X2CrNiMo 17-12-2 - Schmolz + Bickenbach AG

X2CrNiMo 17-12-2 - Schmolz + Bickenbach AG

X2CrNiMo 17-12-2 - Schmolz + Bickenbach AG

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

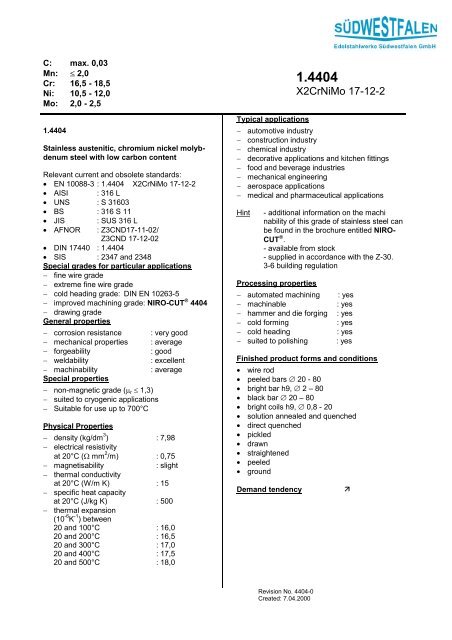

C: max. 0,03<br />

Mn: 2,0<br />

Cr: 16,5 - 18,5<br />

Ni: 10,5 - <strong>12</strong>,0<br />

Mo: 2,0 - 2,5<br />

1.4404<br />

Stainless austenitic, chromium nickel molybdenum<br />

steel with low carbon content<br />

Relevant current and obsolete standards:<br />

EN 10088-3 : 1.4404 <strong>X2CrNiMo</strong> <strong>17</strong>-<strong>12</strong>-2<br />

