POWER SERVICE - APComPower, Inc.

POWER SERVICE - APComPower, Inc.

POWER SERVICE - APComPower, Inc.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>POWER</strong> <strong>SERVICE</strong>

1<br />

Alstom Power <strong>Inc</strong>. (Alstom) is<br />

recognized around the world as a leader in<br />

the design, manufacturing and servicing of<br />

power generation equipment. While our<br />

heritage dates to the late 1800’s, our<br />

capabilities continue to expand and<br />

point us to the future.<br />

At Alstom, we combine<br />

our capabilities and<br />

experience to enhance<br />

the productivity and<br />

performance of your<br />

boilers, pulverizers, air<br />

pollution control systems,<br />

ash handling systems and<br />

auxiliary equipment.<br />

We are an organization that<br />

focuses on customer service and<br />

understands the challenges faced<br />

by plant owners, operators,<br />

maintenance personnel and<br />

management. Whether it is a simple<br />

replacement part, a rebuilt assembly,<br />

a custom fabrication or inventory<br />

management program, Alstom provides<br />

value and service to the customer.

Table of Contents<br />

Intro to the MPS-type Mill ..................................................................................................................3<br />

Alstom Rotating Throats ......................................................................................................................4<br />

Alstom Advanced Static Classifiers ......................................................................................................6<br />

Mill Upgrades for Powder River Basin Coal ........................................................................................7<br />

Roll Wheel............................................................................................................................................9<br />

Yoke and Yoke Air Seal Repairs ..........................................................................................................10<br />

Gearbox Overhauls ............................................................................................................................11<br />

Ceramic Lining and Vacuum Bonded Liners ......................................................................................12<br />

Gear Drive Rebuilds............................................................................................................................13<br />

Yoke and Yoke Air Seal Replacement Parts ........................................................................................14<br />

Plow Assemblies and Replacement Parts ..........................................................................................15<br />

Ring Seat Assembly............................................................................................................................16<br />

Roll Wheel Assembly Replacement Parts ..........................................................................................17<br />

Tire Options ........................................................................................................................................19<br />

Roll Wheel Wear Brackets ................................................................................................................20<br />

Asset Planning and Life Cycle Worksheet ..........................................................................................24<br />

Seal Air Assembly ..............................................................................................................................25<br />

Spring Frame, Pressure Frame and Loading Assembly......................................................................27<br />

Louver and Classifier Assembly ..........................................................................................................29<br />

Turret and Discharge Valve Assembly ................................................................................................31<br />

Contact Information..............................................................................................................Back Cover<br />

