Retractable Tank Washer - Spraying Systems Deutschland GmbH ...

Retractable Tank Washer - Spraying Systems Deutschland GmbH ...

Retractable Tank Washer - Spraying Systems Deutschland GmbH ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

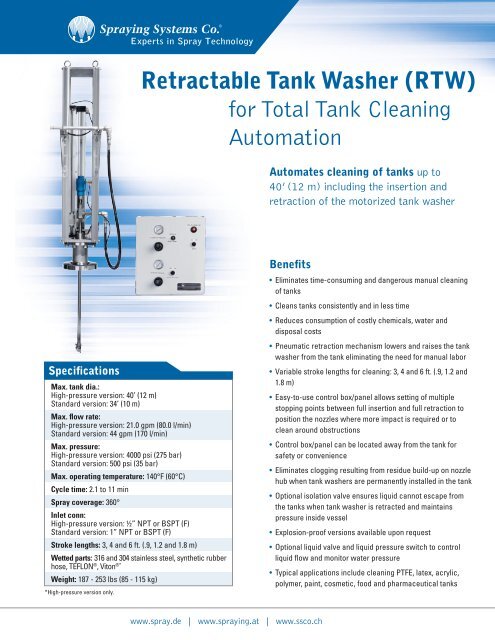

Specifications<br />

Max. tank dia.:<br />

High-pressure version: 40’ (12 m)<br />

Standard version: 34’ (10 m)<br />

Max. flow rate:<br />

High-pressure version: 21.0 gpm (80.0 l/min)<br />

Standard version: 44 gpm (170 l/min)<br />

Max. pressure:<br />

High-pressure version: 4000 psi (275 bar)<br />

Standard version: 500 psi (35 bar)<br />

Max. operating temperature: 140°F (60°C)<br />

Cycle time: 2.1 to 11 min<br />

Spray coverage: 360°<br />

Inlet conn:<br />

High-pressure version: ½” NPT or BSPT (F)<br />

Standard version: 1” NPT or BSPT (F)<br />

Stroke lengths: 3, 4 and 6 ft. (.9, 1.2 and 1.8 m)<br />

Wetted parts: 316 and 304 stainless steel, synthetic rubber<br />

hose, TEFLON ® , Viton ®*<br />

Weight: 187 - 253 lbs (85 - 115 kg)<br />

*High-pressure version only.<br />

<strong>Retractable</strong> <strong>Tank</strong> <strong>Washer</strong> (RTW)<br />

for Total <strong>Tank</strong> Cleaning<br />

Automation<br />

Benefits<br />

www.spray.de | www.spraying.at | www.ssco.ch<br />

Automates cleaning of tanks up to<br />

40’ (12 m) including the insertion and<br />

retraction of the motorized tank washer<br />

• Eliminates time-consuming and dangerous manual cleaning<br />

of tanks<br />

• Cleans tanks consistently and in less time<br />

• Reduces consumption of costly chemicals, water and<br />

disposal costs<br />

• Pneumatic retraction mechanism lowers and raises the tank<br />

washer from the tank eliminating the need for manual labor<br />

• Variable stroke lengths for cleaning: 3, 4 and 6 ft. (.9, 1.2 and<br />

1.8 m)<br />

• Easy-to-use control box/panel allows setting of multiple<br />

stopping points between full insertion and full retraction to<br />

position the nozzles where more impact is required or to<br />

clean around obstructions<br />

• Control box/panel can be located away from the tank for<br />

safety or convenience<br />

• Eliminates clogging resulting from residue build-up on nozzle<br />

hub when tank washers are permanently installed in the tank<br />

• Optional isolation valve ensures liquid cannot escape from<br />

the tanks when tank washer is retracted and maintains<br />

pressure inside vessel<br />

• Explosion-proof versions available upon request<br />

• Optional liquid valve and liquid pressure switch to control<br />

liquid flow and monitor water pressure<br />

• Typical applications include cleaning PTFE, latex, acrylic,<br />

polymer, paint, cosmetic, food and pharmaceutical tanks

2<br />

<strong>Retractable</strong> <strong>Tank</strong> <strong>Washer</strong><br />

Performance Data<br />

High-Pressure <strong>Retractable</strong> <strong>Tank</strong> <strong>Washer</strong><br />

