Lihat Laporan - einrip

Lihat Laporan - einrip

Lihat Laporan - einrip

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

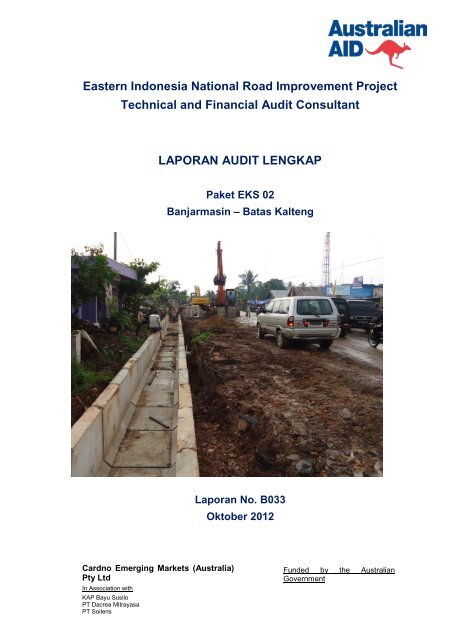

Eastern Indonesia National Road Improvement Project<br />

Cardno Emerging Markets (Australia)<br />

Pty Ltd<br />

In Association with<br />

KAP Bayu Susilo<br />

PT Dacrea Mitrayasa<br />

PT Soilens<br />

Technical and Financial Audit Consultant<br />

LAPORAN AUDIT LENGKAP<br />

Paket EKS 02<br />

Banjarmasin – Batas Kalteng<br />

<strong>Laporan</strong> No. B033<br />

Oktober 2012<br />

Funded by the Australian<br />

Government

SINGKATAN DAN AKRONIM<br />

Technical and Financial Audit Consultant (TFAC)<br />

AIP Australian Indonesia Partnership for Reconstruction and Development<br />

AF Audit Form<br />

AusAID Australian Agency for International Development<br />

CWC Civil Works Contractor<br />

EINRIP Eastern Indonesia National Road Improvement Project<br />

EMU EINRIP Monitoring Unit<br />

GoI Government of Indonesia<br />

GCC General Conditions of Contract<br />

GS General Specification<br />

PMSC Project Management Support Consultant<br />

PMU Project Monitoring Unit<br />

QAP Quality Assurance Plan (managed by RSC)<br />

QCP Quality Control Plan (managed by CWC)<br />

RSC Regional Supervision Consultant<br />

TFAC Technical and Financial Audit Consultant<br />

TOR Terms of Reference (EINRIP-TFAC)<br />

Doc. ID: B033 – <strong>Laporan</strong> Audit Lengkap Paket EKS-02 i

DAFTAR ISI<br />

Technical and Financial Audit Consultant (TFAC)<br />

SINGKATAN DAN AKRONIM ............................................................................................... i<br />

DAFTAR ISI ...........................................................................................................................ii<br />

RINGKASAN AUDIT ............................................................................................................ 1<br />

Audit ............................................................................................................................... 1<br />

Temuan-temuan Umum ...................................................................................................... 1<br />

1 PENDAHULUAN ...................................................................................................... 3<br />

1.1 Tjujan dari Program Audit .......................................................................................... 3<br />

1.2 Gambaran Umum Desain Proyek .............................................................................. 3<br />

1.3 Sejarah Audit yang Sebelumnya ................................................................................ 3<br />

1.4 Tujuan-tujuan dari Audit Kali Ini ................................................................................. 3<br />

1.5 Area-area Khusus untuk Penyelidikan ....................................................................... 4<br />

1.6 Pelaksanaan Audit ..................................................................................................... 4<br />

2 TEMUAN-TEMUAN AUDIT....................................................................................... 5<br />

3 PENGUJIAN MATERIAL ........................................................................................ 11<br />

3.1 Job Mix untuk Aspal ................................................................................................. 11<br />

3.2 Pengujian Geo-grid .................................................................................................. 11<br />

DAFTAR LAPORAN........................................................................................................... 60<br />

LAMPIRAN-LAMPIRAN<br />

Lampiran-1 Audit Forms<br />

Lampiran-2 Hasil-hasil Pengujian<br />

Lampiran-3 Rekaman Daftar Hadir Rapat Penutupan<br />

Lampiran-4 Daftar <strong>Laporan</strong> TFAC<br />

TABEL-TABEL<br />

Tabel 2.1 Ringkasan Temuan-Temuan Audit 5<br />

Doc. ID: B033 – <strong>Laporan</strong> Audit Lengkap Paket EKS-02 ii

Audit<br />

RINGKASAN AUDIT<br />

Technical and Financial Audit Consultant (TFAC)<br />

Audit lengkap sudah dilakukan. Tujuan dari Audit ini adalah untuk mengidentifikasi semua<br />

ketidaksesuaian yang signifikan terhadap Spesifikasi dan Gambar-Gambar dan<br />

menyarankan tindakan-tindakan perbaikan. Metode Kerja juga dikaji bila memungkinkan.<br />

Sampel-sampel terpilih diambil untuk pengujian independen guna memverifikasi<br />

pemenuhannya terhadap Spesifikasi Kontrak.<br />

Temuan-temuan Umum<br />

Secara umum pekaksanaan pekerjaan fisi. Hanya ada sedikit ketidaksesuaian signifikan<br />

yang teridentifikasi yang berkaitan dengan pelaksanaan pekerjaan hingga saat ini. Ada<br />

beberapa hal yang berhubungan dengan variasi yang telah dirancanakan terhadap gambar<br />

desain asli yang masih memerlukan persetujuan. Kegagalan dalam menyelesaikan hal-hal<br />

berikut ini mungkin menyebabkan penundaan lebih lanjut:<br />

a) Usulan / proposal untuk merevisi tikungan di Sta. 0+000 sampai dengan Sta. 0+200 dari<br />

100m menjadi 65 m. Alasan yang diberikan untuk usulan perubahan tersebut adalah<br />

bahwa lokasinya yang berada di dekat abutment jembatan Barito telah menghalangi<br />

pembuatan bagian spiral dari tikungan tersebut. Sebagian dari hal ini memang benar,<br />

tetepai dengan membuat beberapa overlap masih memungkinkan. Pemeriksaan dengan<br />

komputer di lapangan terhadap jari-jari tikungan yang memungkinkan menunjukkan<br />

bahwa tikungan 90m masih dapat dibuat (dibangun) di dalam keterbatasan fisik lapangan<br />

tersebut. Hal ini agar diverifikasi dan gambar kerja (shop drawing) agar dibuat. Solusi ini<br />

memperhatikan keterbatasan keadaan lapangan dan di saat yang sama juga tetap<br />

menjaga kecepatan rencana yang memuaskan (kecepatan rencana desain 60 km/jam<br />

diturunkan menjadi 55 km/jam diusulkan untuk jari-jari 90m);<br />

b) Proposal untuk meninggikan badan jalan dari Sta. 0+200 sampai dengan Sta. 1+350. Hal<br />

ini dipertimbamgkan sebagai penting bukan karena seringnya terjadi pelimpasan air<br />

(banjir) melewati atas permukaan jalan, bukan karena itu, melainkan karena ketinggian<br />

permanen air tanah sangat dekat dengan elevasi permukaan jalan eksisting. Peninggian<br />

badan jalan atau bagian (segmen) jalan dengan perkerasan beton, adalah penting untuk<br />

menyelesaikan permasalahan ini.<br />

Permasalahan paling besar yang berhubungan dengan proyek ini mungkin adalah bahwa<br />

penyelesaian hal-hal/permasalahan variasi yang terlalu lama. Saat ini keadaan pekerjaan<br />

sudah mulai agak berbeda dari desain asli selain dari pada untuk penggunaan geotextil<br />

yang cukup banyak sebagai tambahan dari geogrid yang telah ditentukan 1 . Terlihat adanya<br />

sedkit manfaat bagi pihak manapun dari penundaan/keterlambatan ini. Ada kebutuhan yang<br />

nyata untuk perbaikan/peningkatan dalam proses penyelesaian untuk perubahan desain<br />

yang diusulkan antara Engineer dan Kontraktor dan antara Engineer dan Pemilik. Engineer<br />

(CSE Proyek) pada saat ini mengambil suatu kepemimpinan yang sangat dibutuhkan dalam<br />

1 Fungsi dari geo-grid adalah untuk meningkatkan pondasi struktur perkerasan pada tanah lunak jauh lebih positif dari pada<br />

yang mungkin diberikan oleh geotektil. Fungsi utama dari geotekstil adalah untuk berperan sebagai separator antara tanah<br />

lunak dan material timbunan. Selama sebagian besar dari timbunan pelebaran jalan dibangun di atas perbaikan tanah dasar,<br />

geotekstil nampaknya hanya akan memberikan manfaat yang terbatas. Namun saat ini geotekstil ini telah dipasang maka tidak<br />

ada gunanya untuk memperdebatkan hal ini lebih lanjut.<br />

Doc. ID: B033–<strong>Laporan</strong> Audit Lengkap Paket EKS-02 1

Technical and Financial Audit Consultant (TFAC)<br />

penyelesaian perselisihan review desain. Diharapkan bahwa pihak-pihak dalam kontrak<br />

untuk dapat memperoleh peyelesaian untuk permasalahan variasi.<br />

Kemajuan Proyek ini benar-benar jauh terlambat (behind schedule), tetapi sekarang ini<br />

sedang mengalami peningkatan seara memuaskan. Untuk waktu-waktu mendatang,<br />

kincinya adalah segera menyelesaikan permasalahan variasi.<br />

Doc. ID: B033–<strong>Laporan</strong> Audit Lengkap Paket EKS-02 2

1 PENDAHULUAN<br />

1.1 Tjujan dari Program Audit<br />

Technical and Financial Audit Consultant (TFAC)<br />

Tjuan umum dari program audit adalah untuk menilai pemenuhan terhadap standardstandar<br />

mutu dari pelaksanaan proyek-proyek Eastern Indonesia National Roads<br />

Improvement Projects (EINRIP) yang didanai AusAID. Konsultan Audit Tekns dan<br />