2

3<br />

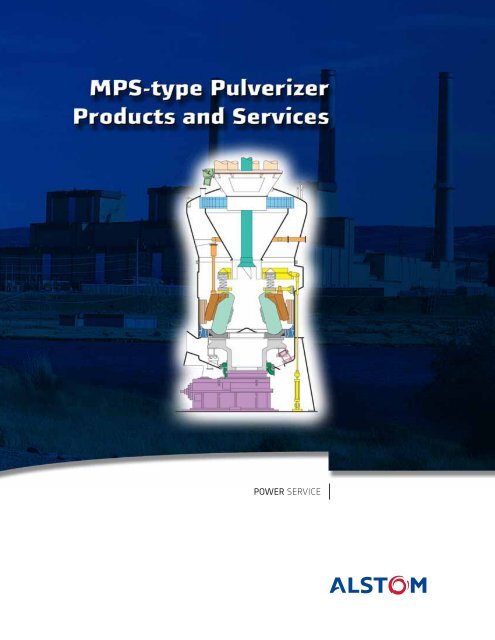

Intro to the MPS-type Mill<br />

The MPS-type mill was originally designed<br />

by Pfeiffer AG of Germany. Babcock &<br />

Wilcox (B&W) bought a license to build the<br />

MPS-type mill in 1971. The first<br />

commercial operation in the USA was<br />

in 1973. B&W needed a fast<br />

replacement to resolve problems<br />

with the CR 77 mill. That license<br />

has since expired.<br />

There are several sizes of<br />

MPS-type mills. The most<br />

common is the MPS 89.<br />

This mill was supplied in<br />

a number of versions, K,<br />

N, NR and G.<br />

Alstom supplies<br />

all the replacement<br />

parts, wear parts and<br />

major casting for all<br />

the MPS 89 models.<br />

Model Table Dia Table Speed Tire Dia<br />

(in) (rpm) (in)<br />

K 89 23.7 65<br />

N 89 23.7 65<br />

NR 89 23.7 65<br />

G 89 21.5 70

Alstom Rotating Throats<br />

The original MPS-type mills had fixed air<br />

ports around the mill table. The primary air<br />

flowing through these ports dried and<br />

transported the coal. The air port design<br />

had several disadvantages. The pressure<br />

drop was high, wear rates were high and<br />

they were not adjustable.<br />

Alstom first developed and patented the<br />

Rotating Throat also know as the<br />

Vane Wheel design. The first<br />

Vane Wheel was designed for<br />

a Combustion Engineering<br />

pulverizer in 1975. After<br />

testing, tuning and<br />

patent approval, the<br />

Vane Wheel<br />

became standard<br />

for all<br />

Combustion<br />

Engineering type<br />

pulverizers.<br />

Competitors saw<br />

the advantages<br />

of Alstom’s<br />

design and copied<br />

the concept and<br />

evaded the patents.<br />

The Alstom Rotating<br />

Throat results from 25<br />

years of design and field<br />

experience and the latest in fluid<br />

flow modeling techniques. Alstom<br />

uses Computational Fluid Dynamic (CFD)<br />

models to analyze the flow throughout the<br />

Rotating Throat and the entire mill. No<br />

other company has applied these scientific<br />

methods to throat design and pulverizer<br />

flow management. As a result, the Alstom<br />

Rotating Throat has lower pressure drop,<br />

minimal spillage, lower wear and better<br />

performance than competitors throats.<br />

4

5<br />

Wing Tips are used to control the open<br />

area of the Rotating Throat and reduce<br />

turbulence at the end of the vanes. Alstom<br />

utlitizes radial blocks called Wing Tips.<br />

These radial blocks are welded to the<br />

trailing edge of the throat vanes to<br />

approximate an air foil shape.<br />

A true air foil shape is not really necessary<br />

in this application. Maximum lift and drag<br />

reduction are not the objectives of this<br />

vane. The vane is intended to turn the flow<br />

with minimum turbulence and simplicity.<br />

The Wing Tip performs these functions well<br />

and allows for easy open area adjustment.

Alstom Advanced<br />

Static Classifiers<br />

Through the use of CFD modeling, Alstom<br />

created an Advanced Static Classifier (ASC)<br />

that out performs the original design and all<br />

competing classifiers. While other<br />

companies may guess at the flow<br />

characteristics, estimate velocities<br />

and ignore particle loading, Alstom<br />

mathematically models the<br />

pulverizer and scientifically designs<br />

classifiers for better performance.<br />

Competitor A<br />

• High pressure drop<br />

• High turbulence<br />

• High wear in lower<br />

section of mill<br />

Competitor B<br />

• High<br />

pressure drop<br />

• Classifier<br />

overloading<br />

• High classifier<br />

outlet velocity<br />

• High classifier<br />

pressure drop<br />

• Poor fineness<br />

Original<br />

• Fixed Vane Angle<br />

• Internal Adjustment<br />

• Flap Return Mechanism<br />

Alstom<br />

• Smooth<br />

uniform flow<br />

through mill<br />

• Low<br />

pressure drop<br />

• Even classifier<br />

loading<br />

• Low wear<br />

• Good fineness<br />

ASC<br />

• Adjustable Vane Angle<br />

• External Adjustment<br />

• Inverted Cone Return<br />

The Alstom Advanced Static Classifier has<br />

several technical improvements over the<br />

original classifier for the MPS mill. It<br />

performs better with improved 200 mesh<br />

and 50 mesh fineness. The classifier is<br />

externally adjustable to control fineness. It<br />

eliminates the discharge doors that are<br />

historically unreliable.<br />

6

7<br />

Mill Upgrades for<br />

Powder River Basin Coal<br />

Powder River Basin (PRB) coal is very<br />

popular for emission reduction and<br />

generation cost reduction. In many cases,<br />

the mill can process this coal with few<br />

operational problems. However, high inlet<br />

temperatures and wet coals do create some<br />

maintenance problems. Castings exposed<br />

to high temperatures can crack. The<br />

wet coal accelerates corrosion in<br />

several areas of the mill. Alstom<br />

offers mill mprovements for PRB<br />

coal firing.<br />

New Cast Iron Yokes<br />

and Ring Seats<br />

Due to the high moisture<br />

content, PRB coal needs<br />

very high inlet air<br />

temperatures to dry it.<br />

Air temperature can be<br />

up to 700°F. The hot<br />

air blows directly on<br />

the yoke and over<br />

time, temperature<br />

and cycles, the yoke<br />

may crack.<br />

Alstom supplies new<br />

high quality cast iron<br />

replacement yokes. These<br />

yokes are cast in the USA<br />

from quality ductile cast<br />

iron. Ductile iron has more<br />

resistance to cracking than<br />

cast grey iron. Yokes come in<br />

several heights.

