Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

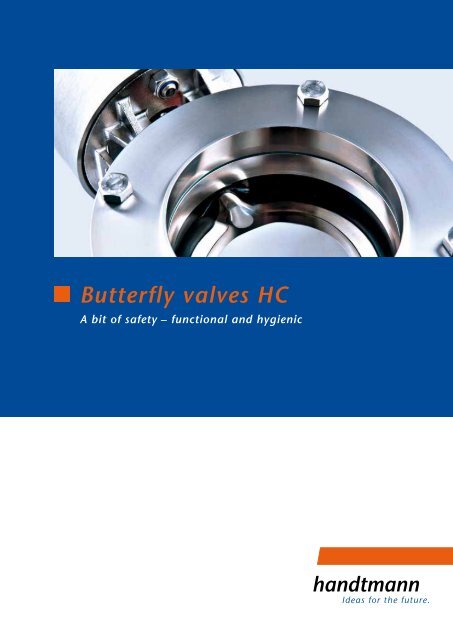

<strong>Butterfly</strong> <strong>valves</strong> <strong>HC</strong><br />

A bit of safety – functional and hygienic

H a n d t m a n n<br />

■ <strong>Butterfly</strong> <strong>valves</strong> <strong>HC</strong><br />

Process and Hygiene<br />

The use of Handtmann butterfly <strong>valves</strong> has been proven effective for decades in<br />

many areas of the food and beverage industry. Safe function with daily operation<br />

– in conjunction with many years of reliable service – is what sets this valve type<br />

apart from the rest.<br />

The variety of <strong>valves</strong>, which can be combined with a control and adjustment unit<br />

if necessary, provides the optimum valve solution for many applications. <strong>Butterfly</strong><br />

<strong>valves</strong> are a cost-effective alternative to distribute and block off fluid and gaseous<br />

processing media.<br />

The Handtmann butterfly valve was structurally revised according to EHEDG<br />

guidelines. The modified product area geometry, the materials used and the<br />

surface quality play a role in achieving a good level of cleanability, which is<br />

confirmed by the institute testing the product.<br />

Reliable and modern – Improved, hygienic construction<br />

and design for even more process and product safety<br />

Design in detail<br />

Safety in detail<br />

Its structural task is to ensure contamination-free operation during<br />

production and CIP cleaning. Microbial deposits and chemical<br />

residue can be prevented in the product area.<br />

This has a crucial effect on these requirements and the subsequent<br />

product quality through the switching functionality of the<br />

butterfly valve. Here the Handtmann know-how lies in the details<br />

and is difficult to recognise at the first glance.<br />

■ Minimizing of the mechanical-dynamic load of the seal<br />

■ Optimum coordination between the sealing<br />

geometry and the installation situation<br />

■ Sealing behaviour with temperature changes<br />

taken into account<br />

Handtmann uses the established EPDM material for its shaped<br />

packing. A standardised, consistent elastomer quality is a<br />

prerequisite to ensure switching functionality, hygiene and the<br />

service life.<br />

■ High abrasion resistance, good antifriction properties<br />

■ High chemical and thermal resistance<br />

■ Good form stability, minimal volume swelling<br />

Mechanical safety as part of the process<br />

■ Reinforced valve shat for torque transfer<br />

■ Forged valve disks with a favourable flow form<br />

■ Increased pressure blow resistance and closing seal<br />

Biological safety as part of the process<br />

■ Optimised vapour geometry<br />

■ Cleanability according to EHEDG guideline<br />

Cost-effectiveness<br />

■ Long service life of seal<br />

■ Seal shape can be used in older valve types<br />

■ Rotary actuators can be disassembled or repaired<br />

■ Small maintenance costs<br />

2 3

H a n d t m a n n<br />

■ <strong>Butterfly</strong> <strong>valves</strong> <strong>HC</strong><br />

<strong>Butterfly</strong> valve types<br />

Switch function manual<br />

Switch function pneumatic<br />

Standard butterfly <strong>valves</strong> Leakage butterfly valve<br />

Handtmann butterfly <strong>valves</strong> are manufactures as different models. Actuation<br />

can optionally be via a manual lever or via the built-in pneumatic actuator.<br />

Possible monitoring of the switch positions is via a proximity switch or a<br />

control head.<br />

■ <strong>Butterfly</strong> <strong>valves</strong> with different process connections<br />

