Detailed specification - DAN SWIFT - J. Lauritzen

Detailed specification - DAN SWIFT - J. Lauritzen

Detailed specification - DAN SWIFT - J. Lauritzen

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

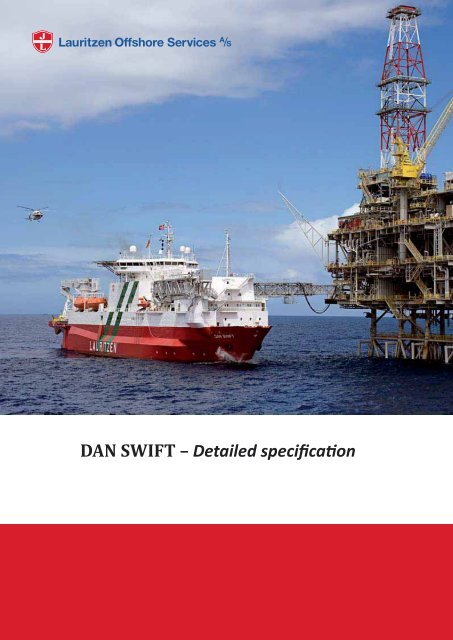

<strong>DAN</strong> <strong>SWIFT</strong> – <strong>Detailed</strong> specificaon<br />

1

Health, Safety and Environment<br />

Health, safety, security and work environment is the top priority for <strong>Lauritzen</strong> Offshore Services. We operate under<br />

a “zero accident” mindset with a no blame culture. We are commied to the acve prevenon of all accidents and<br />

incidents including zero damage to the environment. Our HSSE commitment forms the guiding principle for all our<br />

operaons and is reflected in Onshore & Vessel Procedures as seen in our Governing System.<br />

We have implemented and live up to the stringent HSSE standards required by the Offshore Oil & Gas Industry<br />

while simultaneously conforming to the mandatory codes and guidelines adopted from the Internaonal Marime<br />

Organizaon. We are cerfied according to the ISO 14001;2004 standard.<br />

It is of primary importance that our employees, contractors and suppliers understand, meet and are commied to<br />

the HSSE expectaons set as a part of the employment and contract requirements in an effort toward a connuous<br />

improvement of our operaons and procedures. This is achieved through specific training, drills and safety inducons<br />

on board.<br />

Our employees are our most important assets. Their commitment to the highest HSSE standards is our excellence.<br />

Safety briefing Light signal at the gangway<br />

Technical Speciications - ASV Dan Swift

Introduction<br />

ASV ’Dan Swi’ is the first monohull accommodaon support vessel to service the high end of the offshore market.<br />

In addion to its modern accommodaon facilies, the vessel is equipped with a sophiscated DP2 (K-Pos DP-32)<br />

system, two independent offshore telescopic gangways, large capacity crane, helideck, workshops and storage areas.<br />

Dan Swi is capable of accommodang 256 offshore workers in addion to its own crew and catering staff.<br />

The benefits of using a mono-hull vessel include:<br />

•<br />

•<br />

•<br />

•<br />

•<br />

Large deadweight.<br />

Superior staon keeping and stability.<br />

Fast and flexible deployment between jobs.<br />

Fast and safe disconnecon (hurricanes, gas leaks etc.).<br />

Two independent telescopic gangways ensure flexible connecon paerns and redundancy.<br />

On the following pages, please find detailed descriptions for:<br />

1.<br />

2.<br />

3.<br />

4.<br />

5.<br />

6.<br />

7.<br />

8.<br />

9.<br />

10.<br />

11.<br />

12.<br />

General Descripon<br />

The Bridge, DP Dynamic Posioning, Thrusters<br />

Subdivision<br />

Workshops<br />

A. Deck Capacity<br />

Crane<br />

Helideck<br />

Gangway<br />

Communicaon and IT Facilies<br />

Offices, Conference and Video Facilies<br />

Accommodaon<br />

Recreaonal Areas<br />

I-IV. Appendix – General Arrangement<br />

1

General Description<br />

Main parculars<br />

Length overall (LOA): 149.55 m<br />

Length arcle 2/8: 138.94 m<br />

Breadth moulded: 20.75 m<br />

Breadth extreme: 23.95 m<br />

Depth moulded to 1st deck: 12.35 m<br />

Depth moulded to 2nd deck: 7.00 m<br />

Draught scantling (moulded): 7.80 m<br />

Draught Summer: 7.50 m<br />

Gross Tonnage: 16525 t<br />

Net Tonnage: 4980 t<br />

Deck area, external: 575 m2 Workshops internal: 350 m2 Deck load capacity: up to 9 mt/m2 Flag/Register:<br />

