and total-travel position).<br />

At high breaking capacities, switches fitted<br />

with such contacts have about 50% longer life<br />

expectancy than those fitted with pure silver<br />

contacts. Normally, silver-cadmium oxide<br />

contacts are not suitable for voltages under<br />

50V.

SERVICE RECOMMENDATIONS<br />

Maintenance<br />

<strong>SAIA</strong>-Burgess switches are not usermaintainable<br />

but they should be kept in a<br />

reasonably clean, paint-free condition,<br />

especially in the actuator area. Regular<br />

checks should be made on mounting security<br />

and on the actuating medium to switch<br />

actuator relationship.<br />

Switch Life<br />

The effective life of any switch will depend<br />

upon the model selected, the number and<br />

frequency of operations, circuit conditions<br />

and the severity of the environment. Switch<br />

replacement should be a matter of routine.<br />

6<br />

SWITCH ACTUATION<br />

Simple actuating plunger<br />

Actuating plungers should be operated in the<br />

direction of their axis. The plungers of the<br />

switch series may also be actuated laterally<br />

by cams at a recommendet maximum angle<br />

of 30°.<br />

Actuation by sliding cams.<br />

max. 30º<br />

Actuating levers<br />

All types of Iever (straight, roller, cam-follower)<br />

fitted to <strong>SAIA</strong>-Burgess Snap-Action Switches<br />

are made of stainless steel. Cam-follower<br />

levers are particularly well suited for use with<br />

plastic actuating cams.<br />

If roller or cam-follower levers are approached<br />

in the reverse direction, care must be taken<br />

to ensure that the angle of approach is small<br />

enough not to jam the lever.<br />

Actuation by cams<br />

Abrupt actuation or release of levers shortens<br />

life of the switches.<br />

For this reason cams should preferably provide<br />

a continuous movement. Ideally they<br />

should be of cycloidal form.<br />

,<br />

Long roller lever with continuous actuation.

HEALTH AND SAFETY<br />

<strong>SAIA</strong>-Burgess Electronics have ensured, so<br />

far as it is reasonably practicable, that their<br />

products as described in this Catalogue or in<br />

other current Company publications, or as<br />

specified on Company Installation Drawings,<br />

have been so designed and constructed as to<br />

be safe and without risk to health when<br />

installed by suitably qualified personnel in<br />

accordance with relevant legislation, codes of<br />

practice, regulations (including IEE Wiring<br />

Regulations), the installation recommendations<br />

offered by the Company and the<br />

accepted rules of the art. Their usage should<br />

be confined within the ratings, limitations and<br />

parameters of application indicated in this<br />

Catalogue and elsewhere.<br />

<strong>SAIA</strong>-Burgess Electronics or their<br />

representatives are available at all times to<br />

provide further information and guidance.<br />

7<br />

ENVIRONMENTAL PROTECTION<br />

Protection Classifications<br />

The catalogued range of <strong>SAIA</strong>-Burgess<br />

switches is covered by just four codes.<br />

IP40<br />

(no corresponding NEMA type)<br />

Adequate protection against solids such as<br />

probing fingers and small wires. Liquids, however,<br />

can gain access and, unless externally<br />

protected, the switches should be mounted in<br />

dry or well-sheltered positions.<br />

IP54K<br />

(corresponding generally with NEMA type 4)<br />

Good protection against solid foreign bodies<br />

and liquid spray of an intensity which could be<br />

expected to be emitted from a watering can.<br />

The spray may come from any angle. Switches<br />

may be used out of doors if sheltered<br />

from the worst of the elements or on factory<br />

machines subjected to normal washing down<br />

procedures.<br />

IP6K5<br />

(corresponding generally with NEMA type 13)<br />

Complete protection against solids, including<br />

dust, and against liquid splashing of the<br />

severity to be expected if the switch was<br />

turned round and round under a cold water<br />

tap. This IP code is nominated in DIN<br />

specifications for limit switches.<br />

IP6K7<br />

(corresponding generally with NEMA type 6)<br />

Similar protection to IP65 but this code is<br />

reserved for switches which are factory sealed<br />

and pressure tested.<br />

Switches should not be immersed in any<br />

liquid.<br />

Working Temperatures<br />

For details of the working temperatures applicable<br />

to individual types, refer to the appropriate<br />

specification sheet. Special versions suitable<br />

for temperatures outside these ranges<br />

are possible. Details from <strong>SAIA</strong>-Burgess<br />

Electronics on request.<br />

All quoted temperatures assume stable<br />

operation. They do not imply an ability to<br />

withstand excessive cycling within the range.<br />

APPROVALS<br />

<strong>SAIA</strong>-Burgess Electronics is listed in the BSI<br />

Register of Firms of Assessed Capability<br />

(Registration No. FM/09808) in accordance<br />

with:<br />

BS EN ISO 9001-1994.

F6-Series<br />

8<br />

F6<br />

7.35 (.29)<br />

14.7 (.57)<br />

12.7 (.58)<br />

5.8<br />

(.23)<br />

R1<br />

6.85 (2.7) 8.9 (.35)<br />

A<br />

B<br />

5.4<br />

(2.1)<br />

A = Operating position10.8 mm (.425 in)<br />

B = Free position 11.3 mm (.445 in)<br />

Datum for free position and operating position is button edge of base (stand-off’s).<br />

Switch solution in smallest dimensions<br />

With the F6 we are expanding our product<br />

range with a new micro switch type of special<br />

class.<br />

The approved process of the Twin-Shot- and<br />

Insert-Moulding in our switch production<br />

allows us to minimize the number of parts,<br />

process steps and guarantees the highest<br />

process reliability and quality of our automatic<br />

assembled F6 switch.<br />

Due to the Twin-Shot-Moulding lid, sealing<br />

and cowl are manufactured on a single tool.<br />

The insert moulded terminals allows to give<br />

up the complicated gluing process.<br />

Special characteristics of the F6<br />

• Silicon free materials<br />

• Side actuation of 40° directly on plunger<br />

possible due to:<br />

– POM plunger material with very low sliding<br />

friction<br />

– spherical plunger head<br />

– special plunger leanding concept<br />

• Long overtravel despite small construction<br />

dimensions<br />

• Ice break levers<br />

• Nominal currents of 5 mA to 3 A<br />

with 12/24 VDC<br />

• 5-parts-concept due to Twin-Shot-Moulding<br />

and Insert-Moulding = Elimination of<br />

tolerance chains and high process reliability<br />

• Latest manufacturing technology without<br />

gluing, without mechanical fitting between<br />

cowl and lid

Specifications<br />

Operating temperature<br />

-40°C up to +85°C<br />

Type of protection:<br />

IP6K7<br />

Mechanical life:<br />

Up to 1 mio. cycles<br />

Mechanism:<br />

leaf spring mechanism<br />

Actuators:<br />

Ice break levers<br />

Materials:<br />

Cowl: TPE<br />

Plunger: POM<br />

Lid: PP GF30<br />

Base: PTB<br />

Terminals: CuZn silver plated<br />

Contacts: AgNi 0.15<br />

Circuit diagram F6T85<br />

9<br />

<br />

Common<br />

Normally<br />

open<br />

Normally<br />

closed<br />

Recommended Max. Electrical Ratings<br />

Voltage<br />

VAC<br />

250 50<br />

12 to 24 2<br />

Resistive load<br />

mA<br />

Recommended Min. Electrical Ratings<br />

Voltage Resistive load<br />

VAC<br />

mA<br />

Twin-Shot-Moulding<br />

Insert Moulding<br />

Recommended Max. Electrical Ratings<br />

Voltage Resistive load Cycles<br />

VDC<br />

mA<br />

12 to 24 20<br />

2000<br />

12 to 24 2<br />

Resistive load<br />

mA<br />

F6<br />

500’000<br />

50’000<br />

Recommended Min. Electrical Ratings<br />

Voltage<br />

VDC<br />

Lid Cowl<br />

Sealing<br />

Insert moulded<br />

terminals

Product Range<br />

F6<br />

Operating Characteristics<br />

Actuator Reference Actuating<br />

Force<br />

Maximum<br />

N (ozf)<br />

10<br />

Release<br />

Force<br />

Minimum<br />

N (ozf)<br />

Free<br />

Position<br />

Maximum<br />

mm (in)<br />

Operating<br />

Position<br />

mm (in)<br />

Movement<br />

Differential<br />

Maximumm<br />

m (in)<br />

Plunger F6T85 1.4 (5.03) 0.2 (0.71) 11.3 10.8 ± 0.2 0.2 ± 0.05<br />

(.425 ± .008) (.008 ±.0019)<br />

H<br />

Lever<br />

F6T85H For positions and forces of this actuator please contact Burgess.<br />

R 1,3<br />

(.051)<br />

Datum for free position and operating position is button edge of base (stand-off’s).<br />

Total<br />

Travel<br />

mm<br />

max.<br />

2.0<br />

(.078)