■ Intermediate clamp execution, easy removal of the 2-part valve body<br />

■ Multi-way combination, short discharge with good CIP cleanability<br />

Whatever your needs – Handtmann delivers the<br />

ideal butterfly valve for your application<br />

The easiest type of operation is manual. The different adaptation<br />

possibilities of manual actuation are suitable for all installation<br />

positions.<br />

■ Manual lever with integrated 8 x 45° ball stop,<br />

■ 360° round switch-over, locking optional<br />

■ Manual crank for various settings<br />

■ Bolt-on set for proximity switches<br />

The butterfly <strong>valves</strong> can optionally be equipped with a pneumatic<br />

actuator. The entire nominal size range is covered with 3 actuator<br />

sizes. The actuator with the standard model is spring-closing/air-opening,<br />

other models are available on request.<br />

The switching state of a single butterfly valve is clearly defined via two<br />

possible end positions. They can be recorded via the proximity initiator<br />

or the control head.<br />

■ Actuators are spaciously dimensioned for high torques<br />

■ Integrated assembly points for proximity switches<br />

■ Actuator versions with a settable stroke limitation<br />

■ Actuator versions for the control head or position controller<br />

If safe, mechanical media separation is required, leakage butterfly<br />

<strong>valves</strong> can be used. This cost-effective valve type consists of two<br />

valve disks arranged in succession. One of the valve disks is controlled<br />

via the actuator, the other has forced mechanical control.<br />

The leakage area is equipped with a rinse and leakage valve when<br />

the valve position is closed.<br />

■ Switch function manual or pneumatic<br />

■ Safe media separation<br />

■ Limited switching loss<br />

■ Intermediate clamping execution<br />

4 5

H a n d t m a n n<br />

■ <strong>Butterfly</strong> <strong>valves</strong> <strong>HC</strong><br />

Process automation<br />

Hygiene and automation are closely interrelated. The high demands placed on<br />

quality and quantity can mostly only be met with automated processes. The<br />

complex processes with a variety of process components require an ever-growing<br />

number of "intelligent" control components.<br />

Depending on the requirements, here Handtmann offers different high-quality<br />

control and adjustment components for valve control, monitoring and process<br />

visualisation.<br />

This makes the process reasonable and documentable. User friendliness<br />

and process safety are considerably improved.<br />

Demanding solutions for a smooth flow – Handtmann valve technology<br />

with intelligent control components adapted to the process.<br />

Proximity switch<br />

Control head V.CON<br />

The easiest, most cost-effective way to monitor the switching<br />

position. Assembly is sideways under the actuator or with a bolton<br />

kit on the bottom with manual actuation.<br />

The newly developed control head V.CON is also available for the<br />

Handtmann actuators. Depending on the control head model,<br />

it takes over pneumatic control, recording and acknowledgement<br />

of the switch positions and the monitoring and acknowledgement<br />

of programmed diagnosis and service functions.<br />

■ "High-end" electronics<br />

■ Contact-free, inductive distance measurement system<br />

■ Large, clearly visible LED domed display<br />

■ Easy commissioning<br />

■ Independent determination of the switch positions<br />

■ Service and data interface<br />

■ Connection 24 V, AS-I<br />

Position controller FLOWfix<br />

The intelligent position controller FLOWfix is especially adapted to<br />

the Handtmann actuators. Many tasks in the fluid and gas control<br />

area can often be performed with simpler, more cost-effective solutions<br />

with acceptable precision.<br />

The prescribed adjustment range of the butterfly valve is "intelligently<br />

linearised" through adjustment factors dependent on nominal<br />

sizes. This adjustment principle allows an adjustment tolerance<br />

of 0.5 – 2.0 % depending on the medium.<br />

■ Cost-effective, compact adjustment value<br />

■ Control of fluids and gas / CO ²<br />

■ Housing with display and touch screen<br />

■ Connection 24 V, signal 4 – 20 mA<br />

■ DP profile bus interface<br />

6 7

Technical specifications butterfly <strong>valves</strong><br />

Materials<br />

Product-side 1.4307, 1.4404<br />

Non-product-side 1.4301, 1.4307<br />

Surface<br />

Product-side ≤ 0.8 µm<br />

Non-product-side Finely rotated<br />

Seals<br />

Material EPDM, FDA-compliant<br />

Temperature to 140 °C<br />

Operating data<br />

Operating pressure 0 – 10 bar<br />

Process / CIP 0 – 95 °C<br />

Control air 5 – 8 bar<br />

Sizes<br />

DN nominal sizes 25 – 200<br />

OD nominal sizes 1“ – 4“<br />

Technical specifications control components<br />

Positions Functions<br />

Type Switching Adjustment<br />

Proximity switch 1 / 2 x – –<br />

Feedback head V.CON 2 x – –<br />

Control head V.CON 2 x Open / Closed –<br />

Positioner head FLOWfix 0 – 90 ° Open / Closed 0 – 90 °<br />

Albert Handtmann Armaturenfabrik GmbH & Co. KG · Arthur-Handtmann-Str. 11 · D-88400 Biberach an der Riss<br />

Telefon +49 (0)7351-342-0 · Fax +49 (0)7351-342-4480 · E-Mail: sales.fittings@handtmann.de · www.handtmann.de