Keuangan (Technical and Financial Audit Consultant / (TFAC) melaporkan kepada<br />

AusAID sesuai dengan ketentuan-ketentuan kesepakatan antar kedua pemerintahan<br />

yaitu antara Pemerintah Indonesia dan Australia.<br />

Tujuan-tujuan dari audit dalam bentuknya saat ini adalah:<br />

a) Untuk mengidentifikasi pekerjaan-pekerjaan proyek dan ketidaksesuaian<br />

manajemen.<br />

b) Untuk menginformasikan kepada AusAID mengenai standard-standar mutu dan<br />

tingkat pemenuhan terhadap kontrak yang dicapai dalam pelaksanaan proyek.<br />

c) Untuk membawa/menginformasikan kekurangan-kekurangan mutu proyek dan<br />

manajemen proyek agar menjadi perhatian Direktorat Jenderal Bina Marga<br />

(DJBM). (AusAID membagikan <strong>Laporan</strong>-<strong>Laporan</strong> Audit kepada DJBM).<br />

d) Untuk memberikan saran-saran tindakan perbaikan untuk audit, terutama kepaa<br />

Kontraktor dan Tim-tim Supervisi Lapangan.<br />

1.2 Gambaran Umum Desain Proyek<br />

Proyek ini secara keseluruhan berada pada area tanah lunak alluvial yang dalam<br />

yang terendam secara permanen. Seluruh alinyemen jalan eksisting dipertahankan<br />

kecuali untuk lokasi usulan perbaikan jari-jari tikungan awal yang berada di<br />

Jembatan Barito. Pendekatan ini mengambil keuntungan dari (memanfaatkan)<br />

konsolidasi jangka panjang dari timbunan eksisting pada waktu-waktu sebelumnya.<br />

Suatu perubahan alinyemen akan memerlukan periode pra-konsolidasi timbunan<br />

nyang cukup lama. Desain (perencanaan) telah memperhatikan/memperhitungkan<br />

stabilitas yang buruk dari zona bahu jalan dari timbunan asli dan ketidakcukupan<br />

struktur perkerasan eksisting secara umum.<br />

Panjang proyek ini adalah 12.8 Km.<br />

1.3 Sejarah Audit yang Sebelumnya<br />

Audit kali ini merupakan audit lengkap yang pertama untuk proyek ini. Pada waktu<br />

sebelumnya suatu evaluasi lapangan secara singkat telah dilakukan pada tanggal 17<br />

Mei 2012. Hasil dari evaluasi tersebut telah dilaporkan oleh TFAC kepada EMU<br />

melalui e-mail tertanggal 2 Juni 2012.<br />

1.4 Tujuan-tujuan dari Audit Kali Ini<br />

Tujuan utama dari audit kali ini adalah untuk:<br />

a) Menilai permasalahan variasi yang melibatkan perubahan lingkup pekerjaanpekerjaan<br />

permanen.<br />

Doc. ID: B033–<strong>Laporan</strong> Audit Lengkap Paket EKS-02 3

Technical and Financial Audit Consultant (TFAC)<br />

b) Mengidentifikasi permasalahan-permasalahan utama yang mempengaruhi<br />

pemenuhan terhadap Spesifikasi, Persyaratan Kontrak dan lingkup pekerjaan<br />

kontrak.<br />

1.5 Area-area Khusus untuk Penyelidikan<br />

a) Permasalahan Variasi:<br />

i) Masalah jari-jari tikungan dari Sta. 0+000 ke Sta. 0+200 melibatkan<br />

ketidaksesuaian jari-jari tikungan;<br />

ii) Peninggian badan jalan dari Sta. 0+200 sampai Sta. 1+350, perubahan dalam<br />

hal lingkup pekrjaan;<br />

b) Permasalahan lain yang mungkin menghambat kemajuan pekerjaan seperti<br />

persiapan untuk pekerjaan aspal.<br />

1.6 Pelaksanaan Audit<br />

Audit ini telah dilaksanakan di lapangan sejak tanggal 30 Oktober sampai dengan<br />

tanggal 3 November 2012. Audit ini dilaksanakan oleh:<br />

E.M. James, Team Leader TFAC<br />

Sirojudin Abas Pavement and Materials Engineer, TFAC<br />

Anang Rukadjat Materials Testing Engineer<br />

Rapat Penutupan Audit telah dilaksanakan di Banjarmasin pada tanggal 3 November<br />

2012.<br />

Doc. ID: B033–<strong>Laporan</strong> Audit Lengkap Paket EKS-02 4

2 TEMUAN-TEMUAN AUDIT<br />

Technical and Financial Audit Consultant (TFAC)<br />

Tabel 2.1 menyajikan ringkasan temuan-temuan audit. Untuk informasi lebih lanjut, jendaknya merujuk ke Audit Forms (Lampiran 1).<br />