Ordering References<br />

Switch range: F6<br />

Terminal Types<br />

Actuators<br />

No symbol = Plunger<br />

H Plain lever<br />

Mounting<br />

No symbol = without pegs<br />

B… Several mounting pegs with a max. length of 4.9 mm (.1929 in) and<br />

max. Ø of 2.2 mm (.0866 in) on request.<br />

11<br />

T85<br />

4<br />

(.16)<br />

6.85<br />

(.27)<br />

T8 T84<br />

T81<br />

2.85<br />

(.112)<br />

t851.75<br />

(.068)<br />

T82<br />

2 (.078)<br />

F6<br />

F6

F1NCS-Series<br />

F1NCST8C2<br />

12<br />

Free Position<br />

max. 8.6<br />

(max. .338)<br />

Operating Position<br />

5.4<br />

(.214)<br />

3.45<br />

(.136)<br />

3.35<br />

(.132)<br />

0.9<br />

(.035)<br />

0.8<br />

(.031)<br />

2<br />

5.04 ± 0.15<br />

(.198 ± .006)<br />

1.4 ± 0.1<br />

(.055 ± .004)<br />

4.1 ±0.1<br />

(.161 ±.004)<br />

1<br />

0.9<br />

(.035)<br />

2.65<br />

(.104)<br />

14.4 ± 0.15<br />

(.567 ± .006)<br />

4.8<br />

(.189)<br />

1.4<br />

(.055)<br />

0.5<br />

(.019)<br />

4.7<br />

(.185)<br />

4.2<br />

(.165)<br />

5.2<br />

(.204)<br />

1.2 ± 0.1<br />

(.047 ± .004)<br />

Ø 1.4<br />

(Ø .055)<br />

2.5<br />

(.098)<br />

3.6<br />

(.141)<br />

°<br />

1<br />

±<br />

°<br />

3<br />

With the introduction of the F1NCS, <strong>SAIA</strong>-<br />

Burgess has once more set the standard for<br />

the miniaturisation of switching elements for<br />

electronic equipment.<br />

The new ultra-miniature switches offer the<br />

user many advantages:<br />

• 10% smaller than the F1T8.<br />

• Flux-proof terminal entries.<br />

• With minimized number of parts and<br />

process steps due to the Twin-Shot-<br />

Moulding.<br />

• Latest manufacturing technology without<br />

gluing, mechanical fitting between cowl and<br />

lid.

Specifications<br />

Temperature Range:<br />

-40°C to +85°C<br />

Type of Protection:<br />

Enclosure IP54<br />

Mechanical Life:<br />

10 7 cycles minimum (impact-free actuation)<br />

Mechanism:<br />

Snap-action, coil spring mechanism with<br />

stainless steel spring. Single-pole changeover<br />

contact.<br />

Contacts:<br />

Fine silver<br />

Gold plate on silver<br />

Mounting:<br />

PCB. Locating pins on housing<br />

Actuators:<br />

Plain lever; Cam follower<br />

Materials:<br />

Cowl: TPE<br />

Plunger: POM<br />

Lid: PP GF30<br />

Base: PA66 GF30<br />

Terminals: PCB silver plated<br />

Circuit diagram<br />

F1NCST8<br />

Change-over<br />

13<br />

Normally closed<br />

Normally open<br />

Common<br />

Recommended Max. Electrical Ratings<br />

Voltage<br />

VAC<br />

125<br />

250<br />

up to<br />

30<br />

50<br />

75<br />

125<br />

Resistive load<br />

A<br />

1<br />

1<br />

Resistive load<br />

A<br />

2<br />

0.5<br />

0.25<br />

0.2<br />

1<br />

1<br />

Recommended Max. Electrical Ratings<br />

Voltage<br />

VDC<br />

Inductive load<br />

Inductive load<br />

A<br />

2<br />

0.5<br />

0.25<br />

0.03<br />

The breaking capacities in the table refer to<br />

silver contacts. For gold contacts see the<br />

text above right.<br />

A<br />

Gold-plated contacts are intended for use in<br />

signal circuits where the energy being<br />

switched is at the milliwatt level. Power being<br />

switched must be limited in order to avoid<br />

overheating and possible dispersal of the gold<br />

from the contact area.<br />

See also page 5.<br />

F1NCS

Product Range<br />

F1NCS<br />

Operating Characteristics<br />

Actuator Reference Actuating<br />

Force<br />

Maximum<br />

N (ozf)<br />

14<br />

Release<br />

Force<br />

Minimum<br />

N (ozf)<br />

Free<br />

Position<br />

Maximum<br />

mm (in)<br />

Operating<br />

Position<br />

mm (in)<br />

Movement<br />

Differential<br />

Maximum<br />

mm (in)<br />

Plunger F1NCST8 2.0 (7.2) 0.2 (0.72) 6.5 5.9 (0.23) 0.2<br />

(0.26) ± 0.2 (± 0.008) (0.008)<br />

A1- F1NCST8A1 0.6 (2.2) 0.09 (0.32) 10.5 7.6 (0.30) 0.7<br />

Lever (0.41) ± 1.2 (±0.05) (0.03)<br />

Width of lever<br />

3.0 mm (.12)<br />

AC- F1NCST8AC 0.6 (2.2) 0.09 (0.32) 13.3 10.1 (0.40) 0.7<br />

Lever (0.52) ± 1.2 (±0.05) (0.03)<br />

Width of lever<br />

3.0 mm (.12)<br />

Datum for Free Position and Operating Position: base of switch opposite plunger.<br />

Over<br />

Travel<br />

Flush with case.<br />

The case should not be used as an end stop.

Ordering References<br />

Switch range: F1NCS<br />

Terminal Type<br />

T8 = PCB<br />

see page 8<br />

Circuits<br />

No symbol = Changover<br />

C2 Normally closed<br />

C4 Normally open<br />

Actuators<br />

No symbol = Plunger<br />

A1 Plain lever 18.0 mm (.71 in)<br />

AC Cam follower 18.5 mm (.73 in)<br />

Contacts<br />

No symbol = Fine silver<br />

GP Gold plate on silver<br />

15<br />

F1NCS<br />

F1NCS

F4/F5-Series<br />

16<br />

F4T6<br />

F4T7<br />

F5T8<br />

Among the world’s smallest switches with<br />

power capabilities, these units have surprisingly<br />

high current ratings and are engineered<br />

with precision for long and reliable life.<br />

The use of a double pivot mechanism provides<br />

a wiping action of the contacts to improve<br />

weld-breaking capability. The proven<br />

high capacity stainless steel coil spring<br />

mechanism provides maximum service life and<br />

reliability.<br />

The F4 range is designed for side mounting<br />

with two M2 screws. The much-reduced size<br />

of the F5 is achieved by the omission of<br />

mounting holes. It is intended for use on<br />

printed circuit boards.

