FLOW-prO™ vane WheeL

FLOW-prO™ vane WheeL

FLOW-prO™ vane WheeL

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Alstom has developed its<br />

patented <strong>FLOW</strong>-PRO Vane<br />

Wheel application for RP,<br />

RPS, and RS pulverizers.<br />

It has been designed to<br />

manage the critical air and<br />

coal mixing occurring around<br />

the outer diameter of the<br />

bowl by reducing velocities<br />

and minimizing recirculation<br />

within the pulverizer body<br />

in order to provide increased<br />

equipment service life.<br />

Customer Benefits<br />

Lower velocities for reduced<br />

downstream wear<br />

Reduced localized wear<br />

Increased pulverizer availability<br />

Reduced maintenance costs<br />

Alstom has combined years of<br />

coal pulverization experience with<br />

state-of-the-art computational<br />

fluid dynamics (CFD) technology<br />

to develop this <strong>FLOW</strong>-PRO Vane<br />

Wheel bringing improved pulverizer<br />

performance to customers.<br />

TECHNICAL PRODUCT DATA SHEET<br />

<strong>FLOW</strong>-prO <strong>vane</strong> <strong>WheeL</strong><br />

Upgrades<br />

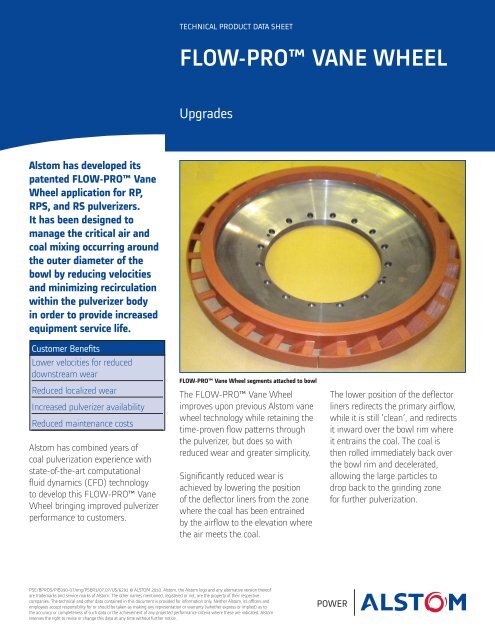

<strong>FLOW</strong>-PRO Vane Wheel segments attached to bowl<br />

The <strong>FLOW</strong>-PRO Vane Wheel<br />

improves upon previous Alstom <strong>vane</strong><br />

wheel technology while retaining the<br />

time-proven flow patterns through<br />

the pulverizer, but does so with<br />

reduced wear and greater simplicity.<br />

Significantly reduced wear is<br />

achieved by lowering the position<br />

of the deflector liners from the zone<br />

where the coal has been entrained<br />

by the airflow to the elevation where<br />

the air meets the coal.<br />

PSE/BPROS/PIB390-07/eng/PSER1/07.07/US/6291 © ALSTOM 2010. Alstom, the Alstom logo and any alternative version thereof<br />

are trademarks and service marks of Alstom. The other names mentioned, registered or not, are the property of their respective<br />

companies. The technical and other data contained in this document is provided for information only. Neither Alstom, its officers and<br />

employees accept responsibility for or should be taken as making any representation or warranty (whether express or implied) as to<br />

the accuracy or completeness of such data or the achievement of any projected performance criteria where these are indicated. Alstom<br />

reserves the right to revise or change this data at any time without further notice.<br />

The lower position of the deflector<br />

liners redirects the primary airflow,<br />

while it is still ‘clean’, and redirects<br />

it inward over the bowl rim where<br />

it entrains the coal. The coal is<br />

then rolled immediately back over<br />

the bowl rim and decelerated,<br />

allowing the large particles to<br />

drop back to the grinding zone<br />

for further pulverization.<br />

POWER

The remaining smaller coal<br />

particles are directed up through the<br />

separator body at a relatively low<br />

velocity, resulting in reduced wear,<br />

enhanced drying, and improved<br />

classifier efficiency.<br />

Theory behind <strong>FLOW</strong>-PRO Force and<br />

Velocity Analysis<br />

The <strong>FLOW</strong>-PRO Vane Wheel<br />

incorporates a resized deflector along<br />

with high-grade liner materials for<br />

the deflector, <strong>vane</strong>s and wing tips.<br />

The CFD and the force and velocity<br />

analysis illustrate that the <strong>FLOW</strong>-<br />

PRO Vane Wheel provides more<br />

uniform flow velocities that results in<br />

substantially reduced localized wear.<br />

Alstom can customize <strong>vane</strong><br />

segments to suit a customer’s needs<br />

for both complete <strong>FLOW</strong>-PRO<br />

Vane Wheels and replacement parts<br />

for existing <strong>vane</strong> wheel assemblies.<br />

In addition to the gains provided by<br />

air flow management, enhanced<br />

wear resistance is provided by:<br />

• AR plate inner segment shroud<br />

• Replacement <strong>vane</strong> liners made from<br />

Triten (chrome-carbide) plate<br />

• Wear-resistant weld overlay<br />

Alstom’s Patented <strong>FLOW</strong>-PRO Vane Wheel<br />

Competitor Vane Wheel*<br />

Features<br />

Deflector liners located in the clean<br />

air region for reduced wear<br />

360 degree flow path for even flow<br />

distribution to the classifier<br />

The flow control gap (between<br />

the rotating and stationary<br />

components) are located out of<br />

the erosion zone<br />

Wingtips retained for efficient air<br />

velocity and spillage control<br />

Small size and steep angle of<br />

deflector liners virtually eliminate<br />

any coal hide out areas<br />

A selection of wear materials and<br />

<strong>vane</strong> wheel attachment methods<br />

are available<br />

PIB 390<br />

PSE/BPROS/PIB390-07/eng/PSER1/07.07/US/6291 © ALSTOM 2010. Alstom, the Alstom logo and any alternative version thereof<br />

are trademarks and service marks of Alstom. The other names mentioned, registered or not, are the property of their respective<br />

companies. The technical and other data contained in this document is provided for information only. Neither Alstom, its officers and<br />

employees accept responsibility for or should be taken as making any representation or warranty (whether express or implied) as to<br />

the accuracy or completeness of such data or the achievement of any projected performance criteria where these are indicated. Alstom<br />

reserves the right to revise or change this data at any time without further notice.<br />

Deflectorless Vane Wheel*<br />

POWER<br />

<strong>FLOW</strong>-prO <strong>vane</strong> Wheel<br />

The Alstom Advantage<br />

Alstom is a leader in the design,<br />

manufacturing and servicing of utility<br />

and industrial power generation<br />

systems. While our heritage dates to the<br />

late 1800s, our capabilities continue to<br />

expand and point us to the future.<br />

Alstom provides the quality and<br />

resources of an OEM while backing<br />

our products with comprehensive<br />

support via a dedicated customer<br />

service organization that delivers the<br />

responsiveness our customers require.<br />

100 YEARS OF EXPERIENCE<br />

+<br />

SOLUTION-BASED<br />

PRODUCTS & SERVICES<br />

+<br />

COMMITMENT TO<br />

CUSTOMER SERVICE<br />

=<br />

THE ALSTOM ADVANTAGE<br />

ContaCt Us<br />

Toll Free: 1.866.257.8664<br />

Direct: 1.860.285.2100<br />

email: windsorparts@power.alstom.com<br />

www.power.alstom.com<br />

* Brighter color indicates higher velocity