Audit Forms menggunakan sistem penomoran yang sama seperti pada Tabel 2.1.<br />

Tabel 2.1 Ringkasan Temuan-Temuan Audit<br />

Ref. Uraian Temuan dan Dampak yang Potensial Tindakan-tindakan Perbaikan<br />

AF-01 Temuan<br />

Drainase sementara dan saluran samping permanen tidak selesai<br />

di sepanjang proyek.<br />

Dampak<br />

Hal ini akan sangat mempengaruhi struktur perkerasan maupun<br />

kemampuan kontraktor untuk melakukan pekerjaan selama musim<br />

hujan.<br />

AF 02 Temuan<br />

Beberapa saluran-U tidak ditempatkan pada posisi yang optimum.<br />

Dampak<br />

Pekerjaan-pekerjaan terbangun tidak memberikan hasil terbaik<br />

untuk baiaya yang telah dikeluarkan. Selama panjang saluran-U<br />

telah dikurangi lokasi-lokasi drainase tersebut seharusnya sudah<br />

dioptimalkan kembali melalui proses rekayasa lapangan (field<br />

engineering).<br />

Tindakan yang Disepakati<br />

Saluran samping akan segera diselesaikan.<br />

Tindakan yang Disepakati<br />

Tidak ada.<br />

Lain-lain:<br />

Baik SSE maupun Kontraktor percaya bahwa semua saluran-U<br />

ditempatkan secara optimal.<br />

Auditor percaya bahwa saluran-saluran pendekat tidak diperlukan pada<br />

pendekat-pendekat ke gorong-gorong melintang bilamana jalan berada<br />

pada/di atas timbunan. Posisi saluran-saluran U yang masih akan dipasang<br />

hendaknya ditinjau ulang oleh Engineer untuk memastikan nilai yang<br />

optimum dari unit-unit yang tersedia.<br />

Doc. ID: B033–<strong>Laporan</strong> Audit Lengkap Paket EKS-02 5

Ref. Uraian Temuan dan Dampak yang Potensial Tindakan-tindakan Perbaikan<br />

AF-03 Temuan<br />

Di beberapa lokasi, platform timbunan dimana geogrid dipasang di<br />

atasnya berada pada elevasi yang tidak cukup.<br />

Dampak<br />

Berfungsinya geogrid secara benar tergantung pada penempatan<br />

elevasi sehingga interlocking (keadaan saling mengunci) dari<br />

lapisan granular yang dipasang di atasnya dapat bekerja dengan<br />

baik.<br />

AF-04 Temuan<br />

Material timbunan pilihan yang tidak sesuai telah ditempatkan di<br />

atas geogrid. Unsuitable selected embankment has been used over<br />

geogrid. Material yang digunakan ini berbeda dengan material yang<br />

telah disetujui.<br />

Dampak<br />

Material timbunan pilihan yang digunakan banyak mengandung<br />

banyak sekali batu karang (rock) yang kemungkinan dapat merusak<br />

geogrid.<br />

AF-05 Temuan<br />

Geogrid yang disuplai ke proyek tidak memenuhi ketentuan<br />

spesifikasi mengenai metode pembuatan ataupun kekakuan radial.<br />

Dampak<br />

Geogrid yang disuplai adalah sesuai untuk tujuan yang<br />

dimaksudkan (maksud pembuatannya) dan dipasang dengan hatihati.<br />

Geogrid yang ditentukan/ dispesifikasikan telah ditemukan<br />

dalam percobaan-percobaan pihak ketiga untuk menyediakan<br />

kekakuan lapisan granular yang lebih besar dari pada jenis yang<br />

telah disuplai ke proyek, sehingga perubahan tersebut akan<br />

mengurangi umur potensial proyek.<br />

Technical and Financial Audit Consultant (TFAC)<br />

Tindakan yang Disepakati<br />

Pada area-area yang terpengaruh, Geo-grid akan dibongkar dan timbunan<br />

akan dilevel kembali dan dipadatkan. Area-area yang nantinya akan<br />

dipasang geogrid di atasnya akan diperiksa dan disetujui sebelum<br />

pemasangan geogrid. Holding Point tambahan ini akan diinstruksikan oleh<br />

Engineer.<br />

Tindakan yang Disepakati<br />

Material-material yang tidak sesuai akan diganti. Untuk selanjutnya hanya<br />

material yang sesuai yang akan digunakan.<br />

Tindakan yang Disepakati<br />

Tidak ada.<br />

Kontraktor dan SSE menyatakan bahwa hasil-hasil pengujian yang ada<br />

adalah valid/sah.<br />

Lainnya:<br />

Material yang disuplai dan digunakan adalah “sesuai untuk tujuannya’ dan<br />

telah disetujui oleh Engineer. Oleh karenanya penerimaan atas semua<br />

geogrid yang telah disuplai adalah direkomendasikan. Jika geogrid<br />

tambahan akan dibeli untuk proyek maka harus memenuhi persyaratan<br />

spesifikasi.<br />

Doc. ID: B033–<strong>Laporan</strong> Audit Lengkap Paket EKS-02 6

Ref. Uraian Temuan dan Dampak yang Potensial Tindakan-tindakan Perbaikan<br />

AF-06 Temuan<br />

Elevasi tanah dasar proprti (lahan) milik pribadi di beberapa lokasi<br />

berada di bawah elevasi bagian atas saluran-U. Desain asli telah<br />

menyertakan/menyediakan saluran-U dengan bentukj yang tidak<br />

simetris untuk menyesuaikan dengan keadaan/masalah ini.<br />

Dampak<br />

Pembuatan saluran-U pra-cetak secara simetris telah<br />

memunculkan potensi terjadinya drainase yang buruk untuk lahan<br />

milik pribadi.<br />

AF-07 Finding<br />

Ketinggian dinding parapet gorong-gorong terhadap permukaan<br />

jalan yang sudah selesai terlihat tidak benar.<br />

Dampak<br />

Ketinggian yang bervariasi terhadap elevasi final permukaan jalan<br />

akan tidak enak dipandang dan mungkin juga merupakan bahaya<br />

bagi keselamatan lalu lintas.<br />

Technical and Financial Audit Consultant (TFAC)<br />

Pengujian kekuatan regangan yang telah dilaksanakan secara jelas tidak<br />

radial selama material yang diajukan tidak mempunyai kekuatan pada<br />

perpanjangan 0.5% dalam arah radial (diagonal) manapun. Geogrid yang<br />

disuplai juga tidak memenuhi ketentuan metode pembuatan ataupun dalam<br />

hal ukuran (dimensional) yang diuraikan di dalam Spesifikasi.<br />

Engineer hendaknya memastikan bahwa material-material tersebut<br />

memenuhi syarat sebelum menyetujuinya. Spesifikasi Khusus untuk Geogrid<br />

hendaknya ditinjau ulang dan mungkin harus menyertakan ketentuanketentuan<br />

mengenai sifat-sifat untuk beberapa jenis geo-grid. Harga satuan<br />

BOQ hendaknya diperluas untuk memasukkan beberapa jenis geo-grid.<br />

Tindakan yang Disepakati<br />

Titik-titik akses drainase untuk lahan-lahan milik pribadi (masyarakat) akan<br />

