Issue No. 7, September 2007 - J. Lauritzen

Issue No. 7, September 2007 - J. Lauritzen

Issue No. 7, September 2007 - J. Lauritzen

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

OCEANS OF KNOW-HOW<br />

<strong>September</strong> <strong>2007</strong><br />

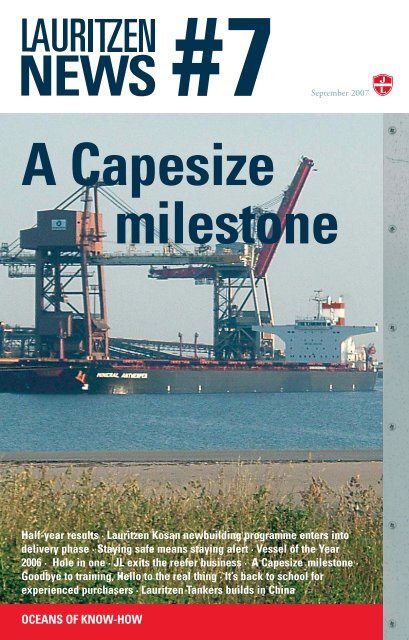

A Capesize<br />

milestone<br />

Half-year results · <strong>Lauritzen</strong> Kosan newbuilding programme enters into<br />

delivery phase · Staying safe means staying alert · Vessel of the Year<br />

2006 · Hole in one · JL exits the reefer business · A Capesize milestone ·<br />

Goodbye to training, Hello to the real thing · It’s back to school for<br />

experienced purchasers · <strong>Lauritzen</strong> Tankers builds in China

4<br />

5<br />

6<br />

8<br />

9<br />

10<br />

13<br />

14<br />

16<br />

18<br />

19<br />

20<br />

Half-year results <strong>2007</strong><br />

<strong>Lauritzen</strong> Kosan newbuilding<br />

programme enters into delivery phase<br />

Staying safe means staying alert<br />

Vessel of the Year 2006<br />

Hole in one<br />

JL exits the reefer business<br />

A Capesize milestone<br />

Allotment gardens - nature and leisure<br />

within the city limits<br />

Goodbye to training, Hello to the<br />

real thing<br />

It’s back to school for experienced<br />

purchasers<br />

<strong>Lauritzen</strong> Tankers builds in China<br />

Namegiving ceremonies

Dear Reader,<br />

The ability to handle uncertainty and change is paramount in today’s business<br />

world with its increasing competitive pressures. The ability to cope with and<br />

even thrive on change can thus be regarded as a major competitive advantage.<br />

The decision to sell JL’s 50% shareholding in NYK<strong>Lauritzen</strong>Cool, and consequently<br />

to exit reefer shipping, is an excellent example. I take pride in the way it<br />

demonstrates our ability to change. JL’s history in the reefer business (see article,<br />

page 10) illustrates our ability to constantly seek new opportunities through<br />

innovation, market development, and flexibility – and to continuously respond<br />

to changing market conditions.<br />

It is, of course, emotional to leave the fascinating reefer industry together with<br />

all our trustworthy customers and dedicated colleagues worldwide. We wish all<br />

our friends in the reefer industry good luck and thank them for the trust they<br />

have shown us during many years. However, our exit from the reefer business<br />

will open new opportunities for JL.<br />

I find it fair to state that the ability to cope with change is built into the culture,<br />

organisation, and management style of JL. I am very pleased with that. But there<br />

is always a risk that complacency might be lurking around the corner. Therefore,<br />

we constantly have to sharpen our skills and competencies and thus our ability<br />

to continuously change.<br />

During the last couple of months, other major changes have occurred. <strong>Lauritzen</strong><br />

Bulkers has ordered no less than four Capesize bulk carriers, manifesting its presence<br />

in this segment of the bulk market. The Capes are the biggest vessels ever ordered<br />

by JL. During the summer, <strong>Lauritzen</strong> Tankers ordered six additional product tankers,<br />

another sign of our continuous fleet build-up in the MR product tanker market.<br />

With 50 owned and time-chartered vessels on order, JL has the biggest newbuilding<br />

portfolio ever recorded. Furthermore, partners will add 15 additional<br />

newbuildings to the JL-managed fleet.<br />

I am pleased to report that JL’s result for the first six months of <strong>2007</strong> was<br />

USD 132 million compared to USD 60 million in 2006 and thus better than<br />

expected and very satisfactory. The outlook for the remaining part of the year<br />

is positive, and the best ever full-year result is expected for <strong>2007</strong>.<br />

