Godwin Pumps adopts keytech PLM - keytech Software GmbH

Godwin Pumps adopts keytech PLM - keytech Software GmbH

Godwin Pumps adopts keytech PLM - keytech Software GmbH

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Success Story<br />

<strong>Godwin</strong> <strong>Pumps</strong> <strong>adopts</strong> <strong>keytech</strong> <strong>PLM</strong><br />

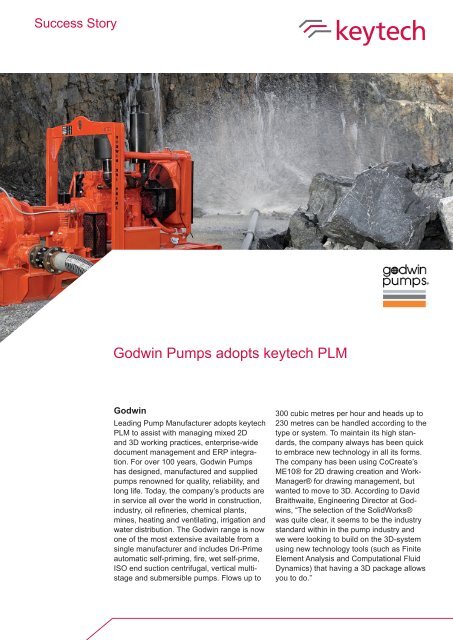

<strong>Godwin</strong><br />

Leading Pump Manufacturer <strong>adopts</strong> <strong>keytech</strong><br />

<strong>PLM</strong> to assist with managing mixed 2D<br />

and 3D working practices, enterprise-wide<br />

document management and ERP integration.<br />

For over 100 years, <strong>Godwin</strong> <strong>Pumps</strong><br />

has designed, manufactured and supplied<br />

pumps renowned for quality, reliability, and<br />

long life. Today, the company’s products are<br />

in service all over the world in construction,<br />

industry, oil refineries, chemical plants,<br />

mines, heating and ventilating, irrigation and<br />

water distribution. The <strong>Godwin</strong> range is now<br />

one of the most extensive available from a<br />

single manufacturer and includes Dri-Prime<br />

automatic self-priming, fire, wet self-prime,<br />

ISO end suction centrifugal, vertical multistage<br />

and submersible pumps. Flows up to<br />

300 cubic metres per hour and heads up to<br />

230 metres can be handled according to the<br />

type or system. To maintain its high standards,<br />

the company always has been quick<br />

to embrace new technology in all its forms.<br />

The company has been using CoCreate’s<br />

ME10® for 2D drawing creation and Work-<br />

Manager® for drawing management, but<br />

wanted to move to 3D. According to David<br />

Braithwaite, Engineering Director at <strong>Godwin</strong>s,<br />

“The selection of the SolidWorks®<br />

was quite clear, it seems to be the industry<br />

standard within in the pump industry and<br />

we were looking to build on the 3D-system<br />

using new technology tools (such as Finite<br />

Element Analysis and Computational Fluid<br />

Dynamics) that having a 3D package allows<br />

you to do.”

<strong>Godwin</strong> - the decision for <strong>keytech</strong> <strong>PLM</strong><br />

