Bond Elut Plexa™ Solid-phase Extraction Products - Crawford ...

Bond Elut Plexa™ Solid-phase Extraction Products - Crawford ...

Bond Elut Plexa™ Solid-phase Extraction Products - Crawford ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

ADVANTAGE NOTE<br />

<strong>Bond</strong> <strong>Elut</strong> Plexa <strong>Solid</strong>-<strong>phase</strong> <strong>Extraction</strong> <strong>Products</strong><br />

Highly reproducible, fast flow rates<br />

Advantage Statement: The <strong>Bond</strong> <strong>Elut</strong> Plexa family of<br />

SPE products delivers consistent fast flow rates and<br />

reproducible results. The absence of fines in the media<br />

means clogging of the cartridges is significantly reduced.<br />

This is important in the high throughput environment,<br />

where SPE must be performed unattended and overnight,<br />

saving valuable analysis time during the day.<br />

Reliability is one of the key parameters when developing<br />

high throughput sample preparation methods. For<br />

solid-<strong>phase</strong> extraction, uniform particles with a narrow<br />

size distribution lead to better flow characteristics for<br />

sample addition and elution. Plexa sorbent particles are<br />

manufactured using proprietary polymerization techniques<br />

to achieve this very narrow distribution of particle sizes<br />

and zero fines, yielding excellent reproducibility from<br />

cartridge-to-cartridge. The absence of particle fines means<br />

that the risk of frit blockage and therefore sample loss<br />

is dramatically reduced — an important prerequisite in<br />

the analysis of biofluids. Proprietary automated fritting<br />

and real-time QC processes also ensure that channels or<br />

voids in the packed sorbent bed are minimized, preventing<br />

breakthrough of analytes due to channeling. All of these<br />

features contribute to reproducible data and improved<br />

method ruggedness. In addition, the polymer architecture<br />

itself enables simple protocols for robust and troublefree<br />

SPE applications. Innovative research, state-of-the<br />

art manufacturing and monitoring within a stringent<br />

quality system has produced the latest generation of high<br />

performance SPE products: <strong>Bond</strong> <strong>Elut</strong> Plexa and Plexa PCX.<br />

Excellent particle integrity<br />

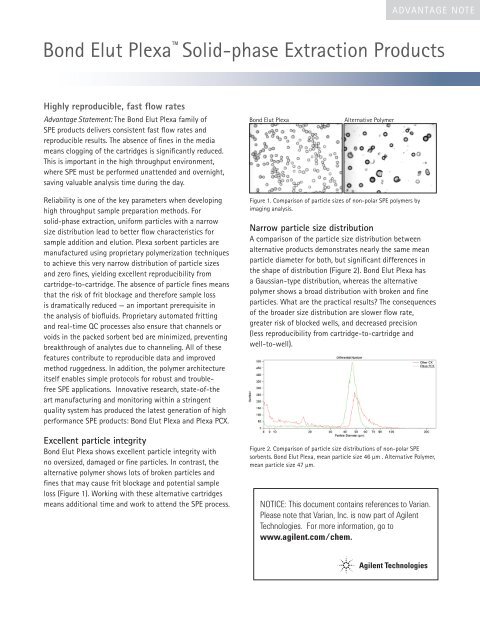

<strong>Bond</strong> <strong>Elut</strong> Plexa shows excellent particle integrity with<br />

no oversized, damaged or fine particles. In contrast, the<br />

alternative polymer shows lots of broken particles and<br />

fines that may cause frit blockage and potential sample<br />

loss (Figure 1). Working with these alternative cartridges<br />

means additional time and work to attend the SPE process.<br />

<strong>Bond</strong> <strong>Elut</strong> Plexa Alternative Polymer<br />

Figure 1. Comparison of particle sizes of non-polar SPE polymers by<br />

imaging analysis.<br />

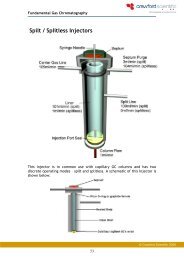

Narrow particle size distribution<br />

A comparison of the particle size distribution between<br />

alternative products demonstrates nearly the same mean<br />

particle diameter for both, but significant differences in<br />

the shape of distribution (Figure 2). <strong>Bond</strong> <strong>Elut</strong> Plexa has<br />