disediakan dimana diperlukan tanpa biaya tambahan.<br />

Tindakan yang Disepakati<br />

Dinding parapets akan dicor kembali jika elevasi bagian atasnya tidak<br />

konsisten.<br />

Lainnya<br />

• Kontraktor percaya bahwa elevasi bagian atas parapet adalah<br />

benar.<br />

• Parapet-parapet tersebut memiliki tipe yang tidak standar tetapi<br />

sudah disetujui oleh PPK.<br />

Doc. ID: B033–<strong>Laporan</strong> Audit Lengkap Paket EKS-02 7

Ref. Uraian Temuan dan Dampak yang Potensial Tindakan-tindakan Perbaikan<br />

AF-08 Temuan<br />

Perubahan jari-jari tikungan dari 100m menjadi 65m pada bagian<br />

awal proyek yang diuusulkkan oleh Kontraktor dan SSE adalah<br />

tidak bisa diterima. Jari-jari tikungan 90m masih dapat disediakan<br />

(dibuat) dan hendaknya digunakan untuk peninjauan ulang<br />

berdasarkan gambar kerja final (shop drawing).<br />

Dampak<br />

Usulan jari-jari tikungan 65m akan memunculkan resiko yang tidak<br />

perlu bagi keselamatan lalu lintas. Dengan meninggikan badan<br />

jalan sampai gradien yang benar, kecepatan natural (asli) yang<br />

membatasi faktor-faktor yang berhubungan dengan jarak<br />

pandangan yang buruk dan gradien vertikal yang buruk seperti<br />

yang ada pada saat ini akan dihilangkan, dengan demikian hal ini<br />

memunculkan suatu ketentuan perubahan kecepatan yang tidak<br />

dapat diterima di dalam alinyemen yang diusulkan.<br />

AF-09 Temuan<br />

Beberapa jenis peralatan yang disyaratkan di dalam spesifikasi<br />

harus disediakan sebelum memulai pekerjaan-pekerjaan yang<br />

terkait: a) bitumen distributer, b) power broom, dan c) bin dingin<br />

pengumpan ke-5 untuk AMP.<br />

Dampak<br />

Peralatan tersebut akan memperbaiki/meningkatkan mutu<br />

penyiapan Base A untuk pelapisan aspal dan memperbaiki/<br />

meningkatkan kontrol terhadap gradasi agregat aspal.<br />

AF-10 Temuan<br />

Peralatan tambahan berikut ini direkomendasikan untuk<br />

meningkatkan pemadatan: sebuah pneumatic roller untuk<br />

penyelesaian Agregat Base A dan sebuah mesin gilas berukuran<br />

medium (intermediate) untuk memadatkan zona bahu jalan yang<br />

lebarnya 1m.<br />

Tindakan yang Disepakati<br />

Technical and Financial Audit Consultant (TFAC)<br />

Agar merevisi gambar-gambar untuk menyediakan jari-jari tikungan 90m.<br />

Lainnya<br />

Diperlukan Guardrail. Rambu-rambu peringatan tambahan juga diperlukan<br />

(untuk detailnya, lihat AF-08). Drainase (saluran) yang akan disediakan<br />

diantara dinding penahan tanah yang diusulkan dan garis pagar lahan hak<br />

milik (PDAM) hendaknya dengan ukuran yang layak – bukan saluran-U<br />

pracetak standar.<br />

Disepakati<br />

Semua item peralatan akan disediakan.<br />

Tindakan<br />

Pneumatic roller akan digunakan untuk pemadatan Base A.<br />

Kontraktor juga menyatakan telah memobilisasi mesin gilas berukuran<br />

medium untuk pemadatan bahu jalan (tidak terlihat oleh auditor)<br />

Doc. ID: B033–<strong>Laporan</strong> Audit Lengkap Paket EKS-02 8

Ref. Uraian Temuan dan Dampak yang Potensial Tindakan-tindakan Perbaikan<br />

Dampak<br />

Pemadatan yang seragam untuk bagian atas agregat base A<br />

adalah sangat sulit tanpa menggunakan pneumatic tyred roller.<br />

Konsekuensi dari tidak diguankannya pneumatic roller adalah<br />

meningkatnya kerusakan permukaan yang sudah dilapis prime coat<br />

akibat lintasan lalu litas dan lain-lain. Mesin gilas dengan ukuran<br />

lebar yang lebih kecil adalah penting untuk pemadatan bahu jalan<br />

pada proyek ini.<br />

AF-11 Temuan<br />

Unit pemecah batu yang ada tidak memenuhi ketentuan. Unit ini<br />

memiliki jaw 2 tahap untuk pemecah tipe jaw.<br />

Dampak<br />

Konfigurasi ini menghasilkan agregat yang pipih (flaky).<br />

AF-12 Temuan<br />

Kalibrasi peralatan laboratorium sudah kadaluwarsa.<br />

Dampak<br />

Minor<br />

AF-13 Temuan<br />

Ketentuan/perlengkapan untuk lalu lintas tidak memuaskan.<br />

Dampak<br />

Dampak yang negative bagi keselamatan publik/masyarakat.<br />

Technical and Financial Audit Consultant (TFAC)<br />

Tindakan yang Disepakati<br />

Kontraktor akan mengoptimalkan setting (penyetelan) dari unit pemecah ini,<br />

dan akan mencoba suatu perubahan ukuran saringan (screen). Jika bentuk<br />

agregat masih tidak memuaskan maka akan ditambahkan kerucut ketiga<br />

atau unit pemecah tipe impact.<br />

Tindakan yang Disepakati<br />

Kontraktor akan mengadakan kalibrasi.<br />

Tindakan yang Disepakati<br />

Kontraktor akan memperbaiki/meningkatkan rambu-rambu dan<br />

pengendalian lalu lintas.<br />

Posisi / Sikap Auditor<br />

Ini merupakan permasalahan yang sedang berlangsung pada semua<br />

proyek. Ada riwayat janji-janji yang tidak dipenuhi pada proyek-proyek<br />

lainnya<br />

.<br />

Doc. ID: B033–<strong>Laporan</strong> Audit Lengkap Paket EKS-02 9

Ref. Uraian Temuan dan Dampak yang Potensial Tindakan-tindakan Perbaikan<br />

AF-14 Temuan<br />

Ketetapan-ketetapan untuk pemeliharaan jalan perlu ditinjau ulang<br />

sebelum datangnya musim hujan.<br />

Dampak<br />

Jika tidak dipelihara dengan baik selama musim hujan akan<br />

meningkatkan ongkos bagi oenggunajalan.<br />

AF-15 Temuan<br />

Segmen jalan di antara Sta. 0+330 sampai dengan Sta. 1+120<br />

(perkiraan) perlku nditinggikan untuk meningkatkan tinggi bebas<br />

(clearance) elevasi permukaan jalan final di atas elevasi air banjir<br />

dan di atas tanah yang terendam.<br />

Dampak<br />

Kerusakan/kegagalan dini pada perkerasan jalan sehubungan<br />

dengan dekatnya dengan air tanah, jika tidak dilakukan.<br />

AF-16 Temuan<br />

Sesuatu untuk memperkecil kemungkinan lalu lintas menggunakan<br />

bahu jalan aspal perlu dibuat/dipasang..<br />

Dampak<br />

Berlalu lalangnya kendaraan (lalu lintas) pada bahu jalan tanpa<br />

pengendalian mungkin menyebabkan kerusakan dini.<br />

AF-17 Temuan<br />

Direkomendasikan penggunaan bahan anti pengelupasan untuk<br />

semua campuran aspal.<br />

Dampak<br />

Ketinggian elevasi air tanah di sepanjang proyek akan<br />

meningkatkan kadar air di dalam lapis-lapis aspal dan dapat<br />

menyebabkan pengelupasan aspal.<br />

Technical and Financial Audit Consultant (TFAC)<br />

Tindakan yang Disepakati<br />

Persyaratan/ketentuan mengenai pemeliharaan akan disediakan di dalam<br />

Kontrak.<br />

Tindakan yang Disepakati<br />

Usulan (proposal) variasi akan memmasukkan peninggian jalan pada<br />

segmen ini. Saluran samping pada segmen ini dan sepanjang 200m pada<br />

setiap sisinya akan disediakan dan dibuat cukup dalam untuk<br />

memungkinkan air mengalir bebas menuju ke saluran-saluran melintang<br />

(cross drains).<br />

Tindakan yang Disepakati<br />

Memasang rumble strips jika disetujui secara resmi oleh Pemilik melalui<br />

Variasi Kontrak.<br />

Tindakan yang Disepakati<br />

Kontraktor mengusulkan bahwa bahan anti pengelupasan akan digunakan<br />

jika stabilitas sisa dari Job Mix kurang dari 95%.<br />

Doc. ID: B033–<strong>Laporan</strong> Audit Lengkap Paket EKS-02 10

3 PENGUJIAN MATERIAL<br />

Technical and Financial Audit Consultant (TFAC)<br />

Temuan-temuan audit telah dipresentasikan/disamoaikan pada Rapat Penutupan<br />

dan disetujui atau setidaknya dipahami oleh yang hadir dalam rapat tersebut. Hasilhasil<br />

pengujian lapangan tidak sepenuhnya dianalisa dan pengujian laboratorium<br />

belum dimulai (dilaksanakan) pada waktu RapatPenutupan tersebut. Oleh karena itu<br />

pengujain-pengujian material dan lapangan kemungkinan menghasilkan temuantemuan<br />

tambahan. Temuan-temuan Tambahan ini telah dimasukkan di dalam Tabel<br />

2.1 dan telah diberi nomor urut referensi.<br />

Hasil-hasil pengujian lapangan secara umum memuaskan (Lampiran 2). Kekuatan<br />

beton untuk bangunan-bangunan struktur lebih baik dari pada yang ada pada<br />

sebagian besar proyek lainnya. Kekuatan beton untuk dinding parapet goronggorong<br />

cenderung rendah (Audit Tambahan 18). Ada yang perlu diperhatikan<br />

mengenai masalah ini untuk pekerjaan dinding parapet sisanya. Pemadatan<br />

timbunan biasa dan timbunan pilihan cukup memuaskan.<br />

Sampel-sampel diambil untuk memverifikasi mutu dari material timbunan pilihan dan<br />

batu (rock) serta material filler yang diusulkan untuk aspal. Hasil-hasil ini akan<br />

ditambahkan ke dalam laporan jika sudah tersedia.<br />

3.1 Job Mix untuk Aspal<br />

Kontraktor belum melengkapi/menyelesaikan job mix untuk aspal. Oleh karenya tidak<br />

ada ketidaksesuaian yang dapat dicatat sehubungan dengan Job Mix untuk aspal<br />

(selain dari pada keadaan yang sudah jauh terlambat namun dapat dibantah<br />

terhadap rencana dimulainya pekerjaan-pekerjaanaspal). Namun beberapa hal<br />

penting telah dicatat: Hal ini hendaknya diperhatikan selama pelaksanaan<br />

percobaan-percobaan campuran aspal (asphalt job mix trials)<br />

a) Beberapa bahan mengisi (fillers) dalam pembahasan termasuk kapur pecahan<br />

(crushed lime) (yang sesuai) dan material yang dinyatakan sebagai abu terbang<br />

namun terlihat seperti abu batu (fine crushed coal). Pada akhirnya tidak boleh<br />

digunakan;<br />

b) Agregat aspal belum tersedia tetapi agregat lain yang diproduksi oleh pemasok<br />

yang diusulkan ternyata sangat pipih (flaky) terutama dalam kisaran 5-10 mm.<br />

Permasalahan ini harus dikoreksi (merujuk ke AF 11);<br />

c) Selama volume lalu lintas memerlukan campuran asphalt wearing dan ashaplt<br />

binder bergradasi kasar dan tanah dasar jalan dalam kondisi basah secara<br />

permanen, perhatian perlu diberikan untuk mencegah masalah pengelupasan di<br />

dalam aspal. Penggunaan bahan anti pengelupasan direkomendasikan karena<br />

disediakan (diakomodasi) di dalam Spesifikasi. Spesifikasi menyatakan tidak ada<br />

ketentuan untuk pembayaran tambahan untuk bahan anti pengelupasan (hal ini<br />

mungkin perlu untuk disediakan tanpa biaya tambahan jika stabilitas yang tersisa<br />

dari aspal tidak sesuai/tidak memenuhi ketentuan). Untuk proyek ini disarankan<br />

bahwa bahan anti pengelupasan dapat digunakan tanpa tergantung pada<br />

apakah kaidah/aturan stabilitas yang tersisa dipenuhi. Oleh sebab itu<br />

pembayaran tambahan hendaknya dipertimbangkan (merujuk ke AF 17).<br />

3.2 Pengujian Geo-grid<br />

Engineer seharusnya sudah menguji material geo-grid sebelum menyetujui untuk<br />

penggunaannya.<br />

Doc. ID: B033–<strong>Laporan</strong> Audit Lengkap Paket EKS-02 11

Doc. ID: B033–EKS 02 Full Audit Report<br />

Technical and Financial Audit Consultant (TFAC)<br />

LAMPIRAN 1<br />

Audit Forms<br />

(seluruh form sudah ditandatangani oleh PPK, CWC, SSE dan TFAC.<br />

Form-form asli yang sudah ditandatangani dipegang oleh TFAC)

Doc. ID: B033–EKS 02 Full Audit Report<br />

Technical and Financial Audit Consultant (TFAC)<br />

Project: EKS 02<br />

Location: Banjarmasin – Bts. Kalteng<br />

Non conformity<br />

Date of Audit: 30 October – 2 November 2012<br />

Closing Meeting: 3 November 2012<br />

Audit Finding<br />

Temporary drainage and side drains incomplete<br />

AF 01<br />

(of 17)<br />

Evidence and Extent<br />

The existing earth side drains are blocked in many places. In some locations the blockage is by<br />

waste dumped from the project<br />

Contract Document Reference<br />

General Specification<br />

Additional Investigation Required:<br />

none<br />

Problem impact:<br />

Potential impact on finished quality<br />

The problem will cause ground water levels to<br />

be higher than necessary during the wet<br />

season. That in turn will increase traffic<br />

damage to the pavement<br />

Cost implication<br />

Immediate and long term pavement<br />

maintenance costs may be significant<br />

Other<br />

Nuisance to property owners<br />

Signed<br />

Engineer or Authorised Assistant<br />

Signed<br />

TFAC<br />

Signed<br />

Quality Manager CWC<br />

Signed<br />

PMSC<br />

Signed<br />

General Superintendant, CWC<br />

Signed<br />

PPK

Non conformity<br />

Project: EKS 02<br />

Location: Banjarmasin – Bts. Kalteng<br />

Date of Audit: 30 Oct – 3 Nov 2012<br />

Doc. ID: B033–EKS 02 Full Audit Report<br />

Technical and Financial Audit Consultant (TFAC)<br />

AF 01<br />

(of 17 )<br />

TFAC suggested corrective actions<br />

Construct new and/or clean all existing earth drains before the wet season (ie immediately).<br />

Remove all excavated material from the table drain zone<br />

Recommended adjustment to Payment Certificate<br />

None -<br />

Audit Finding Agreement Yes / No<br />

Proposed actions by Engineer<br />

If Yes, state corrective action. If NO, give reason.<br />

Will instruct to the Contractor :<br />

- to remove the disposal material<br />

- to clear the material on side ditch<br />

Proposed actions by Employer<br />

Audit Finding Agreement Yes / No<br />

If Yes, state corrective action. If NO, give reason.<br />

Will Instruct to RSC/SSE That the disposal material should be removed as soon as<br />

Response by CWC<br />

Audit Finding Agreement Yes / No<br />

If Yes, state corrective action. If NO, give reason.<br />

The excavated material is placed temporary on the edge of the Shoulder, because after the<br />

widening work is done, the excavated material (from the existing widening) will be used as<br />

common embankment.<br />

Solution:<br />

1. We will finish the work of widening immediately so that the excavated material can<br />

be used as common embankment and the work of natural side drains can begin.<br />

2. For the next work, we will maintain the existing side drains and not placing the<br />

excavated material in the existing side drains.<br />

Comments by PMSC<br />

Audit Finding Agreement Yes / No<br />

If Yes, state corrective action. If NO, give reason.