Sincerely,<br />

Torben Janholt<br />

President & CEO<br />

Although some organisations<br />

may continue successfully with<br />

their current strategies, most<br />

will undoubtedly need to change.<br />

Of course, any change brings<br />

uncertainty, and some organisations<br />

are better at coping<br />

with that situation than others.<br />

Torben Janholt,<br />

President and CEO<br />

3

4<br />

Very satisfactory<br />

half-year results <strong>2007</strong><br />

JL’s result for the first six months of<br />

<strong>2007</strong> was USD 132 million compared<br />

to USD 60 million in 2006. The<br />

result is better than expected and very<br />

satisfactory.<br />

The improvement compared to 2006<br />

was primarily driven by a substantial<br />

strengthening of the bulk market,<br />

increasing activities within JL’s product<br />

tanker division, and gains on securities.<br />

Earnings in <strong>Lauritzen</strong> Kosan and<br />

<strong>Lauritzen</strong> Reefers were better than<br />

expected but lower than last year due<br />

to lower profit from sale of vessels and<br />

for <strong>Lauritzen</strong> Kosan particularly due<br />

to the sale of the small gas carrier<br />

activity towards the end of 2006.<br />

The newbuilding programme further<br />

increased to a total of 50 vessels, including<br />

19 vessels that will be taken on longtime<br />

time-charter. Furthermore, joint<br />

venture partners will add another 15<br />

newbuildings to the JL-managed fleet.<br />

During the first half of <strong>2007</strong>, JL’s 50%<br />

shareholding in NYK<strong>Lauritzen</strong>Cool<br />

was sold to joint-venture partner NYK<br />

Reefers Ltd. As consequence of the<br />

transaction, JL will leave the reefer<br />

market (see article on page 10).<br />

Invested capital (average) 1H USDm<br />

800<br />

600<br />

400<br />

200<br />

0<br />

Bulk Gas Tank Reefer JL<br />

2006 <strong>2007</strong><br />

Fleet<br />

During the first six months of the year,<br />

JL took delivery of two Handysize<br />

bulk carriers, two MR product tankers<br />

(one of which was sold at delivery),<br />

and one 8,000 cbm ethylene gas carrier<br />

(the first of a series of six sister vessels).<br />

Additionally, JL took delivery of four<br />

long-term time-chartered product<br />

tankers and one Handysize bulk carrier.<br />

Year-to-date, investments in 15 fully<br />

or part-owned vessels were approved,<br />

as were divestments in five vessels and<br />

other assets.<br />

After the exit from the reefer business,<br />

JL controls a combined fleet of about<br />

130 vessels at the beginning of August<br />

<strong>2007</strong>. Based on current commitments,<br />

a total of 65 newbuildings will be added<br />

to the fleet during the coming years,<br />

bringing the total fleet to 195 vessels.<br />

Invested capital<br />

During the first half of <strong>2007</strong>, invested<br />

capital increased by USD 255 million<br />

compared with the same period last<br />

year. Average invested capital was<br />

USD 695 million, of which USD 291<br />

million relates to <strong>Lauritzen</strong> Bulkers,<br />

USD 265 million to <strong>Lauritzen</strong> Kosan,<br />

and USD 140 million to <strong>Lauritzen</strong><br />

Tankers.<br />

JL’s newbuilding commitments total<br />

about USD 1.3 billion. In addition,<br />

JL’s investment capacity amounts to<br />

about USD 1 billion.<br />

<strong>Lauritzen</strong> Bulkers<br />

The result before tax was USD 114.4<br />

million compared to USD 34 million<br />

in the same period last year. The result<br />

is considerably better than expected.<br />

Towards the end of the first half of<br />

<strong>2007</strong>, <strong>Lauritzen</strong> Bulkers ordered<br />

four Capesize bulk carriers, further<br />

strengthening its presence in this<br />

segment of the bulk market.<br />

<strong>Lauritzen</strong> Kosan<br />

During the first half of the year,<br />

<strong>Lauritzen</strong> Kosan realised a result<br />

before tax of USD 7.2 million compared<br />

to USD 16.9 million in the<br />

same period last year. The result is<br />

better than expected.<br />

The first of a series of innovative<br />

8,000 cbm ethylene gas carriers was<br />

delivered in May. A further nine identical<br />

vessels will be delivered during<br />

Key figures 1st Half Total Year<br />

<strong>2007</strong> 2006 2006<br />

(USD million) Actual Actual Actual<br />

<strong>Lauritzen</strong> Bulkers 114,4 34,0 93,4<br />

<strong>Lauritzen</strong> Kosan 7,2 16,9 38,3<br />

<strong>Lauritzen</strong> Tankers 13,6 1,6 3,8<br />

<strong>Lauritzen</strong> Reefers 9,9 16,2 13,2<br />

Landbased activities (0,2) (1,2) (3,7)<br />

Other (7,6) (1,3) (8,7)<br />

Result before tax 137,3 66,2 136,3<br />

Tax and minorities (5,8) (6,3) (11,9)<br />

Net result 131,5 59,9 124,4<br />

Cash and securities 10,3 104,4 48,6<br />

Long-term debt, total 44,8 68,1 49,9<br />

Equity (excl. min.) 782,3 614,4 679,8<br />

Total assets 991,8 755,9 929,7

the coming years, five of them owned<br />

by <strong>Lauritzen</strong> Kosan and four by jointventure<br />

partners.<br />

<strong>Lauritzen</strong> Tankers<br />

The result before tax was USD 13.6<br />

million compared to USD 1.6 million<br />

in the same period in 2006. The result<br />

is better than expected.<br />

During the summer, <strong>Lauritzen</strong> Tankers<br />

ordered six additional products tankers,<br />

further strengthening the fleet build-up<br />

in the MR product tanker market.<br />

<strong>Lauritzen</strong> Tankers’ newbuilding programme<br />

comprises 12 owned and timechartered<br />

vessels.<br />

<strong>Lauritzen</strong> Reefers<br />

The result before tax was USD 9.9<br />

million compared to USD 16.2 million<br />

in the same period in 2006. The<br />

result is in line with expectations.<br />

In connection with the 50% sale of<br />

NYK<strong>Lauritzen</strong>Cool, JL’s portfolio<br />

of time-chartered reefer vessels was<br />

transferred to NYKCool AB. Four<br />

reefer vessels will, however, remain<br />

on bareboat charter to <strong>Lauritzen</strong><br />

Reefers and be commercially operated<br />

by NYKCool<br />

Total fleet (August <strong>2007</strong>)<br />

Owned 34<br />

Part-owned 14<br />

T/C 39<br />

Pool 28<br />

Joint charters 12<br />

Comm. mngt. 4<br />

Total 131<br />

N/B (own) 31<br />

N/B (T/C) 19<br />

N/B (partners) 15<br />

Key figures<br />

Return on invested capital for the first<br />

six months of <strong>2007</strong> was 34.5% compared<br />

to 27.7% in the same period in<br />

2006.<br />

Return on equity was 37.7% compared<br />

to 19.6% in the same period in 2006.<br />

Solvency was 78.9% compared to<br />

81.3% last year.<br />

Outlook<br />

Due to the continued strong global<br />

economy and the overall positive outlook<br />

for JL’s business activities, the net<br />

result for <strong>2007</strong> is expected to be substantially<br />

higher than earlier estimated<br />

and the best in the history of JL.<br />

<strong>Lauritzen</strong> Kosan<br />

newbuilding<br />

programme<br />

enters into<br />

delivery phase.<br />

Past issues of this magazine have provided<br />

progress reports on Laurtizen<br />

Kosan’s extensive newbuilding project<br />

of ten ethylene gas carriers being built<br />

at INP shipyard in Ulsan, Korea. The<br />

first of these, the Isabella Kosan, was<br />

delivered on 31 May. After extensive<br />

sea and gas trials, she sailed from<br />