Danish/Danish Internaonal Register<br />

Class<br />

1A1 Passenger Ship, HELDK-SH, DYNPOS-AUTR, CLEAN, BWM-E(s)<br />

Life saving equipment<br />

In accordance with the requirements of the Danish Marime Authories (DMA) and in excess<br />

of SOLAS, Dan Swi carries a total of four life boats - two on each side, and six life ras - three<br />

on each side, a MOB (Man Over Board) boat and an FRB (Fast Rescue Boat) boat.<br />

Navigaon / Communicaon / Satellite TV<br />

• 10 cm and 3 cm ARPA radars<br />

• Electronic Chart System (ECDIS)<br />

• Radio installaon according to GMDSS – area A3<br />

• Inmarsat C. Inmarsat Fleet 77<br />

• V-Satellite system<br />

• Digital automac telephone system<br />

•<br />

VDR<br />

Technical Speciications - ASV Dan Swift

Starboard side<br />

General Arrangement, not to scale<br />

Deck Layout<br />

Deck 10: Bridge and Helideck<br />

Deck 9: Helicopter lounge and Office area<br />

Deck 8: Accommodaon - Officers<br />

Deck 7: Accommodaon – Crew and Coffee Shop<br />

Deck 6: Accommodaon – Workers, Shop, Life boats<br />

and Muster Staons<br />

Deck 5: Accommodaon - Workers, Galley, Mess Clean<br />

& Dirty, IT/day lounge,<br />

Deck 4: Offices, Conference and Video Conference rooms,<br />

Changing Rooms clean and dirty,<br />

A deck storage & Electrical Workshops<br />

Deck 3: Welding Shop<br />

Deck 2: Workshop Hot Works, Gymnasium and Swimming<br />

Pool<br />

Deck 1: Engine Control Room and Thruster Rooms<br />

Propulsion units<br />

Forward : 3 X 1200 kW tunnel thrusters (CPP)<br />

2 X 1500 kW azimuth thrusters (CPP)<br />

A: 2 X 1200 kW azimuth thrusters (CPP)<br />

1 X 2000 kW azimuth thruster (CPP)<br />

Total power: 11,000 kW<br />

Speed and consumpon<br />

Speed: 11.5 knots service speed<br />

Fuel consumpon: Approximately 20 mt/day at service<br />

speed (weather depending). HFO or MDO<br />

Fuel consumpon: Approximately 15-25 mt/day in DP<br />

mode (weather depending).<br />

Tank capacies and systems<br />

Fuel oil: 1,907 cbm<br />

Potable water: about 800 cbm<br />

An-heeling stabilizing system<br />

Supply systems for compressed air, water, power, fuel and<br />

bilge water.<br />

3

The Bridge, DP Dynamic Positioning, Thrusters<br />

Dynamic Posioning System<br />

Dynamic posioning control system and redundancy according to DP2 (K-Pos DP32).<br />

Reference systems include:<br />

•<br />

•<br />

•<br />

•<br />

•<br />

GPS, 1 X DARPS 700 ( 1 X 200 + 1 X 132 )<br />

Laser, 2 X Fanbeam Mk 4.2 w/lt<br />

Radar: 1 X Radius 1000 D with 2 X 700x transponders<br />

Radar: 1 X Artemis Mk 51<br />

2 X gangways<br />

In combinaon with its 11 MW thruster capacity, these reference systems enable safe and efficient operaon even in<br />

harsh weather condions.<br />

Dan Swi is equipped with eight thrusters, five azimuth thrusters (two retractable) and three tunnel thrusters - all<br />

powered by five generators.<br />

This arrangement ensures a very high staon keeping and meeng Environmental Reference Number (ERN)<br />