Total Flow of Two Nozzles (Equal Capacity) gpm or l/min Liquid Inlet Pressure<br />

Nozzle No.<br />

500 psi<br />

(35 bar)<br />

<strong>Spraying</strong> <strong>Systems</strong> Co.<br />

www.spray.de | www.spraying.at | www.ssco.ch<br />

1000 psi<br />

(70 bar)<br />

2000 psi<br />

(140 bar)<br />

3000 psi<br />

(200 bar)<br />

4000 psi<br />

(275 bar)<br />

B64099-0006 4.2 (16.2) 6.0 (23.2) 8.0 (32.4) 10.4 (38.6) 12.0 (46.0)<br />

B64099-0010 7.0 (27.0) 10.0 (38.4) 14.2 (54.0) 17.4 (64.0) 20.0 (76.0)<br />

B64099-0015 10.6 (40.0) 15.0 (58.0) 21.2 (80.0) – –<br />

B64099-0020 14.2 (54.0) 20.0 (76.0) – – –<br />

Nozzles have a 1/8” BSPT (M) connection.<br />

Standard <strong>Retractable</strong> <strong>Tank</strong> <strong>Washer</strong><br />

Total Flow of Two Nozzles (Equal Capacity) gpm or l/min Liquid Inlet Pressure*<br />

High-Pressure RTW Cycle Time Data<br />

Air<br />

Pressure<br />

psi (bar)<br />

Nozzle No.<br />

Air<br />

Consumption<br />

scfm (l/min)<br />

100 psi<br />

(7 bar)<br />

Approx.<br />

Speed<br />

(RPM)<br />

Approx. Time for<br />

One Complete<br />

Cycle (min)<br />

15 (0.7) 2.8 (80) 7 5<br />

30 (2.1) 6.0 (170) 13 2.7<br />

45 (3.0) 9.0 (255) 17 2.1<br />

200 psi<br />

(15 bar)<br />

300 psi<br />

(20 bar)<br />

400 psi<br />

(30 bar)<br />

500 psi<br />

(35 bar)<br />

1/4MEG-0010 3.1 (11.8) 4.4 (17.3) 5.4 (20) 6.3 (24) 7.0 (26)<br />

1/4MEG-0015 4.7 (17.9) 6.6 (26) 8.1 (30) 9.4 (37) 10.5 (40)<br />

1/4MEG-0020 6.2 (24) 8.8 (35) 10.8 (40) 12.4 (49) 13.9 (53)<br />

1/4MEG-0025 7.7 (29) 10.9 (43) 13.3 (50) 15.4 (61) 17.2 (66)<br />

1/4MEG-0030 9.1 (35) 12.9 (51) 15.8 (59) 18.2 (72) 20 (78)<br />

1/4MEG-0035 10.5 (40) 14.8 (59) 18.1 (68) 21 (83) 23 (90)<br />

1/4MEG-0040 11.8 (45) 16.7 (66) 20 (76) 24 (93) 26 (101)<br />

1/4MEG-0050 14.2 (54) 20 (79) 25 (92) 28 (112) 32 (121)<br />

1/4MEG-0060 16.4 (63) 23 (92) 28 (102) 33 (129) 37 (140)<br />

1/4MEG-0070 18.3 (70) 26 (102) 32 (118) 37 (144) 41 (156)<br />

1/4MEG-0080 19.9 (76) 28 (111) 34 (128) 40 (157) 44 (170)<br />

*Flow rates tabulated above include pressure drop through unit.<br />

Pressure drop through the unit in shaded area should be evaluated when sizing pumps.<br />

Consult a <strong>Spraying</strong> <strong>Systems</strong> Co. representative for specific information.<br />

Standard RTW Cycle Time Data<br />

Air<br />

Pressure<br />

psi (bar)<br />

Air<br />

Consumption<br />

scfm (l/min)<br />

Approx.<br />

Speed<br />

(RPM)<br />

Approx. Time for<br />

One Complete<br />

Cycle (min)<br />

5 (0.34) 1.4 (39.6) 3.2 11<br />

7 (0.48) 2.0 (56.6) 6.0 6<br />

10 (0.68) 3.1 (87.7) 8.2 5<br />

TEFLON ® is a registered trademark of DuPont Company.<br />

Viton ® is a registered trademark of DuPont Performance Elastomers.