Korea to Iran to load her first cargo.<br />

“All the tests went very well,” says<br />

Jan Kastrup-Nielsen, president of<br />

<strong>Lauritzen</strong> Kosan, “which is as we<br />

expected. But when you’ve spent so<br />

long reviewing diagrams and drawings,<br />

it’s always a relief when a cargo is<br />

actually loaded.” The next ship in<br />

the series, the Helena Kosan, is due<br />

to be delivered early <strong>September</strong>. All<br />

ten of the vessels are scheduled to be<br />

completed and delivered by 2009.<br />

5

6<br />

Staying sa<br />

means stay<br />

“Our onboard ship management is tight,<br />

and our crews are fully confident with<br />

what it takes to stay safe – and that’s<br />

what matters”<br />

Tommy Thomassen<br />

Senior Vice President, Head of <strong>Lauritzen</strong> Fleet Management<br />

How J. <strong>Lauritzen</strong> ships avoid modern-day pirates,<br />

terrorists, and run-of-the-mill bad guys.<br />

If you have recently enjoyed a couple of<br />

hours in a dark theatre happily eating<br />

popcorn and watching Pirates of the<br />

Caribbean, you can be excused for<br />

thinking of piracy as a threat from the<br />

past. In fact, it is a danger that never<br />

entirely disappeared and one that is<br />

making an impressive comeback off<br />

the west coast of Africa, in some of the<br />

same waters where the Barbary pirates<br />

of centuries past preyed on shipping<br />

in the western Mediterranean.<br />

21st-century pirates are often trained<br />

and heavily armed fighters who use<br />

speedboats equipped with satellite<br />

phones and Global Positioning System<br />

equipment and have the backing of landbased<br />

militias. They are notoriously<br />

active off Somalia's coast. Although no<br />

J. <strong>Lauritzen</strong> vessels have been attacked,<br />

a Danish vessel, the Danica White, was<br />

hijacked in June, 210 nautical miles<br />

off the Somalian coast.<br />

International naval forces do attempt<br />

to protect shipping in this area –<br />

because of Middle East oil production<br />

it attracts heavy traffic – but the size<br />

of the territory to be patrolled gives<br />

the pirates an edge. Even when help<br />

is at the right spot at the right time,<br />

rescue efforts are not always successful:<br />

the USS Carter Hall, part of a US<br />

task force, fired on the Danica White’s<br />

hijackers, but had to call off its pursuit<br />

after the pirates entered Somalia’s territorial<br />

waters.<br />

Awareness and discipline<br />

Large commercial vessels can’t do much<br />

to protect themselves. They are too<br />

slow to outrun the pirates, and most<br />

shipping companies do not allow<br />

ships’ crews to be armed. When asked<br />

to explain J. <strong>Lauritzen</strong>’s 100% success<br />

rate in modern time at avoiding this<br />

danger, Tommy Thomassen, senior<br />

vice president and head of <strong>Lauritzen</strong><br />

Fleet Management (LFM), gives a<br />

disarmingly simple answer. “Our ships<br />

play it safe,” he says. “Off Somalia, for<br />

example, instruction is to stay at least<br />

250 nautical miles from shore. It’s a<br />

matter of staying alert and being disciplined<br />

– observing the right security<br />

level, posting extra guards, and always<br />

being prepared. Our onboard ship<br />

management is tight, and our crews

e<br />

ing alert<br />

are fully confident with what it takes<br />

to stay safe – and that’s what matters ”<br />

Achieving a consistent level of security<br />

awareness and discipline is a matter of<br />

training, and LFM sees that everyone<br />

is trained in security, in Denmark<br />

and the Philippines and in the Baltic<br />

countries. There are three Company<br />

Security Officers, and each ship in the<br />

fleet has a specially trained Ship Security<br />

Officer as part of the International<br />

Ship and Port Security (ISPS) code.<br />

International regulation<br />

A major part of a Security Officer’s<br />

responsibility is ensuring compliance<br />

with the ISPS code that was implemented<br />

in the wake of 9/11. Each<br />

J. <strong>Lauritzen</strong> ship has an individual<br />

security plan, with specific guidelines<br />

about how to respond – and how not<br />

to respond – in emergency situations.<br />

Additionally, all ships undergo rigorous<br />

audits: internal LFM security reviews<br />

and inspections and Flag State security<br />

audits. “These audits are valuable not<br />

only because they document that we<br />

comply with requirements, but also<br />

because they help us and the shipboard<br />

management and crew to continue<br />

stay on our toes when it comes to<br />

security, not allowing us to slowly<br />

doze off” says Tommy Thomassen.<br />

He also notes that the ISPS regulations<br />

were by far one of the fastest<br />

produced and implemented pieces of<br />

maritime regulation ever, and points<br />

out that rules covering port security<br />

are among the most important part of<br />

the code. “The regulations tightened<br />

quayside security with strict visitor<br />

rules and improved search routines for<br />

stowaways and explosives,” he says, “so<br />

they provide a layer of security against<br />

everything from terrorist threats to<br />

common criminals.” ISPS regulations<br />

also focus on the important transition<br />

from sea to port, by requiring ships’<br />

security officer and the port security<br />

officer to coordinate security levels in<br />

a structured manner. In volatile areas<br />

this is vitally important to ship security.<br />

7

8<br />

Vessel of the Year 2006<br />

Congratulations to the master, officers, and crew of the Tessa<br />

Kosan for achieving best-in-fleet inspection performance.<br />

The vessel received only two Ship Specific Remarks in 2006.<br />

Ulrich Voss (on left), Vetting Superintendent, <strong>Lauritzen</strong> Kosan, presents award<br />

plaque to Captain Nestor Aimero.<br />

“The performance of the Tessa Kosan is a<br />

good example of people pulling together to<br />

put our core values into practice.”<br />

Klaus Grøndal<br />

Vetting Manager, <strong>Lauritzen</strong> Kosan<br />

An article in the March 2006 issue<br />

of this magazine reported on the<br />

initial success of <strong>Lauritzen</strong> Kosan’s<br />

Zero Remarks vetting programme. It<br />

encourages high standards of vetting<br />

inspections through monetary awards<br />

to ships’ welfare accounts whenever a<br />

ship posts an inspection score of 0-4<br />

remarks. Successful vetting is crucial in<br />

gaining business from the oil majors,<br />

and it is also an opportunity to promote<br />

<strong>Lauritzen</strong> Kosan as a safe and responsible<br />

shipowner. As Klaus Grøndal,<br />

vetting manager of <strong>Lauritzen</strong> Kosan,<br />

puts it, “Vetting inspections are the<br />

entry ticket to all our business. <strong>No</strong>t<br />

doing well can have serious consequences,<br />

as an unsuccessful inspection<br />

can end up with the vessel being<br />

rejected by our customers, with loss of<br />

goodwill and earnings as a result”. A<br />

rejected vessel is required to be satisfactorily<br />

re-inspected before it again<br />

may do business for the individual<br />

customer, which is not only costly<br />

but also time-consuming.<br />

During 2006, there were a total of 86<br />

inspections carried out, of which 17%<br />

received zero ship-specific remarks.

