VAHLE konkret 2005 deutsch Satz

VAHLE konkret 2005 deutsch Satz

VAHLE konkret 2005 deutsch Satz

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

• IKEA Salzgitter: Where „Billy races through the hall<br />

Airbus 380: Europe’s „superbird“ has taken off<br />

The „Affiche Galerij“ in The Hague: Bringing art to the people<br />

Crane tuning with <strong>VAHLE</strong> in Hong Kong<br />

The LTU Arena in Düsseldorf with an electrically powered retractable roof<br />

CPS® at Kaeser<br />

Valencia’s hub port<br />

The world’s largest copper mine<br />

„Kai zen“ with <strong>VAHLE</strong>: Taking small steps towards success

<strong>VAHLE</strong>-Service: Close to its customers all around the world<br />

Worldwide Partners<br />

<strong>VAHLE</strong> China: From<br />

a representative office<br />

to a Trading Company<br />

Xiang Li has been the new general<br />

manager of our subsidiary<br />

in Shanghai since March of<br />

this year. With him in charge,<br />

the already successful work<br />

will be continued with six additional<br />

employees.<br />

In order to live up to the challenges<br />

of the Chinese market,<br />

the previous „Representative<br />

Office“ was turned into an independent<br />

„Trading Company“<br />

starting July 1 st , 2004.<br />

This enables us to react more<br />

quickly and efficiently to the<br />

needs of the market and our<br />

customers.<br />

The activities particularly focus<br />

on automobile, steel and po-<br />

wer plant technology as well<br />

as storage technology.<br />

Additional emphasis is placed<br />

on port technology, because<br />

the largest manufacturer of<br />

container cranes, the company<br />

ZPMC, is based in Shanghai.<br />

Change of management - On August 1, <strong>2005</strong> Michael<br />

Pavlidis (left) was appointed as manager of technology (development,<br />

process planning and quality management). He thus follows<br />

the footsteps of Werner Runte (right), who is retiring after<br />

33 years with the company from Kamen. Managing Director Josef<br />

Hötte (center) bade farewell to the previous Technical Director.<br />

<strong>VAHLE</strong> on the<br />

Bosporus Strait<br />

After studying mechanical engineering<br />

in Germany, Mehmet<br />

Bebeck returned to Turkey in<br />

1985. He worked at a firm that<br />

built cranes and used many<br />

<strong>VAHLE</strong> products. Mehmet Bebeck<br />

was so convinced of their<br />

quality that he began to sell<br />

<strong>VAHLE</strong> products himself. In<br />

1999 he founded his own firm<br />

BM Makina and assumed the<br />

representation of <strong>VAHLE</strong> in<br />

Turkey.<br />

Along with companies who<br />

build cranes, steel plants, the<br />

automobile industry and the<br />

Turkish railway are among his<br />

clients.<br />

Satisfying these customers is<br />

Mehmet Bebeck’s main priority.<br />

Even if they have questions<br />

about a <strong>VAHLE</strong> product on a<br />

weekend, Bebeck and his staff<br />

will not hesitate to help them.<br />

Thanks to the extra efforts<br />

made and <strong>VAHLE</strong>’s good reputation,<br />

they have been able to<br />

increase the turnover from<br />

year to year.<br />

Successful in the Alps<br />

Andreas Bergthaler is the head<br />

of the <strong>VAHLE</strong> marketing company<br />

in Oberweis, Austria.<br />

From there the 39- year old<br />

and his young staff manage<br />

customer service activities in<br />

Austria and offer the whole array<br />

of products from Kamen.<br />

The main areas of application<br />

for <strong>VAHLE</strong> products are storage<br />

and conveyor technology, mechanical<br />

and plant engineering<br />

as well as the steel and mining<br />

industry. Special solutions for<br />

building stages, cable railways<br />

as well as rotating cupola<br />

roofs for observatories have<br />

also been successfully implemented.<br />

<strong>VAHLE</strong>’s regular clientel<br />

in Austria is continually expanding.<br />

Imprint<br />

Editor-in-chief:<br />

Thomas Hagermann,<br />

Paul <strong>VAHLE</strong> GmbH & CO KG,<br />

D-59172 Kamen (Germany)<br />

Tel.: 0049 2307 704 0,<br />

www.vahle.de<br />

Editorial staff: Klaus Kukuk,<br />

Jan-Uwe Ronneburger,<br />

Frank Niewerth<br />

Photos: Syndikat medienpool,<br />

Dagmar Frigge, Codelco, Airbus,<br />

AFT, Mauritius, HIT, viastore,<br />

Klaus Kukuk, G.P. Müller<br />

Design, Realization:<br />

Syndikat medienpool, Unna<br />

Print: B-W-H, Hannover

