Renshape® SL7840 Resin

Renshape® SL7840 Resin

Renshape® SL7840 Resin

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

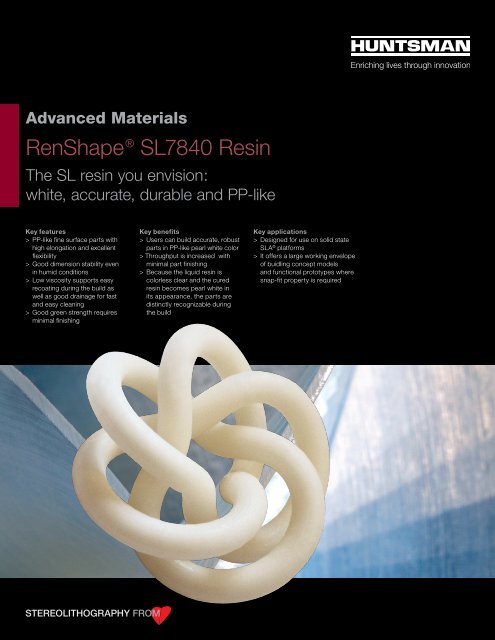

Advanced Materials<br />

® RenShape <strong>SL7840</strong> <strong>Resin</strong><br />

The SL resin you envision:<br />

white, accurate, durable and PP-like<br />

Key features<br />

> PP-like fine surface parts with<br />

high elongation and excellent<br />

flexibility<br />

> Good dimension stability even<br />

in humid conditions<br />

> Low viscosity supports easy<br />

recoating during the build as<br />

well as good drainage for fast<br />

and easy cleaning<br />

> Good green strength requires<br />

minimal finishing<br />

stereolithographY From<br />

Key benefits<br />

> Users can build accurate, robust<br />

parts in PP-like pearl white color<br />

> Throughput is increased with<br />

minimal part finishing<br />

> Because the liquid resin is<br />

colorless clear and the cured<br />

resin becomes pearl white in<br />

its appearance, the parts are<br />

distinctly recognizable during<br />

the build<br />

Key applications<br />

> Designed for use on solid state<br />

SLA ® platforms<br />

> It offers a large working envelope<br />

of buidling concept models<br />

and functional prototypes where<br />

snap-fit property is required

Liquid material properties<br />

For more information<br />

www.huntsman.com/advanced_materials<br />

advanced_materials@huntsman.com<br />

Europe/Africa: Huntsman Advanced Materials (Switzerland) GmbH / Klybeckstrasse 200 / P.O.<br />

Box / 4002 Basel / Switzerland / Tel. +41 61 299 11 11 / Fax +41 61 299 11 12<br />

India/Middle East: Huntsman Advanced Materials (India) Pvt. Ltd / 5th Floor, Bldg. No. 10 / Solitaire<br />

Corporate Park, 167 / Guru Hargovindji Marg, Chakal, Andheri (East) / Mumbai – 400 093<br />

/ India / Tel. +91 22 4095 1556 - 60 / Fax +91 22 4095 1300/1400/1500<br />

Condition Value<br />

Appearance Clear liquid<br />

Density at 25°C (77°F) 1,13 g/cm 3<br />

Viscosity at 28°C (82°F) 320 cps<br />

at 30°C (86°F) 270 cps<br />

Penetration depth, Dp 5 mils<br />

Critical exposure, Ec 15 mJ/cm 2<br />

Part building layer thickness* 0,10 mm (0,004 in.)<br />

* Dependent upon part geometry and build parameters.<br />

Post cured material properties<br />

Test method Value 90-minute UV post-cure Value 90-minute UV+2 hours at<br />

80°C (176°F) thermal postcure<br />

Hardness ASTM D-2240 86 Shore D 87 Shore D<br />

Flexural modulus ASTM D-790 1 600–2 200 MPa (232–319 ksi) 1 600–2 200 MPa (232–319 ksi)<br />

Flexural strength ASTM D-790 65–80 MPa (9 400–11 100 psi) 62–80 MPa (9 000–11 100 psi)<br />

Tensile modulus ASTM D-638 1 700–2 200 MPa (247–319 ksi) 1 600–2 200 MPa (232–319 ksi)<br />

Tensile strength ASTM D-638 36–45 MPa (5 200–6 500 psi) 37–45 MPa (5 400–6 500 psi)<br />

Elongation at break ASTM D-638 11–17% 11–18%<br />

Impact strength, notched Izod ASTM D-256 37–60 J/m (0.7–1.1 ft.-lb./in.) 35–60 J/m (0.66–1.1 ft.-lb./in.)<br />

Heat deflection temperature ASTM D-648 at 66 psi 48°C (118°F) 46°C (115°F)<br />

Glass transition, T g DMA, E” peak 58°C (136°F) 59°C (138°F)<br />

Coefficient of thermal expansion TMA (T