(99,99,87).<br />

DP plots shown in the figure are<br />

calculated with the following<br />

condions:<br />

1. All eight thrusters available<br />

2. Wind rotang<br />

3. Current of 1.46 knots rotang<br />

The blue curve shows the limit for<br />

the vessel´s ability to keep posion.<br />

Technical Speciications - ASV Dan Swift<br />

Liming 1 minute mean wind speed in<br />

knots at 10 m above sea level<br />

PORT<br />

300<br />

240<br />

210<br />

Wind speed: Automade<br />

Significant wave height: DNV (ERN)<br />

Mean zero up-grossing period: DNV (ERN)<br />

BOW<br />

330 30<br />

20 40<br />

60<br />

150<br />

ERN (99.99.87).<br />

Wind direcon,<br />

coming from [deg]<br />

STBD<br />

100 [knots]<br />

120<br />

STERN<br />

Rotang dal current:1.46 knots<br />

Rotang wind induced current: 0.000´Uwi knots<br />

80<br />

60

Bridge, DP Control Staon Bridge, manned DP Control Staon<br />

Bridge, DP Control<br />

Staon<br />

Bridge General Arrangement, not to scale<br />

5

Gangways<br />

Dan Swi is equipped with two flexible telescopic gangways, the largest of their type ever built, which offer easy and safe<br />

passage for the 256 passengers from Dan Swi to a fixed or floang offshore unit.<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

Length 38.5 m<br />

Stroke +/- 8 m<br />

Alarm points for angle and stroke<br />

Free width 1.2 m<br />

Max gangway rotaon 180 degrees<br />

Max liing angle 24.0 degrees (+15.7 m)<br />

Max lowering angle 16.5 degrees (- 10.9 m)<br />

Gangway pedestal height adjustable (2, 5 & 7 m)<br />

The two-gangway soluon ensures<br />

complete flexibility with one<br />

gangway located forward starboardside<br />

and one mid-ship port-side.<br />

The vessel is able to posion<br />

itself opmally according to<br />

prevailing weather condions<br />

whereby providing a safe working<br />

environment even in harsh weather.<br />

Two gangways provide increased<br />

redundancy / efficiency.<br />

Minimum Requirements for landing<br />

plaorm: 6 x 6 m – free height 12 m<br />

Technical Speciications - ASV Dan Swift<br />

VERTICAL LOAD<br />

Dead load Live load Wind load<br />

18,0 T 9,2 T 0,3 T<br />

18 t 9.2 t 0.3 t<br />

LONGITUDINAL LOAD<br />

Dead load Live load Wind load<br />

2,9 T 0 3,3 T<br />

2.9 t<br />

TRANSVERSE LOAD<br />

Dead load Live load Wind load<br />

2,3 T 0 4,1 T<br />

2.3 t<br />

3.3 t<br />

4.1 t<br />

Structural design of the landing plaorm must meet the following requirements

Gangway on port side Gangway entry<br />

Available services via gangway<br />

in four 2” pipes:<br />

Compressed air<br />

Fresh water<br />

Sea water<br />

Gas oil<br />

7

Waterght Compartments, not to scale<br />

Subdivision<br />

Below main deck the vessel is divided into nine waterght compartments and five main fire zones which comprise the<br />

following main machinery equipment. This will ensure a high degree of redundancy and will minimize faults due to fire<br />

and flooding.<br />

WT (waterght) Compartment no. 1 (most forward)<br />

No. 1, 2 and 3 tunnel thrusters, SW cooling pumps, Central coolers, FW cooling pumps, emergency fire pump and<br />

provision refrigeraon plant.<br />

WT Compartment no. 2<br />

No. 4 and 5 retractable azimuth thrusters.<br />

WT Compartment no. 3<br />

Air condion chillers and forward electrical load centers including forward load 6.6kV / 460V transformers and<br />

converter drives for retractable azimuth thrusters no. 4 and 5.<br />

WT Compartment no. 4<br />

Water generaon and distribuon plant consisng of two reverse osmosis plants and potable / technical water<br />

distribuon systems. The vacuum system and sewage plant are placed in this compartment but separate from the<br />

sanitary water systems. The large air compressors for the an-heeling system are located here.<br />