Need of <strong>PLM</strong>-system<br />

As with any successful business, zeal to<br />

adopt new technology has to be tempered<br />

with the need to maintain existing processes<br />

and data. <strong>Godwin</strong>s have in excess of<br />

20,000 ME10® drawings and these need to<br />

be live and working for the next five years.<br />

Braithwaite explained their plans for implementation<br />

of 3D-CAD and how it affected<br />

their PDM selection process “We see 3 to<br />

5 years time before all of the legacy data<br />

in 2D becomes ‘for reference’ only, rather<br />

than live working drawings. At present,<br />

we’re going to be working with 2D and 3D,<br />

developing new drawings and new parts<br />

in 2D, as well as introducing 3D; so we’re<br />

running two CAD-systems at the same time<br />

and will be for at least the next two years,<br />

possibly three. It will be three to five years<br />

“<strong>keytech</strong> <strong>PLM</strong> is not just a drawing<br />

management system; it’s a document<br />

management system.”<br />

before we drop 2D all together and just use<br />

it for maintaining legacy data.” As a result,<br />

<strong>Godwin</strong>s needed a PDM-system that would<br />

allow them to manage and work with both<br />

their extensive 2D drawing data and newer<br />

data generated within SolidWorks®.<br />

Initially <strong>Godwin</strong>s explored expanding the<br />

implementation of its existing 2D drawing<br />

management system, but it discovered<br />

limitations when handling SolidWorks®<br />

data. Braithwaite explains that “It worked<br />

to a point but had limitations so we could<br />

just store 2D and 3D information in one<br />

management system, but there were issues<br />

in that it was not supported properly, we<br />

could not carry out certain functions such as<br />

creating Bills of Materials combining the two<br />

sets of information and could not do simple<br />

things like batch plots. So, we started<br />

looking around for another PDM package<br />

that would enable us to manage the legacy<br />

data and the new SolidWorks® data in one<br />

system.”<br />

Exploring their options further, <strong>Godwin</strong>s<br />

revisited its 3D-CAD supplier. Braithwaite<br />

explains that “SolidWorks is supplied with<br />

a basic document management system,<br />

PDMWorks® Workgroup, which will handle<br />

the SolidWorks data, but it wouldn’t allow us<br />

to access the legacy 2D data; we couldn’t<br />

mix the two.” Having discounted PDMWorks<br />

Workgroup, the final short list came down to<br />

two potential systems, PDMWorks® Enterprise<br />

and <strong>keytech</strong> <strong>PLM</strong>.<br />

While <strong>Godwin</strong>s saw the benefit of a single<br />

supplier and support from the SolidWorks®<br />

channel, critical issues meant <strong>keytech</strong> <strong>PLM</strong><br />

gained the competitive edge. As Braithwaite<br />

explained, “PDMWorks® Enterprise would<br />

allow us to store and view ME10® drawings<br />

alongside SolidWorks data, but currently it<br />

had issues with combining the two to create<br />

Bill of Materials for transferring to our<br />

ERP-system. It did not allow us to do all<br />

the things we wanted to do, most critically,<br />

running two live systems – which <strong>keytech</strong><br />

<strong>PLM</strong> does.”<br />

Alongside the ability to control and management<br />

two CAD-systems, <strong>Godwin</strong>s are also<br />

looking to <strong>keytech</strong> <strong>PLM</strong> to assist with providing<br />

more access across the enterprise. As<br />

Braithwaite explains, “The other advantage<br />

and the reason we picked up on <strong>keytech</strong> <strong>PLM</strong><br />