Dimensions<br />

• Variable stroke lengths: 3, 4 and<br />

6 ft. (.9, 1.2 and 1.8 m)<br />

• Flange: 4” 150# ANSI<br />

• Min. tank opening: 3.75” (95 mm)<br />

• Designed to operate in a vertical<br />

position<br />

Standard RTW<br />

fully extended<br />

ST + 30” (750 mm)<br />

ST + 22” (550 mm)<br />

8”<br />

(200 mm)<br />

10”<br />

(254 mm)<br />

Stroke (ST)<br />

Standard RTW<br />

fully retracted<br />

12”<br />

(300 mm)<br />

12”<br />

(300 mm)<br />

10”<br />

(254 mm)<br />

<strong>Spraying</strong> <strong>Systems</strong> Co.<br />

www.spray.de | www.spraying.at | www.ssco.ch<br />

3

Ordering Information<br />

RTW<br />

Manual Control Automatic Control<br />

+ OR +<br />

+<br />

High-Pressure <strong>Retractable</strong> <strong>Tank</strong> <strong>Washer</strong><br />

With Manually-Operated Control Panel<br />

<strong>Tank</strong> <strong>Washer</strong> Nozzle<br />

Control Panel<br />

RTW + THA-300 _ ST + B64099 - 00 __ + AJT-60754<br />

| | | | |<br />

<strong>Tank</strong> <strong>Washer</strong> Stroke Nozzle Capacity Pneumatic Control<br />

Type Length Type Size Panel<br />

With Automatic Control Panel<br />

<strong>Tank</strong> <strong>Washer</strong> Nozzle<br />

Control Panel<br />

RTW + THA-300 _ ST + B64099 - 00 __ + AJT-60752 + AJT-60750<br />

| | | | | |<br />

<strong>Tank</strong> <strong>Washer</strong> Stroke Nozzle Capacity Valve PLC Control<br />

Type Length Type Size Package Panel<br />

Standard <strong>Retractable</strong> <strong>Tank</strong> <strong>Washer</strong><br />

With Manually-Operated Control Panel<br />

<strong>Tank</strong> <strong>Washer</strong> Nozzle<br />

Control Panel<br />

RTW + AA190AG _ ST + 1/4 MEG 00 __ + AJT-60754<br />

| | | | | |<br />

<strong>Tank</strong> <strong>Washer</strong> Stroke Nozzle Inlet Nozzle Capacity Pneumatic Control<br />

Type Length Conn Type Size Panel<br />

With Automatic Control Panel<br />

<strong>Tank</strong> <strong>Washer</strong> Nozzle<br />

Control Panel<br />

RTW + AA190AG _ ST + 1/4 MEG 00 __ + AJT-60752 + AJT-60750<br />

| | | | | | |<br />

<strong>Tank</strong> <strong>Washer</strong> Stroke Nozzle Inlet Nozzle Capacity Valve PLC Control<br />

Type Length Conn Type Size Package Panel<br />

Explosion-proof versions available.<br />

Manual Control<br />

Panel RTW<br />

Experts in Spray Technology<br />

P.O. Box 7900, Wheaton, IL 60189-7900 USA<br />

Tel: 1.800.95.SPRAY Intl. Tel: 1.630.665.5000<br />

Fax: 1.888.95.SPRAY Intl. Fax: 1.630.260.0842<br />

www.spray.com<br />

Bulletin No. 624 Printed in the U.S.A. ©<strong>Spraying</strong> <strong>Systems</strong> Co. 2007<br />

Valve<br />

Package<br />

Spray<br />

Nozzles<br />

<strong>Retractable</strong> <strong>Tank</strong> <strong>Washer</strong><br />

Spray<br />

Control<br />

Spray<br />

Analysis<br />

PLC Control<br />

Panel<br />

Spray<br />

Fabrication