WT Compartment no. 5<br />

Recreaonal area with swimming pool and gymnasium.<br />

WT Compartment no. 6<br />

Besides a number of venlaon switchboards and water fog sprinkler pump room, this compartment houses the<br />

workshops at the two upper levels and storage area at the lower level. The facilies located in these workshops are<br />

described elsewhere.<br />

WT Compartment no. 7<br />

This compartment houses on the lower floor AE no. 1, 2, 3 and 4 and ancillary systems such as SW, FW, Fuel and Air<br />

and lube oil purificaon plant. Both 6.6 kV switchboard and 460 V switchboard are physically divided and placed in<br />

separate rooms located in SB and PS at the upper level in this compartment. Between the two switchboard rooms<br />

the Engine Control room is located. A waterght door gives easy access between the ECR and the EA placed in<br />

compartment 7 and 8.<br />

WT Compartment no. 8<br />

This compartment houses on the lower floor AE no. 5 and ancillary systems such as SW, FW, Fuel & Air and the two<br />

thermal oil heaters are installed here. Fuel oil and Lube oil purificaon plant as well as the incinerator and garbage<br />

handling facilies are located in this compartment.<br />

WT Compartment no. 9<br />

The azimuth thrusters no. 6, 7 and 8 and frequency converter drive for thruster no. 8 are placed in this compartment.<br />

Technical Speciications - ASV Dan Swift

Engine Control Room, not to scale<br />

Subdivision in Waterght Compartments, not to scale<br />

Engine Control Room<br />

9 8 7 6 5 4 3 2 1<br />

9

Workshops<br />

Workshop Descripon<br />

The workshop and storage facilies are placed below main deck frame 63-86 on three levels. All levels are served by<br />

the 10 mT gantry crane on deck 6 through a 1.11 m x 2.22 m hatch in deck 4, main deck. The two upper levels in the<br />

workshop are equipped with hatches allowing the gantry crane to serve all levels.<br />

The upper level is arranged as welding / pipe workshop with all necessary facilies including monorail liing appliances<br />

and point extracon as well as room extracon to ensure a proper working environment. The welding equipment<br />

includes MIG/MAG and TIG welding machines, electric arc welding as well as plasma cuers. For details please see<br />

below.<br />

The middle level is arranged with welding/pipe workshop and a machinery workshop well equipped with all necessary<br />

tools and machinery. Like the upper level, this level is equipped with monorail liing appliances and point extracon<br />

as well as room extracon to ensure a proper working environment. For details please see aached GA with list of<br />

equipment.<br />

The lower level is storage area and is arranged for safe storage of steel, pipes etc. Furthermore, it is equipped with a<br />

pallet storage rack system, storage shelves and storage cabinets.<br />

The vessel offers significant workspace and storage areas with approximately 575 square meters external deck space<br />

and 350 square meters internal workshop area fully furnished with tools and work staons.<br />

List of equipment:<br />

10 Cabinets with shelves<br />

10 Cabinets with drawers<br />

8 Workbenches<br />

8 Welding tables<br />

4 CGI Outlet staons with cabinet<br />

6 Welding inverters<br />

4 MIG/MAG welding machines<br />

2 TIG welding machines<br />

4 Grinding machines<br />

2 Bench drilling machines<br />

1 Column drilling machine<br />

1 Lathe 2m<br />

1 Band grinder<br />

1 Manual hydraon pipe bander<br />

1 Plasma cuer<br />

1 Cold iron saw with 2 roller tables 2m<br />

Technical Speciications - ASV Dan Swift

Welding Shop Deck 3 , not to scale<br />

Welding Shop<br />

Workshop hot Deck 2 , not to scale<br />

11

Aft. Deck Capacity<br />

A deck, load capacity<br />

Technical Speciications - ASV Dan Swift<br />

A deck, partly covered area<br />

The a deck is divided into a number of storage areas; an open area served by the two knuckle boom cranes, areas<br />

partly covered by the accommodaon structure served by the gantry crane, and indoor workshops and storage areas<br />

served by the gantry crane. The knuckle boom cranes have a capacity of 10 T and 30 T, respecvely. The gantry crane<br />

has a 10 T capacity. For further informaon see the detailed descripon of the crane and working area.<br />

To a great extent, the open deck a is covered with wood for easier and safer handling of goods. Both the wood-covered<br />

deck and the plain steel deck are equipped with D-rings for easy and safe securing of goods.<br />

