First class biomass - Siempelkamp

First class biomass - Siempelkamp

First class biomass - Siempelkamp

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

siempelkamp | machineRY and Plants<br />

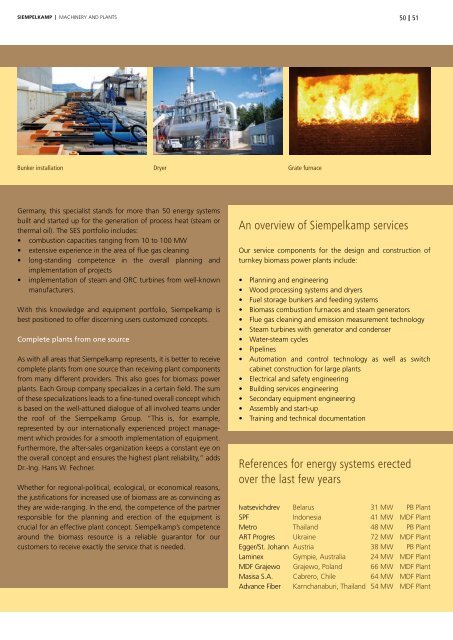

Bunker installation Dryer Grate furnace<br />

germany, this specialist stands for more than 50 energy systems<br />

built and started up for the generation of process heat (steam or<br />

thermal oil). the ses portfolio includes:<br />

• combustion capacities ranging from 10 to 100 MW<br />

• extensive experience in the area of flue gas cleaning<br />

• long-standing competence in the overall planning and<br />

implementation of projects<br />

• implementation of steam and ORC turbines from well-known<br />

manufacturers.<br />

With this knowledge and equipment portfolio, siempelkamp is<br />

best positioned to offer discerning users customized concepts.<br />

Complete plants from one source<br />

as with all areas that siempelkamp represents, it is better to receive<br />

complete plants from one source than receiving plant components<br />

from many different providers. this also goes for <strong>biomass</strong> power<br />

plants. each group company specializes in a certain field. the sum<br />

of these specializations leads to a fine-tuned overall concept which<br />

is based on the well-attuned dialogue of all involved teams under<br />

the roof of the siempelkamp group. “this is, for example,<br />

represented by our internationally experienced project management<br />

which provides for a smooth implementation of equipment.<br />

Furthermore, the after-sales organization keeps a constant eye on<br />

the overall concept and ensures the highest plant reliability,” adds<br />

dr.-ing. hans W. Fechner.<br />

Whether for regional-political, ecological, or economical reasons,<br />

the justifications for increased use of <strong>biomass</strong> are as convincing as<br />

they are wide-ranging. in the end, the competence of the partner<br />

responsible for the planning and erection of the equipment is<br />

crucial for an effective plant concept. siempelkamp’s competence<br />

around the <strong>biomass</strong> resource is a reliable guarantor for our<br />

customers to receive exactly the service that is needed.<br />

An overview of <strong>Siempelkamp</strong> services<br />

References for energy systems erected<br />

over the last few years<br />

ivatsevichdrev belarus 31 mW Pb Plant<br />

sPF indonesia 41 mW mdF Plant<br />

metro thailand 48 mW Pb Plant<br />

aRt Progres ukraine 72 mW mdF Plant<br />

egger/st. Johann austria 38 mW Pb Plant<br />

laminex gympie, australia 24 mW mdF Plant<br />

mdF grajewo grajewo, Poland 66 mW mdF Plant<br />

masisa s.a. cabrero, chile 64 mW mdF Plant<br />

advance Fiber Karnchanaburi, thailand 54 mW mdF Plant<br />

50<br />

51<br />

Our service components for the design and construction of<br />

turnkey <strong>biomass</strong> power plants include:<br />

• Planning and engineering<br />

• Wood processing systems and dryers<br />

• Fuel storage bunkers and feeding systems<br />

• Biomass combustion furnaces and steam generators<br />

• Flue gas cleaning and emission measurement technology<br />

• Steam turbines with generator and condenser<br />

• Water-steam cycles<br />

• Pipelines<br />

• Automation and control technology as well as switch<br />

cabinet construction for large plants<br />

• Electrical and safety engineering<br />

• Building services engineering<br />

• Secondary equipment engineering<br />

• Assembly and start-up<br />

• Training and technical documentation