The average amount of money awarded<br />

per inspection was increased by 75%<br />

in 2006, and there were a growing<br />

number of USD 500 awards for a<br />

perfect score. The award money is<br />

used for the benefit of the entire crew,<br />

both those working at the time of the<br />

inspection and those who join the ship<br />

at a later date. Funds can be spent on<br />

anything from video games to karaoke<br />

systems to sports equipment. The idea<br />

of identifying an overall winner as the<br />

Vessel of the Year is a new addition to<br />

the programme – one for which the<br />

officers and crew of the Tessa Kosan<br />

were awarded a commemorative plaque<br />

and a 32” flat-screen TV.<br />

“This programme is all about encouraging<br />

team effort, and it’s obviously<br />

been very successful,” says Klaus<br />

Grøndal. “We’re not only paying out<br />

more reward money, but the steady<br />

reduction in crew-related remarks<br />

also indicates a real change in attitude<br />

and awareness. The performance of<br />

the Tessa Kosan is a good example<br />

of people pulling together to put our<br />

core values into practice.”<br />

Hole in one<br />

While anchored on the roads off<br />

Newcastle, Australia, the Pasha<br />

Bulker – on long-term time charter to<br />

<strong>Lauritzen</strong> Bulkers – ran aground during<br />

a major storm on 8 June <strong>2007</strong>,<br />

just off the local golf club at <strong>No</strong>bbys<br />

Beach. The vessel remained grounded<br />

on the beach only a few meters from<br />

the greens, where it became a tourist<br />

attraction and certainly also a distraction<br />

for the club’s keen golfers.<br />

After the dramatic grounding all 22<br />

Korean and Filipino crew members<br />

were successfully rescued from the<br />

vessel by helicopter. The vessel had<br />

no cargo onboard, as it was waiting<br />

to load coal. During further stormy<br />

weather, the ship was pushed onto<br />

the beach and was stuck in the sand,<br />

completely trapped between the<br />

beach and the reef. There were fears<br />

that it could break up and cause environmental<br />

problems.<br />

The vessel’s Japanese owners, together<br />

with salvage experts, decided to try to<br />

refloat the ship. After the third attempt,<br />

it was successfully towed off<br />

the reef on 2 July <strong>2007</strong>. Minor<br />

repairs were conducted in Newcastle<br />

harbour before the Pasha Bulker was<br />

towed for major repairs.<br />

The incident caused extraordinary<br />

media attention worldwide, but fortunately<br />

neither the crew nor the<br />

environment suffered any damage.<br />

As time-charter owners, <strong>Lauritzen</strong><br />

Bulkers had no responsibility for the<br />

navigation of the vessel nor for the<br />

rescue, but we thank the owners and all<br />

Australian authorities involved in the<br />

rescue operation for a job well done.<br />

9

10<br />

For more than a century, J. <strong>Lauritzen</strong> reefer ships have<br />

served worldwide markets. Seen here, the Knud <strong>Lauritzen</strong><br />

off New Zealand with a full load of containers.<br />

The end of an era<br />

reefer business<br />

A history of more than 100<br />

years has come to an end with<br />

J. <strong>Lauritzen</strong>’s sale of its 50%<br />

share of NYK<strong>Lauritzen</strong>Cool to<br />

NYK Reefers Limited, JL’s professional<br />

and dedicated partner<br />

during the last four years. As<br />

a consequence of the transaction,<br />

NYK will take full control<br />

of the company, which has<br />

been renamed NYKCool AB.<br />

Pioneer of the reefer trades<br />

JL was a pioneer in the development<br />

of the reefer trades, carrying citrus from<br />

Spain to England as early as 1905.<br />

During the 1920’s, JL installed electrical<br />

ventilation systems in the cargo holds<br />

of its vessels in order to improve the<br />

still rather primitive carrying conditions<br />

for perishable cargoes. Regular services<br />

were established from Italian ports to<br />

the UK, from Sicily and Spain to<br />

Gdyniain in Poland, and between the<br />

Canary Islands and Antwerp in the<br />

Netherlands. In 1925 JL opened its<br />

first overseas office in Valencia, Spain.<br />

During the 1930’s, JL expanded its<br />

reefer activities considerably. In 1931,<br />

JL performed its first shipment of<br />

bananas from West Africa to France.<br />

This was a major achievement, since<br />

there was no experience in transportation<br />

of bananas over such long distances.<br />

Also in 1932, JL negotiated a long-term<br />

contract concerning transportation of<br />

bananas from the West Indies to Europe,<br />

and JL subsequently became instrumental<br />

in the development of the trans-<br />

atlantic banana trades. JL consequently<br />

played a leading role in the expansion<br />

of the reefer business during the 1930’s,<br />

and JL’s reefer activities were also<br />

extended to include Chile, Ecuador,<br />

Brazil, and South Africa.<br />

On the vessel side, the first of a series of<br />

three general cargo vessels were reconstructed<br />

at Elsinore Shipyard in Denmark,<br />

part of the J. <strong>Lauritzen</strong> Group,<br />

in the beginning of the 1930’s. These<br />

converted refrigerated vessels played<br />

an important role in the early phase of<br />

the development of the reefer trades.<br />

A new milestone was reached in 1935,<br />

when JL took delivery of its first purpose-built<br />

reefer vessel, equipped with<br />

specialised cooling machinery, also from<br />

the shipyard in Elsinore. The YRSA,<br />

later renamed African Reefer, was JL’s<br />

first vessel to carry the “Reefer” name<br />

and traded for JL until 1963. During<br />

the second half of the 1930’s, JL further<br />

expanded its fleet of dedicated<br />

reefer vessels and the African Reefer<br />

was followed by a series of sister vessels.

“J. <strong>Lauritzen</strong> has enjoyed a strong partnership with NYK Reefers and<br />

a very good cooperation with our Swedish colleagues. As a part of<br />

<strong>Lauritzen</strong>’s overall strategy we decided to sell our reefer fleet in 2006,<br />