Specifications<br />

Housing:<br />

Glass fibre reinforced Polyamide (PA 6.6)<br />

Plunger:<br />

Polyamide (PA 6.6)<br />

Mechanism:<br />

Double pivot, snap-action coil spring mechanism<br />

with stainless steel spring.<br />

Single pole changeover or normally open<br />

Contacts:<br />

Fine silver<br />

Gold plate on silver<br />

Terminals:<br />

F4T6: 2.0 mm faston<br />

F4T7: Solder<br />

F5T8: PCB<br />

All terminals are gold flashed.<br />

Temperature Range:<br />

-40°C to +85°C<br />

Mechanical Life:<br />

10 7 cycles minimum (impact free actuation)<br />

Type of protection:<br />

Enclosure – IP40<br />

Mounting:<br />

F4: Side mounting<br />

F5: PCB<br />

Actuators:<br />

Plain lever; Cam follower<br />

Accessories:<br />

Lug mounting frame, insulating sheet,<br />

spring-leaf actuator<br />

Approvals:<br />

UL; CSA;<br />

Circuit diagram F4/F5<br />

17<br />

Common<br />

Change-over<br />

Normally<br />

closed<br />

Normally<br />

open<br />

Recommended Max. Electrical Ratings<br />

Voltage<br />

VAC<br />

125<br />

250<br />

Recommended Max. Electrical Ratings<br />

Voltage<br />

VDC<br />

up to<br />

30<br />

50<br />

75<br />

125<br />

250<br />

Resistive load<br />

A<br />

5<br />

5<br />

Resistive load<br />

A<br />

5<br />

2<br />

1<br />

0.5<br />

0.25<br />

Inductive load<br />

A<br />

5<br />

5<br />

Inductive load<br />

A<br />

5<br />

2<br />

1<br />

0.06<br />

0.03<br />

The breaking capacities in the table refer to<br />

silver contacts. For gold contacts see the<br />

text above right.<br />

Gold-plated contacts are intended for use in<br />

signal circuits where the energy being switched<br />

is at the milliwatt level. Power being<br />

switched must be limited in order to avoid<br />

overheating and possible dispersal of the gold<br />

from the contact area.<br />

See also page 5.<br />

F4<br />

F5

Product Range<br />

F4<br />

Operating Characteristics<br />

F5<br />

Actuator Reference Actuating<br />

Force<br />

Maximum<br />

N (ozf)<br />

Plunger F5 T8 1.4 (5) 0.25 (0.9) 9.5 8.75 (0.34) 0.13<br />

(0.37) ± 0.3 (± 0.012) (0.005)<br />

F4T6 1.4 (5) 0.25 (0.9) 8.8 8.1 (0.32) 0.13<br />

F4T7 (0.35) + 0.3/– 0.2<br />

(+0.01/– 0.008)<br />

(0.005)<br />

Y1- F5T8Y1 0.6 (2.2) 0.07 (0.25) 10.7 8.8 (0.35) 0.7<br />

Lever (0.42) ± 1.1 (± 0.04) (0.03)<br />

Width of lever<br />

3.0 mm (.12)<br />

18<br />

<br />

<br />

F4T6Y1 0.6 (2.2) 0.07 (0.25) 10.0 8.2 (0.32) 0.7<br />

F4T7Y1 (0.39) + 1.0/– 0.7<br />

(+ 0.04/–0.03)<br />

(0.03)<br />

YC-Lever F5T8YC 0.7 (2.5) 0.09 (0.32) 12.4 10.9 (0.43) 0.45<br />

(0.49) ± 0.85 (± 0.03) (0.02)<br />

Width of lever<br />

3.0 mm (.12)<br />

Datum for Free Position and Operating Position<br />

F4 – Centre of fixing hole<br />

F5 – Terminal shoulder<br />

<br />

Release<br />

Force<br />

Minimum<br />

N (ozf)<br />

Free<br />

Position<br />

Maximum<br />

mm (in)<br />

Operating<br />

Position<br />

mm (in)<br />

Movement<br />

Differential<br />

Maximum<br />

mm (in)<br />

F4T6YC 0.7 (2.5) 0.09 (0.32) 11.7 10.3 (0.41) 0.45<br />

F4T7YC (0.46) + 0.8 /– 0.55<br />

(+ 0.03/– 0.02)<br />

(0.02)<br />

Over<br />

Travel<br />

Flush with case.<br />

The case should not be used as an end stop.

Ordering References<br />

Switch range: F4 Side mounting<br />

F5 PCB mounting<br />

Terminal type<br />

T6 = Faston<br />

T7 = Solder<br />

T8 = PCB<br />

see page 12<br />

Circuit No symbol = Changover<br />

C2 Normally closed* *(F4 only)<br />

C4 Normally open<br />

Actuators<br />

No symbol = Plunger<br />

Y1 Plain lever 21.0 mm (.83 in)<br />

YC Cam follower 16.9 mm (.67 in)<br />

Contacts<br />

No symbol = Fine silver<br />

GP Gold plate on silver<br />

19<br />

F4<br />

F5

FK4-Series<br />

20<br />

FK4T6<br />

FK4T7<br />

FK4T8<br />

Moulded-cased, single-pole changeover,<br />

snap-action switches which open or close the<br />

conductors at two points, thereby increasing<br />

the available contact separation.<br />

FK4 switches are slightly smaller than<br />

V4 Series although mounting positions interchange.

Specifications<br />

Housing:<br />

Glass fibre reinforced Polyamide (PA 6.6)<br />

Plunger:<br />

Polyamide (PA 6.6); Polyacetal (POM) for lever<br />

types<br />

Mechanism:<br />

Double-break snap-action coil spring<br />

mechanism with stainless steel springs<br />

Contacts:<br />

Fine silver<br />

Gold plate on silver<br />

Terminals:<br />

T6: 2.0 mm faston<br />

T7: Solder<br />

T8: PCB<br />

All terminals are gold flashed<br />

Temperature Range:<br />

-40°C to +85°C<br />

Mechanical Life:<br />

10 7 cycles minimum (impact free actuation)<br />

Type of Protection:<br />

Enclosure – IP40<br />

Mounting:<br />

FK4T6/T7: side mounting<br />

FK4T8: PCB<br />

Actuators:<br />

Plain lever; Cam follower<br />

Accessories:<br />

Insulating sheet<br />

Approvals:<br />

UL, CSA, SEMKO<br />

Circuit diagram FK4<br />

1 + 2 Normally closed<br />

3 + 4 Normally open<br />

21<br />

Recommended Max. Electrical Ratings<br />

Voltage<br />

VAC<br />

125<br />

250<br />

Voltage<br />

VDC<br />

up to<br />

30<br />

50<br />

75<br />

125<br />

250<br />

Resistive load<br />

A<br />

5<br />

5<br />

Inductive load<br />

A<br />

5<br />

5<br />

Recommended Max. Electrical Ratings<br />

Resistive load<br />

A<br />

5<br />

2<br />

1<br />

0.5<br />

0.25<br />

Inductive load<br />

A<br />

5<br />

2<br />

1<br />

0.06<br />

0.03<br />

The breaking capacities in the table refer to<br />

silver contacts. For gold contacts see the<br />

text above right.<br />

FK4<br />

Gold-plated contacts are intended for use in<br />

signal circuits where the energy being switched<br />

is at the milliwatt level. Power being<br />

switched must be limited in order to avoid<br />

overheating and possible dispersal of the gold<br />

from the contact area.

Product Range<br />

FK4<br />

Operating Characteristics<br />

Actuator Reference Actuating<br />

Force<br />

Maximum<br />

N (ozf)<br />

22<br />

Release<br />

Force<br />

Minimum<br />

N (ozf)<br />

Free<br />

Position*<br />

Maximum<br />

mm (in)<br />

Operating<br />

Position*<br />

mm (in)<br />

Movement<br />

Differential<br />

Maximum<br />

mm (in)<br />

Plunger FK4T6 1.8 (6.5) 0.25 (0.9) 9.4 (0.37) 8.25 (0.32)<br />

± 0.25 (± 0.01)<br />

0.5 (0.02)<br />

FK4T7 1.8 (6.5) 0.25 (0.9) 9.4 (0.37) 8.25 (0.32)<br />

± 0.25 (± 0.01)<br />

0.5 (0.02)<br />

FK4T81) 1.8 (6.5) 0.25 (0.9) 12.75 (0.5) 11.60 (0.45)<br />

± 0.45 (± 0.02)<br />

0.5 (0.02)<br />

Y1 FK4T6Y1 0.8 (2.9) 0.09 (0.3) 12.1 (0.48) 8.25 (0.32) 1.85 (0.07)<br />

Lever ± 0.9 (± 0.04)<br />

FK4T7Y1 0.8 (2.9) 0.09 (0.3) 12.1 (0.48) 8.25 (0.32)<br />

± 0.9 (± 0.04)<br />

1.85 (0.07)<br />

Width of lever: FK4T8Y1 0.8 (2.9) 0.09 (0.3) 15.6 (0.61) 11.55 (0.45) 1.85 (0.07)<br />

3.0 (.12) ± 1.1 (± 0.04)<br />

YC FK4T6YC 1.0 (3.6) 0.1 (0.4) 13.5 (0.53) 10.4 (0.41) 1.3 (0.05)<br />

Lever ± 0.6 (± 0.02)<br />

FK4T7YC 1.0 (3.6) 0.1 (0.4) 13.5 (0.53) 10.4 (0.41)<br />

± 0.6 (± 0.02)<br />

1.3 (0.05)<br />

Width of lever: FK4T8YC 1.0 (3.6) 0.1 (0.4) 17.0 (0.67) 13.7 (0.54) 1.3 (0.05)<br />

3.0 (.12) ± 0.8 (± 0.03)<br />

Datum for Free Position and Operating Position<br />

* FK4T6/7 – Centre of fixing hole<br />

1 FK4T8 – Terminal shoulder<br />

Over<br />

Travel<br />

Flush with case.<br />

The case should not be used as an end stop.

