Annual report 2009 - Siempelkamp

Annual report 2009 - Siempelkamp

Annual report 2009 - Siempelkamp

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

laminating plants including the order and warehouse management system as well<br />

as material fl ow control.<br />

Firmly-established in the market is our multi-piston press for short-cycle laminating.<br />

This press concept accommodates those manufacturers who frequently need to<br />

change their board sizes.<br />

Compared to a standard short-cycle press, a multi-piston press features an even<br />

pressure distribution for high board size variations. This even pressure distribution<br />

is achieved by arranging more press cylinders with shorter distances between them<br />

in length and cross direction. With individual hydraulic control of each press cylinder,<br />

precise adjustment of the pressure distribution is attained.<br />

We also specialize in handling equipment designed for panels, decorative papers,<br />

paper lay-up systems, loader and unloader units, as well as storage system technology.<br />

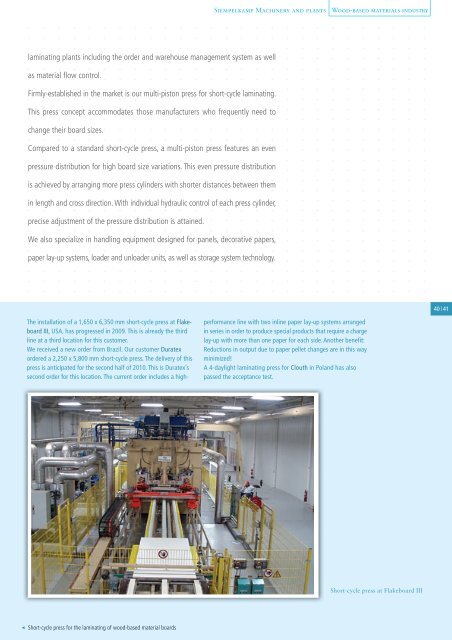

The installation of a 1,650 x 6,350 mm short-cycle press at Flakeboard<br />

III, USA, has progressed in <strong>2009</strong>. This is already the third<br />

line at a third location for this customer.<br />

We received a new order from Brazil. Our customer Duratex<br />

ordered a 2,250 x 5,800 mm short-cycle press. The delivery of this<br />

press is anticipated for the second half of 2010. This is Duratex’s<br />

second order for this location. The current order includes a high-<br />

Short-cycle press for the laminating of wood-based material boards<br />

<strong>Siempelkamp</strong> Machinery and plants<br />

performance line with two inline paper lay-up systems arranged<br />

in series in order to produce special products that require a charge<br />

lay-up with more than one paper for each side. Another benefi t:<br />

Reductions in output due to paper pellet changes are in this way<br />

minimized!<br />

A 4-daylight laminating press for Clouth in Poland has also<br />

passed the acceptance test.<br />

Wood-based materials industry<br />

Short-cycle press at Flakeboard III<br />

40 41