Ring Seats also are stressed by the<br />

high temperature associated with PRB<br />

operation. Cracks often occur in the outside<br />

wall and bottom of the seats. Alstom can<br />

repair ring seats but sometimes<br />

replacement is more economical. Alstom<br />

makes these replacements from high quality<br />

ductile cast steel.<br />

Stainless Steel Pyrites Gates<br />

and Stainless Parts<br />

It is hot and corrosive in the bottom of the<br />

pulverizer. With PRB coal, water washing<br />

and fire fighting can also occur. The<br />

standard steel pyrite gate rusts and<br />

corrodes quickly in these conditions<br />

and soon the gate is stuck open<br />

or closed.<br />

Alstom offers<br />

complete new<br />

stainless steel<br />

pyrite gates. If most<br />

of the gate assembly is<br />

in good condition,<br />

a stainless gate may be<br />

all that’s needed to assure<br />

reliable operation.<br />

Stainless Seal Air Header<br />

After several years of PRB coal firing, Seal<br />

Air Headers can corrode away. The wet coal<br />

sits on the top of the header. With time,<br />

temperature and humidity, the header rots<br />

through from the top. For extended<br />

operation with PRB, a stainless steel header<br />

is recommended. Save those expensive roll<br />

wheel assemblies from contamination! A<br />

hole in this header can result in<br />

contamination of the wheels.<br />

Heavy Duty Pyrite Plows<br />

To avoid fires and explosions, the windbox<br />

area needs to be kept clean of rejects and<br />

debris. It is best to avoid spillage by<br />

maintaining the throat area, but the pyrite<br />

plows are still important.<br />

Brushes are not recommended for this area.<br />

They do not sweep the debris and allow<br />

build up that can lead to fires.<br />

Alstom Heavy Duty Pyrite Plows sweep the<br />

mill properly and stand up to tramp iron<br />

and rock.<br />

8

Roll Wheel<br />

Alstom offers high quality Roll Wheel<br />

Rebuilds and new Roll Wheel Assemblies.<br />

The Alstom rebuilds are performed at our<br />

Regional Service Centers.<br />

• Complete disassembly<br />

and cleaning<br />

• Dimensional inspection<br />

of shaft, hub, etc.<br />

• Worn consumable<br />

parts replaced<br />

• Major components<br />

repaired<br />

• Reassembled to strict<br />

procedures and<br />

tolerances<br />

• Upgrades to Triple<br />

Seals, Vent Valve and<br />

Weld Overlay Tires are<br />

available<br />

• Replace, Repair, Rotation<br />

(R 3 ) Programs<br />

Roll Wheel Assembly<br />

Repaired Hub<br />

Weld Treaded Tire<br />

9 Triple Seal Upgrade

Yoke and Yoke Air<br />

Seal Repairs<br />

The Yoke Air Seal contains the hot primary air<br />

within the mill. They prevent dusty hot air<br />

from contaminating the mill bay and<br />

potentially the gearbox. They<br />

also reduce heat transfer into<br />

the gearbox. If your<br />

gearbox oil is running<br />

hot or contaminated,<br />

the Yoke/Air seal<br />

may need<br />

replacement or<br />

repair. Alstom<br />

can repair the<br />

yoke saving<br />

substantial<br />

cost over<br />

replacement.<br />

The air seal<br />

labyrinth rings can<br />

be replaced to<br />

match.<br />

Case Steel Housing<br />

Call Alstom For:<br />

• Yoke Repairs<br />

• Air Seal Labyrinth Rings<br />

• Yoke Sleeves for field repair<br />

• Over and undersized Labyrinth Rings for<br />

field repairs<br />

• Cast Steel Air Seal Housing<br />

• Two Piece Air Seal Housing for field<br />

installation without gearbox removal<br />

10

11<br />

Gearbox Overhauls<br />

The MPS-type gearbox is a well-designed<br />

and built machine. It can provide long,<br />

reliable service when properly assembled<br />

and maintained.<br />

After 20 years or more of service,<br />

a rebuild or replacement may<br />

be needed to maintain reliability.<br />

Alstom has the parts, gearboxes and<br />

services:<br />

• Replacement parts for the<br />

gear drive, gears,<br />

bearing, shafts, seals<br />

• Rebuilds to as-new<br />

condition as an<br />

economic alternative<br />

to new units<br />

• New gearboxes in<br />

stock and in<br />

production<br />

• Fleet rebuild<br />

programs<br />

• Rental agreements<br />

• Purchase options

Ceramic Lining and<br />

Vacuum Bonded Liners<br />

The use of ceramic lining is best for<br />

high erosion, low impact locations. Alstom<br />

offers the most comprehensive wear<br />

solutions for all wear issues.<br />

• Vacuum Bonded Tiles<br />

Thin Dynawear II Ceramic Tiles are<br />

bonded directly to the component.<br />

This is especially useful where space or<br />

component size doesn’t allow thick tile.<br />

This arrangement is very impact resistant,<br />

but limited to moderate temperatures.<br />

• Plug Welded Tile<br />

The most common ceramic<br />

application. Used in<br />

cones, wall liners,<br />

turrets.<br />

• Brazed<br />

Tungsten<br />

Carbide<br />

Very high wear<br />

resistance and<br />

excellent impact<br />

resistance. More<br />

expensive than<br />

the ceramic<br />

options and used<br />

in specialized<br />

locations.<br />

• Specialty Ceramics<br />

Call for more information.<br />

12

13<br />

Gear Drive Rebuilds<br />

Alstom offers gear inspection and re-grinding. Call to discuss options.