Ordering References<br />

Switch range: FK4<br />

Terminal Type<br />

T6 = Faston<br />

T7 = Solder<br />

T8 = PCB<br />

see page 16<br />

Actuators<br />

No symbol = Plunger<br />

Y1 Plain lever 21.0 mm (.83 in)<br />

YC Cam follower 16.9 mm (.67 in)<br />

Contacts<br />

No symbol = Fine silver<br />

GP Gold plate on silver<br />

23<br />

FK4<br />

FK4

X5-Series<br />

24<br />

X5G3<br />

max. 6.2 (.24)<br />

5.0 (.20)<br />

1.5 (.06)<br />

2.0 (.08)<br />

2.2 (.09)<br />

1.1 (.04)<br />

5.08 (.20)<br />

5.3 (.20)<br />

6.5 (.26)<br />

12.8 (.50)<br />

5.08 (.20)<br />

5.0 (.20)<br />

0.9 (.35)<br />

Ø 2.0 (.08)<br />

6.5 (.26)<br />

2.9 (.11)<br />

0.4 (.016)<br />

5.8 (.23)<br />

Important features<br />

• The highest number of components in the<br />

smallest possible space<br />

• Extremely low weight<br />

(approximately 0.6 g per item)<br />

• May be mounted directly onto PCBs<br />

• Minimal space requirement<br />

• For low current applications<br />

• Miniature size<br />

(Length: 12,8 mm, width: 5,8 mm,<br />

height 6,5 mm)<br />

• Long mechanical life because of the coil<br />

spring mechanism<br />

• Nominal currents up to 3A /125 VAC<br />

Typical applications<br />

• Telecommunications<br />

• Small domestic appliances<br />

• Recreational items<br />

• Automotive

Specifications<br />

Housings:<br />

Thermoplastic<br />

Plunger:<br />

Thermoplastic<br />

Mechanism:<br />

Snap-action, coil spring mechanism with<br />

stainless steel spring<br />

Contacts:<br />

Silver<br />

Contact carrier:<br />

Brass<br />

Terminals:<br />

Solder<br />

Temperature range:<br />

65°C<br />

Type of protection:<br />

Enclosure IP 40<br />

Mountings:<br />

– PCB<br />

– Side mounting<br />

Mechanical life:<br />

5·105cycles minimum<br />

Approvals:<br />

UL 1054, CSA<br />

Circuit diagram X5<br />

25<br />

<br />

Common<br />

Normally<br />

open<br />

Normally<br />

closed<br />

Recom. max. electrical ratings X5<br />

Voltage<br />

VAC<br />

125<br />

250<br />

Resistive<br />

load<br />

A<br />

3<br />

1.5<br />

The breaking capacities in the tables refer to<br />

silver/silver contacts.<br />

X5

Product Range<br />

Ordering Charcteristics<br />

Actuator Reference Actuating<br />

Force<br />

Maximum<br />

N (ozf))<br />

26<br />

Release<br />

Force<br />

Minimum<br />

N (ozf))<br />

Free<br />

Position<br />

Maximum<br />

mm (in)<br />

Operating<br />

Position<br />

mm (in)<br />

Movement<br />

Differential<br />

Maximum<br />

mm (in)<br />

Full<br />

Overtravel<br />

Position<br />

mm (in)<br />

Plunger 5.3 (.21)<br />

X5G3 1.5 (5.35) 0.2 (0.72) 6.2 5.5 ± 0.3 0.2 5.0<br />

(0.24) (0.22 ± 0.01) (0.008) (0.20)<br />

J-Lever 12.1 (.48)<br />

X5G3..J1 0.5 (1.80) 0.05 (0.18) 9.5 7.2 ± 1.5 0.8 5.3<br />

(0.37) (0.28 ± 0.06) (0.032) (0.21)<br />

Width of lever<br />

3.6 mm (.14)<br />

6.2 (.24)<br />

5.5 (.22)<br />

4.2 (.16)<br />

8.6 (.34)<br />

X5

Ordering References<br />

Switch range: X5<br />

Actuating forces<br />

G = Standard force Fs max. 150 cN<br />

Circuits<br />

3 = Changeover<br />

Terminal type<br />

03= PCB, vertical<br />

Housing designs<br />

K = Thermoplastic lid: black<br />

base: copperbrown<br />

Contacts<br />

1 = Silver / Silver<br />

Approval classes<br />

in accordance with UL/CSA<br />

A = 1.5 A 250 VAC approved<br />

3.0 A 125 VAC approved<br />

B = 1.0 A 125 VAC<br />

N = No approvals<br />

Electrical rating classes<br />

in accordance with EN / IEC<br />

N = No approvals<br />

Actuators<br />

No digit = without lever<br />

J0 to J9 = Straight lever<br />

L0 to L9 = Cam follower<br />

M0 to M9 = Formed lever<br />

Actuator length<br />

No digit = Standard type<br />

AA to YY = Specials for customers<br />

27<br />

X 5<br />

X5

X4–Series<br />

28<br />

X4..03…<br />

+ 0.1<br />

2.35 (.09) – 0.15<br />

X4..04…<br />

0.5 (.02)<br />

X4..08…<br />

2.4 (.09)<br />

+ 0.05<br />

– 0.02<br />

2.5<br />

3.45 (.14)<br />

(.10)<br />

9.5 (0.37) ± 0.1<br />

12.3 (.48)<br />

19.9 (.78)<br />

7.5 (.30)<br />

+ 0.25<br />

– 0.35<br />

8.85 (.35) 6.65 (0.26)<br />

3.2 (.13)<br />

5.25 (.21)<br />

+ 0.20<br />

– 0.25<br />

+ 0.05<br />

2.3 (.09) – 0.02<br />

2.3 (.09)<br />

4.5 (.18) 10.65 (.42)<br />

1.3 (.05)<br />

3.1 (.12)<br />

4 (.16)<br />

6.4 (.25)<br />

±0.2<br />

1.4 (.06)<br />

2.8 (.11)<br />

6.4 (.25)<br />

±0.2<br />

4 (.16)<br />

6.4 (.25)<br />

±0.2<br />

+ 0.2<br />

– 0.3<br />

9.65 (.38)<br />

3.6<br />

(.14)<br />

8.1 (.32)<br />

5.5 (.22)<br />

Detail A<br />

62°<br />

Detail A<br />

1.3<br />

(.05)<br />

0.3 (.01)<br />

1.0<br />

(.04)<br />

Important features<br />

• Wide range of solder, faston an PCB<br />

terminals<br />

• Various operating actuators may be<br />

specified<br />

• Lever may be clipped on later<br />

• Versions with maximum electrical rating of<br />

12 A at 250AC<br />

• Actuating forces between 75 and 330 cN<br />

Decisive advantages<br />

• High degree of switching accuracy<br />

• Its greater precision ensures greater<br />

functional safety<br />

• The crosspoint contacts are ideal for low<br />

current/voltage applications<br />

Typical applications<br />

• Small domestic appliances<br />

• Telecommunications<br />

• Recreational items<br />

• Automotive industry

Specifications<br />

Housing:<br />

Thermoplastic<br />

Plunger:<br />

Thermoplastic<br />

Mechanism:<br />

Snap-action, coil-spring mechanism with<br />

stainless steel spring<br />

Contacts:<br />

Fine silver (Ag), gold-plate on silver and<br />

gold-plate on silver crosspoint<br />

Contact carrier:<br />

Brass<br />

Terminals:<br />

Solder, faston, PCB, side-facing PCB and<br />

PCB terminals with 0.1” pitch<br />

Temperature range:<br />

Between –40 °C and + 85 °C.<br />

Type of protection:<br />

Enclosure – IP 40<br />

Mounting:<br />

Side mounting or PCB<br />

Mechanical life:<br />

106 cycles minimum<br />

Approvals:<br />

UL 1054: UL, C-UL<br />

EN 61058-1: SEV, VDE<br />

Circuit diagram X4<br />

29<br />

<br />

Common<br />

Normally<br />

open<br />

Normally<br />

closed<br />

Recommended max. ratings X4<br />

X4 F<br />

X4 G<br />

X4 C<br />

Voltage<br />

VAC<br />

250<br />

250<br />

250<br />

Resistive<br />

load<br />

A<br />

12<br />

6<br />

3<br />

Motor<br />

load<br />

A<br />

6<br />

3<br />

2<br />

The breaking capacities in the tables refer to<br />

silver contacts<br />

X4

Product Range<br />

Ordering Characteristics<br />

Actuator Reference Actuating<br />

Force<br />

Maximum<br />

N (ozf))<br />

Release<br />

Force<br />

Min.<br />

N (ozf))<br />

Free<br />

Position<br />

Max.<br />

mm (in)<br />

Operating<br />

Position<br />

mm (in)<br />

Movement<br />

Differential<br />

Maximum<br />

mm (in)<br />

Full Overtravel<br />

Pos.<br />

max.<br />

mm (in)<br />

Plunger 7.5 (.30)<br />

2.4<br />

(.09)<br />

X4F 3.3 (11.869) 0.55 8.8<br />

(1.978) (0.35)<br />

8.4+ 0.1/-0.3<br />

(0.33 ± 0.004/-0.01)<br />

0.2<br />

(0.008)<br />

7.7<br />

(0.30)<br />

X4G 2.0 (7.193) 0.35 8.8 8.4+ 0.1/-0.3 0.2 7.7<br />

(1.258) (0.35) (0.33 ± 0.004/-0.01) (0.008) (0.30)<br />