and it is therefore only natural that NYK takes over our 50% shareholding<br />

of the joint marketing company.<br />

Torben Janholt, President & CEO, J. <strong>Lauritzen</strong><br />

: JL exits the<br />

Modern reefer vessels<br />

In 1953 a new series of modern reefer<br />

vessels was ordered at the <strong>Lauritzen</strong><br />

Group’s shipyards in Elsinore and<br />

Aalborg, Denmark. Major innovations<br />

included replacing inflammable cork<br />

with glass wool as insulation material<br />

and replacing traditional wooden gratings<br />

with aluminium gratings. Diesel<br />

engines from Burmeister & Wain gave<br />

the vessels a service speed of 18 knots.<br />

The African Reefer, delivered in 1935,<br />

was J. <strong>Lauritzen</strong>’s first purpose-built<br />

reefer vessel equipped with specialised<br />

cooling machinery.<br />

In the second half of the 1950s more<br />

new vessels were ordered, and the vessels’<br />

carrying capacity was increased<br />

to almost 250,000 cbft. A noticeable<br />

change was made in their appearance<br />

as these vessels, instead of being white,<br />

were painted the same JL-red as the<br />

company’s polar vessels.<br />

Between 1968 and 1974, six sister<br />

vessels were built at Aalborg Shipyard.<br />

These were the so-called Italian reefer<br />

class, with a cargo carrying capacity of<br />

422,000 cbft. and able to make a laden<br />

speed of 22 knots.<br />

The pool concept<br />

Around 1970, a pool concept was<br />

adopted by J. <strong>Lauritzen</strong> in order to<br />

secure economies of scale through the<br />

control of a larger number of vessels<br />

from other owners. Thus a jointventure<br />

with Peninsular and Oriental<br />

Steam Navigation Company Ltd.<br />

(P&O) was established in 1971 under<br />

the name of <strong>Lauritzen</strong>-Peninsular<br />

Reefers (LPR). The company was owned<br />

on a fifty-fifty basis between JL and<br />

P&O, but vessels belonging to other<br />

reefer owners were also operated by<br />

LPR. By 1975, LPR controlled a combined<br />

fleet of some 25 reefer vessels.<br />

During this period, JL’s fleet of reefer<br />

vessels gradually expanded with bigger<br />

ships, and in the late 1970’s four sister<br />

vessels – the Asian Reefer, Balkan Reefer,<br />

Canadian Reefer, and Ecuadorian Reefer<br />

– were delivered, each with a hold<br />

capacity of 588,000 cbft. and a speed<br />

of 22 knots. The partnership existed<br />

until 1983, when P&O decided to<br />

withdraw. Consequently, JL became<br />

the sole owner of LPR and the company<br />

name was changed to <strong>Lauritzen</strong><br />

Reefers.<br />

After 1983, the <strong>Lauritzen</strong> Reefers’<br />

pool was gradually developed, including<br />

JL’s reefer vessels as well as vessels<br />

belonging to other reefer owners. JL<br />

contributed the majority of the vessels<br />

employed in the pool, which in the<br />

beginning of the 1990’s comprised<br />

about 65 specialised reefer vessels.<br />

JL/LR became a market leader with<br />

regards to trade development as well as<br />

technological innovation. An example<br />

of trend-setting technological innovation<br />

was the development of the Family<br />

11

12<br />

“It is obviously emotional for us to leave the reefer business and we<br />

wish NYKCool a fair wind. We want to thank all our trustworthy customers<br />

worldwide for their continued support. We also thank the many<br />

dedicated employees of JL who over many years worked hard to meet<br />

our customers’ demands.”<br />

Torben Janholt, President & CEO, J. <strong>Lauritzen</strong><br />

Class reefer vessels (758,725 cbft.<br />

capacity under deck and 118 FEU<br />

reefers on deck) delivered from<br />

Danyard (Aalborg and Frederikshavn<br />

Shipyards) in 1990-91. A reefer-industrial<br />

cluster had gradually evolved<br />

within the <strong>Lauritzen</strong> Group, which<br />

included construction at Danyard of<br />

state-of-the-art reefer vessels equipped<br />

with advanced cooling machinery produced<br />

by Sabroe Refrigeration, ownership<br />

of reefer vessels by J. <strong>Lauritzen</strong>,<br />

and commercial management of tonnage<br />

by <strong>Lauritzen</strong> Reefers’ pool.<br />

Over the years <strong>Lauritzen</strong> Reefers worked<br />

diligently to optimise the return on<br />

voyages by exploiting the flexibility<br />

of the reefer ships’ holds to carry dry<br />

cargoes on return voyages. The reefer<br />

trades are characteristically from the<br />

southern to the northern hemisphere,<br />

and the ability to carry packaged<br />

goods or, at a later date, containers on<br />

the return voyages could significantly<br />

improve the bottom-line. This concept<br />

peaked during the years of cooperation<br />

with the NOBOA group, with<br />

bananas and other fruits as fronthaul<br />

cargoes for the US and Japan markets<br />

and cars as backhaul cargoes from<br />

Japan to Chile, Peru, and Ecuador.<br />

Major acquisitions<br />

<strong>Lauritzen</strong> Reefers’ pool was terminated<br />

in 1996, after which LR was established<br />

as a stand-alone entity operating tonnage<br />

solely owned and time-chartered<br />

by JL.<br />

In December 2000, JL acquired Cool<br />

Carriers from <strong>No</strong>rwegian Leif Hoegh<br />

& Co. and subsequently merged<br />

<strong>Lauritzen</strong> Reefers and Cool Carriers,<br />

creating <strong>Lauritzen</strong>Cool. Following this<br />

initial strategic move, JL became<br />

instrumental in the consolidation of<br />

the reefer industry. <strong>Lauritzen</strong> Reefers<br />

and Cool Carriers were a perfect<br />

strategic fit, which combined two of<br />

the strongest brand names in the<br />

industry, with robust market positions<br />

in all major trades, strong conceptual<br />

skills, and long-lasting customer relationships.<br />

Furthermore, both companies<br />

had experience with land-based<br />

reefer logistics as a supplement to<br />

ocean transportation, and on that<br />

basis <strong>Lauritzen</strong>Cool Logistics (LCL)<br />

was established.<br />

In August 2003, a strategic partnership<br />

was established between NYK Reefers<br />

and <strong>Lauritzen</strong>Cool. This was shortly<br />

followed by NYK’s acquisition of 50%<br />

of LCL in January 2004 and NYK’s<br />

subsequent 50% acquisition of<br />

<strong>Lauritzen</strong>Cool in <strong>September</strong> 2005,<br />