Yoke and Yoke Air Seal Replacement Parts<br />

MPS-type Mill Plow – Yoke Air Seal Assembly<br />

Item Description Part No.<br />

1 Yoke - Cast Iron, 35-3/4" height 249335E<br />

Yoke - Cast Iron, 47-7/8" height 249334E<br />

Yoke - Cast Iron, 29-7/8" height 170726E<br />

Yoke Repair Kit for Ring Seat Pilot Crack GP-13274<br />

Yoke Repair Kit for Air Seal Surface GP-13410<br />

Conversion Kit Short to Tall Yoke GP-13397<br />

2 Plow Spacer 146134B<br />

3 Plow Assembly - Long 149654D<br />

4 Plow Assembly - Short 145401C<br />

5 Clamping Ring Segment Set - Top 155232D<br />

6 Clamping Ring Segment Set - Bottom 155231D<br />

Seal - 0.010" Thick 8800331<br />

Seal - 0.010" Thick 8800328<br />

7 Cap Screw 1/2x2 13-3074<br />

8 Lock Washer 15-2004<br />

9 Seal Ring Set (8 segments) 3084489-1<br />

10 Air Seal Housing Assembly, Cast Steel, Split 2 piece 3084487-A<br />

16 Air Seal Support 129309C<br />

Ring, Outer Clamp Set (Four 90) 3000926<br />

Ring, Inner Clamp Set (Four 90) 3000927<br />

14

15<br />

Plow Assemblies and Replacement Parts<br />

14<br />

15<br />

5<br />

6<br />

1<br />

Upper Plow Assembly<br />

(1 Required Per Mill)<br />

13<br />

Plow Assembly<br />

(2 Required Per Mill)<br />

4<br />

3<br />

2<br />

8<br />

10 11 12<br />

Item Application<br />

SLOPED<br />

BOTT OM MILL<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

11<br />

12<br />

FLAT<br />

BOTT OM MILL<br />

7<br />

Lower Plow Assembly<br />

(1 Required Per Mill)<br />

13<br />

Plow Assembly<br />

14<br />

Torsion Spring<br />

15<br />

W ear Plate<br />

Note: P/N-HD Designates Heavy Duty Plow<br />

9<br />

Description Part No.<br />

Upper Plow Assembly 8000113<br />

Plow Shims 8000113-6<br />

Plow Shaft 8000113-14<br />

Torsion Spring 8000113-15<br />

W ear Plate 8000108<br />

W ear Plate 8000111<br />

Lower Plow Assembly 8000117<br />

Plow Shaft GP-13407<br />

Torsion Spring 8000117-25<br />

W ear Plate 8000116<br />

W ear Plate GP-13408<br />

W ear Plate 8000281<br />

8002749<br />

8002789-25<br />

8001392<br />

PLOW ASSEMBLIES

Ring Seat Assembly<br />

MPS-type Mill Throat – Table Assembly<br />

Item Description Part No.<br />

1 1/2-13 UNC x 3/4 SHCS<br />

2 1/2 Lock Washer<br />

3 1/2-13 UNC x 2-1/4 SHCS<br />

4 1/2 Lock Washer<br />

5 Cover Cone - Cast Steel 8000233<br />

6 Gasket 31018-0346<br />

7 3/4-10 UNC x 1-1/2<br />

8 3/4 Lock Washer<br />

9 Cover Plate 129314C<br />

10 Wedge Bolt 8000069<br />

11 Grinding Segment Assembly (12 Pieces) 8002745<br />

11 Grinding Segment Assembly (12 Pieces)<br />

Continuous Taper (improved) 8002745-A<br />

11 Grinding Segment Assembly (12 Pieces)<br />

Low Profile Track - Must use Low Profile Tire 8002745-LP<br />

11 Grinding Segment Assembly (12 Pieces) MPS 89G 8002743<br />

12 Drive Pin 95745A<br />

14 Ring Seat Seal Set (6 Pieces) 4667176<br />

14 Ring Seat Seal Set (6 Pieces) MPS 89G 8000024<br />

15 Ring Seat - Cast Steel 170728E<br />

16 Conical Spring Washer 3.15x1.61x.0.197 118255D-F<br />

17 1.5-6UNC-2B Hex Nut<br />

18–20 Alstom Rotating Throat GP-12907<br />

16

17<br />

Roll Wheel Assembly Replacement Parts<br />

MPS-type Mill Roll Wheel Assembly

Item Description Part No.<br />

1 2-4.5NCx3 Cap Screw<br />

2 2" Lock Washer<br />

3 2" Washer<br />

4 1-8UNC Hex Nut<br />

5 1" Lock Washer<br />

6 1" Washer<br />

7 Plate, Brack, Wear (Std Direction) See following for options<br />

8 Wear Bracket See following for options<br />

9 Hex Head Cap Screw 11/2 x 41/2" lg MD8-00053-PP<br />

10 Lock Washer 11/2 15-2013<br />

11 Roll Shaft Retainer 8000241<br />

12 Bracket, Roll Wheel 8004218<br />

13 Pivot Pin 8000261<br />

14 Pivot Block 8000226<br />

14 Pivot Block – Special 8000226-Spl<br />

15 Upper Bracket Liner See following for options<br />

16 Hex Screw 3/4 - 10UNC - 2 x 11/2<br />

17 Hex Head Magnetic Pipe Plug 8004099<br />

18 Key 3023681<br />

19 Roll Shaft 8000040<br />

20 O-Ring 4620443<br />

21 Vent Valve 352315<br />

22 Sleeve - Roll Seal 8000254<br />

23 Set Screw 13-7056<br />

24 Roll Seal Retainer 8000711<br />

25 Seal – Viton GP-10109<br />

25 Roll Seal Spacer 8000045<br />

26 Keeper (Triple Seal Upgrade) GP-11293<br />

27 Screw (Triple Seal Upgrade) MD8-00098-EF<br />

28 Seal – Roll Air 8000250<br />

29 Lock Washer 1/2" 15-9004<br />

30 Hex Socket Hd Cap Screw 1/2" 13-4075<br />

31 Cylindrical Roller Bearing GP-10107<br />

32 Roll Bearing Spacer 8000270<br />

33 O-Ring – Roll Seal Retainer GP-10162-V<br />

34 Wheel – Cast Steel 8001933<br />

35 Washer 11/2" MD8-00017-AC<br />