X4C 0.75 (2.697) 0.13 8.8 8.4+ 0.1/-0.3 0.2 7.7<br />

(0.467) (0.35) (0.33 ± 0.004/-0.01) (0.008) (0.30)<br />

J11- 17.5 (.69)<br />

X4F ..J11 1.16 (4.172) 0.18 12.2 10.2 ± 1 0.6 8.4<br />

Lever (0.647) (0.48) (0.40 ± 0.039) (0.024) (0.33)<br />

X4G..J11 0.7 (2.517) 0.094 12.2 10.2 ± 0.9 0.5 8.5<br />

Width of lever<br />

4 mm (.16)<br />

12.7 (.50)<br />

X4C..J11 0.28 (1.007)<br />

(0.338)<br />

0.031<br />

(0.107)<br />

(0.48)<br />

12.2<br />

(0.48)<br />

(0.40 ± 0.035)<br />

10.3 ± 0.9<br />

(0.40 ± 0.035)<br />

(0.02)<br />

0.4<br />

(0.016)<br />

(0.33)<br />

8.7<br />

(0.34)<br />

L11- X4F ..L11 1.21 (4.352) 0.19 17.6 15.6 ± 1.1 0.6 14.0<br />

Lever (0.683) (0.69) (0.61± 0.043) (0.024) (0.55)<br />

X4G..L11 0.82 (2.949) 0.11 17.6 15.6 ± 1 0.5 14.1<br />

(0.395) (0.69) (0.61± 0.039) (0.02) (0.56)<br />

Width of lever<br />

4 mm (.16)<br />

12.7 (.50)<br />

X4C..L11 0.29 (1.043) 0.033<br />

(0.118)<br />

17.6<br />

(0.69)<br />

15.7 ± 1<br />

(0.61± 0.039)<br />

0.4<br />

(0.016)<br />

14.3<br />

(0.56)<br />

S11- X4F ..S11 1.21 (4.352) 0.19 17.6 15.6 ± 1.2 0.6 14.1<br />

Lever (0.683) (0.69) (0.61± 0.047) (0.024) (0.56)<br />

X4G..S11 0.82 (2.949) 0.11 17.6 15.6 ± 1.1 0.5 14.2<br />

(0.395) (0.69) (0.61± 0.043) (0.02) (0.56)<br />

Width of roller<br />

4 mm (.16)<br />

12.7 (.50)<br />

X4C..S11 0.29 (1.043) 0.036<br />

(0.129)<br />

17.6<br />

(0.69)<br />

15.7 ± 1.1<br />

(0.62± 0.043)<br />

0.4<br />

(0.016)<br />

14.4<br />

(0.57)<br />

30<br />

6.1 (.24)<br />

6.1 (.24)<br />

6.1 (.24)<br />

16 (.63)<br />

5.9 (.23)<br />

15.1 (.59)<br />

60º<br />

Ø 4.8<br />

(.19)<br />

X4

Ordering References<br />

Switch range: X4<br />

Actuating Forces<br />

F = Extra strong force<br />

G = Strong force<br />

C = Low force<br />

Circuits<br />

3 = Changeover<br />

4 = Normally closed(NC)<br />

5 = Normally open (NO)<br />

Terminal Type<br />

03 = Solder<br />

04 = Faston 2.8 x 0.5 mm DIN<br />

Housing design<br />

K = Thermoplastic<br />

Contacts<br />

1 = Silver<br />

8 = Gold, gold plate cross bar<br />

Actuators<br />

No digit = without lever<br />

J0 to J9 = Straight lever<br />

L0 to L9 = Simulated roller lever<br />

M0 to M9 = Customer specified lever (KV)<br />

S0 to S9 = Roller lever<br />

31<br />

<br />

Approval classes<br />

in accordance with UL/C-UL<br />

A = 12 A 125/250 VAC<br />

B = 6 A 125/250 VAC<br />

C = 3 A 125/250 VAC<br />

D = 0,1 A 125 AC<br />

N = No approvals<br />

Mounting position of the actuator<br />

1 = Mounting over terminal pos. 1<br />

2 = Mounting over terminal pos. 2<br />

/ = Plunger<br />

with X4F and X4G<br />

not possible<br />

(except gold contacts)<br />

Electrical rating classes<br />

in accordance with EN/IEC<br />

A = 12 (6) A 250 V~ 1E4 T85 µ approved<br />

B = 6 (3) A 250 V~ 5E4 T85 µ approved<br />

C = 3 (2) A 250 V~ 5E4 T85 µ approved<br />

F = 10 (4) A 250 V~ 1E4 T125 µ approved<br />

L = 1 A 30 V = not approved<br />

M = 0,3 A 30 V ~ 1E4 not approved<br />

X 4<br />

X4

XC-Series<br />

32<br />

XC3<br />

XC5<br />

XC9<br />

+ 0.1<br />

2.35 – 0.15<br />

(.09)<br />

+ 0.05<br />

2.5 – 0.02<br />

(.10)<br />

0.5<br />

(.02)<br />

8.1<br />

(.32)<br />

5.5<br />

(.22)<br />

0.5<br />

(.02)<br />

0.5<br />

(.02)<br />

2.4<br />

(.09)<br />

7.5<br />

(.30)<br />

1 4 2<br />

8.85 3.45<br />

(.35) (.14)<br />

9.5 ± 0.1<br />

(.37)<br />

+ 0.25<br />

19.9 – 0.35<br />

(.78)<br />

1 4 2<br />

12.3 ± 0.3<br />

(.48)<br />

8.85<br />

(.35)<br />

6.65<br />

(.26)<br />

3.2<br />

(.13)<br />

+ 0.20<br />

5.25 – 0.25<br />

(.20)<br />

1 4 2<br />

4.7±<br />

0.3<br />

(.19)<br />

12.3 ± 0.3<br />

(.48)<br />

7.6<br />

7.6<br />

(.30) (.30)<br />

+ 0.05<br />

2.3 – 0.02<br />

(.09)<br />

2.9±<br />

0.3<br />

(.11)<br />

3.4 ± 0.1<br />

(.13)<br />

1.3<br />

(.05)<br />

1.0<br />

(.04)<br />

4.5<br />

(.18)<br />

3.1<br />

(.12)<br />

4.8<br />

(.19)<br />

2.4<br />

(.09)<br />

4<br />

(.16)<br />

6.4 ± 0.2<br />

(.25)<br />

1.2<br />

(.5)<br />

2.8<br />

(.11)<br />

0.35<br />

(.02)<br />

9.5<br />

(.37)<br />

+ 0.2<br />

– 0.3<br />

1.6<br />

(.07)<br />

3.6<br />

(.14)<br />

1.3 x 0.5<br />

(.05 x .02)<br />

Important features<br />

• Serated silver contacts for power switching;<br />

option of gold-plated contacts in conventional<br />

form and crosspoint contacts for lowcurrent<br />

applications.<br />

• Ample overtravel – plunger can be<br />

depressed flush with case.<br />

• Wide range of CrNi stainless steel levers for<br />

clip-on attachment.<br />

• Various terminal options e.g, solder, faston,<br />

pcb, etc.<br />

• Low and high-force versions.<br />

• Terminal spacing 0.1” (0.25mm) international<br />

pitch.<br />

Significant advantages<br />

• Excellent performance; high quality<br />

standards<br />

• Short and flexible delivery times<br />

• Design service for special models to meet<br />

particular applications.<br />

Typical applications<br />

• Telecommunications<br />

• Small domestic appliances<br />

• Office equipment<br />

• Automotive industry

Specifications<br />

Housing:<br />

Phenolic-Melamine, Thermosetting<br />

Plunger:<br />

POM for T85<br />

PBT for T140<br />

Mechanism:<br />

Stainless steel snap-action coil spring<br />

mechanism<br />

Contacts:<br />

Pure silver (Ag) or 10 µm Gold (Au),<br />

microprofile<br />

Contact Carrier:<br />

CuZn or CuSn<br />

Terminals:<br />

Solder, faston and various PCB terminals<br />

(side of housing or side of lid, as well as<br />

1/10” o lin pitch)<br />

Temperature Range:<br />

Between – 40°C and +85°C.<br />

Type of Protection:<br />

Enclosure IP40<br />

Mounting:<br />

Side mounting through mounting holes<br />

Mechanical Life:<br />

up to 5 ·10 7cycles (sinusoidal actuation)<br />

Approvals:<br />

VDE, UL, CSA<br />

Circuit diagramm XC<br />

33<br />

Common<br />

<br />

Normally<br />

open<br />

Normally<br />

closed<br />

Recom. Max. Electrical Ratings XC<br />

Voltage Resistive<br />

Motor<br />

load<br />

load<br />

VAC<br />

A<br />

250 5 1<br />

Recom. Max. Electrical Ratings XCF<br />

Voltage Resistive Terminal Motor<br />

load<br />

load<br />

VAC<br />

A<br />

250 5<br />

10<br />

Voltage<br />

VAC<br />

4/5<br />

other<br />

2<br />

2<br />

Recom. Max. Electrical Ratings XCH<br />

Resistive<br />

load<br />

A<br />

The breaking capacities in the table refer to<br />

silver contacts.<br />

A<br />

A<br />

Motor<br />

load<br />

250 1 0,1<br />

A<br />

XC<br />

Recom. Max. Electrical Ratings XCC<br />

Voltage Resistive<br />

Motor<br />

load<br />

load<br />

A<br />

VAC A<br />

250 2 0,5<br />

Recom. Max. Electrical Ratings XCK<br />

Voltage<br />

VAC<br />

250<br />

250<br />

Resistive<br />

load<br />

A<br />

5<br />

3<br />

2) To be indicated, when ordering.<br />

Motor<br />

load<br />

A<br />

2 2)<br />

1

Product Range<br />

Operating Characteristics<br />

Maximum Minimum Maximum<br />

Maximum Maximum<br />

N (ozf) N (ozf) mm (in) mm (in)<br />

<br />

mm (in) mm (in)<br />

Plunger XC.. 1.7 (6.07) 0.3 (1.07) 8.8 (0.34) 8.4 (0.33) 0.1 (0.003) 7.7 (0.303)<br />