whereby NYK<strong>Lauritzen</strong>Cool was<br />

created. Finally, NYK acquired the<br />

remaining 50% of NYK<strong>Lauritzen</strong>Cool,<br />

effective 1 June <strong>2007</strong>, thereby taking<br />

full control of the company.<br />

Ongoing excellence<br />

For JL, the recent transaction marks<br />

the end of an era with intimate customer<br />

relationships and great colleagues.<br />

We thank them all for their<br />

trust and support, and wish them all<br />

the best of luck in the future.<br />

J. <strong>Lauritzen</strong> will endeavour to bring<br />

the entrepreneurship, innovative skills,<br />

and flexibility that we have gained<br />

within the reefer industry with us<br />

in our constant effort to become a<br />

world-class shipping company, irrespective<br />

of within which segments of<br />

shipping we concentrate our efforts.<br />

Background source for article:<br />

Søren Thorsøe. “J. <strong>Lauritzen</strong> 1884-1984.”<br />

The World Ship Society, Kendal, 1984.<br />

Hiroshi Yamafuji (on left), CEO, NYK Reefers and Torben Janholt,<br />

President & CEO, J. <strong>Lauritzen</strong>

A Capesize milestone<br />

<strong>Lauritzen</strong> Bulkers places<br />

first-ever order for Capesize<br />

newbuildings with Korea’s<br />

Hyundai shipyard.<br />

Although <strong>Lauritzen</strong> Bulkers acquired<br />

two time-charter Capesize vessels last<br />

year, the order with Hyundai is the<br />

first for newbuildings of this size.<br />

They are scheduled for delivery during<br />

the last quarter of 2009 and the first<br />

quarter of 2010. In addition, two similar<br />

Capesizes have been ordered from<br />

Japanese yards. “At 180,000 tons deadweight,<br />

they’re the biggest ships we’ve<br />

ever ordered,” says Jens Ditlev <strong>Lauritzen</strong>,<br />

president of <strong>Lauritzen</strong> Bulkers. “In<br />

the larger picture, these four Capesize<br />

purchases are part of our ongoing<br />

strategy of taking every opportunity<br />

to strengthen the <strong>Lauritzen</strong> Bulkers<br />

fleet, which is today at a record level<br />

of more than 85 ships.” The growth<br />

strategy is further evidenced by the<br />

fact that <strong>Lauritzen</strong> Bulkers is awaiting<br />

delivery of more than 40 other vessels,<br />

including purchased, contracted, and<br />

time-chartered ships. They are to be<br />

delivered between now and 2011, and,<br />

encompassing a variety of vessel sizes<br />

and types, indicate <strong>Lauritzen</strong> Bulkers’<br />

determination to increase its fleet across<br />

all segments.<br />

Capesize ships – so called because they<br />

are too large to traverse the Panama<br />

Canal and therefore must round the<br />

Cape of Good Hope and Cape Horn<br />

to travel between oceans – represent<br />

the largest type of bulker carriers. The<br />

“In the larger picture, these four Capesize<br />

purchases are part of our ongoing strategy<br />

of taking every opportunity to strengthen the<br />

<strong>Lauritzen</strong> Bulkers fleet, which is today at a<br />

record level of more than 85 ships.”<br />

Jens Ditlev <strong>Lauritzen</strong><br />

President, <strong>Lauritzen</strong> Bulkers<br />

ships on order at Hyundai are being<br />

built to meet the latest CSR (Common<br />

Structural Rules) and PSPC (Performance<br />

Standard for Protective Coating) standards.<br />

The application of these standards<br />

serve various purposes, namely<br />

to prolong the service life of the vessel,<br />

increase its safety, and at the same time<br />

reduce its maintenance. They will be<br />

used primarily to transport iron ore,<br />

and are 292 metres long, have a 45<br />

metre beam, and draw an 18-metre<br />

draft fully loaded. Because of the enormous<br />

pressure of being loaded at rates<br />

of up to 15,000 tons per hour, the<br />

four new vessels will also incorporate<br />

a stress-monitoring system to protect<br />

their hulls.<br />

13

14<br />

Allotment<br />

gardens –<br />

nature and<br />

leisure within<br />

the city limits<br />

For the past 12 months, JL’s working<br />

environment has been slightly different<br />

from our posh neighbourhood in downtown<br />

Copenhagen.<br />

At Sankt Annae Plads our nearest<br />

neighbour is the new Opera house.<br />

At our temporary premises at Amager<br />

Strandvej the Opera House has been<br />

replaced with a small green enclave<br />

containing a concentration of small,<br />

unique sheds – so-called allotment<br />

gardens. Compared to the downtown<br />

neighbourhood with its charming<br />

boutiques, art galleries, and gourmet<br />

restaurants at every turn, the contrast<br />

of the new surroundings is striking.<br />

Allotment gardens form a characteristic<br />

feature of Danish cultural life, and<br />

the roots of this phenomenon can be<br />

tracked back to the late Middle Ages,<br />

when gardens were situated outside<br />

town walls and served as an important<br />

food supply. In the 1890s, due to the<br />

Industrial Revolution, poor housing,<br />

and an increase in population, the<br />

interest in allotment gardens increased.<br />

In that period the city of Copenhagen<br />

broke its old boundaries and many<br />

large, dense five-story buildings were<br />

constructed. These flats were often<br />

very small, some with only a view of a<br />

backyard, and the residents longed for<br />

natural surroundings and the outdoors.<br />

As a result, areas in the vicinity of the<br />

city were rented by the municipalities<br />

for allotments, so that people could<br />

get into contact with nature and live a<br />

healthy outdoor life.<br />

Rest and recreation – and necessity<br />

The size of the gardens ranged between<br />

200 and 400 square meters, and often<br />

the plots included a small shed built<br />

with the aid of the most primitive<br />

tools and materials. The allotment<br />

holders spent most their leisure hours<br />

in their gardens, taking great pride in<br />

creating a small paradise of their own.<br />

Where there used to be squares with<br />

heaps of rubbish outside the city, the<br />

outskirts now offered wide green areas,<br />

fruit trees, and neat little houses.<br />

However, the allotment gardens have<br />

not only served as place of pure rest<br />

and recreation: during the Second<br />

World War, they provided a welcome<br />

and vital supply of vegetables and<br />

fruits for a nation suffering under government<br />

rationing.