Viastore uses VKS10 in Germany’s largest IKEA storehouse<br />

Where „Billy“ races through the hall<br />

The city of Salzgitter, the<br />

third largest industrial<br />

base in Lower Saxony with a<br />

workforce of approximately<br />

54,000 has become a main<br />

hub for the region of South-<br />

East Lower Saxony. The<br />

„Ikea-Lager und Service<br />

GmbH“ (Ikea Storage and<br />

Service Ltd.) is based here.<br />

With almost 11,000 employees,<br />

the Swedish furniture<br />

house generates its largest<br />

country turnover in Germany<br />

and is Germany’s numberone<br />

name in furniture. Even<br />

today, the classic „Billy shelf<br />

system“ is still part of the<br />

basic configuration in many<br />

people’s first own apartment.<br />

Visiting the currently largest<br />

new building in Salzgitter’s industrial<br />

zone: the Swedish furnishing<br />

house has generously<br />

expanded its distribution center<br />

here. Mayor Helmut Knebel<br />

is proud of the large-scale project:<br />

„This investment is taking<br />

on a gigantic dimension. We<br />

are delighted that the cooperation<br />

between IKEA and the<br />

city has again stood the test of<br />

time.“<br />

New Construction<br />

Technology<br />

In the words of the managing<br />

director of IKEA Lager- und<br />

Service GmbH, Dieter Imberger,<br />

The ca. 32 meter tall shelf access machines look like scrawny<br />

yellow giants, when they zoom through the halls of the IKEA<br />

storehouse in Salzgitter. They are fed with electricity from the<br />

VKS 10 from <strong>VAHLE</strong>.<br />

the new hall comprises a surface<br />

of 92,000 square meters<br />

and is up to 32 meters high.<br />

One of its peculiarities is the<br />

new concrete and steel technology.<br />

150,000 pallet spots<br />

are available in the hall, and<br />

together with the 120,000 in<br />

the already existing building,<br />

there are now a total of<br />

270,000. Imberger: „To visualize<br />

this, you would have to<br />

image a row of such pallet<br />

spots from here to Dortmund.“<br />

With an overall surface of<br />

around 40 hectares, this main<br />

Ikea storage facility is nearly<br />

ten times the size of an Ikea<br />

furnishing store.<br />

Germany’s Largest<br />

Distribution Center<br />

Once completed, the distribution<br />

center in Salzgitter will<br />

become the largest in Germany<br />

and play a main role in IKEA’s<br />

process of expansion. According<br />

to IKEA, which currently<br />

has 33 stores, it is aiming for<br />

up to 60 stores.<br />

The distribution specialist viastore<br />

located in Stuttgart supplied<br />

the IKEA logistics center<br />

in Salzgitter with 14 viapal<br />

shelf access machines, the pallet<br />

conveyor technology, the<br />

shelf steel structures for approximately<br />

85,000 pallets as<br />

well as the material flow operating<br />

devices. Up to 10,000<br />

pallets are supposed to be<br />

transported in and out every<br />

day.<br />

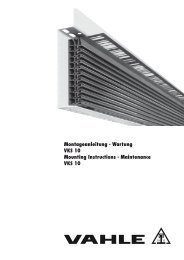

Reliable VKS10<br />

To make certain that everything<br />

runs smoothly in the gigantic<br />

pallet storage facility,<br />

the supplier viastore uses<br />

<strong>VAHLE</strong> products. The new safety<br />

conductor VKS10 guarantees<br />

a reliable and safe supply<br />

of electrical current to the sor-<br />

ting machines. This is also a<br />

must when the shelf access<br />

machines zoom through the<br />

storage corridors at speeds of<br />

up to 200 meters per minute.<br />

However, not only the reliability<br />

of the products from Kamen<br />

has won over the engineers<br />

from Stuttgart, but also the<br />

price-quality aspect.<br />

Time-tested product<br />

As of now, the cooperation<br />

between <strong>VAHLE</strong> and viastore<br />

has also stood the test of time<br />

at other installations by the<br />

logistic specialist.<br />

The VKS10 conductor system<br />

can accommodate up to 10<br />

copper conductors in its housing.<br />

Due to the low phase distance<br />

of only 14 mm, a conductor<br />

system has been developed<br />

which is very compact.<br />

With parallel connection of<br />

conductor rails a maximum<br />

continuous current of 280 A<br />

can be transmitted.<br />

A special support sheet metal<br />

profile allows the user support<br />

distances of up to 4.5 meters.<br />

This eliminates complicated<br />

on-site support construction<br />

and reduces installation costs.