Project: EKS 02<br />

Location: Banjarmasin – Bts. Kalteng<br />

suggestion<br />

Date of Audit: 30 October – 2 November 2012<br />

Closing Meeting: 3 November 2012<br />

Audit Finding<br />

Some U ditches are not located in optimum positions<br />

Evidence and Extent<br />

Visual – several locations<br />

Contract Document Reference<br />

Not applicable – a design review issue<br />

Doc. ID: B033–EKS 02 Full Audit Report<br />

Technical and Financial Audit Consultant (TFAC)<br />

AF 02<br />

(of 17)<br />

Additional Investigation Required:<br />

..<br />

Review U ditch locations. Avoid use in open field areas with good natural drainage (field<br />

lower than the road)<br />

Problem<br />

impact:<br />

Potential impact on<br />

finished quality<br />

none<br />

Cost implication<br />

Uditches wasted<br />

Signed<br />

Engineer or Authorised Assistant<br />

Signed<br />

TFAC<br />

Signed<br />

Quality Manager CWC<br />

Signed<br />

PMSC<br />

Signed<br />

General Superintendant, CWC<br />

Signed<br />

PPK<br />

Original<br />

ground free<br />

draining to<br />

culvert.<br />

Therefore U<br />

ditch primarily

suggestion<br />

Project: EKS 02<br />

Location: Banjarmasin – Bts. Kalteng<br />

Date of Audit: 30/11 to 3/12/2012<br />

Doc. ID: B033–EKS 02 Full Audit Report<br />

Technical and Financial Audit Consultant (TFAC)<br />

AF 02<br />

(of 17)<br />

TFAC suggested corrective actions<br />

None for completed work. Review proposed remaining u ditch locations and ensure best<br />

use is made of available u ditches<br />

Recommended adjustment to Payment Certificate<br />

none<br />

Audit Finding Agreement Yes / No<br />

Proposed actions by Engineer<br />

If Yes, state corrective action. If NO, give reason.<br />

The side ditch In that location is need to continue the drainage until the box culvert, and it is<br />

provided in the original drawing.<br />

Proposed actions by Employer<br />

Agree with the Engineer proposed action<br />

Response by CWC<br />

Audit Finding Agreement Yes / No<br />

If Yes, state corrective action. If NO, give reason.<br />

Audit Finding Agreement Yes / No<br />

If Yes, state corrective action. If NO, give reason.<br />

Actually, we already review and the location of U-Ditch in original drainage so that the U-<br />

Ditch can accommodate the water from local residence and public facility, but are not<br />

shifted all, because we maintenance the water from the road/existing ground can flow into<br />

the culvert.<br />

Comments by PMSC<br />

Audit Finding Agreement Yes / No<br />

If Yes, state corrective action. If NO, give reason.

Non<br />

conformity<br />

Project: EKS 02<br />

Location: Banjarmasin – Bts. Kalteng<br />

Date of Audit: 30 October – 2 November 2012<br />

Closing Meeting: 3 November 2012<br />

Doc. ID: B033–EKS 02 Full Audit Report<br />

Technical and Financial Audit Consultant (TFAC)<br />

Audit Finding<br />

The platform for geogrid is not sufficiently level<br />

Evidence and Extent<br />

Several locations<br />

Contract Document Reference<br />

SS 3.5.1.3 Construction<br />

The surface on which the geotextile or geogrid is to be placed shall be as flat<br />

and smooth as possible. All<br />

Additional Investigation Required:<br />

.<br />

none<br />

Problem impact:<br />

Potential impact on<br />

finished quality<br />

The geogrid will not be<br />

effective at locations<br />

where its support<br />

platform is not level<br />

Cost implication<br />

Increased future<br />

maintenance cost<br />

Signed<br />

Engineer or<br />

Authorised<br />

Assistant<br />

Signed<br />

TFAC<br />

Signed<br />

Quality Manager CWC<br />

Signed<br />

PMSC<br />

Selected<br />

embankment<br />

rutted and<br />

contains oversize.<br />

Geogrid cannot<br />

li fl t l tf<br />

Signed<br />

General Superintendant, CWC<br />

Signed<br />

PPK<br />

AF 03<br />

(of 17)

Non conformity<br />

Project: EKS 02<br />

Location: Banjarmasin – Bts. Kalteng<br />

Date of Audit: 30 Oct – 3 Nov 2012<br />

Doc. ID: B033–EKS 02 Full Audit Report<br />

Technical and Financial Audit Consultant (TFAC)<br />

AF 03<br />

(of 17)<br />

TFAC suggested corrective actions<br />

The platform should be re-leveled at places where the grogrid cannot lie flush with the<br />

support platform. The Engineer should make any platform on which geogrid is to be placed<br />

a Holding Point, An Engineers instruction is required for this.<br />

Recommended adjustment to Payment Certificate<br />

none<br />

Proposed actions by Engineer<br />

Audit Finding Agreement Yes / No<br />

If Yes, state corrective action. If NO, give reason.<br />

Will instruct to the contractor to repair the granular selected embankment, reshaping, recompacting<br />

and place the geogrid.<br />

Proposed actions by Employer<br />

Agree with the Engineer proposed action<br />

Response by CWC<br />

Audit Finding Agreement Yes / No<br />

If Yes, state corrective action. If NO, give reason.<br />

Audit Finding Agreement Yes / No<br />

If Yes, state corrective action. If NO, give reason.<br />

In several location, especially in location without geotextile in widening, the result of GSE<br />

(after compacted) cannot lie flat so that we use the Motor Grader to make the GSE become<br />

flat. However, we will rework the compacted and after compaction we will make the GSE flat<br />

with Motor Grader.<br />

We already assigned two workers to remove the oversize material, even in quarry.<br />

However, we will check again to avoid the same thing happens.<br />

Comments by PMSC<br />

Audit Finding Agreement Yes / No<br />

If Yes, state corrective action. If NO, give reason.

Non<br />

conformity<br />

Project: EKS 02<br />

Location: Banjarmasin – Bts. Kalteng<br />

Date of Audit: 30 October – 2 November 2012<br />

Closing Meeting: 3 November 2012<br />

Audit Finding<br />

Unsuitable selected embankment used over geo-grid<br />

Evidence and Extent<br />

Seen at sta …….<br />

Contract Document Reference<br />

Engineers instruction re source of selected embankment?<br />

Additional Investigation Required:<br />

..<br />

none<br />

Problem impact:<br />

Potential impact on finished<br />

quality<br />

Geogrid may be damaged.<br />

Selected embankment will not<br />

perform well if in swampy<br />

area. Geogrid not required if<br />

not swampy<br />

Cost implication<br />

Unnecessary use of geogrid<br />

cost about Rp30000/m2<br />

Oversize in selected<br />

embankment likely to rupture<br />

geogrid<br />

Signed<br />

Engineer or Authorised<br />

Assistant<br />

Signed<br />

TFAC<br />

Signed<br />

Quality Manager CWC<br />

Signed<br />

PMSC<br />

Doc. ID: B033–EKS 02 Full Audit Report<br />

Technical and Financial Audit Consultant (TFAC)<br />

Signed<br />

AF 04<br />

(of 17)<br />

General Superintendant, CWC<br />

Signed<br />

PPK

Project: EKS 02<br />

Location: Banjarmasin – Bts. Kalteng<br />

Date of Audit: 30 Oct – 3 Nov 2012<br />

Doc. ID: B033–EKS 02 Full Audit Report<br />

Technical and Financial Audit Consultant (TFAC)<br />

AF 04<br />

(of 17 )<br />

TFAC suggested corrective actions<br />

Use the approved selected embankment or base B or Base A over geogrid only. The<br />

approved selected embankment should not contain material exceeding say 50mm. A grizzly<br />

may be needed at the quarry to remove oversize. Unsuitable selected embankment should<br />

be removed from swampy areas. Geogrid should not be used over areas that are not<br />

swampy (eg sta 8+500 to 12+400)<br />

Recommended adjustment to Payment Certificate<br />

None. But geogrid should only be measured for payment when placed correctly.<br />

Audit Finding Agreement Yes / No<br />

Proposed actions by Engineer<br />

If Yes, state corrective action. If NO, give reason.<br />

- We did the geogrid work at that location is according with the design drawing.<br />

- If decrease will become the problem.<br />

- Will instruct to the contractor to repair and remove the oversize materials by<br />

manually.<br />

Agree with the Engineer proposed action<br />

Response by CWC<br />

Audit Finding Agreement Yes / No<br />

If Yes, state corrective action. If NO, give reason.<br />

Audit Finding Agreement Yes / No<br />

If Yes, state corrective action. If NO, give reason.<br />

We agree to repair and remove the oversize material of GSE from the beginning of widening<br />

work, we already assigned two workers to remove the oversize material even in quarry.<br />

The placement of geogrid, we follow the original contract, we never change and review the<br />

location of geogrid.. so, the location of geogrid where the original contract is indicated, we<br />

will install it.<br />

Comments by PMSC<br />

Audit Finding Agreement Yes / No<br />

If Yes, state corrective action. If NO, give reason.