While allotment gardens in the past<br />

were an integral part of urban working<br />

class culture, today they are more likely<br />

to be associated with a summer getaway<br />

for urban families with children – and<br />

even for the highly paid. It is the freedom<br />

to get out of the apartment for<br />

the summer and take a break from the<br />

demands of modern life that attracts.<br />

People are able to socialize and relax<br />

in the atmosphere they have created.<br />

There is a Danish word that fits this<br />

lifestyle perfectly – hygge. Although<br />

Danes say it cannot be translated, it<br />

roughly means to be cosy and relaxed<br />

in warm surroundings with friends<br />

and family. Many allotment holders<br />

put a great deal of effort into creating<br />

that cosy and comfy atmosphere in<br />

their allotments.<br />

For almost a year now JL has taken a<br />

break from the throbbing life of the city.<br />

But we will soon leave these natural<br />

surroundings behind in order to return<br />

to our renovated headquarters on 24<br />

<strong>September</strong>. Who knows – perhaps we<br />

will feel a little nostalgic about trading<br />

the allotment gardens’ atmosphere of<br />

tranquillity for the bustling environment<br />

of Frederiksstaden, with its cultural<br />

institutions, wide avenues, and<br />

opulent dwellings.<br />

15

16<br />

Goodbye to<br />

training, Hello<br />

to the real thing<br />

As of 1 August three trainees made the<br />

transition to real jobs, more responsibility . . .<br />

and larger paycheques.<br />

Jannik Jarnsborg,<br />

Assistant Chartering Manager,<br />

<strong>Lauritzen</strong> Bulkers<br />

Like all J. <strong>Lauritzen</strong> trainees, Jannik<br />

Jarnsborg has completed a two-year<br />

programme of general shipping education<br />

courses supplemented by equally<br />

intensive on-the-job training – spending<br />

his first year of training with<br />

<strong>Lauritzen</strong> Kosan and the second one<br />

with <strong>Lauritzen</strong> Bulkers. His final academic<br />

project was to write and defend<br />

a paper on the time-charter business,<br />

which brought together his studies<br />

and his practical experience with the<br />

sales and purchase of vessels and time<br />

charters. Being rapidly immersed in the<br />

details of vessel purchasing and time<br />

chartering was demanding, he says, but<br />

mastering the technical details wasn’t<br />

the most challenging part of the trainee<br />

programme.<br />

“If you can handle it, you’re given<br />

pretty much responsibility right away.<br />

That means the phone is ringing, you<br />

have people pulling you from all sides,<br />

and it’s up to you to find out how to<br />

prioritize everything. It was tough at<br />

first, but I think that’s one of the most<br />

valuable parts of the trainee programme<br />

– learning how to juggle competing<br />

demands on your time and to be<br />

aware of how you’re doing the job.”<br />

He recently had the chance to spend<br />

two weeks at J. <strong>Lauritzen</strong>’s Singapore<br />

office gaining direct experience of<br />

overseas operations and seeing exactly<br />

how they do their jobs. “I’m looking<br />

forward to being a full-fledged<br />

employee after 1 August,” he says.<br />

“To being an equal among equals<br />

and giving it my best effort. And,<br />

of course, to collecting a bigger<br />

paycheque . . . that’ll be nice, too.”<br />

Monica Christensen,<br />

Assistant Operations Manager,<br />

<strong>Lauritzen</strong> Kosan<br />

For the past two years, Monica Christensen<br />

has balanced the theoretical side<br />

of her trainee education with almost<br />

daily contact with ship captains and<br />

agents. As a member of the operations<br />

department of <strong>Lauritzen</strong> Kosan, she<br />

has literally been at the crossroads of<br />

worldwide shipping activity, engaged<br />

in everything from coordinating load-

ing and discharge ports and determining<br />

cargo discharge temperatures to<br />

appointing agents and updating schedules.<br />

“Our academic classes in shipping<br />

gave us a solid background in the<br />

shipping business, but the actual job<br />

training has definitely been ‘learning<br />

by doing’,” she says. “After 1 August,<br />

I know I’ll have the feeling of more<br />

responsibility, but in reality I’ve been<br />

allowed to do my job pretty independently<br />

already.”<br />

Her training has also included rotating<br />

one-week stretches as a duty officer on<br />

call for captains, agents, or charterers<br />

who need to contact <strong>Lauritzen</strong> Kosan<br />

outside of regular office hours. Usually<br />

this isn’t a problem, but, she observes<br />

that “if you’re very unlucky you might<br />

have to work through the night, so it<br />

can be demanding. But even as a trainee<br />

you get to be the one who sorts things<br />

out and solves problems, and that’s<br />

exciting.” In the next few years <strong>Lauritzen</strong><br />

Kosan will be taking delivery of technically<br />

advanced newbuildings from<br />

Korea that have ethylene capacity,<br />

and, along with everyone else, Monica<br />

Christensen will be learning a new<br />

and complex side of the business. “It’s<br />

a challenge,” she says, “but that’s what<br />

I love about this job. You never know<br />

for sure what’s going to happen next.”<br />

Christian Grønlund,<br />

Assistant Chartering Manager,<br />

<strong>Lauritzen</strong> Kosan<br />

Christian Grønlund has already had<br />

broad practical experience, even by JL<br />

trainee standards. After spending his<br />

first year in JL’s Bunkers Department<br />

trading oil, he moved to <strong>Lauritzen</strong><br />

Kosan, where he has worked in both<br />

the Operations Department and<br />

the Chartering Department. As of 1<br />

August he will continue with <strong>Lauritzen</strong><br />

Kosan as an assistant chartering manager.<br />

“Basically, my job is to keep vessels<br />

employed, to make sure they have<br />

cargo to sail with,” he says. “You could<br />

compare it to a hotel, which ideally<br />

would maintain 100% occupancy. We<br />

try to come as close to that as we can<br />

for our ships, largely on contract, but<br />

also through the spot market.”<br />

He also confirms that the most intense<br />

part of the training period was learn-<br />

ing to cope with serious job responsibilities<br />

right from the start. “This was<br />

especially true when I first started with<br />

the Bunkers Department,” he says.<br />

“One day, about a month after I began,<br />

I realized that – at age 21 – I was buying<br />

oil for ten vessels and trading for a<br />

total amount of about USD 10 million.<br />

Let’s just say it both made me nervous<br />

and really focused me on not making a<br />

mistake.” Christian Grønlund credits<br />

all his senior colleagues – but especially<br />

his assigned mentors – for providing<br />

the help and advice he needed. Asked<br />

about the future, he points out that<br />

there is always room for growth within<br />

the shipping industry – and always<br />

something more to learn. On that note,<br />

he is soon travelling to Korea to get a<br />

firsthand view of <strong>Lauritzen</strong> Kosan’s<br />

newbuilding projects. The future looks<br />

wide open.<br />

17

18<br />

It’s back to school<br />

for experienced<br />

purchasers<br />

Two members of <strong>Lauritzen</strong><br />

Fleet Management’s purchasing<br />

department earn marine purchasing<br />

and supply diplomas<br />

in year-long distance-learning<br />

programme.<br />

“Until now, the<br />

shipping industry<br />

has never had a<br />

specific course for<br />

maritime purchasing<br />

and supply.”<br />

Henrik Steffensen<br />

Head of Purchasing Department,<br />

<strong>Lauritzen</strong> Fleet Management<br />

“Well, at least that’s behind me,” thinks<br />

nearly every graduate who leaves<br />

school and gets a job. <strong>No</strong>t necessarily,<br />

as Henning Andersen (above left) and<br />

Klaus Christoffersen, both seasoned<br />

J. <strong>Lauritzen</strong> purchasers with years of<br />

experience, recently discovered. During<br />

the past year, they participated in the<br />

first class of a groundbreaking new<br />

course launched by the International<br />

Marine Purchasing Association(IMPA)<br />

in co-operation with the National Sea<br />

Training Centre (NSTC) and Lloyds<br />

Maritime Academy. After final exams<br />

in July, both men emerged as successful<br />

graduates with diplomas in marine<br />

purchasing and supply.<br />

The diploma is intended for all purchasing<br />

practitioners in shipowning,<br />

operating, and management companies<br />

as well as all ship suppliers around the<br />

globe. Comprised of eight discrete<br />

modules, the course considers different<br />

purchasing models, incorporates appropriate<br />

marine insurance and English<br />

law, and explains how they interface<br />

with other areas such as finance and<br />

administration. Except for the final<br />

exam, all course work and testing is<br />

delivered by distance-learning methods,<br />

via the Internet.<br />

A maritime focus<br />

“Until now, the shipping industry has<br />

never had a specific course for maritime<br />

purchasing and supply,” says Henrik<br />

Steffensen, head of purchasing for<br />

<strong>Lauritzen</strong> Fleet Management and an<br />

IMPA board member involved with<br />

establishing the new programme.<br />

“Most courses were set up with indus-<br />

trial production companies in mind<br />

and are more concerned with stock<br />

planning, production planning, and so<br />

on. This course was developed from a<br />

strictly maritime point of view, so it’s<br />

much more useful for shipping companies.<br />

It offers a unique opportunity<br />

to gain a recognised qualification in<br />

marine purchasing and supply, which<br />

is why we’re requiring all our current<br />

and future employees to complete it.”<br />

The various course modules were<br />

created by industry experts with<br />

specialised backgrounds as diverse as<br />

a port captain with customs expertise<br />

and a London law school professor.<br />

Henning Andersen and Klaus Christoffersen<br />

say that the course offered a<br />

combination of benefits, both strategic<br />

and operational. “With our past experience,<br />

we were familiar with a good<br />

deal of the basic information,” says<br />

Klaus Christoffersen, “and that’s just<br />

as well since some of the modules, like<br />

the one covering English law, were<br />

pretty demanding.”