The deck areas can be divided into different zones:<br />

Open, served by knuckle boom cranes wood-covered 9 t/m 2 80 m 2<br />

Open, served by knuckle boom cranes wood-covered 5 t/m 2 378 m 2<br />

Open, served by knuckle boom cranes wood-covered 2.2 t/m 2 82 m 2<br />

Open, served by knuckle boom cranes steel deck 5 t/m 2 68 m 2<br />

Open, served by knuckle boom cranes steel deck 2.2 t/m 2 82 m 2<br />

Partly covered, served by transverse crane steel deck 5 t/m 2 128 m 2<br />

Partly covered, served by transverse crane steel deck 2.2 t/m 2 259 m 2<br />

On the open a deck, eight container posions with twist locks for 20’ containers are located (max. capacity is 21<br />

pieces. 20´ loaded in three high). Besides the regular container posions, containers can be stored in a number of ways<br />

as the deck is equipped with D-rings for easy and safe securing of goods and containers. The a deck is equipped with a<br />

number of 440 V container sockets which can be ulized for reefer containers or similar.<br />

The two ulity staons situated in each side of the a deck comprise compressed air, fresh water, power and telephone-<br />

& data-connecons. The electrical power connecons are rated as 2x3x230V 35A and 2x3x460V 60A all 60Hz. The<br />

telephone and data connecons are ethernet cables connected to the ship’s network. The compressed air is rated 7 bar<br />

and the fresh water supply is rated 5 bar.

A deck, open and partly covered area<br />

Two 20 “ cont.<br />

Above each other<br />

Two 20 “ cont.<br />

Above each other<br />

One<br />

10”<br />

Skipp<br />

One<br />

10”<br />

One<br />

10”<br />

A deck, container arrangement<br />

One<br />

10”<br />

Two 20 “ cont<br />

Above each other<br />

Handling Area<br />

Two 20 “ cont.<br />

Above each other<br />

Skip<br />

Skip<br />

A deck, wooden area (brown) and steel area (red)<br />

Mooring g<br />

lines<br />

One 20”cont.<br />

Adjust crane if two<br />

One<br />

10”<br />

One<br />

6” 6<br />

One<br />

6”<br />

Skipp<br />

Skipp<br />

A deck, open area<br />

One<br />

6”<br />

One<br />

10”<br />

Two 20 “ cont.<br />

Above each other<br />

Two 20 “ cont.<br />

Above each other<br />

13

Crane<br />

Technical Speciications - ASV Dan Swift<br />

Boom Tip Height [m]<br />

44<br />

42<br />

40<br />

38<br />

36<br />

34<br />

32<br />

30<br />

28<br />

26<br />

24<br />

22<br />

20<br />

18<br />

16<br />

14<br />

12<br />

10<br />

8<br />

6<br />

4<br />

2<br />

0<br />

-2<br />

-4<br />

-6<br />

-8<br />

-10<br />

Crane in acon<br />

The offshore knuckle-boom crane is classed to offer man-riding capabilies, in addion to the offshore construcon<br />

support it is primarily intended for. It is installed on starboard side of a deck (at frame 16).<br />

Capacity:<br />

Load radius main winch hook (one fall):<br />

Max: 44.0 m<br />

Min: 7.7 m<br />

Boom angles above horizontal:<br />

Main Boom max ( o ) 84.4 o<br />

Main Boom min ( o ) 0 o<br />

Main Boom stowed ( o ) 0 o<br />

Hook level main winch:<br />

Configuraon<br />

Hook level in meter (m) above datum point<br />

At minimum load<br />

radius<br />

At maximum load<br />

radius<br />

Minimum Maximum Minimum Maximum<br />

One fall -8.6 10.5 NA 2.2<br />

Slewing range: 360o Unlimited<br />

Liing Capacies<br />

Winch<br />

Type<br />

Merge<br />

Hook load<br />

SWL<br />

Wire<br />

falls<br />

Hoisng<br />

height<br />

Hoisng speed<br />

SWL Reduced<br />

load<br />

Ton Pcs m m/min m/min<br />

10 1 150 66 120<br />

20 2 75 33 60<br />

30 3 20 22 40<br />

Boom Tip Height [m]<br />

44<br />

42<br />

40<br />

38<br />

36<br />

34<br />

32<br />

30<br />

28<br />

26<br />

24<br />

22<br />

20<br />

18<br />

16<br />

14<br />

12<br />

10<br />

8<br />

6<br />

4<br />

2<br />

0<br />

-2<br />

-4<br />

-6<br />

-8<br />

-10<br />

-12<br />

-14<br />

-16<br />

-18<br />

Load Chart Sea Lift (Vessel to Vessel), Main Winch, 2 Falls, DAF = 1.30<br />

<br />

<br />

<br />

Upper Limit<br />

Lower Limit<br />

2.6<br />

Load Chart Internal Lift, Main Winch, 2 Falls, DAF = 1.25<br />

2.5<br />

5<br />

5<br />

9<br />

9<br />

-12<br />

-14<br />

13<br />

20<br />

17<br />

20<br />

-16<br />

-8 -6 -4 -2 0 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 32 34 36 38 40 42 44 46<br />

