Combining High-Resolution Pulsed TIVA and ... - ASM International

Combining High-Resolution Pulsed TIVA and ... - ASM International

Combining High-Resolution Pulsed TIVA and ... - ASM International

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

This is evident when comparing Fig. 5(b), a digitally zoomed<br />

overlay image obtained using a 0.85-NA 100x NIR lens, to<br />

Fig. 5(a), the overlay image obtained by using a SIL in superhemispherical<br />

mode <strong>and</strong> a 20x NIR backing lens.<br />

Circuit Analysis<br />

The CAD navigation tool showed that the site highlighted<br />

by pulsed <strong>TIVA</strong> with SIL pointed to a particular transistor. On<br />

circuit analysis <strong>and</strong> layout tracing, it is unambiguous that the<br />

<strong>TIVA</strong> signal came from an input to a level restorer circuit that<br />

fed to the failing signal (Fig. 6).<br />

Fig. 6: Block diagram of circuitry of interest. Circled transistor<br />

T1 is highlighted by high-resolution pulsed <strong>TIVA</strong>.<br />

Transistor T1, a PMOSFET, is the input of a level restorer<br />

circuitry made up of two inverters: the larger D1, which feeds<br />

forward, <strong>and</strong> the smaller D2, which helps to hold the state. A<br />

wrong input from either a leaky or a slow PMOS T1 could<br />

change the state of the restorer, causing the signal to flip <strong>and</strong><br />

the reported failure. The level restorer is powered by the<br />

voltage supplies VDD1 <strong>and</strong> VDD2, which also supported the<br />

observed failure.<br />

III. Physical Failure Analysis<br />

PFI <strong>and</strong> PFA approach<br />

As mentioned earlier, with technology scaling of ICs, nonvisible<br />

defects have become common phenomena in FA. On<br />

top of this challenge, the electrical failure signature for many<br />

of the failures is soft, as presented in this study. Therefore, the<br />

utilization of non-destructive PFI is essential to indicate the<br />

exact failing location before attempting PFA. This section<br />

demonstrates the successful use of nanoprobing to reveal faults<br />

in the level restorer. The theory of nanoprobing [4] has been<br />

adequately described in the literature.<br />

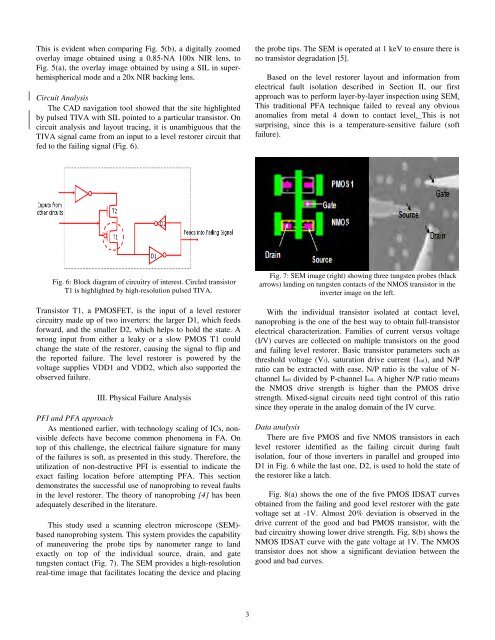

This study used a scanning electron microscope (SEM)based<br />

nanoprobing system. This system provides the capability<br />

of maneuvering the probe tips by nanometer range to l<strong>and</strong><br />

exactly on top of the individual source, drain, <strong>and</strong> gate<br />

tungsten contact (Fig. 7). The SEM provides a high-resolution<br />

real-time image that facilitates locating the device <strong>and</strong> placing<br />

3<br />

the probe tips. The SEM is operated at 1 keV to ensure there is<br />

no transistor degradation [5].<br />

Based on the level restorer layout <strong>and</strong> information from<br />

electrical fault isolation described in Section II, our first<br />

approach was to perform layer-by-layer inspection using SEM.<br />

This traditional PFA technique failed to reveal any obvious<br />

anomalies from metal 4 down to contact level. This is not<br />

surprising, since this is a temperature-sensitive failure (soft<br />

failure).<br />

Fig. 7: SEM image (right) showing three tungsten probes (black<br />

arrows) l<strong>and</strong>ing on tungsten contacts of the NMOS transistor in the<br />

inverter image on the left.<br />

With the individual transistor isolated at contact level,<br />

nanoprobing is the one of the best way to obtain full-transistor<br />

electrical characterization. Families of current versus voltage<br />

(I/V) curves are collected on multiple transistors on the good<br />

<strong>and</strong> failing level restorer. Basic transistor parameters such as<br />

threshold voltage (Vt), saturation drive current (Isat), <strong>and</strong> N/P<br />

ratio can be extracted with ease. N/P ratio is the value of Nchannel<br />

Isat divided by P-channel Isat. A higher N/P ratio means<br />

the NMOS drive strength is higher than the PMOS drive<br />

strength. Mixed-signal circuits need tight control of this ratio<br />

since they operate in the analog domain of the IV curve.<br />

Data analysis<br />

There are five PMOS <strong>and</strong> five NMOS transistors in each<br />

level restorer identified as the failing circuit during fault<br />

isolation, four of those inverters in parallel <strong>and</strong> grouped into<br />

D1 in Fig. 6 while the last one, D2, is used to hold the state of<br />

the restorer like a latch.<br />

Fig. 8(a) shows the one of the five PMOS IDSAT curves<br />

obtained from the failing <strong>and</strong> good level restorer with the gate<br />

voltage set at -1V. Almost 20% deviation is observed in the<br />

drive current of the good <strong>and</strong> bad PMOS transistor, with the<br />

bad circuitry showing lower drive strength. Fig. 8(b) shows the<br />

NMOS IDSAT curve with the gate voltage at 1V. The NMOS<br />

transistor does not show a significant deviation between the<br />

good <strong>and</strong> bad curves.