Non conformity<br />

Doc. ID: B033–EKS 02 Full Audit Report<br />

Project: EKS 02<br />

Location: Banjarmasin – Bts. Kalteng<br />

Date of Audit: 30 October – 2 November 2012<br />

Closing Meeting: 3 November 2012<br />

Technical and Financial Audit Consultant (TFAC)<br />

AF 05<br />

(of 17)<br />

Audit Finding<br />

Geogrid type and strength does not comply with the intended Specification. The specification<br />

requires a radial stiffness of 390 kN/m at a strain of 0.5%. The test data is inconclusive but it<br />

would appear that the test was longitudinal rather than radial a specified.<br />

Evidence and Extent<br />

Visual on site – test report ………<br />

Contract Document Reference<br />

SS 3.5.1.2<br />

Additional Investigation Required:<br />

Determine if the Special Specification for geogrid was included in the contract documents. Note that<br />

the Bill of Quantities refers to the Special Specification Pay Item SS 3.5.1 (as above) and Drawing<br />

EKS 02 – R – 1006 and other refers to the special specification SS 3.5.1 for geogrid<br />

Problem impact:<br />

Potential impact on finished quality<br />

Reduced strength of geogrid. Potential for rupture<br />

Cost implication<br />

Geogrid provided is lower cost than the specified geogrid<br />

.<br />

Signed<br />

Engineer or Authorised Assistant<br />

Signed<br />

TFAC<br />

Signed<br />

Quality Manager CWC<br />

Signed<br />

PMSC<br />

Signed<br />

General Superintendant, CWC<br />

Signed<br />

PPK

Non conformity<br />

Project: EKS 02<br />

Location: Banjarmasin – Bts. Kalteng<br />

Date of Audit: 30 Oct – 3 Nov 2012<br />

Doc. ID: B033–EKS 02 Full Audit Report<br />

Technical and Financial Audit Consultant (TFAC)<br />

AF 05<br />

(of 17 )<br />

TFAC suggested corrective actions<br />

Any new purchase should be the specified strength. The contractor should request to provide a<br />

manufacturers guarantee that the geogrid is fit for purpose and will not rupture.<br />

Recommended adjustment to Payment Certificate<br />

A reduced price should be determined for the lower grade geogrid provided based on the material<br />

supply price difference.<br />

Audit Finding Agreement Yes / No<br />

Proposed actions by Engineer<br />

If Yes, state corrective action. If NO, give reason.<br />

The geogrid already carried out test in Puslitbang Bandung with the test result is in the<br />

specification required.<br />

Proposed actions by Employer<br />

Already instruct to the SSE to distribute the geogrid test result.<br />

Response by CWC<br />

Audit Finding Agreement Yes / No<br />

If Yes, state corrective action. If NO, give reason.<br />

Audit Finding Agreement Yes / No<br />

If Yes, state corrective action. If NO, give reason.<br />

Reffering to the document of geogrid test result from Puslitbang Bandung, our geogrid is<br />

qualifying the specification requirement. The test on Puslitbang is attended by Contractor,<br />

Engineer and Representative of geogrid fabricator. So thers are no reason to reject our<br />

geogrid material.<br />

Comments by PMSC<br />

Audit Finding Agreement Yes / No<br />

If Yes, state corrective action. If NO, give reason.

Doc. ID: B033–EKS 02 Full Audit Report<br />

Technical and Financial Audit Consultant (TFAC)<br />

Project: EKS 02<br />

Location: Banjarmasin – Bts. Kalteng<br />

Non conformity<br />

Date of Audit: 30 October – 2 November 2012<br />

Closing Meeting: 3 November 2012<br />

Audit Finding<br />

Private property ground levels are below the u ditch top at some locations.<br />

Evidence and Extent<br />

Several locations<br />

Contract Document Reference<br />

Drawings<br />

Additional Investigation Required:<br />

Identify locations.<br />

Problem impact:<br />

Potential impact on finished quality<br />

Some potential for unnecessary flooding of<br />

private property<br />

Cost implication<br />

minor<br />

Original asymmetrical design matching<br />

adjoining property<br />

Signed<br />

Engineer or Authorised<br />

Assistant<br />

Signed<br />

TFAC<br />

Signed<br />

Quality Manager CWC<br />

Signed<br />

PMSC<br />

AF 06<br />

(of 17)<br />

As built symmetrical U ditch with wall height<br />

above adjoining ground<br />

Signed<br />

General Superintendant, CWC<br />

Signed<br />

PPK

Non conformity<br />

Project: EKS 02<br />

Location: Banjarmasin – Bts. Kalteng<br />

Date of Audit: 30 Oct – 3 Nov 2012<br />

Doc. ID: B033–EKS 02 Full Audit Report<br />

Technical and Financial Audit Consultant (TFAC)<br />

AF 06<br />

(of 17)<br />

TFAC suggested corrective actions<br />

Assess each situation. Where benefit could be gained and there is no risk of back flow.,<br />

propose a discharge opening into U ditches from adjoining property.<br />

Recommended adjustment to Payment Certificate<br />

None, no additional payment because as built is a simplification of the original design<br />

Audit Finding Agreement Yes / No<br />

Proposed actions by Engineer<br />

If Yes, state corrective action. If NO, give reason.<br />

Will instruct to the contractor :<br />

- to make hole on the out side U-Ditch<br />

- to make the little side ditch on the out side U-ditch for the water flow direct to U-ditch<br />

Proposed actions by Employer<br />

Audit Finding Agreement Yes / No<br />

If Yes, state corrective action. If NO, give reason.<br />

Will instruct to the SSE to make the side ditch access to the U-ditch and set the U-ditch<br />

below position then the side ditch.<br />

Response by CWC<br />

Audit Finding Agreement Yes / No<br />

If Yes, state corrective action. If NO, give reason.<br />

From the results of Field Engineering was obtained that the existing ground elevation in the<br />

design are not the same as the existing condition, and the U-Ditch dimensions in the Cross<br />

Section (not typical) at some locations that are impossible to be implemented, so in the field,<br />

we adjusting the conditions of the field so that the function U-Ditch as well as a retaining<br />

wall duct can be met. However for the location where there is a U-Ditch wall higher than<br />

existing ground around it, then we will undertake improvement / action so that water can<br />

flow into the U-Ditch based on in site conditions.<br />

Comments by PMSC<br />

Audit Finding Agreement Yes / No<br />

If Yes, state corrective action. If NO, give reason.

Project: EKS 02<br />

Location: Banjarmasin – Bts. Kalteng<br />

Non conformity<br />

Date of Audit: 30 October – 2 November 2012<br />

Closing Meeting: 3 November 2012<br />

Audit Finding<br />

Culvert parapet heights may be incorrect<br />

Doc. ID: B033–EKS 02 Full Audit Report<br />

Technical and Financial Audit Consultant (TFAC)<br />

AF 07<br />

(of 17)<br />

Evidence and Extent<br />

Visual. Culvert parapets must be a fixed height above the finished surface level. It appears<br />

that parapets have been cast to a fixed height.<br />

Contract Document Reference<br />

Drawing<br />

Additional Investigation Required:<br />

Surveyor to check all parapets<br />

Problem impact:<br />

Potential impact on finished quality<br />

None<br />

Cost implication<br />

None<br />

Other<br />

Appearance and safety issues<br />

Standard drawing<br />

Signed<br />

Engineer or Authorised Assistant<br />

Signed<br />

TFAC<br />

Signed<br />

Quality Manager CWC<br />

Signed<br />

PMSC<br />

As built culvert parapet must be a uniform<br />

height above finished surface level – safety<br />

auditor will require guardrail for both options.<br />

Signed<br />

General Superintendant, CWC<br />

Signed<br />

PPK

Non conformity<br />

Project: EKS 02<br />

Location: Banjarmasin – Bts. Kalteng<br />

Date of Audit: 30 Oct – 3 Nov 2012<br />

Doc. ID: B033–EKS 02 Full Audit Report<br />

Technical and Financial Audit Consultant (TFAC)<br />

AF 07<br />

(of 17 )<br />

TFAC suggested corrective actions<br />

If heights of already cast culverts are incorrect they will have to be recast. It is noted that the<br />

parapets are a non-standard type. It is likely that the safety auditor will require guardrail at<br />

all culverts in which case the recast parapets should allow for culverts should provide for<br />

guardrail connection points. As built levels may vary from original design levels so it is<br />

always preferable to finish casting parapet walls after the final pavement height is known.<br />

Recommended adjustment to Payment Certificate<br />

none<br />

Audit Finding Agreement Yes / No<br />

Proposed actions by Engineer<br />

If Yes, state corrective action. If NO, give reason.<br />

Yes<br />

Proposed actions by Employer<br />

Yes<br />

Response by CWC<br />

Audit Finding Agreement Yes / No<br />

If Yes, state corrective action. If NO, give reason.<br />

Audit Finding Agreement Yes / No<br />

If Yes, state corrective action. If NO, give reason.<br />

Our parapets is following the standard drawing. Our design of parapets have bean<br />

discussed with the SSE (previous SSE before Mr.Ardis) and PPK almost one year ago and<br />

they agree with the design of our parapet.<br />

For the high of parapet, we already calculated from top of elevation of surface design. We<br />

plotted on Autocad drawing, so the top elevation of existing surface road as vertical<br />

alignment. Than if any different between top elevation and the surface asphalt level is not<br />

problem and not see the paraper is not uniform.<br />

Comments by PMSC<br />

Audit Finding Agreement Yes / No<br />

If Yes, state corrective action. If NO, give reason.

Non conformity<br />

Doc. ID: B033–EKS 02 Full Audit Report<br />

Technical and Financial Audit Consultant (TFAC)<br />

Project: EKS 02<br />

Location: Banjarmasin – Bts. Kalteng<br />

Date of Audit: 30 October – 2 November 2012<br />

Closing Meeting: 3 November 2012<br />

AF 08<br />

(of 18)<br />

Audit Finding<br />

The proposed curve radius design change at sta 0+050 to 0+200 from 100 m to 65 m is<br />

unacceptable because it reduces the curve design speed from 60 kph to about 45kph and increases<br />

the accident risk. A 90m radius solution is possible within existing site constraints, allowing a 55 kph<br />

operating speed, and is recommended.<br />

Evidence and Extent<br />

Shop drawings – one location<br />

Contract Document Reference<br />

Drawings<br />

Additional Investigation Required:<br />

.a detailed shop drawing must be prepared showing a retaining wall and v drain (or other drain type)<br />

treatment on the right side adjacent to the PADM fence, guard rail on both sides, a 90 m radius curve, at least<br />