17<br />

13<br />

17<br />

13.6<br />

20<br />

15.1<br />

20<br />

Working Radius [m]<br />

13<br />

17<br />

20<br />

-20<br />

-8 -6 -4 -2 0 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 32 34 36 38 40 42 44 46<br />

Working Radius [m]<br />

20<br />

20<br />

17<br />

17<br />

15.1<br />

20<br />

13<br />

17<br />

13.9<br />

15

Crane, secon of General Arragement. not to scale<br />

Addionally, a second Crane is installed on port side of a deck<br />

(at frame 14).<br />

Capacity:<br />

Load radius main winch hook (one fall):<br />

Liing Capacies<br />

Max: 25.0 m<br />

Min: 5.5 m<br />

Winch Hook load Hoisng Hoisng speed<br />

Type SWL<br />

height<br />

SWL<br />

Ton m m/min<br />

Merge 10 30 0-30<br />

Crane on A deck<br />

15

Helideck<br />

Dan Swi is approved for helicopter operaons up to Sikorsky S-61 (diameter) and S-92 (weight) helicopters, and is<br />

equipped with state-of-the-art helicopter recepon facilies and a helicopter refueling system.<br />

Size<br />

•<br />

•<br />

max weight 12,800 kg<br />

Octagonal shape 22.2 m<br />

Rules and regulaons:<br />

UK CAA CAP 437,<br />

Norwegian CAA,<br />

NMD “Green Book” Ship Rules,<br />

SOLAS and<br />

Brazilian NORMAM Regulaon for Helicopter decks<br />

Danish Aviaon Limitaons, not to scale<br />

Technical Speciications - ASV Dan Swift<br />

Helideck , not to scale

Helicopter landed on Dan Swi<br />

Helideck dimensions, not to scale<br />

17

Communication and IT Facilities<br />

The vessel has an IP-based telephone system, where phones in the cabins and offices can be dedicated to charterer´s<br />

use only. The telephone system can be configured to interface to charterer´s offshore or landbased phone system. External<br />

calls are routed via the vessels VSAT connecon, which have two satellite antennas for redundancy in case of noline-of-sight<br />

caused by rig or plaorm.<br />

The computer network onboard is Ethernet with a fiber opc backbone, and the network is split into several VLANS,<br />

where 1 or more VLANS can be dedicated for the charterer´s use only. Charterer´s VLAN can be connected to charterer´s<br />

landbased network by e.g. VPN and router. The vessel is online and has Internet connecon via the VSAT.<br />

The network is used for distribuon of the live satellite TV for the lounges and cabins.<br />

Technical Speciications - ASV Dan Swift

Example of a communicaon and IT set-up:<br />

SiPass POB card reader<br />

SiPass Access Control System<br />

Client PC<br />

SiPass Access Control System<br />

Charterer’s<br />

Phone<br />

system<br />

(Router)<br />

SiPass VLAN<br />

HiPath VLAN<br />

IP Phone System Client PC<br />

IDSN30<br />

IP Phone System<br />

(Siemens HiPath 3800)<br />

IP Phones<br />

Administration VLAN<br />

Whats’Up Administration<br />

Infotainment<br />

(Live TV)<br />

Infotainment<br />

Front Ends<br />

(Optional)<br />

Infotainment System<br />

(Optional)<br />

Clock VLAN<br />

Central Clock System<br />

IP Clocks<br />

LAN<br />

Internet Café<br />

VLAN<br />

(Workers Lounge)<br />

Internet Browsing PCs<br />

Satellite installaon on Dan Swi<br />

JL Desktop PCs<br />

Kongsberg Systems<br />

Hernis Camera System<br />

JL Printer & Scanners JL Servers<br />

WLAN<br />

<strong>Lauritzen</strong> VLAN<br />

Charterer’s VLAN<br />

Printers &<br />

scanners<br />

Kongsberg VLAN<br />

Desktop PCs<br />

Servers<br />

Charterer’s<br />

Network<br />

Charterer’s<br />

Network<br />

Charterer’s<br />

Router<br />

Charterer’s<br />

Phone<br />

system<br />

19

Ofices, Conference and Video Facilities<br />

Offices for charterer, auditorium and conference room are all located on deck 4 with easy access from main deck, both<br />

