. . . an Overview - Siemens India

. . . an Overview - Siemens India

. . . an Overview - Siemens India

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

micromaxindia.com<br />

. . . <strong>an</strong> <strong>Overview</strong>

micromaxindia.com<br />

Our Vision<br />

Be the Best in the business of control & automation.<br />

Our Mission<br />

Our objective<br />

Perfection & professionalism to ensure that products<br />

confirm to specifications meeting customer requirement in<br />

perform<strong>an</strong>ce, reliability <strong>an</strong>d price.

micromaxindia.com<br />

M<strong>an</strong>ufacture<br />

20 years of continued service<br />

with presence in <strong>India</strong> & abroad<br />

Successful execution of over<br />

600 turnkey projects<br />

Remote Terminal Units<br />

Process Instruments<br />

VFD P<strong>an</strong>el<br />

PLC P<strong>an</strong>el<br />

DCS P<strong>an</strong>el<br />

Operator Console<br />

Control P<strong>an</strong>el / Control Desk<br />

Our Expertise<br />

Solution Partner<br />

PLC – Non redund<strong>an</strong>t / Redund<strong>an</strong>t<br />

Distributed Control System<br />

Variable Frequency Drive<br />

Erection services<br />

Commissioning services<br />

Detailed Engineering<br />

Application Software Development<br />

P<strong>an</strong>el Building Turnkey EPC Contractor

micromaxindia.com<br />

Power Pl<strong>an</strong>t<br />

WHRB<br />

FBC<br />

Boilers<br />

Turbine<br />

CPP<br />

Co generation<br />

CCPP<br />

DG<br />

PCMS<br />

255 Projects<br />

Machine Tool<br />

Hydrostatic Pipe<br />

Testing machine<br />

Spiral fin Welding<br />

Machine<br />

Shear Machine<br />

Milling Machine<br />

RHF Machine<br />

Draw Bench M/C<br />

Stretch Reducing<br />

Blade Moulding<br />

Plasma Welding<br />

Machines<br />

65 Projects<br />

Process Pl<strong>an</strong>t<br />

Food Processing<br />

Formaldehyde<br />

Stripper<br />

Centrifuge<br />

Stone wool Insulation<br />

Dipping Machine<br />

MRP<br />

Gypsum Board<br />

212 Projects<br />

Business Verticals<br />

Paper Pl<strong>an</strong>t<br />

Deinking<br />

Color Kitchen<br />

Hydra Pulper<br />

Stock Preparation<br />

Pre Reeler<br />

Paper Machine<br />

Cutter<br />

Super Calendar<br />

Re winder<br />

Reel Wrapping<br />

48 Projects<br />

Cement Pl<strong>an</strong>t<br />

Plastering<br />

Kiln<br />

Raw Material<br />

Preparation<br />

Raw Mill<br />

11 Projects<br />

Sugar Pl<strong>an</strong>t<br />

Mill<br />

Boiling House<br />

Refiner<br />

PAN<br />

Centrifuge<br />

8 Projects

micromaxindia.com<br />

Customer : YADU SUGARS, Uttar Pradesh, <strong>India</strong><br />

Project : 10000 TCD Sugar Pl<strong>an</strong>t with (20 + 12) MW Cogeneration Pl<strong>an</strong>t Automation<br />

Requirements of the customer:<br />

– Automation of<br />

» Mill House<br />

» Boiling House<br />

» 2 * 90 TPH Boiler<br />

» 20 MW & 12 MW Turbine<br />

Reference – Sugar Pl<strong>an</strong>t<br />

Scope of Work:<br />

– Supply of Field Instruments, Erection Material, Cables, Cable Trays for 2 * 70 TPH Travelling Grate Boiler<br />

– Supply of DCS – PCS 7 for Boiler with Remote I/O for Power House<br />

– Supply of DCS – PCS 7 with Remote I/O station for Mill House & Boiling House<br />

– Erection & Commissioning of complete automation package

micromaxindia.com<br />

Reference – Sugar Pl<strong>an</strong>t<br />

Customer : YADU SUGARS, Uttar Pradesh, <strong>India</strong><br />

Project : 10000 TCD Sugar Pl<strong>an</strong>t with (20 + 12) MW Cogeneration Pl<strong>an</strong>t Automation<br />

The Solution:<br />

– AS 417-4H Bundle (1No.) for Cogeneration with Remote I/O P<strong>an</strong>els for Boiler 1, Boiler 2 <strong>an</strong>d<br />

Power House networked on PROFIBUS. A total of ~2800 I/Os hooked to the system.<br />

– Drives (34 Nos.) of ABB make networked through Y Link module on PROFIBUS.<br />

– For Sugar, Hot Redund<strong>an</strong>t AS 417-4H Bundle (1 No.) with Remote I/O P<strong>an</strong>el for Mill House<br />

<strong>an</strong>d Boiling House. A total of ~1500 I/Os hooked to the system.<br />

– I/O P<strong>an</strong>els interfaced on PROFIBUS FO with OLM G11<br />

– The Sugar & Cogeneration DCS established on Ring redund<strong>an</strong>cy.<br />

– A cost effective solution was conceived for the customer.<br />

– The price <strong>an</strong>d the expertise was the decisive reason for the customer to finalise the order on us.<br />

– The concept of TIA with flexibility of exp<strong>an</strong>sion had been the winning point.

micromaxindia.com<br />

Benefits to the customer:<br />

– High Availability due to Hot Redund<strong>an</strong>cy<br />

– Flexibility of exp<strong>an</strong>sion during commissioning<br />

– Monitoring & Control established from both the areas<br />

– Savings in cable cost with remote I/O p<strong>an</strong>el <strong>an</strong>d by communicating drives on PROFIBUS.<br />

