Information for the certification of weld shops in rail

Information for the certification of weld shops in rail

Information for the certification of weld shops in rail

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

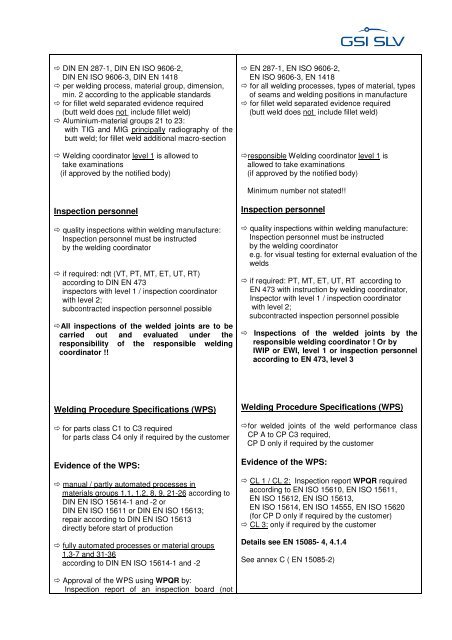

DIN EN 287-1, DIN EN ISO 9606-2,<br />

DIN EN ISO 9606-3, DIN EN 1418<br />

per <strong>weld</strong><strong>in</strong>g process, material group, dimension,<br />

m<strong>in</strong>. 2 accord<strong>in</strong>g to <strong>the</strong> applicable standards<br />

<strong>for</strong> fillet <strong>weld</strong> separated evidence required<br />

(butt <strong>weld</strong> does not <strong>in</strong>clude fillet <strong>weld</strong>)<br />

Alum<strong>in</strong>ium-material groups 21 to 23:<br />

with TIG and MIG pr<strong>in</strong>cipally radiography <strong>of</strong> <strong>the</strong><br />

butt <strong>weld</strong>; <strong>for</strong> fillet <strong>weld</strong> additional macro-section<br />

Weld<strong>in</strong>g coord<strong>in</strong>ator level 1 is allowed to<br />

take exam<strong>in</strong>ations<br />

(if approved by <strong>the</strong> notified body)<br />

Inspection personnel<br />

quality <strong>in</strong>spections with<strong>in</strong> <strong>weld</strong><strong>in</strong>g manufacture:<br />

Inspection personnel must be <strong>in</strong>structed<br />

by <strong>the</strong> <strong>weld</strong><strong>in</strong>g coord<strong>in</strong>ator<br />

if required: ndt (VT, PT, MT, ET, UT, RT)<br />

accord<strong>in</strong>g to DIN EN 473<br />

<strong>in</strong>spectors with level 1 / <strong>in</strong>spection coord<strong>in</strong>ator<br />

with level 2;<br />

subcontracted <strong>in</strong>spection personnel possible<br />

All <strong>in</strong>spections <strong>of</strong> <strong>the</strong> <strong>weld</strong>ed jo<strong>in</strong>ts are to be<br />

carried out and evaluated under <strong>the</strong><br />

responsibility <strong>of</strong> <strong>the</strong> responsible <strong>weld</strong><strong>in</strong>g<br />

coord<strong>in</strong>ator !!<br />

Weld<strong>in</strong>g Procedure Specifications (WPS)<br />

<strong>for</strong> parts class C1 to C3 required<br />

<strong>for</strong> parts class C4 only if required by <strong>the</strong> customer<br />

Evidence <strong>of</strong> <strong>the</strong> WPS:<br />

manual / partly automated processes <strong>in</strong><br />

materials groups 1.1, 1.2, 8, 9, 21-26 accord<strong>in</strong>g to<br />

DIN EN ISO 15614-1 and -2 or<br />

DIN EN ISO 15611 or DIN EN ISO 15613;<br />

repair accord<strong>in</strong>g to DIN EN ISO 15613<br />

directly be<strong>for</strong>e start <strong>of</strong> production<br />

fully automated processes or material groups<br />

1.3-7 and 31-36<br />

accord<strong>in</strong>g to DIN EN ISO 15614-1 and -2<br />

Approval <strong>of</strong> <strong>the</strong> WPS us<strong>in</strong>g WPQR by:<br />

Inspection report <strong>of</strong> an <strong>in</strong>spection board (not<br />

EN 287-1, EN ISO 9606-2,<br />

EN ISO 9606-3, EN 1418<br />

<strong>for</strong> all <strong>weld</strong><strong>in</strong>g processes, types <strong>of</strong> material, types<br />

<strong>of</strong> seams and <strong>weld</strong><strong>in</strong>g positions <strong>in</strong> manufacture<br />

<strong>for</strong> fillet <strong>weld</strong> separated evidence required<br />

(butt <strong>weld</strong> does not <strong>in</strong>clude fillet <strong>weld</strong>)<br />

responsible Weld<strong>in</strong>g coord<strong>in</strong>ator level 1 is<br />

allowed to take exam<strong>in</strong>ations<br />

(if approved by <strong>the</strong> notified body)<br />

M<strong>in</strong>imum number not stated!!<br />

Inspection personnel<br />

quality <strong>in</strong>spections with<strong>in</strong> <strong>weld</strong><strong>in</strong>g manufacture:<br />

Inspection personnel must be <strong>in</strong>structed<br />

by <strong>the</strong> <strong>weld</strong><strong>in</strong>g coord<strong>in</strong>ator<br />

e.g. <strong>for</strong> visual test<strong>in</strong>g <strong>for</strong> external evaluation <strong>of</strong> <strong>the</strong><br />

<strong>weld</strong>s<br />

if required: PT, MT, ET, UT, RT accord<strong>in</strong>g to<br />

EN 473 with <strong>in</strong>struction by <strong>weld</strong><strong>in</strong>g coord<strong>in</strong>ator,<br />

Inspector with level 1 / <strong>in</strong>spection coord<strong>in</strong>ator<br />

with level 2;<br />

subcontracted <strong>in</strong>spection personnel possible<br />

Inspections <strong>of</strong> <strong>the</strong> <strong>weld</strong>ed jo<strong>in</strong>ts by <strong>the</strong><br />

responsible <strong>weld</strong><strong>in</strong>g coord<strong>in</strong>ator ! Or by<br />

IWIP or EWI, level 1 or <strong>in</strong>spection personnel<br />

accord<strong>in</strong>g to EN 473, level 3<br />

Weld<strong>in</strong>g Procedure Specifications (WPS)<br />

<strong>for</strong> <strong>weld</strong>ed jo<strong>in</strong>ts <strong>of</strong> <strong>the</strong> <strong>weld</strong> per<strong>for</strong>mance class<br />

CP A to CP C3 required,<br />

CP D only if required by <strong>the</strong> customer<br />

Evidence <strong>of</strong> <strong>the</strong> WPS:<br />

CL 1 / CL 2: Inspection report WPQR required<br />

accord<strong>in</strong>g to EN ISO 15610, EN ISO 15611,<br />

EN ISO 15612, EN ISO 15613,<br />

EN ISO 15614, EN ISO 14555, EN ISO 15620<br />

(<strong>for</strong> CP D only if required by <strong>the</strong> customer)<br />

CL 3: only if required by <strong>the</strong> customer<br />

Details see EN 15085- 4, 4.1.4<br />

See annex C ( EN 15085-2)