36 Hex Socket Head Cap Screw 11/2" 9-2478<br />

37 Roll Bearing Spacer 8000271<br />

38 Spherical Roller Bearing, Position 11, 456431 GP-10108<br />

39 Roll Shaft Retainer 8000240<br />

40 O-Ring GP-2617-V<br />

41 Bearing Cover 8002689<br />

Bearing Cover Shim Set AB7-AA<br />

42 Hex Socket Magnetic Plug 3/4-NPTF 8004099<br />

42 Gasket (Sold Separately) 8000181<br />

43 Tire (See Options Below)<br />

44 Tire Clamp Ring 3023188<br />

18

19<br />

Tire Options<br />

Alstom offers a large selection of<br />

MPS-type mill tires. Alstom has a variety<br />

of tire sizes and geometries.<br />

We also have a selection of materials and<br />

weld overlays.<br />

Materials<br />

Trade Standard Relative<br />

Name Wear<br />

NiHard ASTM A532 Class I, Type D 1<br />

HiChrome ASTM A532 Class II, Type D 2<br />

Weld<br />

Overlay 4.5C – 25CR 4<br />

Description Material Part No.<br />

Standard 65" MPS 89 Tire Hi Chrome 8001466<br />

Standard 70" MPS 89G Tire Hi Chrome 6017253<br />

65" MPS 89 Tire NiHard 8000076<br />

Heavy Duty 66" MPS 89 Tire -<br />

Thicker Side Wall and Tread Hi Chrome 8001466HD<br />

Heavy Duty 70" MPS 89 Tire -<br />

Thicker Side Wall and Tread Hi Chrome 6017253HD<br />

Low Profile 65" MPS 89 Tire<br />

(must be used with 8002745-LP segments) Hi Chrome 4665232<br />

Rewelded Std 65" Tire Weld Overlay 8001466-RBLD<br />

Rewelded Std 70"” Tire Weld Overlay 6017253-RBLD

Original Style –<br />

Standard Direction with Extension<br />

Original Style –<br />

Opposite Direction with Extension<br />

Aero Style –<br />

Curved Design<br />

Roll Wheel Wear Brackets<br />

Protect those expensive Roll Wheel<br />

Brackets from wear. Alstom offers many<br />

styles and materials to match your coal and<br />

operating conditions.<br />

Original Style<br />

Flat plate<br />

Standard Direction<br />

The early MPS-type mills had throats that<br />

swirled the air clockwise as viewed from<br />

above. The Wear Bracket was on the right<br />

side of the roll wheel when looking in the<br />

mill door.<br />

Standard Extension<br />

The extension adds<br />

protection on the left side<br />

of the bracket<br />

Opposite Direction<br />

Many MPS-type mills have been modified<br />

and the air now swirls counterclockwise as<br />

viewed from above. The Wear Bracket<br />

must be on the left side when looking in<br />

the mill door.<br />

Opposite Extension<br />

The extension adds protection on the right<br />

side of the bracket.<br />

Aero Style<br />

The Wear Bracket is curved at the bottom to<br />

improve flow above the throat and around<br />

the roll wheel assembly. It covers all around<br />

the bracket, both right and left sides.<br />

Panel Liners<br />

Alstom offers Wear Bracket assemblies with<br />

replaceable ceramic panels.<br />

20

21<br />

Roll Wheel Wear Brackets<br />

Alstom offers Several Material options to match your operation<br />

Cost Impact Resistance Wear Resistance<br />

AR400 Plate Low High Low<br />

Chrome Carbide Plate Moderate High Moderate<br />

Vacuum Bonded Ceramic Moderate Moderate High<br />

85% Alumina Ceramic Tiles High Low High<br />

90% Alumina Ceramic Tiles High Low High<br />

Part No.<br />

Original Flat Plate with Welded Ceramic<br />

Tiles, Std and Opposite Directions<br />

Wear Bracket, 1" 85% Alumina Ceramic Tile,<br />

Std Direction, Side and Bottom Protection 8800335<br />

Wear Bracket, 1" 85% Alumina Ceramic Tile,<br />

Extension to 8800335 8800335-F<br />

Wear Bracket, 1" 85% Alumina Ceramic Tile,<br />

Opposite Direction, Side and Bottom Protection 8800335-A<br />

Wear Bracket, 1" 85% Alumina Ceramic Tile,<br />

Extension to 8800335-A 8800335-G<br />

Replaceable Panels Design<br />

Standard Direction<br />

Wear Bracket Assembly with replaceable Panels,<br />

1" 85% Alumina Ceramic Tile, Std Direction,<br />

Side and Bottom Protection 8800335-B-1<br />

Wear Bracket Assembly with replaceable Panels,<br />

1" 90% Alumina Ceramic Tile, Std Direction,<br />

Side and Bottom Protection 8800335-B-2<br />

Wear Bracket Assembly with replaceable Panels,<br />

1" 85% Alumina Ceramic Tile, Extension to 8800335-B-1 8800335-H<br />

Wear Bracket Assembly with replaceable Panels,<br />

1" 90% Alumina Ceramic Tile, Extension to 8800335-B-2 8800335-H-1<br />

Backing Plate Only, For Clip on Panels,<br />

Std Direction, Side and Bottom Protection 8800335-B<br />

Backing Plate Only For Clip on Panels, Extension to 8800335-H-A<br />

Ceramic Panel, 1" 85% Alumina Ceramic Tile,<br />

Top, Assembly 8800335-B-1, Assembly 8800335-I 8800335-B-7<br />

