Centrifugal casting machines - Küttner - Engineering and Contracting

Centrifugal casting machines - Küttner - Engineering and Contracting

Centrifugal casting machines - Küttner - Engineering and Contracting

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

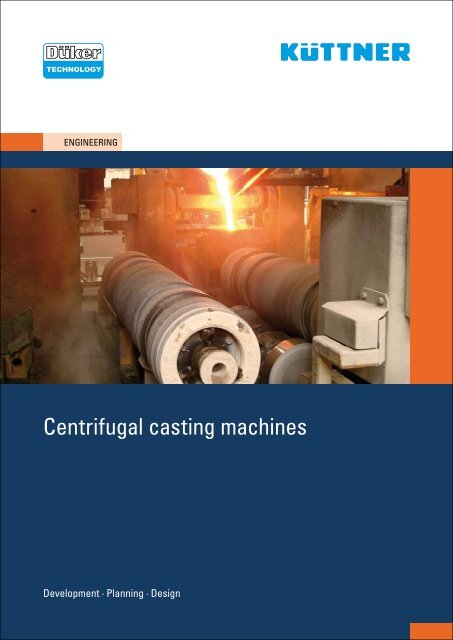

TECHNOLOGY<br />

ENGINEERING<br />

<strong>Centrifugal</strong> <strong>casting</strong> <strong>machines</strong><br />

Development · Planning · Design

<strong>Centrifugal</strong> <strong>casting</strong> <strong>machines</strong> from Düker – over 500 years of experience in iron <strong>casting</strong><br />

The name Düker has stood for top quality iron cas-<br />

ting for more than 500 years. Today we are one of<br />

the leading manufacturers of fittings, pressure<br />

pipe fittings for drinking water <strong>and</strong> gas supplies<br />

<strong>and</strong> of pipes <strong>and</strong> fittings for drainage technology.<br />

We also manufacture highly resistant enamelled<br />

components <strong>and</strong> pipes for the chemical <strong>and</strong> pharmaceutical<br />

industries. Another production field of<br />

our business is job <strong>casting</strong>s where we act as a contract<br />

manufacturer for parts for the printing, automotive<br />

<strong>and</strong> mechanical engineering industries.<br />

Training<br />

2<br />

Service<br />

Consultancy<br />

<strong>Centrifugal</strong><br />

<strong>casting</strong> <strong>machines</strong><br />

from Düker<br />

Installation<br />

Planning<br />

Düker <strong>Engineering</strong> – worldwide service<br />

With this background of immense experience, we also plan <strong>and</strong> build complete<br />

centrifugal <strong>casting</strong> plants, cokeless cupola furnaces <strong>and</strong><br />

control systems for manufacturing business all over the world.<br />

No two of these designs are the same up to now. Every project<br />

is individual <strong>and</strong> depends on the site conditions <strong>and</strong> the specific<br />

requirements of the customer. Since we have also been using<br />

our <strong>machines</strong> for many years for our own production operation,<br />

our customers have a unique range of expertise at their disposal,<br />

which is constantly being updated <strong>and</strong> extended.<br />

Implementation/<br />

Design<br />

We thereby offer our customers worldwide a convenient <strong>and</strong><br />

customized all-round service which is virtually unique – from<br />

the design, planning <strong>and</strong> construction to assembly, commissioning<br />

<strong>and</strong> training your personnel – you receive everything from<br />

a single source.<br />

Vergiessung der Kokillen an der teilautomatischen Düker-Schleudergussanlage A200<br />

A comparison of centrifugal <strong>casting</strong><br />

Rotation symmetrical bodies, such as pipes, cylindrical sleeves, bearing cages<br />

or bushes, are currently almost exclusively manufactured using centrifugal<br />

<strong>casting</strong>. A distinction is made between two processes:<br />

Hot mould process<br />

• Preheated <strong>and</strong> spray-coated moulds<br />

• No energy-intensive final annealing<br />

• Long service life of the mould<br />

De Lavaud process<br />

• Untreated, water-cooled mould<br />

• Primarily used for the mass production of pressure pipes<br />

We design centrifugal <strong>casting</strong> <strong>machines</strong> which use both processes.<br />

Depending on the product <strong>and</strong> quantity involved you can choose between a<br />

wide range of machine concept, from manual mode to a fully automatic<br />

complete system.<br />

Certified quality<br />

We received certification to DIN EN ISO 9001<br />

way back in 1993. Since then our quality management<br />

system has been updated <strong>and</strong> improved<br />

on an on-going basis by means of regular inspections<br />

<strong>and</strong> also internal <strong>and</strong> external audits.<br />

3

<strong>Centrifugal</strong> <strong>casting</strong> <strong>machines</strong> from Düker – tailored to your individual needs<br />