was the potential for the company. <strong>keytech</strong><br />

<strong>PLM</strong> is not just a drawing management<br />

system; it’s a document management system.<br />

Our previous system was a drawing<br />

management system, solely used for CAD<br />

data. <strong>keytech</strong> is going to be used by all departments<br />

within the company. We can give<br />

access to everybody within the company to<br />

the technical data, drawings, etc.”<br />

The implementation of <strong>keytech</strong>:<br />

Phase One<br />

In terms of scope for roll-out, <strong>Godwin</strong>s are<br />

planning a two stage implementation. Phase<br />

One will see it set-up within the Engineering<br />

Department. This will provide the<br />

Drawing Office, Service, Quality Assurance

and Development departments. <strong>keytech</strong><br />

will be used to manage all documents,<br />

not just CAD-data, but also sales sheets,<br />

data sheets, O and M books – essentially,<br />

anything that the staff produce and control<br />

will be stored, managed and controlled<br />

within <strong>keytech</strong> <strong>PLM</strong>.<br />

Phase Two<br />

The second Phase of implementation is to<br />

expand access to the remaining departments,<br />

which will critically mean Sales and<br />

Purchasing department will be using <strong>keytech</strong><br />

<strong>PLM</strong> alongside <strong>Godwin</strong>s’ ERP-system. ERP<br />

integration was the third critical selection<br />

criteria for the PDM-system. As Braithwaite<br />

explains, “<strong>Godwin</strong>s’ have our own in-house<br />

developed ERP-system and we’re now in<br />

the process of replacing it. So, I wanted a<br />

system that would integrate with the newer<br />

proprietary ERP-systems. So that was another<br />

reason that we went down the <strong>keytech</strong><br />

route. We want to set-up a document<br />

management system which is<br />

independent but<br />

would integrate<br />

tightly with<br />

our<br />

new<br />

ERPsystem.”<br />

Phase Three<br />

A product of <strong>Godwin</strong>.<br />

Phase Three of implementation will see use<br />

of the <strong>keytech</strong> <strong>PLM</strong> expanded beyond its UK<br />

manufacturing and design centre. <strong>Godwin</strong><br />

<strong>Pumps</strong> is owned by <strong>Godwin</strong>s <strong>Pumps</strong> of<br />

America, so the next step is that <strong>keytech</strong><br />

<strong>PLM</strong> is going to be used communicate and<br />

share data with the US. As the US part<br />

of the company is currently using Auto-<br />

CAD, this might have caused issues with<br />

other PDM suppliers or as Braithwaite put<br />

it “They don’t use SolidWorks, they use<br />

AutoCAD, so if we’d have gone down the<br />

route of PDMWorks® Enterprise, we would<br />

have been struggling to integrate within our<br />

document management system.“<br />

Pros of data management<br />

When asked about why the design and manufacturing<br />

industry has begun to believe in<br />

the benefits of data management, Braithwaite<br />

explained how he saw <strong>keytech</strong> <strong>PLM</strong> fitting<br />

into the company’s processes and the benefits<br />

that would naturally ensue from adoption<br />

of the system, “Everyone now works electronically.<br />

We were printing 150 drawings a<br />

day in different departments – we don’t need<br />

to do that. If everyone has controlled access<br />

to the latest issue of a drawing, and we can<br />

set permissions as to who sees what and<br />

who does what with it – It has to be the way<br />

forward.”<br />

About <strong>keytech</strong><br />

<strong>keytech</strong> is a leader in the integration of<br />

CAD-, ERP- and Data Management-systems<br />

into cohesive, yet affordable, environments<br />

that fulfill its customers’ requirements<br />

and boost their productivity across many<br />

areas of the enterprise. With integration of<br />

major 2D- and 3D-CAD-systems and integrations<br />

into major ERP-systems, <strong>keytech</strong>’s<br />

flagship offering, <strong>keytech</strong> <strong>PLM</strong>, is a scalable<br />

solution, beginning with simple document<br />

management and ending in a complete Product<br />

Lifecycle Management solution.<br />

NB: Brand and product names are trademarks of their<br />

respective owners.<br />

Note to Editors: All supplied images are copyright to <strong>Godwin</strong><br />

<strong>Pumps</strong>. High resolution imagery can be supplied on request.

<strong>Godwin</strong> <strong>Pumps</strong> Ltd.<br />

Quenington, Cirencester,<br />

Gloucestershire GL7 5BX<br />

Tel.: 01285 750 271<br />

Fax: 01285 750 352<br />

sales@godwinpumps.co.uk<br />

www.godwinpumps.co.uk<br />

<strong>keytech</strong> <strong>Software</strong> <strong>GmbH</strong><br />

Suderwichstraße 68<br />

45665 Recklinghausen<br />

Tel.: +49 2361 985 80 0<br />

Fax: +49 2361 985 80 23<br />

info@<strong>keytech</strong>.de<br />

www.<strong>keytech</strong>.de