+0.1/–0.3<br />

XCC.. 0.6 (2.14) 0.1 (3.57) 8.8 (0.34) 8.4 (0.33) 0.1 (0.003) 7.7 (0.303)<br />

7.5 (.30)<br />

+0.1/–0.3<br />

2.4 (.09)<br />

XCF.. 3.0 (10.7) 0.5 (1.78) 8.8 (0.34) 8.4 (0.33) 0.1 (0.003) 7.7 (0.303)<br />

+0.1/–0.3<br />

XCK.. 1.2 (4.28) 0.2 (0.71) 8.8 (0.34) 8.4 (0.33) 0.1 (0.003) 7.7 (0.303)<br />

(+0.003/–0.011)<br />

+0.1/–0.3<br />

XCH.. 0.35 (1.24) 0.07 (0.24) 8.8 (0.34) 8.4 (0.33) 0.1 (0.003) 7.7 (0.303)<br />

J1- XC.. -J1 0.6 (2.14) 0.08 (0.28) 12.2 (0.48) 10.2 (0.401) 0.5 (0.019) 8.5 (0.337)<br />

Lever ± 0.9 (± 0.035)<br />

XCC.. -J1 0.22 (0.78) 0.025 (0.08) 12.2 (0.48) 10.3 (0.404) 0.4 (0.015) 8.7 (0.342)<br />

± 0.9 (± 0.035)<br />

XCF.. -J1 1.05 (3.74) 0.16 (0.57) 12.2 (0.48) 10.2 (0.401) 0.6 (0.023) 8.4 (0.330)<br />

± 1.0 (± 0.039)<br />

XCK.. -J1 0.42 (1.49) 0.056 (0.19) 12.2 (0.48) 10.3 (0.405) 0.5 (0.019) 8.7 (0.342)<br />

± 0.9 (± 0.035)<br />

XCH.. -J1 0.13 (0.46) 0.02 (0.07) 12.2 (0.48) 10.4 (0.409) 0.4 (0.015) 8.8 (0.346)<br />

± 0.9 (± 0.035)<br />

L1- XC.. -L1 0.7 (2.49) 0.09 (0.32) 17.6 (0.69) 15.6 (0.614) 0.5 (0.019) 14.1 (0.555)<br />

Lever ± 1.0 (± 0.039)<br />

XCC..-L1 0.23 (0.82) 0.026 (0.09) 17.6 (0.69) 15.7 (0.618) 0.4 (0.015) 14.3 (0.562)<br />

± 1.0 (± 0.039)<br />

XCF.. -L1 1.1 (3.92) 0.17 (0.60) 17.6 (0.69) 15.6 (0.614) 0.6 (0.023) 14.0 (0.551)<br />

± 1.1 (± =.043)<br />

XCK.. -L1 0.43 (1.53) 0.058 (0.20) 17.6 (0.69) 15.7 (0.618) 0.4 (0.015) 14.3 (0.562)<br />

± 1.0 (± 0.039)<br />

XCH..-L1 0.14 (0.49) 0.021 (0.07) 17.6 (0.69) 15.8 (0.622) 0.4 (0.015) 14.4 (0.566)<br />

± 1.0 (± 0.039)<br />

S1- XC.. -S1 0.7 (2.49) 0.09 (0.32) 17.6 (0.69) 15.6 (0.614) 0.5 (0.019) 14.2 (0.559)<br />