Ceramic Panel, 1" 90% Alumina Ceramic Tile,<br />

Top, Assembly 8800335-B-2, Assembly 8800335-I-1 8800335-B-7-90%<br />

Ceramic Panel, 1" 85% Alumina Ceramic Tile,<br />

Side, Assembly 8800335-B-1, Assembly 8800335-C-1 8800335-BC-5<br />

Ceramic Panel, 1" 90% Alumina Ceramic Tile,<br />

Side, Assembly 8800335-B-2, Assembly 8800335-C-2 8800335-BC-5-90%<br />

Ceramic Panel, 1" 85% Alumina Ceramic Tile,<br />

Two per Assembly, Side and Bottom,<br />

Assembly 8800335-B-1, Assembly 8800335-C-1 8800335-BC-6<br />

Ceramic Panel, 1" 90% Alumina Ceramic Tile,<br />

Two per Assembly, Side and Bottom,<br />

Assembly 8800335-B-2, Assembly 8800335-C-2 8800335-BC-6-90%<br />

Ceramic Panel, 1" 85% Alumina Ceramic Tile,<br />

Top, Assembly 8800335-H, Assembly 8800335-C-1 8800335-C-7<br />

Ceramic Panel, 1" 90% Alumina Ceramic Tile,<br />

Top, Assembly 8800335-H-1, Assembly 8800335-C-2 8800335-C-7-90%<br />

Ceramic Panel, 1” 85% Alumina Ceramic Tile,<br />

Side, Assembly 8800335-H 8800335-F-8<br />

Ceramic Panel, 1” 85% Alumina Ceramic Tile,<br />

Side, Assembly 8800335-H-1 8800335-F-8-90%

Part No.<br />

Replaceable Panels Opposite Direction<br />

Wear Bracket Assembly with replaceable Panels,<br />

1" 85% Alumina Ceramic Tile, Opposite Direction,<br />

Side and Bottom Protection 8800335-C-1<br />

Wear Bracket Assembly with replaceable Panels,<br />

1" 90% Alumina Ceramic Tile, Opposite Direction,<br />

Side and Bottom Protection 8800335-C-2<br />

Wear Bracket Assembly with replaceable Panels,<br />

1" 85% Alumina Ceramic Tile, Extension to 8800335-C-1 8800335-I<br />

Wear Bracket Assembly with replaceable Panels,<br />

1" 90% Alumina Ceramic Tile, Extension to 8800335-C-2 8800335-I-1<br />

Backing Plate Only, For Clip on Panels,<br />

Opposite Direction Side and Bottom Protection 8800335-C<br />

Backing Plate Only, For Clip on Panels,<br />

Extension to 8800335-C 8800335-I-A<br />

Ceramic Panel, 1" 85% Alumina Ceramic Tile,<br />

Top, Assembly 8800335-B-1, Assembly 8800335-I 8800335-B-7<br />

Ceramic Panel, 1" 90% Alumina Ceramic Tile,<br />

Top, Assembly 8800335-B-2, Assembly 8800335-I-1 8800335-B-7-90%<br />

Ceramic Panel, 1" 85% Alumina Ceramic Tile,<br />

Side, Assembly 8800335-B-1, Assembly 8800335-C-1 8800335-BC-5<br />

Ceramic Panel, 1" 90% Alumina Ceramic Tile, Side,<br />

Assembly 8800335-B-2, Assembly 8800335-C-2 8800335-BC-5-90%<br />

Ceramic Panel, 1" 85% Alumina Ceramic Tile,<br />

Two per Assembly, Side and Bottom, Assembly 8800335-B-1,<br />

Assembly 8800335-C-1 8800335-BC-6<br />

Ceramic Panel, 1" 90% Alumina Ceramic Tile,<br />

Two per Assembly, Side and Bottom, Assembly 8800335-B-2,<br />

Assembly 8800335-C-2 8800335-BC-6-90%<br />

Ceramic Panel, 1" 85% Alumina Ceramic Tile,<br />

Top, Assembly 8800335-H, Assembly 8800335-C-1 8800335-C-7<br />

Ceramic Panel, 1" 90% Alumina Ceramic Tile,<br />

Top, Assembly 8800335-H-1, Assembly 8800335-C-2 8800335-C-7-90%<br />

Ceramic Panel, 1" 85% Alumina Ceramic Tile,<br />

Side, Assembly 8800335-I 8800335-G-8<br />

Ceramic Panel, 1" 90% Alumina Ceramic Tile,<br />

Side, Assembly 8800335-I-1 8800335-G-8-90%<br />

Complete Kits, Replaceable Panel Style Lower<br />

Wear Bracket and AR400 Upper Wear Bracket<br />

Kit, Wear Bracket, Complete Lower Std and Ext in<br />

1" 85% Alumina Ceramic Tile, Upper AR400 Plate 8800335-Z-1<br />

Kit, Wear Bracket, Complete Lower Opp and Ext in<br />

1" 85% Alumina Ceramic Tile, Upper AR400 Plate 8800335-Z-2<br />

Kit, Wear Bracket, Complete Lower Std and Ext in<br />

1" 85% Alumina Ceramic Tile replaceable Panels,<br />

Upper AR400 Plate 8800335-Z-3<br />

Kit, Wear Bracket, Complete Lower Std and Ext in<br />

1" 90% Alumina Ceramic Tile replaceable Panels,<br />

Upper AR400 Plate 8800335-Z-3-A<br />

Kit, Wear Bracket, Complete Lower Opp and Ext in<br />

1" 85% Alumina Ceramic Tile replaceable Panels,<br />

Upper AR400 Plate 8800335-Z-4<br />

Kit, Wear Bracket, Complete Lower Opp and Ext in<br />

1" 90% Alumina Ceramic Tile replaceable Panels,<br />

Upper AR400 Plate 8800335-Z-4-A<br />

Specials<br />

Wear Bracket Special, 1" 85% Alumina Ceramic Tile,<br />

One Piece, Flat Plate, Opposite Direction,<br />

Side and Integral Pivot Block Protection 8800335-M<br />

Wear Bracket Special, 1" 85% Alumina Ceramic Tile,<br />

One Piece, Flat Plate, Std Direction,<br />

Side and Bottom Protection, Relief for Housing Clearance 8800335-N<br />

22

23<br />

Part No.<br />

Aero Style with AR400, Chrome Carbide or<br />

Vacuum Bonded Ceramic Tiles,<br />

Standard and Opposite Directions<br />