10 chevron signs type W 1, two advisory speed limit signs 55 km / h type W26, curve widening at least 90cm<br />

and super elevation 10 %. Signs size 90 cm?.<br />

Problem impact:<br />

Potential impact on finished quality<br />

5<br />

none<br />

Cost implication<br />

Additional cost for warning signs and guardrail not provided by<br />

the original contract<br />

Other<br />

Accident risk if proposed solution adopted<br />

.<br />

Signed<br />

Engineer or Authorised Assistant<br />

Signed<br />

TFAC<br />

Signed<br />

Quality Manager CWC<br />

Signed<br />

PMSC<br />

Adjoining property fence line showing<br />

adequate space for curve<br />

improvement provided a retaining<br />

wall is used<br />

Signed<br />

General Superintendant, CWC<br />

Signed<br />

PPK

Non-conformity<br />

Project: EKS 02<br />

Location: Banjarmasin – Bts. Kalteng<br />

Date of Audit:<br />

Doc. ID: B033–EKS 02 Full Audit Report<br />

Technical and Financial Audit Consultant (TFAC)<br />

AF 08<br />

(of 18)<br />

TFAC suggested corrective actions<br />

Adopt a 90 m radius solution, commence super elevation transition at bridge abutment (sta<br />

0+059 approx), provide a 10 % super elevation, 90 cm curve widening, guardrail from the<br />

bridge abutment both sides to the end of the ST point at about sta 200, at least 10 chevron<br />

signs type W1 (5 left and 5 right) placed on the outside of the curve), two advisory speed<br />

signs type W26. A retaining wall plus V or other drain type if necessary adjacent to the<br />

existing PADM property fence line.<br />

Recommended adjustment to Payment Certificate<br />

A variation may be required for the recommended additional safety equipment.<br />

Audit Finding Agreement Yes / No<br />

Proposed actions by Engineer<br />

If Yes, state corrective action. If NO, give reason.<br />

1. Agree with the last discussion in Base camp with TFAC Team Leader, That the R =<br />

90 m and will prepare the drawing.<br />

2. The u-ditch still can install at that location according the result of land use survey on<br />

30 October 2012.<br />

3. Wll instruct to the contractor for place the u-ditch follow the original design drawing<br />

Proposed actions by Employer<br />

Agree with the Engineer proposed actions<br />

Response by CWC<br />

Audit Finding Agreement Yes / No<br />

If Yes, state corrective action. If NO, give reason.<br />

Audit Finding Agreement Yes / No<br />

If Yes, state corrective action. If NO, give reason.<br />

The Calculation of change in radius has been discussed between the Contractor, Engineer,<br />

and Mr.Ted James, which acquired 90m radius decisions most likely to use.<br />

For the proposed addition of Retaining wall for drainage will we review again based on field<br />

conditions.<br />

Comments by PMSC<br />

Audit Finding Agreement Yes / No<br />

If Yes, state corrective action. If NO, give reason.

Non conformity<br />

Doc. ID: B033–EKS 02 Full Audit Report<br />

Technical and Financial Audit Consultant (TFAC)<br />

Project: EKS 02<br />

Location: Banjarmasin – Bts. Kalteng<br />

Date of Audit: 30 October – 2 November 2012<br />

Closing Meeting: 3 November 2012<br />

AF 09<br />

(of 17)<br />

Audit Finding<br />

Some items of specified equipment have not been provided: 5 th cold feed bin for AMP, rotary<br />

broom (road work type), bitumen distributer with spray bar complying to GS 6.1.3.2<br />

Evidence and Extent<br />

Equipment not on site. Contractor will mobilise before commencement of asphalt work<br />

Contract Document Reference<br />

Additional Investigation Required:<br />

..<br />

Off site application rate rrial for bitumen distributer including lateral distribution test

Non conformity<br />

Problem impact:<br />

Potential impact on finished quality<br />

Significant negative if not provided<br />

Cost implication<br />

None<br />

Signed<br />

Engineer or Authorised Assistant<br />

Signed<br />

TFAC<br />

Project: EKS 02<br />

Location: Banjarmasin – Bts. Kalteng<br />

Date of Audit: 30 Oct – 3 Nov 2012<br />

Signed<br />

Doc. ID: B033–EKS 02 Full Audit Report<br />

Quality Manager CWC<br />

Signed<br />

PMSC<br />

Technical and Financial Audit Consultant (TFAC)<br />

Signed<br />

AF 09<br />

(of 17)<br />

General Superintendant, CWC<br />

Signed<br />

PPK

Non conformity<br />

Project: EKS 02<br />

Location: Banjarmasin – Bts. Kalteng<br />

Date of Audit: 30 Oct – 3 Nov 2012<br />

Doc. ID: B033–EKS 02 Full Audit Report<br />

Technical and Financial Audit Consultant (TFAC)<br />

AF 09<br />

(of 17 )<br />

TFAC suggested corrective actions<br />

Each of the listed equipment items should be provided before the commencement of<br />

asphalt works. The substitution of AC BC for AC Base is permitted by GS…… at the same<br />

unit price as AC BC at contractors option if a fifth bin is not provided.<br />

Note that few bitumen distributers in Indonesia comply with GS 6.1.3.2. A conforming<br />

bitumen distributer should be provided for this project. The traffic level on the road is quite<br />

high so prime coat will be easily damaged if the Base A is not properly prepared including<br />

removal of segregation, uniform compaction, rotary brooming and uniform application of the<br />

correct prime application rate (probably about 0.7 l/m2 but subject to Engineers instruction<br />

or approval)<br />

Recommended adjustment to Payment Certificate<br />

None – AC work should not proceed until equipment is provided<br />

Audit Finding Agreement Yes / No<br />

Proposed actions by Engineer<br />

If Yes, state corrective action. If NO, give reason.<br />

Yes<br />

Proposed actions by Employer<br />

Yes<br />

Response by CWC<br />

Audit Finding Agreement Yes / No<br />

If Yes, state corrective action. If NO, give reason.<br />

Audit Finding Agreement Yes / No<br />

If Yes, state corrective action. If NO, give reason.<br />

We will check and re-evaluation, so that what is required in the specifications can be met.<br />

Comments by PMSC<br />

Audit Finding Agreement Yes / No<br />

If Yes, state corrective action. If NO, give reason.

Suggestion<br />

Doc. ID: B033–EKS 02 Full Audit Report<br />

Project: EKS 02<br />

Location: Banjarmasin – Bts. Kalteng<br />

Date of Audit: 30 October – 2 November 2012<br />

Closing Meeting: 3 November 2012<br />

Technical and Financial Audit Consultant (TFAC)<br />

AF 10<br />

(of 17)<br />

Audit Finding<br />

The following additional equipment is suggested to improve methods of work and outcomes:<br />

Pneumatic tyred roller for Base A preparation and a Intermediate sized smooth drum or<br />

intermediate combination steel pneumatic roller (+/-1.0 to 1.2m drum width) for optimum<br />

compaction of the shoulder zone<br />

Evidence and Extent<br />

Not applicable<br />

Contract Document Reference<br />

GS 5.1.3.3 .<br />

Additional Investigation Required:<br />

.not applicable<br />

Problem impact:<br />

Potential impact on finished quality<br />

significant<br />

Cost implication<br />

Some cost to contractor but a potential cost saving in terms<br />

of the time required to achieve the specified compaction<br />

and surface preparation of aggregate base before priming<br />

Signed<br />

Engineer or Authorised Assistant<br />

Signed<br />

TFAC<br />

Signed<br />

Quality Manager CWC<br />

Signed<br />

PMSC<br />

Signed<br />

General Superintendant, CWC<br />

Signed<br />

PPK

suggestion<br />

Project: EKS 02<br />

Location: Banjarmasin – Bts. Kalteng<br />

Date of Audit: 30 Oct – 3 Nov 2012<br />

Doc. ID: B033–EKS 02 Full Audit Report<br />

Technical and Financial Audit Consultant (TFAC)<br />

AF 10<br />

(of 17 )<br />

TFAC suggested corrective actions<br />

The Engineer should instruct the use of a pneumatic tyred roller to finish all base A before<br />

priming as allowed by GS 5.1.3 to get optimum compaction uniformity in the base A surface.<br />

It is usually not satisfactory to use the asphalt roller because work scheduling is then<br />

difficult. He should also instruct an intermediate sized roller to allow compaction of the final<br />

shoulder layer and compaction of the shoulder asphalt layer.<br />

Recommended adjustment to Payment Certificate<br />

none<br />

Audit Finding Agreement Yes / No<br />

Proposed actions by Engineer<br />

If Yes, state corrective action. If NO, give reason.<br />

Yes<br />

Proposed actions by Employer<br />

yes<br />

Response by CWC<br />

Audit Finding Agreement Yes / No<br />

If Yes, state corrective action. If NO, give reason.<br />

Audit Finding Agreement Yes / No<br />

If Yes, state corrective action. If NO, give reason.<br />

We already mobilize the Pneumatic Tyre Roller for Aggregate class-A work<br />

We already mobilize also for Intermediate Sized Roller for compaction of the final shoulder<br />

layer (Aggregate class-A) and Asphalt Layer.<br />

Comments by PMSC<br />

Audit Finding Agreement Yes / No<br />

If Yes, state corrective action. If NO, give reason.