main staircases and staircase from gangway PS.<br />

11 offices are located onboard with a total of 49 work staons; this number can be increased if required. All office spaces<br />

are equipped with telephone and ethernet sockets.<br />

The auditorium is situated on deck 4 forward of the auditorium and has a seang capacity of 60 seats. The auditorium<br />

is equipped with a large projector screen and high spec audio system which gives the audience a real movie experience<br />

when watching film in the auditorium.<br />

Apart from entertainment, the auditorium can be used for conferences and educaonal purposes as it is equipped with<br />

the necessary PA system and whiteboards.<br />

The conference room located on deck 4 has a seang capacity of 12-14 persons prepared for video conference.<br />

An internet-cafe is integrated in the worker´s lounge on deck 5 forward.<br />

Live TV and movies can be arranged in both public spaces and cabins.<br />

Technical Speciications - ASV Dan Swift

Conference Room<br />

Video Conference Room<br />

Video Conference Room to the le and conference room to the right on deck 4, not to scale<br />

Offices on deck 4, not to scale<br />

21

Accommodation & Recreational Areas<br />

The vessel is able to operate independently for extended periods of me and has been designed to offer the passengers<br />

and crew a wide variety of facilies onboard, in order to make their stay comfortable through modern accommodaon<br />

and recreaonal facilies.<br />

The layout of the vessel is:<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

291 berths in total of which 256 passenger berths<br />

Four single cabins<br />

34 double cabins<br />

46 four-person cabins<br />

Galley, mess and dayrooms<br />

Hospital<br />

Offices<br />

Conference rooms<br />

Technical Speciications - ASV Dan Swift<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

Private TVs<br />

Cinema<br />

Gymnasium<br />

Swimming pool<br />

Library<br />

Coffee shop<br />

Sun terrace on top of accommodaon areas<br />

Indoor smoking facilies<br />

Day-lounge / internet café equipped with computers<br />

and tv<br />

Pay phones<br />

Lounge areas in connecon with accommodaon<br />

facilies<br />

Coffee shop<br />

Satellite TV<br />

Gymnasium and swimming pool on deck 2, not to scale Gymnasium on deck 2

One of the mess rooms on deck 5 Accommodaon cabin<br />

Workers accommodaon on deck 5 & 6 and galley & messes on deck 5, not to scale<br />

Smoking room and IT/day lounge on deck 5, not to scale<br />

All details believed to be correct, but not guaranteed Version 1a - June 2010<br />

23

APPENDIX<br />

General Arrangement, scale 1:400<br />

Technical Speciications - ASV Dan Swift - APPENDIX<br />

I

APPENDIX<br />

General Arrangement, scale 1:400<br />

Technical Speciications - ASV Dan Swift - APPENDIX<br />

II

APPENDIX<br />

General Arrangement, scale 1:400<br />

Technical Speciications - ASV Dan Swift - APPENDIX<br />

III

APPENDIX<br />

General Arrangement, scale 1:400<br />

Technical Speciications - ASV Dan Swift - APPENDIX<br />

IV

Commercial Management:<br />

<strong>Lauritzen</strong> Offshore Pte. Ltd.<br />

1 Harbour Front Avenue<br />

# 15-08 Keppel Bay Tower<br />

Singapore 098632<br />

Phone: +65 6275 8000<br />

Technical Speciications - ASV Dan Swift<br />

Technical Management:<br />

<strong>Lauritzen</strong> Offshore Services A/S.<br />

28, Sankt Annae Plads<br />

P.O. Box 2147<br />

DK - 1291 Copenhagen K<br />

Denmark<br />

Phone: +45 3396 8000

![41367 JL News 11 [6].indd - J. Lauritzen](https://img.yumpu.com/11983725/1/166x260/41367-jl-news-11-6indd-j-lauritzen.jpg?quality=85)