Plate, Bracket, Wear (Standard Direction) 8000223L<br />

Roll Bracket Liner, AR400 Plate, One Piece,<br />

Flat Plate, Std Direction, Side and Bottom Protection 8000222<br />

Roll Bracket Liner, AR400 Plate, One Piece,<br />

Flat Plate, Extension to 8000222 for Opposite Direction 8000222F<br />

Roll Bracket Liner, AR400 Plate, One Piece, Flat Plate,<br />

Opposite Direction, Side and Bottom Protection 8000222-A<br />

Roll Bracket Liner, Chrome Carbide, Three Pieces,<br />

Curved as shown 8000222CC<br />

Roll Bracket Liner, Vacuum Bonded Ceramic Tile,<br />

Three Pieces, Curved as shown 8000222VBC<br />

Roll Bracket Liner, 1" 85% Alumina Ceramic Tile,<br />

One Piece, Flat Plate, Std Direction,<br />

Side and Bottom Protection 8800335<br />

Roll Bracket Liner, 1" 85% Alumina Ceramic Tile,<br />

One Piece, Flat Plate,<br />

Extension to 8800335 for Opposite Direction 8800335-F<br />

Roll Bracket Liner, 1" 85% Alumina Ceramic Tile,<br />

One Piece, Flat Plate, Opposite Direction,<br />

Side and Bottom Protection 8800335-A<br />

Upper Bracket Liners<br />

Plate, Bracket, Wear (Standard Direction) 8000223L<br />

Roll Bracket Liner, AR400 Plate, One Piece,<br />

Flat Plate, Std Direction, Side and Bottom Protection 8000222

Asset Planning and Life Cycle Worksheet<br />

24

25<br />

Seal Air Assembly<br />

MPS-type Mill Seal Air Assembly

Item Description Part No.<br />

1 Air Pipe Support – 26 in 84392B<br />

1 Air Pipe Support – 22 in 118213D-0002<br />

2 Seal Air Header, No Support or Inlet 118213-PD<br />

2 Seal Air Header Assembly with Supports and Inlet 118213D<br />

2 Inlet Pipe Only 118213D-003<br />

3 5/8" Hex Head Cap Screw<br />

4 Upper Seal Air Pipe Flange 95790A<br />

5 Air Seal Extension 84391B<br />

6 Gasket 95748A<br />

7 5/8" Lock Washer<br />

8 5/8" Nut<br />

9 3/4" Hex Head Cap Screw<br />

10 Gasket<br />

11 Bearing Guide GP-11089<br />

12 Pipe Support (84386B) GP-11088<br />

13 3/4" Nut<br />

14 3/4" Lock Washer<br />

15 Bearing Cartridge Case (each) 8005528<br />

16 Self Aligning Ball Bushing GP-11092<br />

17 Intermediate Seal Air Pipe (55.375 OL) 3026862<br />

17 Intermediate Seal Air Pipe (66.625 OL) 4555376-A<br />

17 Intermediate Seal Air Pipe (68.563 OL) 4555376<br />

17 Intermediate Seal Air Pipe (68.563 OL) 3026862<br />

17 Intermediate Seal Air Pipe (83.000 OL) 3026862<br />

18 Hex Socket Head Cap Screw 13-4168<br />

19 Lock Washer 15-9005<br />

20 Bearing Cover 8004221<br />

21 Self Aligning Ball Bushing GP-11093<br />

22 Bearing Ring 3018775<br />

23 Bearing Case 8005527<br />

Complete Assemblies<br />

Description Part No.<br />

Complete Assemblies, Items 12 to 23<br />

Specify Intermediate Seal Air Pipe Length 8000255<br />

Complete Assemblies, Items 11 to 23<br />

Specify Intermediate Seal Air Pipe Length C-PLVC-0931<br />

26

27<br />

Spring Frame, Pressure Frame<br />

and Loading Assembly<br />

MPS-type Mill Pressure Frame Assembly

Item Description Part No.<br />

1 Spring Frame (Cast Steel) 170721E<br />

2 Spring, Compression 7001613<br />

3 Pressure Frame (Cast Steel) 170722E<br />

4 Screw Hex Head 1-1/4" 3135<br />

5 Lock Washer<br />

6 Wear Plate, Pressure Frame 8000110<br />

Wear Plate, Housing, 4 Holes 8000112<br />

Wear Plate, Housing, 2 Holes 3062857<br />

7 Pivot Block 8000226<br />

8 Set Screw 5/8"x 1-1/2" Cup Point<br />

9 Split Pin<br />

10 Clevis Pin<br />

11 Washer<br />

12 Link<br />

13 Eye<br />

Pull Down Stud 2"-8UNC x 6" Lg 3018951<br />

Seal Loading Rod 8001473<br />

14 Wire Rope Assembly, 144.75 OAL 8800520<br />

14 Wire Rope Assembly, 132.25 OAL 130206B Mk 2<br />

14 Wire Rope Assembly, 124 OAL 8800511<br />

14 Wire Rope Assembly, 136 OAL 8800517<br />

14 Wire Rope Assembly, 147.25 OAL 8800516<br />

14 Wire Rope Assembly, 159 Eye to End Length 84832B<br />

14 Lower Load Rod, 66" OAL 8001474<br />

14 Clevis Assembly 3022591<br />

15 Nut<br />

16 Top Plate<br />

17 Tension Cylinder 4675536<br />

17 Tension Cylinder 6028679<br />

17 Tension Cylinder 8801999<br />

18 Tie Rod<br />

19 Eye Loading Cylinder<br />

20 Bushing<br />

21 Nut<br />

22 Screw 2"<br />

23 Lock Washer<br />

24 Pin<br />

25 Split Pin<br />

26 Clevis 8005529<br />

Not Shown<br />

Loading Rod Seal Kit 7004533<br />

Loading Rod Seal Kit 8004344<br />

Pressure Frame Liner - Ceramic Panel GP-10910<br />

28

29<br />

Louver and Classifier Assembly<br />

MPS-type Mill Classifier Discharge Assembly

Item Description Part No.<br />

Louver Section, Two Half Sections<br />

(104x19.5, 24 Vane) 179610E<br />

Louver Section (105x19.62, 28 Vane) 170735E<br />