An immediate success<br />

The 2006-<strong>2007</strong> course, the first one<br />

of its kind, was even more successful<br />

than anticipated, with 60 people signing<br />

up. The second year, with more<br />

than 40 people enrolled, has followed<br />

suit. Participants in 2006-<strong>2007</strong> were<br />

chiefly from European companies,<br />

but also included representatives from<br />

companies in Japan, Hong Kong,<br />

and the Middle East. In addition to<br />

J. <strong>Lauritzen</strong>, other major Danish<br />

shipowners such as AP Moeller Maersk,<br />

Torm, and Scanlines took part.<br />

As for the return to the routine of<br />

studying and taking tests, it seems as if<br />

little has changed. “It’s a good thing to<br />

do the course together, the way Klaus<br />

and I did,” says Henning Andersen.<br />

“That way you’ve got someone to<br />

compare notes with – and someone to<br />

keep up with.”<br />

<strong>Lauritzen</strong><br />

Tankers builds<br />

in China<br />

Newbuildings on order from<br />

GSI offer attractive combination<br />

of price and design.<br />

Six new recently purchased medium<br />

range (MR) product carriers are the<br />

first vessels <strong>Lauritzen</strong> Tankers will<br />

take delivery of in China. They are<br />

to be built at Guangzhou Shipyard<br />

International Co., Ltd. (GSI), which<br />

is a part of China State Shipbuilding<br />

Corp. (CSSC), South China’s largest<br />

modern integrated shipbuilding enterprise.<br />

“GSI is one of the best – and<br />

best known – yards in China building<br />

tankers. They focus exclusively on<br />

product carriers, and count other<br />

Danish shipping companies among<br />

their customers,” says Erik Donner,<br />

vice president of operations and<br />

chartering for <strong>Lauritzen</strong> Tankers.<br />

In the past, <strong>Lauritzen</strong> Tankers has<br />

worked with shipyards in Korea and<br />

Japan, but GSI was able to offer an<br />

attractive combination of price and<br />

design – all six ships will be built to<br />

meet the latest IMO II/III regulations.<br />

“This new design is 50,500 dwt.,” says<br />

Erik Donner, “which fits with our<br />

strategy of concentrating on the larger<br />

end of the MR scale. Because these<br />

ships have a larger cubic capacity<br />

(58,000 cbm), they’re able to handle a<br />

broader range of voyage combinations<br />

than smaller MRs. This gives us greater<br />

trading flexibility and potentially higher<br />

earnings.”<br />

The first of the ships will be delivered<br />

in the fourth quarter of 2010, and the<br />

remaining five will follow in 2011. All<br />

six vessels will be owned and operated<br />

by <strong>Lauritzen</strong> Tankers. This brings the<br />

total number of ships on order to ten:<br />

two smaller newbuildings are coming<br />

from Korea early next year and two<br />

from Japan in 2010. “In terms of<br />

price negotiation and design flexibility,<br />

it’s very important to have good longterm<br />

relationships with shipyards,<br />

which we’ve already established in<br />

Japan and Korea,” says Erik Donner.<br />

“We’re happy to be able to add GSI<br />

to the mix. And we hope that this<br />

new established relationship will<br />

bring additional future newbuildings.”<br />

“This new design is<br />

50,500 dwt, which fits<br />

with our strategy of<br />

concentrating on the<br />

larger end of the MR<br />

scale.”<br />

Erik Donner<br />

Vice President, Operations and<br />

Chartering, <strong>Lauritzen</strong> Tankers<br />

19

Namegiving ceremonies<br />

Mrs Karen Heering (far right) was sponsor<br />

for the Freja Selandia on 28 March<br />

<strong>2007</strong>.<br />

As reported in this and earlier issues of<br />

<strong>Lauritzen</strong> News, J. <strong>Lauritzen</strong>’s current<br />

newbuilding programme is extensive,<br />

including more than 50 vessels to be<br />

delivered within the next couple of<br />

years.<br />

When a newbuilding is delivered, it’s<br />

time for festive activities at the Far<br />

Eastern shipyards involved. Each<br />

delivery is celebrated at the shipyards<br />

by representatives from the yard,<br />

the shipowners, clients, business<br />

associates, representatives from the<br />

J. <strong>Lauritzen</strong> Group – and not least<br />

by the sponsors.<br />

Editors<br />

Torben Janholt<br />

Tove Elisabeth Nielsen<br />

Jens Søndergaard<br />

Facts on J. <strong>Lauritzen</strong> A/S<br />

J. <strong>Lauritzen</strong> A/S<br />

Sankt Annæ Plads 28<br />

1250 Copenhagen K<br />

Denmark<br />

Tel: +45 3396 8000<br />

<strong>September</strong> <strong>2007</strong><br />

J. <strong>Lauritzen</strong> A/S operates globally through these business units: <strong>Lauritzen</strong> Bulkers, <strong>Lauritzen</strong> Kosan, and <strong>Lauritzen</strong> Tankers.<br />

JL employs a staff of approximately 600 persons and together with partners/associates controls a combined fleet of about 200 vessels representing bulk<br />

and gas carriers and product tankers.<br />

For more details on JL’s business activities and on the fleet, see www.j-lauritzen.com<br />

20 January <strong>2007</strong><br />

Sofie Bulker delivered from the Shin Kurushima Dockyard.<br />

Sponsor: Sofie Wegeberg, daughter of Carl Wegeberg, Vice President,<br />

<strong>Lauritzen</strong> Bulkers–Tonnage Procurement.<br />

19 February <strong>2007</strong><br />

Freja Dania delivered from the Shin Kurushima Dockyard.<br />

Sponsor: Tove Elisabeth Nielsen, Senior Vice President, J. <strong>Lauritzen</strong>.<br />

12 March <strong>2007</strong><br />

Belaia delivered from Imabari Shipbuilding Co., Japan. Sponsor:<br />

Margarita Tidemand, spouse of Sverre Tidemand, Managing Director<br />

and member of the BOD of Belships ASA.<br />

28 March <strong>2007</strong><br />

Freja Selandia delivered from the Shin Kurushima Dockyard.<br />

Sponsor Karen Heering, spouse of Niels Heering, attorney-at-law,<br />

member of the BOD of J. <strong>Lauritzen</strong>.<br />

12 July <strong>2007</strong><br />

Freja Fionia delivered from the Shin Kurushima Dockyard.<br />

Sponsor: Cheryl Talam Hansen, spouse of Tom K. Talam Hansen,<br />

Managing Director, J. <strong>Lauritzen</strong> Singapore.<br />

23 July <strong>2007</strong><br />

Perla Bulker delivered from the Tsuneishi Fukuyama Shipyard.<br />

Sponsor Anne Bruun Larsen, Senior Operations Manager, <strong>Lauritzen</strong> Bulkers.<br />

7 August <strong>2007</strong><br />

Charlotte Bulker delivered from the Hakodate Shipyard.<br />

Sponsor Charlotte Warsberg, daughter of Torben Warsberg,<br />

Vice President, <strong>Lauritzen</strong> Bulkers-Chartering/Capesize.<br />

Editorial support and design<br />

Cross-Border Communications<br />

Copenhagen<br />

<strong>Lauritzen</strong> News is a semi-annual<br />

publication. Reproduction<br />

permitted only after agreement<br />

with the editors.

![41367 JL News 11 [6].indd - J. Lauritzen](https://img.yumpu.com/11983725/1/166x260/41367-jl-news-11-6indd-j-lauritzen.jpg?quality=85)