Non conformity<br />

Project: EKS 02<br />

Location: Banjarmasin – Bts. Kalteng<br />

Date of Audit: 30 October – 2 November 2012<br />

Closing Meeting: 3 November 2012<br />

Doc. ID: B033–EKS 02 Full Audit Report<br />

Technical and Financial Audit Consultant (TFAC)<br />

AF 11<br />

(of 17)<br />

Audit Finding<br />

The available aggregate is too flaky for use in asphalt. The crushing plant does not comply<br />

with Drawing General Note requirements (2 stage jaw to jaw)<br />

Evidence and Extent<br />

Visual – small samples at the contractors base camp laboratory. Conflicting information on<br />

site that a) a new crushing plant would be provided and b) the existing crushing plant will be<br />

adjusted to improve aggregate shape,<br />

Contract Document Reference<br />

Additional Investigation Required:<br />

Test for aggregate shape after improvement of crushing plant<br />

Problem impact:<br />

Potential impact on finished quality<br />

Reduced performance of asphalt<br />

Cost implication<br />

Potential cost increase to contractor if flaky aggregate is<br />

used<br />

other<br />

Signed<br />

Engineer or Authorised Assistant<br />

Signed<br />

TFAC<br />

Signed<br />

Quality Manager CWC<br />

Signed<br />

PMSC<br />

Signed<br />

General Superintendant, CWC<br />

Signed<br />

PPK

Project: EKS 02<br />

Location: Banjarmasin – Bts. Kalteng<br />

Date of Audit: 30 Oct – 3 Nov 2012<br />

Doc. ID: B033–EKS 02 Full Audit Report<br />

Technical and Financial Audit Consultant (TFAC)<br />

AF 11<br />

(of 17)<br />

TFAC suggested corrective actions<br />

Drawing…. General Notes require a three stage crushing plant with an impact third stage.<br />

At least the crushing plant should be adjusted to deliver better shaped aggregate before the<br />

asphalt job mix is produced and during production of asphalt aggregates<br />

Recommended adjustment to Payment Certificate<br />

none<br />

Audit Finding Agreement Yes / No<br />

Proposed actions by Engineer<br />

If Yes, state corrective action. If NO, give reason.<br />

Agree with TFAC suggested<br />

Proposed actions by Employer<br />

Agree with TFAC suggested<br />

Response by CWC<br />

Audit Finding Agreement Yes / No<br />

If Yes, state corrective action. If NO, give reason.<br />

Audit Finding Agreement Yes / No<br />

If Yes, state corrective action. If NO, give reason.<br />

1. The Flakiness is just occurred for the screen 10mm, but for screen 20mm and 30mm<br />

flakiness is not occurred.<br />

2. Solution: we will change the screen 10mm, if the flakiness is still occurred, we will<br />

add the cone crusher to solve this issued.<br />

Comments by PMSC<br />

Audit Finding Agreement Yes / No<br />

If Yes, state corrective action. If NO, give reason.

Doc. ID: B033–EKS 02 Full Audit Report<br />

Technical and Financial Audit Consultant (TFAC)<br />

Project: EKS 02<br />

Location: Banjarmasin – Bts. Kalteng<br />

Non conformity<br />

Date of Audit: 30 October – 2 November 2012<br />

Closing Meeting: 3 November 2012<br />

Audit Finding<br />

All laboratory equipment calibration was out of date<br />

Evidence and Extent<br />

Inspection of calibration certificates at Contractors Base Camp laboratory<br />

Contract Document Reference<br />

:<br />

Additional Investigation Required:<br />

none<br />

Problem impact:<br />

Potential impact on finished quality<br />

Can be significant<br />

Cost implication<br />

none<br />

Signed<br />

Engineer or Authorised Assistant<br />

Signed<br />

TFAC<br />

Signed<br />

Quality Manager CWC<br />

Signed<br />

PMSC<br />

Signed<br />

AF 12<br />

(of 17)<br />

General Superintendant, CWC<br />

Signed<br />

PPK

Non conformity<br />

Project: EKS 02<br />

Location: Banjarmasin – Bts. Kalteng<br />

Date of Audit: 30 Oct – 3 Nov 2012<br />

Doc. ID: B033–EKS 02 Full Audit Report<br />

Technical and Financial Audit Consultant (TFAC)<br />

AF 12<br />

(of 17)<br />

TFAC suggested corrective actions<br />

Arrange for calibration of all proving rings. Replace proving rings with calibrated rings to<br />

avoid delay<br />

Recommended adjustment to Payment Certificate<br />

none<br />

Audit Finding Agreement Yes / No<br />

Proposed actions by Engineer<br />

If Yes, state corrective action. If NO, give reason.<br />

No not all – if any we must do recalibration<br />

Proposed actions by Employer<br />

Agree with engineer<br />

Response by CWC<br />

Audit Finding Agreement Yes / No<br />

If Yes, state corrective action. If NO, give reason.<br />

Audit Finding Agreement Yes / No<br />

If Yes, state corrective action. If NO, give reason.<br />

The last calibration for all of our laboratory equipment is conducted on September 11, 2011<br />

so we will arrange for calibration of all laboratory equipment. (especially for Proving Rings).<br />

Comments by PMSC<br />

Audit Finding Agreement Yes / No<br />

If Yes, state corrective action. If NO, give reason.

Project: EKS 02<br />

Location: Banjarmasin – Bts. Kalteng<br />

Non conformity<br />

Date of Audit: 30 October – 2 November 2012<br />

Closing Meeting: 3 November 2012<br />

Audit Finding<br />

Inadequate provision for traffic<br />

Evidence and Extent<br />

throughout<br />

Contract Document Reference<br />

various<br />

Additional Investigation Required:<br />

..none<br />

Problem impact:<br />

Potential impact on finished quality<br />

none<br />

Cost implication<br />

none<br />

Signed<br />

Engineer or Authorised Assistant<br />

Signed<br />

TFAC<br />

Signed<br />

Quality Manager CWC<br />

Signed<br />

PMSC<br />

Doc. ID: B033–EKS 02 Full Audit Report<br />

Technical and Financial Audit Consultant (TFAC)<br />

Signed<br />

AF 13<br />

(of 17 )<br />

General Superintendant, CWC<br />

Signed<br />

PPK

Non conformity<br />

Project: EKS 02<br />

Location: Banjarmasin – Bts. Kalteng<br />

Date of Audit: 30 Oct – 3 Nov 2012<br />

Doc. ID: B033–EKS 02 Full Audit Report<br />

Technical and Financial Audit Consultant (TFAC)<br />

AF 13<br />

(of 17 )<br />

TFAC suggested corrective actions<br />

Additional traffic safety provision needs to be made at locations where equipment is working<br />

and where there are large level differences between the shoulder and the pavement<br />

Recommended adjustment to Payment Certificate<br />

None at this stage but the CSE might consider an djustment to the Provision for Traffic pay<br />

item if there is no improvement<br />

Proposed actions by Engineer<br />

Audit Finding Agreement Yes / No<br />

If Yes, state corrective action. If NO, give reason.<br />

Yes the contractor must add traffic signs. They are sometimes lost or broken.<br />

Proposed actions by Employer<br />

Yes<br />

Response by CWC<br />

Audit Finding Agreement Yes / No<br />

If Yes, state corrective action. If NO, give reason.<br />

Audit Finding Agreement Yes / No<br />

If Yes, state corrective action. If NO, give reason.<br />

We will improve the traffic sign, barrier and traffic warning.<br />

Actually, for each of our equipment there are 2 workers (one for flagman and one for helper)<br />

to follow the equipment to arrange the traffic. However, we will check and improve it.<br />

Comments by PMSC<br />

Audit Finding Agreement Yes / No<br />

If Yes, state corrective action. If NO, give reason.

Non conformity<br />

Doc. ID: B033–EKS 02 Full Audit Report<br />

Technical and Financial Audit Consultant (TFAC)<br />

Project: EKS 02<br />

Location: Banjarmasin – Bts. Kalteng<br />

Date of Audit: 30 October – 2 November 2012<br />

Closing Meeting: 3 November 2012<br />

Audit Finding<br />

Maintenance of the existing road may need to be improved before the wet season<br />

Evidence and Extent<br />

Many areas of broken asphalt that are likely to be difficult to maintain through the wet<br />

season.<br />

Contract Document Reference<br />

Additional Investigation Required:<br />

..<br />

none<br />

AF 14<br />

(of 17)

Problem impact:<br />

Potential impact on finished<br />

quality<br />

none<br />

Cost implication<br />

Significant cost to contractor<br />

Signed<br />

Engineer or Authorised Assistant<br />

Signed<br />

TFAC<br />

Doc. ID: B033–EKS 02 Full Audit Report<br />

Signed<br />

Quality Manager CWC<br />

Signed<br />

PMSC<br />

Technical and Financial Audit Consultant (TFAC)<br />

Signed<br />

General Superintendant, CWC<br />

Signed<br />

PPK

Non conformity<br />

Project: EKS 02<br />

Location: Banjarmasin – Bts. Kalteng<br />

Date of Audit: 30 Oct – 3 Nov 2012<br />

Doc. ID: B033–EKS 02 Full Audit Report<br />

Technical and Financial Audit Consultant (TFAC)<br />

AF 14<br />

(of 17)<br />

TFAC suggested corrective actions<br />

Consideration should be given, subject to employer approval, to remove asphalt from<br />

severely broken areas and maintain as a gravel road until the new pavement is placed<br />

because re-asphalting now within months of construction of the new pavement would be<br />

wasteful and prohibitively expensive.<br />

Note tjhat maintenance costs including materials are fully covered by GS 10.1.2. Therefore<br />

low cost solutions are needed<br />

Recommended adjustment to Payment Certificate<br />

None. But non-payment of Pay Item 10.1.1 and 10.1.2 might be considered if the pavement<br />

is not maintained. Note that pay items 10.1,1-5 include supply of materials (see 10.1.7.2)<br />

Proposed actions by Engineer<br />

Contractors need funds to maintain roads with aggregate A<br />

OK. the 10.1.4. item number is canceled.<br />

Proposed actions by Employer<br />

Audit Finding Agreement Yes / No<br />

If Yes, state corrective action. If NO, give reason.<br />

Audit Finding Agreement Yes / No<br />

If Yes, state corrective action. If NO, give reason.<br />

- Maintenance of the road is still needed to cover lubang2 although until aggregate<br />

- Pay of the small maintenance items, should be paid only<br />

Response by CWC<br />

Audit Finding Agreement Yes / No<br />

If Yes, state corrective action. If NO, give reason.<br />

Maintenance and repairs to roads and road shoulders are approximately 8 times we did,<br />