Louver Section (105x19.62, 24 Vane) 229154E<br />

Vane, Classifier 8000057<br />

Vane, Classifier, AR400 Material 8000057-1<br />

Vane, Classifier Louver, Corten Material 8002048<br />

Vane, Louver Section 8002499<br />

Vane, Louver Section 8002767<br />

Louvers, Classifier, Adjustable 8004239<br />

Blade, Classifier Extension 83960-0<br />

Cone, Ceramic Lined 147772D MK-1<br />

Cone, Classifier, Ceramic Lined 8800802<br />

Cone Ceramic Lined 8800829<br />

Cone, Classifier, Ceramic Lined 8802364<br />

Cone, Classifier Repair 8802364-1<br />

Cone, Classifier, Without Ceramic 8001404<br />

Cone, Classifier Section 8001406<br />

Cone, Classifier Ceramic Lined 4626195<br />

Cone, Classifier Ceramic Lined 4634261<br />

Cone, Classifier Ceramic Lined 4656554<br />

Gate, Flap 3023403<br />

Gate, Flap, MPS-89 Mill 3023404<br />

Classifier, Discharge Section 24 3028144<br />

Discharge, Assembly Section 3067836<br />

Field Aleration Items Only 439058E<br />

Hinge, Gate 4519546<br />

Discharge, Classifier Assembly 8000228<br />

Plate, Cone Throat Seg 8001380<br />

Plate, Cone Throat 7 Per Set 8001389<br />

Discharge, Assembly Classifier 8001409<br />

Discharge, Assembly 8001412<br />

Classifier Discharge Assembly 24 8001415<br />

Discharge, Assembly Section 8001416<br />

Section, Classifier, Discharge 8001417<br />

Discharge, Assembly Classifier 8001420<br />

Classifier Discharge Section Assembly 8002769<br />

Bracket, Relief Gate Hinge 8002779<br />

Gate, Flap, Classifier 8005243<br />

Section, Classifier Discharge 8005719-1<br />

Plate Bottom GP-13411<br />

30

31<br />

Turret and Discharge Valve Assembly

33<br />

Turret and Discharge Valve Assembly<br />

Item Description Part No.<br />

5 Mounting Bracket - RH GP-13020-A<br />

10 Mounting Bracket - LH GP-13020<br />

15 Lever Arm GP-13026-A<br />

20 Lever Arm GP-13026<br />

25 Screw - Set 13-7072<br />

30 Collar - Shaft V00-2330<br />

35 Grease Fitting MP-2653<br />

40 Screw - Hex Head 13-3132<br />

45 Washer - Lock 15-2007<br />

50 Washer - Plain 1655<br />

55 Screw - Hex Head 13-3079<br />

60 Nut - Jam 11-4010<br />

65 U-Bolt V00-2058<br />

70 Washer - Plain MD8-00022-AC<br />

75 Nut - Hex 11-2006<br />

80 Lever Arm GP-13027<br />

90 Pin - Cotter 751<br />

95 Pin - Clevis GP-13032<br />

100 Turnbuckle GP-13044<br />

105 Arm Key GP-13045<br />

110 Arm Key GP-13046<br />

115 Arm Key GP-13037<br />

120 Valve Plate GP-13038<br />

130 Screw - Set 13-8028<br />

135 Nut - Jam 11-4006<br />

140 Bearing - Bushing Type GP-13041<br />

145 O-Ring MP-8002<br />

150 Nut - Wing MD8-00076-AC<br />

155 Washer - Lock 15-2000<br />

160 Washer - Plain MD8-00022-AA<br />

165 Cover Plate GP-13023<br />

170 Cover Plate GP-13022-A<br />

175 Cover Plate GP-13021-A<br />

180 Cover Plate GP-13022<br />

185 Cover Plate GP-13021<br />

190 Pin - Clevis GP-13033<br />

195 Shaft GP-13031<br />

200 Shaft GP-13030<br />

205 Lever Arm GP-13028<br />

210 Valve Lever GP-13039<br />

215 Turret Housing - Ceramic Lined GP-13019<br />

Not Shown<br />

Turret Liner with 1/8” Ceramic GP-10908-CERMA<br />

Turret Liner Set, 14 pcs, Ceramic Lined GP-12766<br />

Swing Valve Hinge 145382C<br />

Swing Valve Hinge and Shaft 145382C-1<br />

Turret Liner - Ceramic 189677C-1

S E R V I C E C E N T E R S<br />

34

US Headquarters<br />

Service Centers<br />

Horsburgh & Scott<br />

Aurora, CO<br />

Tyler, TX<br />

Cleveland, OH<br />

Erlanger, KY<br />

Suwanee, GA<br />

Harrisburg, PA<br />

Windsor, CT<br />

Alstom Power <strong>Inc</strong>.<br />

2000 Day Hill Road<br />

Windsor, CT 06095-0500<br />

Tel: 860.285.5400<br />

Fax: 860.285.9611<br />

www.service.power.alstom.com<br />

PSE/BPROB/MPSPLV07/eng/PSER1/10.07/US/6358<br />

© 2008 Alstom Power <strong>Inc</strong>. 06095. Alstom, the Alstom logo and any alternative version thereof are trademarks and service marks of Alstom. The other names mentioned, registered or not, are the property of their respective companies. This document<br />

is submitted in confidence and is to be used solely for the purpose for which it is furnished. Any technical and other data contained in this document is provided for information only. Neither Alstom nor its officers or employees accept responsibility for<br />

or should be taken as making any representation, warranty or guarantee (whether expressed or implied) as to the accuracy or completeness of such data or the achievement of any projected performance criteria where these are indicated. Alstom<br />

reserves the right to revise or change this data at any time without further notice.