Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

K MELTING SHOP<br />

Internet-PDF from “Casting Plant & Technology “ 02 / 2012, pages 22 – 23<br />

© Giesserei-Verlag, Düsseldorf<br />

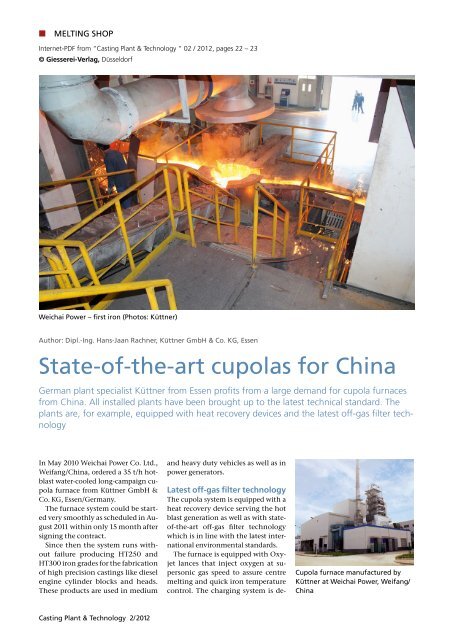

Weichai Power – first iron (Photos: Küttner)<br />

Author: Dipl.-Ing. Hans-Jaan Rachner, Küttner GmbH & Co. KG, Essen<br />

<strong>State</strong>-<strong>of</strong>-<strong>the</strong>-<strong>art</strong> <strong>cupolas</strong> <strong>for</strong> <strong>China</strong><br />

German plant specialist Küttner from Essen pr<strong>of</strong>its from a large demand <strong>for</strong> cupola furnaces<br />

from <strong>China</strong>. All installed plants have been brought up to <strong>the</strong> latest technical standard. The<br />

plants are, <strong>for</strong> example, equipped with heat recovery devices and <strong>the</strong> latest <strong>of</strong>f-gas filter technology<br />

In May 2010 Weichai Power Co. Ltd.,<br />

Weifang/<strong>China</strong>, ordered a 35 t/h hotblast<br />

water-cooled long-campaign cupola<br />

furnace from Küttner GmbH &<br />

Co. KG, Essen/Germany.<br />

The furnace system could be st<strong>art</strong>ed<br />

very smoothly as scheduled in August<br />

2011 within only 15 month after<br />

signing <strong>the</strong> contract.<br />

Since <strong>the</strong>n <strong>the</strong> system runs without<br />

failure produ cing HT250 and<br />

HT300 iron grades <strong>for</strong> <strong>the</strong> fabrication<br />

<strong>of</strong> high precision castings like diesel<br />

engine cylinder blocks and heads.<br />

These products are used in medium<br />

Casting Plant & Technology 2/2012<br />

and heavy duty vehicles as well as in<br />

power generators.<br />

Latest <strong>of</strong>f-gas filter technology<br />

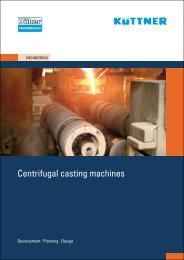

The cupola system is equipped with a<br />

heat recovery device serving <strong>the</strong> hot<br />

blast generation as well as with state<strong>of</strong>-<strong>the</strong>-<strong>art</strong><br />

<strong>of</strong>f-gas filter technology<br />

which is in line with <strong>the</strong> latest international<br />

environmental standards.<br />

The furnace is equipped with Oxyjet<br />

lances that inject oxygen at supersonic<br />

gas speed to assure centre<br />

melting and quick iron temperature<br />

control. The charging system is de-<br />

Cupola furnace manufactured by<br />

Küttner at Weichai Power, Weifang/<br />

<strong>China</strong>

Cupola top charging<br />

Coke bed measurement<br />

signed <strong>for</strong> a reliable heavy duty operation<br />

and assures precise raw material<br />

dosing and feeding.<br />

Use <strong>of</strong> recovered heat<br />

Recently fur<strong>the</strong>r cupola furnace systems<br />

have been ordered also from<br />

FAW Foundry Co. Ltd., Jilin/<strong>China</strong>,<br />

and Chongqing Machinery & Electronics<br />

Holding Corp. Ltd., Chongqing/<br />

<strong>China</strong>.<br />

FAW Foundry Co. has decided to use<br />

<strong>the</strong> recovered heat <strong>of</strong> <strong>the</strong> cupola furnace<br />

<strong>for</strong> several applications like <strong>for</strong><br />

heating <strong>of</strong> six core drying furnaces,<br />

heating <strong>of</strong> a sand storage and <strong>of</strong> shower<br />

water.<br />

The cupola plant design <strong>for</strong> Chongqing<br />

MEC will consider also metallurgical<br />

options to a djust <strong>the</strong> carbon<br />

content between 2.8 and 3.8 mass -%<br />

and to remove sulphur <strong>for</strong> <strong>the</strong> production<br />

<strong>of</strong> no dular iron. Both fur na ces<br />

will st<strong>art</strong> <strong>the</strong>ir operation in 2013.<br />

www.kuettner.com<br />

Casting Plant & Technology 2/2012