a Gaussian-type distribution, whereas the alternative<br />

polymer shows a broad distribution with broken and fine<br />

particles. What are the practical results? The consequences<br />

of the broader size distribution are slower flow rate,<br />

greater risk of blocked wells, and decreased precision<br />

(less reproducibility from cartridge-to-cartridge and<br />

well-to-well).<br />

Figure 2. Comparison of particle size distributions of non-polar SPE<br />

sorbents. <strong>Bond</strong> <strong>Elut</strong> Plexa, mean particle size 46 µm . Alternative Polymer,<br />

mean particle size 47 µm.

<strong>Bond</strong> <strong>Elut</strong> Plexa <strong>Solid</strong>-<strong>phase</strong> <strong>Extraction</strong> <strong>Products</strong><br />

<strong>Bond</strong> <strong>Elut</strong> Plexa<br />

Acidic<br />

Method optimized for acids<br />

1. Condition: 500 µL CH 3 OH, followed by 500 µL water<br />

2. Apply 100 µL plasma diluted 1:3 with 1% formic acid<br />

3. Wash: 500 µL 5% CH 3 OH<br />

4. <strong>Elut</strong>e: 500 µL CH 3 OH<br />

Simple protocols<br />

<strong>Bond</strong> <strong>Elut</strong> Plexa<br />

<strong>Bond</strong> <strong>Elut</strong> Plexa, the non-polar polymer, is universally<br />

applicable and the best choice for the extraction of a wide<br />

range of acidic, neutral and basic analytes from different<br />

matrices.<br />

<strong>Bond</strong> <strong>Elut</strong> Plexa PCX<br />

<strong>Bond</strong> <strong>Elut</strong> Plexa PCX is a cation exchanger with mixedmode<br />

sorbent characteristics and therefore suitable for<br />

the extraction and clean-up of weak bases from biofluids.<br />

<strong>Bond</strong> <strong>Elut</strong> Plexa PCX demonstrates the same excellent<br />

distribution and outstanding particle integrity as <strong>Bond</strong><br />

<strong>Elut</strong> Plexa. A highly controlled sulfonation process results<br />

in zero fines for <strong>Bond</strong> <strong>Elut</strong> Plexa PCX. Figure 3 shows the<br />

general protocol for trouble-free SPE applications with<br />

either <strong>Bond</strong> <strong>Elut</strong> Plexa or <strong>Bond</strong> <strong>Elut</strong> Plexa PCX.<br />

Faster flow rates and no clogging<br />

The practical effect of particle integrity on flow rate is<br />

shown in Figure 4. To compare flow rates between Plexa<br />

PCX and another CX polymeric sorbent, 12 wells were<br />

conditioned with 500 µL methanol followed by 500 µL<br />

of water. Plasma, diluted to 1:3 with phosphoric acid,<br />

was then added to every well, and a constant vacuum of<br />

5 in. Hg was applied. The time was recorded, enabling<br />

flow rates to be calculated.<br />

Neutral<br />

Method optimized for bases and neutrals<br />

1. Condition: 500 µL CH 3 OH, followed by<br />

500 µL water<br />

2. Apply 100 µL plasma diluted 1:3 with<br />

2% NH 3<br />

3. Wash: 500 µL 5% CH 3 OH<br />

4. <strong>Elut</strong>e: 500 µL CH 3 OH<br />

Plexa PCX<br />

Basic<br />

Mixed-mode method optimized for bases<br />

1. Condition: 500 µL CH OH, followed by 500 µL water<br />

3<br />

2. Apply 100 µL plasma diluted 1:3 with 2% H PO 3 4<br />

3. Acidic wash: 500 µL aqueous 2% formic acid<br />

4. Neutral Wash: 500 µL CH OH-CH CN (1:1, v/v)<br />

3 3<br />

5. <strong>Elut</strong>e: 500 µL CH OH-CH CN + 5 % NH (28-30%)<br />

3 3 3<br />

Figure 3. General acid/basic screening using <strong>Bond</strong> <strong>Elut</strong> Plexa and Plexa PCX. Indicated volumes are based on <strong>Bond</strong> <strong>Elut</strong> 96 Plexa 10 mg plate.<br />