Lever ± 1.1 (± =.043)<br />

XCC..-S1 0.23 (0.82) 0.026 (0.09) 17.6 (0.69) 15.7 (0.618)<br />

± 1.1 (± =.043)<br />

0.4 (0.015) 14.4 (0.566)<br />

XCF.. -S1 1.1 (3.92) 0.17 (0.60) 17.6 (0.69) 15.6 (0.614)<br />

± 1.2 (± 0.047)<br />

0.6 (0.023) 14.1 (0.555)<br />

XCK.. -S1 0.43 (1.53) 0.058 (0.20) 17.6 (0.69) 15.7 (0.618)<br />

± 1.1 (± =.043)<br />

0.4 (0.015) 14.4 (0.566)<br />

Width of roller:<br />

4 mm (.16)<br />

12.7 (.50)<br />

XCH..-S1 0.14 (0.49) 0.021 (0.07) 17.6 (0.69) 15.8 (0.622)<br />

± 1.1 (± =.043)<br />

0.4 0.015) 14.5 (0.570)<br />

Operating characteristics shown above are<br />

specified from mounting hole centres.<br />

34<br />

Actuator Reference Actuating<br />

Force<br />

Width of lever:<br />

4 mm (.16)<br />

Width of lever:<br />

4 mm (.16)<br />

8.8 (.35)<br />

8.4 (.33)<br />

12.2 (.48)<br />

10.2 (.40)<br />

17.6 (.69)<br />

15.6 (.61)<br />

17.6 (.69)<br />

15.6 (.61)<br />

6.1 (.24)<br />

6.1 (.24)<br />

6.1 (.24)<br />

18.0 (.71)<br />

12.7 (.50)<br />

16 (.63)<br />

5.9 (.23)<br />

12.7 (.50)<br />

16.8 (.66)<br />

60º<br />

Ø 4.8<br />

(.19)<br />

Release<br />

Force<br />

Free<br />

Position<br />

Operating<br />

Position<br />

Movement<br />

Differential<br />

XC<br />

Total travelled<br />

Position

Ordering References<br />

Basic types XC XCK XCH<br />

XCF XCC<br />

Circuits<br />

No symbol = Changeover<br />

4 Normally closed (NC 2)<br />

5 Normally open (NO 4)<br />

Terminal types<br />

3 Solder<br />

4 Faston 2.8 x 0.5 mm DIN<br />

5 Faston 2.8 x 0.5 mm IEC/AMP<br />

8 PCB (straight)<br />

9 PCB (1/10” pitch)<br />

10 Side mounting PCB, Base side<br />

11 Side mounting PCB, cover side<br />

Other teminals on special request.<br />

Version<br />

No symbol Housing material<br />

MP<br />

Europe up to 85°C<br />

UL up to 90°C<br />

– W (High temperature 140°C) Housing material<br />

Polyester PBT<br />

Europe up to 140°C<br />

UL up to 130°C<br />

Contacts<br />

No symbol = Plunger<br />

81 µ profile Au 10 µm<br />

Actuators<br />

No symbol = Plunger<br />

J1 Straight lever r = 18,0 mm (0.71 in)<br />

J2 Straight lever r = 25,0 mm (0.98 in)<br />

J5 Straight lever r = 40,0 mm (1.57 in)<br />

S1 Roller lever r = 16,8 mm (0.66 in)<br />

L1 Cam follower r = 16,0 mm (0.63 in)<br />

Other actuators on special request.<br />

35<br />

XC.<br />

XC

V4NC-Series<br />

36<br />

V4NCT7<br />

Free Position<br />

Operating Position<br />

Final Position<br />

V4NSCT8<br />

Free Position<br />

Operating Position<br />

2.4 ±0.1<br />

(.094 ±.004)<br />

Final Position<br />

3.4<br />

(.134)<br />

2.4 ±0.1<br />

(.094 ±.004)<br />

7±0.15<br />

(.275 ±.006)<br />

0.5 (3x)<br />

(.02 3x)<br />

7±0.15<br />

(.275 ±.006)<br />

0.5 (3x)<br />

(.02 3x)<br />

10.8<br />

(.425)<br />

7.5<br />

(.295)<br />

Ø 2.54 +0.05<br />

(Ø .1 ±.002)<br />

Ø 2.25 +0.1<br />

(Ø .088 ±.004)<br />

10.16<br />

(.4)<br />

9.53 ±0.05<br />

(.375 ±.002)<br />

19.85 ±0.15<br />

(.781 ±.006)<br />

5.3<br />

(.208)<br />

2 4 1<br />

5.08<br />

(.2)<br />

5.16<br />

(.203)<br />

10.8<br />

(.425)<br />

7.5<br />

(.295)<br />

Ø 2.54 +0.05<br />

(Ø .1 ±.002)<br />

Ø 2.25 +0.1<br />

(Ø .088 ±.004)<br />

10.16<br />

(.4)<br />

9.53 ±0.05<br />

(.375 ±.002)<br />

19.85 ±0.15<br />

(.781 ±.006)<br />

5.3<br />

(.208)<br />

2 4 1<br />

5.08<br />

(.2)<br />

5.16<br />

(.203)<br />

1<br />

(.039)<br />

2.25 ±0.1<br />

(.088 ±.004)<br />

7.7 ±0.1<br />

(.303 ±.004)<br />

2.6<br />

(.102)<br />

1<br />

(.039)<br />

2.25 ±0.1<br />

(.088 ±.004)<br />

7.7 ±0.1<br />

(.303 ±.004)<br />

2.6<br />

(.102)<br />

Ø 4.4 ±0.05<br />

(Ø .173 ±.002)<br />

1.75 (.069)<br />

2.95<br />

(.116)<br />

6.4<br />

(.252)<br />

Ø 2.3<br />

(Ø .09)<br />

Ø 1.7 ±0.15<br />

(Ø .067 ±.006)<br />

Ø 6.25<br />

(Ø .246) Ø 2.3<br />

(Ø .09)<br />

0.8<br />

(.031)<br />

6.4<br />

(.252)<br />

3.6<br />

(.141)<br />

4<br />

(.157)<br />

An exciting new range of sub-miniature<br />

switches embracing a host of innovative<br />

design features:<br />

• Seven terminal options all sealed<br />

• Mounting holes or moulded pegs<br />

• Standard and low force models<br />

• Wide range of clip on levers – two styles<br />

• Choice of lever position<br />

• Silver contacts for power switching;<br />

gold on silver for logic circuits<br />

• Long overtravel versions<br />

• Snap-on terminal covers<br />

The ultimate in versatility.