AISI : 316 L<br />

UNS : S 31603<br />

BS : 316 S 11<br />

JIS : SUS 316 L<br />

AFNOR : Z3CND<strong>17</strong>-11-02/<br />

Z3CND <strong>17</strong>-<strong>12</strong>-02<br />

DIN <strong>17</strong>440 : 1.4404<br />

SIS : 2347 and 2348<br />

Special grades for particular applications<br />

fine wire grade<br />

extreme fine wire grade<br />

cold heading grade: DIN EN 10263-5<br />

improved machining grade: NIRO-CUT 4404<br />

drawing grade<br />

General properties<br />

corrosion resistance : very good<br />

mechanical properties : average<br />

forgeability : good<br />

weldability : excellent<br />

machinability : average<br />

Special properties<br />

non-magnetic grade (r 1,3)<br />

suited to cryogenic applications<br />

Suitable for use up to 700°C<br />

Physical Properties<br />

density (kg/dm 3 ) : 7,98<br />

electrical resistivity<br />

at 20°C ( mm 2 /m) : 0,75<br />

magnetisability : slight<br />

thermal conductivity<br />

at 20°C (W/m K) : 15<br />

specific heat capacity<br />

at 20°C (J/kg K) : 500<br />

thermal expansion<br />

(10 -6 K -1 ) between<br />

20 and 100°C : 16,0<br />

20 and 200°C : 16,5<br />

20 and 300°C : <strong>17</strong>,0<br />

20 and 400°C : <strong>17</strong>,5<br />

20 and 500°C : 18,0<br />

Typical applications<br />

1.4404<br />

<strong>X2CrNiMo</strong> <strong>17</strong>-<strong>12</strong>-2<br />

automotive industry<br />

construction industry<br />

chemical industry<br />

decorative applications and kitchen fittings<br />

food and beverage industries<br />

mechanical engineering<br />

aerospace applications<br />

medical and pharmaceutical applications<br />

Hint - additional information on the machi<br />

nability of this grade of stainless steel can<br />

be found in the brochure entitled NIRO-<br />

CUT .<br />

- available from stock<br />

- supplied in accordance with the Z-30.<br />

3-6 building regulation<br />

Processing properties<br />

automated machining : yes<br />

machinable : yes<br />

hammer and die forging : yes<br />

cold forming : yes<br />

cold heading : yes<br />

suited to polishing : yes<br />

Finished product forms and conditions<br />

wire rod<br />

peeled bars 20 - 80<br />

bright bar h9, 2 – 80<br />

black bar 20 – 80<br />

bright coils h9, 0,8 - 20<br />

solution annealed and quenched<br />

direct quenched<br />

pickled<br />

drawn<br />

straightened<br />

peeled<br />

ground<br />

Demand tendency <br />

Revision No. 4404-0<br />

Created: 7.04.2000

Properties, applications and processing<br />

Corrosion resistance (PRE = 23.1 to 28.5)<br />

Due to the addition of between 2 and 3% molybdenum,<br />

the corrosion resistance of 1.4404 is<br />

significantly better than that of 1.4301 and<br />

1.4307, especially in chloride containing environments.<br />

1.4404 displays excellent resistance to corrosion<br />

in most natural waters and atmospheres (urban,<br />

rural and industrial), provided the chloride and<br />

salt concentrations are low to moderate. Resistance<br />

to reducing acids is restricted to low concentrations<br />

at low temperatures.<br />

Due to its low carbon content, 1.4404 is resistant<br />

to intergranular corrosion even after welding.<br />

Please note that 1.4404 is not resistant to sea<br />

water.<br />

Heat treatment / mechanical properties<br />

Optimal mechanical and fabrication properties<br />

are realised after solution annealing in the temperature<br />

range 1020 - 1<strong>12</strong>0°C followed by rapid<br />

cooling in air or water.<br />

In the solution annealed condition, the following<br />

mechanical properties may be attained when<br />

testing in the longitudinal direction:<br />

Property Specification Typical<br />

- yield strength (N/mm 2 ) Rp0,2 : 200 360<br />

- tensile strength (N/mm 2 ) Rm : 500 – 700 660<br />

- tensile elongation (%) A5 : 40 48<br />

- hardness HB : 215 200<br />

- impact energy (J) @ 25°C ISO-V : 100 220<br />

Elevated temperature properties<br />

The following minimum tensile properties at various<br />

temperatures are specified in the EN 10088-<br />

3 : 1995 standard.<br />

Minimum proof stress (N/mm 2 )<br />

250<br />

225<br />

200<br />

<strong>17</strong>5<br />

150<br />

<strong>12</strong>5<br />

100<br />

75<br />

0<br />

100<br />

0.2% proof stress<br />

200<br />

1% proof stress<br />

300<br />

Test temperature ( C)<br />

400<br />

500<br />

600<br />

Weldability<br />

1.4404 is readily weldable using all welding processes.<br />

Should a filler material be<br />

required, Novonit 4430, can be used. Maximum<br />

interpass temperature during welding is<br />

150°C.<br />

Heat treatment after welding is not necessary,<br />

and even large sections are resistant to intercrystalline<br />

corrosion after welding, due to the low<br />

carbon content.<br />

Forging<br />

Work pieces are usually pre-heated to between<br />

1150 - 1180°C with forging taking place between<br />

1180 und 950°C. After forging, the forged component<br />

must be rapidly cooled in either air or<br />

water to avoid the formation of any undesirable<br />

phases which might adversely affect the corrosion<br />

and/or mechanical properties.<br />

Machining<br />

The machinability of NIRO-CUT 4404 is better<br />

than that of NIRO-CUT 4401 as a result of its<br />

lower carbon content. The absence of titanium<br />

stabilisation also makes 1.4404 far more machinable<br />

than the titanium stabilised 1.4571 grade.<br />

The following machining parameters can be used<br />

as a guideline when machining NIRO-CUT 4404<br />

using a coated hard metal cutting tool.<br />

Depth of cut (mm)<br />

Tensile strengths<br />

Feed rate (mm/rev)<br />

Rm in N/mm 2 6 mm 3 mm 1 mm<br />

0,5 mm/r 0,4 mm/r 0,2 mm/r<br />

solution annealed<br />

(550 - 620) 135 m/min <strong>17</strong>0 m/min 215 m/min<br />

General comments<br />

Due to advances in the production of stainless<br />

steels, namely reduction of the carbon content to<br />

very low levels, 1.4404 has all but replaced the<br />

titanium stabilised 1.4571 grades. 1.4404 is just<br />

as resistant to intercrystalline corrosion as the<br />

titanium grades and does not suffer from knifeline<br />

corrosion. 1.4404 also has a much better<br />

surface finish that the titanium stabilised grade<br />

and can be readily mechanically and electropolished.<br />

Due to the absence of titanium additions<br />

and the resulting hard precipitates, 1.4307<br />

is much more machinable than 1.4541 which<br />

allows higher cutting speeds and results in longer<br />

tool life.<br />

Revision No. 4404-0<br />

Created: 7.04.2000