For SPE cartridges, elution volume should be 1-2 mL, with higher volumes for less polar analytes.<br />

Flow rate (mL/min)<br />

0.8<br />

0.7<br />

0.6<br />

0.5<br />

0.4<br />

0.3<br />

0.2<br />

0.1<br />

0<br />

1 2 3 4 5 6 7 8 9 10 11 12<br />

Well Number<br />

Figure 4. Plexa PCX (blue) demonstrates faster and more reproducible<br />

flow rates. Mean flow rate for Plexa PCX = 0.47 mL/min (%RSD = 24%),<br />

alternative CX polymer mean flow rate = 0.27 mL/min (%RSD=38%).<br />

Typical properties<br />

Parameters <strong>Bond</strong> <strong>Elut</strong> Plexa <strong>Bond</strong> <strong>Elut</strong> Plexa PCX<br />

Pore size (nominal) 120 Å 120 Å<br />

Particle size 45 µm 45 µm<br />

Specific surface<br />

area m2 /g<br />

450 m2 /g 450 m2 /g<br />

pH range stability 1-14 1-14<br />

Chemical resistance<br />

(solvents)<br />

Retention capacity<br />

/ Ion exchange<br />

capacity<br />

Broad range of protic<br />

and non-protic polar<br />

and non-polar solvents<br />

10% of sorbent mass*<br />

Broad range of protic<br />

and non-protic polar<br />

and non-polar solvents<br />

Cation exchange<br />

loading of 1.0 mmol/g<br />

(determined by<br />

elemental analysis of<br />

sulfur content)<br />

*highly dependent on matrix type and specific analyte characteristics<br />

These properties are characteristic but do not constitute specifications.<br />

PCX<br />

Other CX Polymer

<strong>Bond</strong> <strong>Elut</strong> Plexa <strong>Solid</strong>-<strong>phase</strong> <strong>Extraction</strong> <strong>Products</strong><br />

Conclusion<br />

Higher bed packing efficiency in an SPE device is achieved<br />

if the sorbent particles have a very narrow size distribution.<br />

This leads to higher performance. SPE sorbents that contain<br />

a large degree of fines will cause blockage of the sample<br />

and lead to a slow, variable flow of solvent and analyte<br />

through the sorbent bed. Thus, assay variability with respect<br />

to recovery rates will increase.<br />

<strong>Bond</strong> <strong>Elut</strong> Plexa sorbent particles are nearly mono-dispersed<br />

in size, resulting in a very homogeneous packing. Therefore,<br />

reproducible results with excellent recoveries and sharp<br />

elution profiles are the standard. <strong>Bond</strong> <strong>Elut</strong> Plexa products<br />

are highly amenable to a high throughput or automated<br />

platforms due to excellent well-to-well and cartridge-tocartridge<br />

flow reproducibility.<br />

Varian, Inc.<br />

www.varianinc.com<br />

North America: 800.926.3000, 925.939.2400<br />

Europe The Netherlands: 31.118.67.1000<br />

Asia Pacific Australia: 613.9560.7133<br />

Latin America Brazil: 55.11.3238.0400<br />

Other sales offices and dealers throughout the world _ check our Web site.<br />

Chromatography • Spectroscopy • Mass Spectrometry • Magnetic Resonance Spectroscopy and Imaging • X-Ray Crystallography • Dissolution • Consumables • Data Systems • Vacuum<br />

<strong>Bond</strong> <strong>Elut</strong> Plexa, Varian, the Varian logo and the Varian Care logo are trademarks or registered trademarks of Varian, Inc. in the U.S. and<br />

other countries. © 2009 Varian, Inc.<br />

SI-1935 04/09 Printed in U.S.A.