Specifications<br />

Housing:<br />

Glass fibre reinforced Polyamide (PA 6.6)<br />

Plunger:<br />

Polyacetal (POM)<br />

Mechanism:<br />

Snap-action coil spring mechanism with<br />

stainless steel spring. Changeover, normallyclosed<br />

or normally-open<br />

Contacts:<br />

Fine silver<br />

Gold plate on silver<br />

Gold alloy on silver palladium (crosspoint)<br />

Terminals:<br />

All terminals are gold flashed<br />

Refer to page 39<br />

Temperature Range:<br />

– 40°C to +85°C<br />

Mechanical Life:<br />

5 x10 6 cycles minimum (impact free actuation)<br />

Type of Protection:<br />

V4NC – Enclosure IP 40<br />

V4NCS – Enclosure IP 6K7<br />

Flux-proof terminal entries<br />

Mounting:<br />

Side mounting<br />

Versions with moulded mounting pegs of<br />

2.25 mm or 3.2 mm diameter are also available.<br />

Please consult Burgess.<br />

Actuators:<br />

Plain lever<br />

Cam follower Choice<br />

of two styles<br />

Roller lever<br />

Accessories:<br />

Lug mounting frame<br />

Clip-on terminal covers<br />

Insulating sheet<br />

Circuit diagram V4NC<br />

Common<br />

37<br />

Normally<br />

closed<br />

Normally<br />

open<br />

Recom. Max. El. Ratings V4NC(S)-series<br />

Voltage<br />

VAC<br />

125<br />

250<br />

Voltage<br />

VDC<br />

up to<br />

30<br />

50<br />

75<br />

125<br />

250<br />

Resistive load<br />

A<br />

5<br />

5<br />

Resistive load<br />

A<br />

5<br />

1<br />

0.75<br />

0.5<br />

0.25<br />

Inductive load<br />

A<br />

2<br />

2<br />

Recom. Max. El. Ratings V4NC(S)-series<br />

Inductive load<br />

A<br />

3<br />

1<br />

0.75<br />

0.03<br />

0.03<br />

Recom. Max. El. Ratings V4NCS-series<br />

Voltage<br />

VDC/VAC<br />

Resistive load<br />

mA<br />

Inductive load<br />

mA<br />

12 to 30 10 10<br />

Recom. Max. El. Ratings V4NC-series<br />

Voltage<br />

VDC/VAC<br />

Resistive load<br />

mA<br />

Inductive load<br />

mA<br />

12 to 30 100 100<br />

The breaking capacities in the tables refer to<br />

silver contacts. For gold contacts see the<br />

text on right.<br />

V4NC<br />

Recom. Max. El. Ratings V4NC(S)4-series<br />

Voltage Resistive load Inductive load<br />

VAC<br />

125<br />

250<br />

A<br />

10<br />

10<br />

Gold-plated contacts are intended for use in<br />

signal circuits where the energy being switched<br />

is at the milliwatt level. Power being<br />

switched must be limited in order to avoid<br />

overheating and possible dispersal of the gold<br />

from the contact area.<br />

A<br />

5<br />

5<br />

Recom. Max.El. Ratings V4NC(S)4-series<br />

Voltage<br />

VDC<br />

up to<br />

30<br />

50<br />

75<br />

125<br />

250<br />

Voltage<br />

VDC/VAC<br />

Resistive load<br />

A<br />

10<br />

1<br />

0.75<br />

0.5<br />

0.25<br />

Resistive load<br />

mA<br />

Inductive load<br />

A<br />

3<br />

1<br />

0.75<br />

0.03<br />

0.03<br />

Recom. Max. El. Ratings V4NCS4-series<br />

Inductive load<br />

mA<br />

12 to 30 10 10<br />

Recom. Max. El. Ratings V4NC4-series<br />

Voltage<br />

VDC/VAC<br />

Resistive load<br />

mA<br />

Inductive load<br />

mA<br />

12 to 30 100 100

Product Range<br />

Operating Characteristics<br />

Actuator Reference Actuating<br />

Force<br />

Maximum<br />

N (ozf)<br />

38<br />

Release<br />

Force<br />

Minimum<br />

N (ozf)<br />

Free<br />

Position<br />

Maximum<br />

mm (in)<br />

Operating<br />

Position<br />

mm (in)<br />

V4NC<br />

Movement<br />

Differential<br />

Maximum<br />

mm (in)<br />

Plunger V4NC.. 1.7 (6.114) 0.3 (1.079) 9.2 (.362) 8.4 (.331) 0.1 (.004)<br />

V4NC4.. 2.5 (8.992) 0.5 (1.798) 9.2 (.362) 8.4 (.331) 0.1 (.004)<br />

V4NCE.. 1.7 (6.114) 0.3 (1.079) 9.7 (.382) 8.9 (.350) 0.1 (.004)<br />

V4NC4E.. 2.5 (8.992) 0.5 (1.798) 9.7 (.382) 8.9 (.350) 0.1 (.004)<br />

V4NCS.. 2.5 (8.992) 0.5 (1.798) 9.2 (.362) 8.4 (.331) 0.1 (.004)<br />

V4NC4S.. 2.8 (10.071) 0.7 (2.517) 9.2 (.362) 8.4 (.331) 0.1 (.004)<br />

V4NCSE.. 2.5 (8.992) 0.5 (1.798) 9.7 (.382) 8.9 (.350) 0.1 (.004)<br />

V4NC4SE.. 2.8 (10.071) 0.7 (2.517) 9.7 (.382) 8.9 (.350) 0.1 (.004)<br />

A1 V4NC.. 0.8 (2.877) 0.07 (0.251) 13.4 (.527) 10.85 (.427) 0.4 (.016)<br />

Lever V4NC4.. 1.1 (3.956) 0.1 (0.359) 13.4 (.527) 10.85 (.427) 0.4 (.016)<br />

V4NCE.. 0.8 (2.877) 0.07 (0.251) 14.8 (.582) 12.4 (.488) 0.4 (.016)<br />

V4NC4E.. 1.1 (3.956) 0.1 (0.359) 14.8 (.582) 12.4 (.488) 0.4 (.016)<br />

Width of lever:<br />

4.0 mm (.16)<br />

V4NCS.. 0.9 (3.237) 0.1 (0.359) 13.4 (.527) 10.8 (.425) 0.4 (.016)<br />

V4NC4S.. 1.1 (3.956) 0.15 (0.539) 13.4 (.527) 10.8 (.425) 0.4 (.016)<br />

V4NCSE.. 0.9 (3.237) 0.1 (0.359) 14.8 (.582) 12.4 (.488) 0.4 (.016)<br />

V4NC4SE.. 1.1 (3.956) 0.15 (0.539) 14.8 (.582) 12.4 (.488) 0.4 (.016)<br />

AC1 V4NC.. 0.8 (2.877) 0.07 (0.251) 16.1 (.634) 13.5 (.531) 0.4 (.016)<br />

Lever V4NC4.. 1.1 (3.956) 0.1 (0.359) 16.1 (.634) 13.5 (.531) 0.4 (.016)<br />

V4NCE.. 0.8 (2.877) 0.07 (0.251) 17.6 (.693) 15.1 (.594) 0.4 (.016)<br />

V4NC4E.. 1.1 (3.956) 0.1 (0.359) 17.6 (.693) 15.1 (.594) 0.4 (.016)<br />

Width of lever:<br />

4.0 mm (.16)<br />

V4NCS.. 0.9 (3.237) 0.1 (0.359) 16.1 (.634) 13.4 (.527) 0.4 (.016)<br />

V4NC4S.. 1.1 (3.956) 0.15 (0.539) 16.1 (.634) 13.4 (.527) 0.4 (.016)<br />

V4NCSE.. 0.9 (3.237) 0.1 (0.359) 17.6 (.693) 15.1 (.594) 0.4 (.016)<br />

V4NC4SE.. 1.1 (3.956) 0.15 (0.539) 17.6 (.693) 15.1 (.594) 0.4 (.016)<br />

AR1 V4NC.. 0.8 (2.877) 0.07 (0.251) 18.1 (.712) 16.0 (.630) 0.4 (.016)<br />

Lever V4NC4.. 1.2 (4.316) 0.1 (0.359) 18.1 (.712) 16.0 (.630) 0.4 (.016)<br />

V4NCE.. 0.8 (2.877) 0.07 (0.251) 19.2 (.756) 17.3 (.681) 0.4 (.016)<br />

V4NC4E.. 1.2 (4.316) 0.1 (0.359) 19.2 (.756) 17.3 (.681) 0.4 (.016)<br />

Width of roller:<br />

4.0 mm (.16)<br />

V4NCS.. 0.9 (3.237) 0.1 (0.359) 18.1 (.712) 15.9 (.626) 0.4 (.016)<br />

V4NC4S.. 1.2 (4.316) 0.15 (0.539) 18.1 (.712) 15.9 (.626) 0.4 (.016)<br />

V4NCSE.. 0.9 (3.237) 0.1 (0.359) 19.2 (.756) 17.3 (.681) 0.4 (.016)<br />

V4NC4SE.. 1.2 (4.316) 0.15 (0.539) 19.2 (.756) 17.3 (.681) 0.4 (.016)<br />

A10 V4NC.. 1.3 (4.676) 0.13 (0.467) 10.7 (.421) 9.4 (.370) 0.2 (.008)<br />

Lever V4NC4.. 1.7 (6.114) 0.2 (0.719) 10.7 (.421) 9.4 (.370) 0.2 (.008)<br />

V4NCE.. 1.3 (4.676) 0.13 (0.467) 11.5 (.453) 10.2 (.401) 0.2 (.008)<br />

V4NC4E.. 1.7 (6.114) 0.2 (0.719) 11.5 (.453) 10.2 (.401) 0.2 (.008)<br />

Width of lever:<br />

4.0 mm (.16)<br />

V4NCS.. 1.8 (6.474) 0.2 (0.719) 10.7 (.421) 9.3 (.366) 0.2 (.008)<br />

V4NC4S.. 2.0 (7.193) 0.3 (1.079) 10.7 (.421) 9.3 (.366) 0.2 (.008)<br />

V4NCSE.. 1.8 (6.474) 0.2 (0.719) 11.5 (.453) 10.1 (.397) 0.2 (.008)<br />

V4NC4SE.. 2.0 (7.193) 0.3 (1.079) 11.5 (.453) 10.1 (.397) 0.2 (.008)<br />

AR10 V4NC.. 1.3 (4.676) 0.13 (0.467) 15.8 (.622) 14.7 (.579) 0.2 (.008)<br />

Lever V4NC4.. 1.9 (6.834) 0.2 (0.719) 15.8 (.622) 14.7 (.579) 0.2 (.008)<br />

V4NCE.. 1.3 (4.676) 0.13 (0.467) 16.5 (.649) 15.4 (.606) 0.2 (.008)<br />

V4NC4E.. 1.9 (6.834) 0.2 (0.719) 16.5 (.649) 15.4 (.606) 0.2 (.008)<br />

Width of roller<br />

4.0 mm (.16)<br />

Operating characteristics<br />

Operating characteristics shown above are<br />

specified from mounting hole centres.<br />

V4NCS.. 1.8 (6.474) 0.2 (0.719) 15.8 (.622) 14.7 (.579) 0.2 (.008)<br />

V4NC4S.. 2.1 (7.553) 0.3 (1.079) 15.8 (.622) 14.7 (.579) 0.2 (.008)<br />

V4NCSE.. 1.8 (6.474) 0.2 (0.719) 16.5 (.649) 15.4 (.606) 0.2 (.008)<br />

V4NC4SE.. 2.1 (7.553) 0.3 (1.079) 16.5 (.649) 15.4 (.606) 0.2 (.008)<br />

<br />

<br />

(± (± (± <br />

<br />

(± <br />

(± (±<br />

0.3 mm/± .012 in)<br />

1.3 mm/± .051 in)<br />

1.3 mm/± .051 in)<br />

1.2 mm/± .047 in)<br />

0.7 mm/± .027 in)<br />

0.6 mm/± .023 in)<br />

Over<br />

Travel<br />

Flush with case.<br />

The case should not be used asan end stop.

Ordering References<br />

Switch range: V4NC<br />

Actuating Force<br />

No symbol = Standard force<br />

4 High force<br />

Type of Sealing<br />

No symbol = Unsealed<br />

S Sealed IP 6K7<br />

Overtravel<br />

No symbol = Standard<br />

E With extended over travel<br />

Terminal types<br />

Circuit No symbol = Changeover C2 Normally closed<br />

C4 Normally open<br />

Actuators<br />

No symbol = Plunger<br />

A1 Plain lever 18.0 mm (.71 in) A7 Plain lever 60.0 mm (2.36 in)<br />

A2 Plain lever 25.0 mm (.98 in) AC1 Cam follower 18.5 mm (.73 in)<br />

A3 Plain lever 32.0 mm (1.26 in) AR1 Roller lever 16.0 mm (.63 in)<br />

Levers fitted at end nearest to Plunger. an attached “0” such as A10, AR10<br />

specifies fixing at end of the opposite to plunger.<br />

Contacts<br />

No symbol = Fine silver<br />

AUX Gold alloy on silver palladium crosspoint<br />

GP Gold plate on silver<br />

Ni1 Silver-Nickel contact<br />

39<br />

5.5 max.<br />

6.4 6.4 6.4<br />

8.7 max.<br />

K1 K2 K3<br />

Mounting<br />

No symbol = Mounting holes<br />

B… several mounting pegs on request<br />

9.7 max.<br />

V4NC<br />

V4NC

Panel-mounted Actuators for<br />

use with the V4NC Series<br />

Long Overtravel stainless steel Plunger<br />

QA4<br />

40<br />

PBA 4<br />

Typical Assembly,<br />

V4NCT7, PBA 4, PBRG & BZR<br />

14.55 1.5<br />

(.57) (.45)<br />

,<br />

,<br />

,<br />

8.65<br />

(.34)<br />

12.1 max<br />

(.47)<br />

3.6<br />

4.6<br />

(.18)<br />

7.5<br />

(.29)<br />

6.45<br />

(.25)<br />

2.6 5.08 10.16<br />

(.10) (.20) (.40)<br />

20.0 max.<br />

(.78)<br />

(.14)<br />

Long Overtravel stainless steel Plunger<br />

QA4 Moulded frame,<br />

Stainless steel plunger<br />

Overtravel actuator,<br />

2 locknuts<br />

The sleeve is threaded M6 fine<br />

A comprehensive new range of panel-mounted<br />

actuators with the following features:<br />

• Can be fitted to all standard travel<br />

V4NC switches.<br />

• Simple clip-on attachment.<br />

• Choice of either round or square push<br />

buttons and bezels.<br />

• Single hole mounting (Ø 6.35 mm) or via<br />

switch mounting holes.<br />

• Panel sealing if required.<br />

• Long overtravel stainless steel actuator<br />

version with 5 mm min. overtravel.<br />

Recom. max. El. Ratings V4NC(S)<br />

Voltage Resistive Inductive<br />

Load<br />

load<br />

VAC<br />

max.<br />

A<br />

250 5 2<br />

A<br />

Clip-on frame:<br />

Glass fibre reinforced Polyamide (PA 6.6)<br />

Bezel:<br />

ABS polymer – black<br />

Cowl:<br />

Synthetic Rubber<br />

“O”-Ring:<br />

Nitrile<br />

Locknut:<br />

Brass Nickel plate<br />

Button:<br />

ABS Polymer<br />

Basic switches:<br />

V4NC<br />

(see pages 36–39)<br />

Temperature Range:<br />