– The flexibility of operation of Cogeneration Pl<strong>an</strong>t from Sugar <strong>an</strong>d vice versa is made possible thereby<br />

reducing operational costs.<br />

Reference – Sugar Pl<strong>an</strong>t<br />

Customer : YADU SUGARS, Uttar Pradesh, <strong>India</strong><br />

Project : 10000 TCD Sugar Pl<strong>an</strong>t with (20 + 12) MW Cogeneration Pl<strong>an</strong>t Automation<br />

– Uniformity in the usage of modules benefitting the customer with less inventory reducing mainten<strong>an</strong>ce costs.

micromaxindia.com<br />

ES CUM OS<br />

AS 417-4H<br />

Bundle<br />

SYSTEM CONFIGURATION OF SIEMENS PCS7 DCS<br />

System Configuration<br />

OS 1 OS 2 OS 3 ES CUM OS<br />

OS 1 OS 1 OS 3 OS 4<br />

ET200M Remote<br />

I/O Station<br />

Redund<strong>an</strong>t Ethernet<br />

AS 417-4H<br />

Bundle<br />

PROFIBUS FO<br />

ET200M Remote<br />

I/O Station<br />

Boiler System Power House Mill House Boiling House<br />

10000 TCD Sugar Mill with 32 MW Cogeneration Pl<strong>an</strong>t<br />

Automation at M/s. Yadu Sugars Limited, Badu<strong>an</strong>

micromaxindia.com<br />

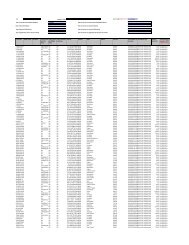

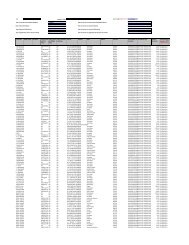

PCS 7 References – Partial List<br />

S.No. Customer Execution Period Project<br />

1 Chilwaria Sugars Limited- II 2008-2009 1*80 TPH Bagasse fired Boiler<br />

2 Ruby Macons Limited 2009-2010 5 MW Captive Power Pl<strong>an</strong>t<br />

3 Hitech Steel Minerals 2009-2010 5 MW Captive Power Pl<strong>an</strong>t<br />

4 Malabar Cements Limited 2009-2010 5000 TPD Cement Pl<strong>an</strong>t<br />

5 Ramakrishna Solvex 2009-2010 7.3 MW Captive Power pl<strong>an</strong>t<br />

6 Renuka Sugars Limited 2009-2010 1*100 TPH Boiler Automation<br />

7 Basai Steels 2009-2010 20 MW Captive Power Pl<strong>an</strong>t<br />

8 Gokak Sugars Limited, 2010-2011 94 TPH Dumping Grate Boiler<br />

9 Sah<strong>an</strong>ur<strong>an</strong>g, Thail<strong>an</strong>d 2010-2011 1*200 TPH Boiler Automation<br />

10 Obeik<strong>an</strong> Glass, Saudi Arabia 2010-2011 800 TPD Float Glass Automation

micromaxindia.com<br />

PCS 7 References – Partial List<br />

S.No. Customer Execution Period Project<br />

11 Yadu Sugars, Saj<strong>an</strong>pur 2010-2011 10000TCD Sugar Pl<strong>an</strong>t Automation<br />

12 Yadu Sugars, Saj<strong>an</strong>pur 2010-2011 32 MW Power Pl<strong>an</strong>t Automation<br />

13 Green Pl<strong>an</strong>et Limited 2010-2011 7.3MW Cogen Power Pl<strong>an</strong>t<br />

14 Green Pl<strong>an</strong>et Limited 2010-2011 7.3MW Cogen Power Pl<strong>an</strong>t<br />

15 Green Pl<strong>an</strong>et Limited 2010-2011 7.3MW Cogen Power Pl<strong>an</strong>t<br />

16 Gujarat NRE Limited 2010-2011 8*20 TPH WHR Boiler<br />

17 Sh<strong>an</strong>tha Power 2011-2012 10MW Independent Power Pl<strong>an</strong>t<br />

18 NR Agarwal Limited 2011-2012 1*85 TPH Power Pl<strong>an</strong>t<br />

19 Aurobindo Pharma 2011-2012 60 TPH Boiler Automation<br />

20 Gag<strong>an</strong> Ferro Industries 2011-2012 12 MW Power Pl<strong>an</strong>t Automation

micromaxindia.com<br />

Our Focus<br />

Building Process Expertise<br />

Building Technical Expertise<br />

Market Penetration<br />

Time M<strong>an</strong>agement<br />

Work Scheduling<br />

Key Factors

micromaxindia.com<br />

Our approach<br />

Introduction of PET (Program for Enterprise Tr<strong>an</strong>sformation)<br />

Team based approach instead of Departments<br />

Composite Team encompassing all employees<br />

Team based approach to nurture <strong>an</strong>d motivate the skill sets of the<br />

individuals.<br />

Responsibility of h<strong>an</strong>dling the projects taken by front runners, reporting to<br />

Team leaders.<br />

Increased Motivation <strong>an</strong>d involvement.<br />

Key Factors

micromaxindia.com<br />

New Initiative<br />

Venturing into m<strong>an</strong>ufacturing of Special Purpose Machines (SPM )<br />

Complete Packaging solution for a PET Bottle m<strong>an</strong>ufacturing unit.<br />

Repeat orders for six machines within one year based on quality<br />

product <strong>an</strong>d perform<strong>an</strong>ce

micromaxindia.com<br />

Th<strong>an</strong>k you<br />

The long <strong>an</strong>d finite way of achievement in business<br />

……………………..Winning customer Loyalty