Top photograph: Casting station.<br />

Bottom photograph: <strong>Centrifugal</strong> <strong>casting</strong> frame<br />

We need very few details for planning your system<br />

– simply tell us what products you wish to produce<br />

<strong>and</strong> in what quantities <strong>and</strong> the design of any exis-<br />

ting equipment. We will then design the ideal cen-<br />

trifugal <strong>casting</strong> system for your needs.<br />

Wide range of system types<br />

• Single-station <strong>machines</strong> for small production<br />

rates <strong>and</strong> special applications with just one<br />

mould. This machine is flexible enough for a wide<br />

range of products.<br />

• Multi-station <strong>machines</strong> for mass production<br />

with high quantities per hour. Several moulds<br />

are used in parallel.<br />

• Flange <strong>machines</strong> (both vertical <strong>and</strong> horizontal)<br />

for large diameters of up to 3,000 mm with short<br />

product lengths.<br />

Basic layout of a single station machine<br />

Single station machine for truck cylinder liners<br />

Casting discharge device<br />

Modernisation<br />

The installation of a completely new system is<br />

not always the best solution for the needs of the<br />

customer. Therefore we can also modernise<br />

existing systems – regardless of their location.<br />

Modernisation is also a good solution if the<br />

existing system only has to be improved, auto-<br />

mated <strong>and</strong> fitted with a modern control <strong>and</strong><br />

measuring system to meet changed requirements.<br />

It makes no difference to us whether<br />

the existing system was supplied by us or by<br />

another manufacturer.<br />

4 5

<strong>Centrifugal</strong> <strong>casting</strong> <strong>machines</strong> – from manual to fully automatic … <strong>and</strong> everything in between<br />

Manual <strong>machines</strong> offer high flexibility <strong>and</strong> quick<br />

change of machine set-up for different products.<br />

Highly automated systems provide maximum<br />

precision <strong>and</strong> perfect processes for mass produc-<br />

tion. That reduces waste, increases availability <strong>and</strong><br />

extends the service life of the <strong>machines</strong> <strong>and</strong> also<br />

guarantees uniform high quality.<br />

Each system can be fitted with a process visua-<br />

lisation system <strong>and</strong> a link to a database-based<br />

process control system.<br />

We are the global leader in this area <strong>and</strong> unique in<br />

the range of services we offer.<br />

Machine type A100 for cast iron soil pipes Machine type D5 for pressure pipes<br />

Machine type B80 for cylinder liners<br />

Machine type B90 for cylinder liners<br />

After we have carefully planned, designed <strong>and</strong> produced your machine, it will<br />

be pre-installed at our plant in Karlstadt, Germany. At the same time our in-<br />

ternal specialists develop your individual machine control system which<br />

complies with all the relevant st<strong>and</strong>ards <strong>and</strong> is also suitable for remote<br />

maintenance.<br />

We also offer practical training courses to make your personnel familiar<br />

with the function <strong>and</strong> the control of our centrifugal <strong>casting</strong> machine <strong>and</strong> their<br />

controllers. This transfer of expertise means that production can be started<br />

immediately after the assembly work <strong>and</strong> commissioning procedure have been<br />

6 7<br />

completed.<br />

Convincing data<br />

Depending on the system type, the following<br />

dimensions <strong>and</strong> quantities can be produced:<br />

Pipe dimensions:<br />

External diameter: from 30 mm to 3,000 mm<br />

Internal diameter: from 18 mm to 2,800 mm<br />

Pipe lengths: from 500 mm to 6,000 mm<br />

Production capacities extend up to 250 pipes<br />

or sleeves per hours – depending on the wall<br />

thickness <strong>and</strong> setting time.<br />

Training <strong>and</strong> maintenance<br />

Naturally we are also available for you after the<br />

commissioning procedure for your new or moder-<br />

nised centrifugal <strong>casting</strong> <strong>machines</strong>. For example<br />

we can provide training courses <strong>and</strong> advan-<br />

ced training for your personnel, keep your sys-<br />

tem working correctly with regular service <strong>and</strong><br />

maintenance work <strong>and</strong> also keep you up to date<br />

with possible modernisation options.

TECHNOLOGY<br />

ENGINEERING<br />

GLASS LINING TECHNoLoGIES<br />

JobbING FouNDRy<br />

FITTINGS AND vALvES<br />

DRAINAGE TECHNoLoGy<br />

09.12 Subject to technical changes <strong>and</strong> printing errors.<br />

<strong>Küttner</strong> <strong>Centrifugal</strong> Casting GmbH<br />

Würzburger Straße 16<br />

D-97753 Karlstadt/Main<br />

Phone +49 9353 791-235<br />

Fax +49 9353 791-175<br />

Internet: www.kuettner-cc.com<br />

E-Mail: info@kuettner-cc.com