Centrifugal casting machines - Küttner - Engineering and Contracting

Centrifugal casting machines - Küttner - Engineering and Contracting

Centrifugal casting machines - Küttner - Engineering and Contracting

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Centrifugal</strong> <strong>casting</strong> <strong>machines</strong> – from manual to fully automatic … <strong>and</strong> everything in between<br />

Manual <strong>machines</strong> offer high flexibility <strong>and</strong> quick<br />

change of machine set-up for different products.<br />

Highly automated systems provide maximum<br />

precision <strong>and</strong> perfect processes for mass produc-<br />

tion. That reduces waste, increases availability <strong>and</strong><br />

extends the service life of the <strong>machines</strong> <strong>and</strong> also<br />

guarantees uniform high quality.<br />

Each system can be fitted with a process visua-<br />

lisation system <strong>and</strong> a link to a database-based<br />

process control system.<br />

We are the global leader in this area <strong>and</strong> unique in<br />

the range of services we offer.<br />

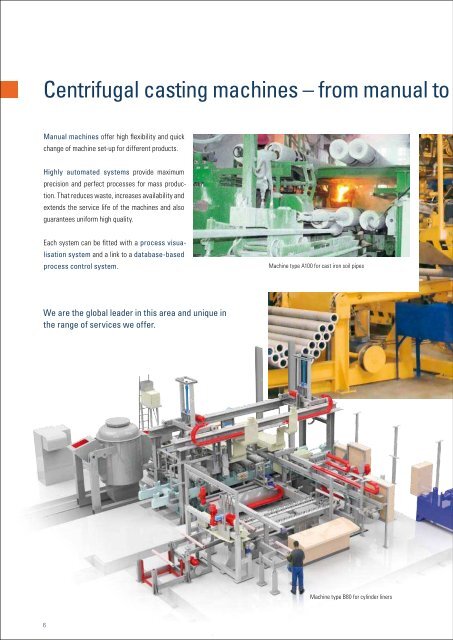

Machine type A100 for cast iron soil pipes Machine type D5 for pressure pipes<br />

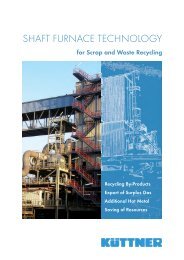

Machine type B80 for cylinder liners<br />

Machine type B90 for cylinder liners<br />

After we have carefully planned, designed <strong>and</strong> produced your machine, it will<br />

be pre-installed at our plant in Karlstadt, Germany. At the same time our in-<br />

ternal specialists develop your individual machine control system which<br />

complies with all the relevant st<strong>and</strong>ards <strong>and</strong> is also suitable for remote<br />

maintenance.<br />

We also offer practical training courses to make your personnel familiar<br />

with the function <strong>and</strong> the control of our centrifugal <strong>casting</strong> machine <strong>and</strong> their<br />

controllers. This transfer of expertise means that production can be started<br />

immediately after the assembly work <strong>and</strong> commissioning procedure have been<br />

6 7<br />

completed.<br />

Convincing data<br />

Depending on the system type, the following<br />

dimensions <strong>and</strong> quantities can be produced:<br />

Pipe dimensions:<br />

External diameter: from 30 mm to 3,000 mm<br />

Internal diameter: from 18 mm to 2,800 mm<br />

Pipe lengths: from 500 mm to 6,000 mm<br />

Production capacities extend up to 250 pipes<br />

or sleeves per hours – depending on the wall<br />

thickness <strong>and</strong> setting time.<br />

Training <strong>and</strong> maintenance<br />

Naturally we are also available for you after the<br />

commissioning procedure for your new or moder-<br />

nised centrifugal <strong>casting</strong> <strong>machines</strong>. For example<br />

we can provide training courses <strong>and</strong> advan-<br />

ced training for your personnel, keep your sys-<br />

tem working correctly with regular service <strong>and</strong><br />

maintenance work <strong>and</strong> also keep you up to date<br />

with possible modernisation options.