The Airbus A380 is moving into new dimensions<br />

Europe’s „superbird“ has taken off<br />

and Great Britain. Six thou- with the control signals are<br />

sand people are working on it, transmitted using a 30-con-<br />

not including the ca. 100 supductor cable on a <strong>VAHLE</strong> motor<br />

pliers worldwide. The gigantic cable reel. (I hope the previous<br />

parts are brought to Toulouse sentence is correct as I don’t<br />

by ship and truck, where they have the original, also I cannot<br />

are assembled.<br />

make sense of the following<br />

sentence)! The cable tray in an<br />

Engine tests<br />

only 40-millimeter wide cable<br />

carrier is ensured by the appropriate<br />

conduits.<br />

Precision is the main imperative<br />

not only when building the<br />

A380, but also in all of<br />

<strong>VAHLE</strong>’s solutions.<br />

Europe is celebrating its<br />

most successful industrial<br />

project: the giant jumbo A<br />

380 - a new airplane that<br />

has taken on dimensions<br />

which were hardly imaginable<br />

a few years ago. Yet in<br />

this very year – ten years after<br />

the initial idea – three<br />

specimen of the Airbus A380<br />

became reality: 73 meters<br />

long, 24 meters high, a<br />

wingspan from the tip of the<br />

left to right wing of 79.80<br />

meters with a wing surface<br />

of 845 square meters. Now<br />

for the first time, a jet has<br />

three decks, one for cargo<br />

and baggage, and two for<br />

the nearly 800 passengers<br />

depending on the seating arrangement.<br />

It is as if two<br />

large airplanes were packed<br />

into one. Airports must adjust<br />

to the magnitude of this<br />

airplane.<br />

On April 27th, <strong>2005</strong> the „big<br />

goose“, as the A380 is also<br />

called by engineers, took off<br />

for its first flight in front of<br />

thousands of curious onlookers.<br />

The first impression was disappointing.<br />

The super bird does<br />

not appear to be gigantic.<br />

Maybe Airbus should put a<br />

small A318 next to it, so that<br />

people can understand the dimensions<br />

of it. It is the gigantic<br />

hall painted silver-blue at<br />

the Airbus site that triggers<br />

the illusion. The building – one<br />

of the largest in Europe – is<br />

five-hundred meters long, 250<br />

meters wide, and 46 meters<br />

high. It also offers 34,000<br />

square meters of office space<br />

on six floors.<br />

Only gradually do the onlookers<br />

realize the size of the<br />

A380. From the gallery at the<br />

height of the tail unit it becomes<br />

apparent what a colossus<br />

is standing there in the hall.<br />

The workers and engineers<br />

pottering about 20 meters below<br />

on the ground look like<br />

ants. The airplane requires a<br />

surface of 100 x 100 meters,<br />

while the working platforms to<br />

the left and right of the plane<br />

are elevated five floors.<br />

A product from<br />

all over Europe<br />

The A380 is a product that is<br />

as European as almost no<br />

other. The individual parts for<br />

the superbird are manufactured<br />

at 16 sites between Spain<br />

At the site the airplane manufacturer<br />

tests not only the preliminary<br />

models, but also all<br />

subsequent airplanes of the<br />

series after assembly. A new<br />

test stand has been built at<br />

Toulouse Airport for engine<br />

tests and test runs. This test<br />

stand has a diameter of over<br />

100 meters.<br />

Twenty-meter high walls and<br />

gates protect the outside<br />

world from the sound. The two<br />

giant gates with their own engines<br />

are fed by two <strong>VAHLE</strong><br />

cable carrier assemblies. The<br />

reliable W45 cable carriers<br />

were installed for this purpose.<br />

During the test run of the<br />

enormous Rolls Royce engines,<br />

the thrust must be directed<br />

upwards. Six connected, maneuverable<br />

deflectors with frequency<br />

controlled motors are<br />

in charge of this task. The<br />

electrical current supply along<br />

The <strong>VAHLE</strong> system can be<br />

recognized in the crosssection<br />

profile of the machine.<br />

The W45 FR cable carrier assemblies<br />

have a new kind of<br />

clamping profile for flat and<br />

round cables. With the combination<br />

of the basic clamping<br />

profile and one or more enhanced<br />

profiles - 6 mm index – it is<br />

possible to clamp together<br />

round cables of different diameters<br />

and flat cables of different<br />

sizes.

The „Affiche Galerij“ in The Hague<br />

Bringing Art<br />

to the People<br />

In the past decades cultural<br />

activities have been developed<br />

in public places in The<br />

Hague, which can hardly be<br />

found anywhere else in the<br />

Netherlands.<br />

Music festivals, outdoor cinema,<br />

the famous sculpture<br />

exposition in the city and of<br />

course the world-famous<br />

firework festival on the beach<br />

in the suburb of Scheveningen<br />

attract culture buffs<br />

to the Oranje city every year.<br />

Since October 2004 the center<br />

has a new attraction. In<br />

the long awaited underground<br />

„Deluxe“ station of<br />

the city railway at the Spuiplein<br />

square there is a continuous<br />

poster exposition, the<br />

„Affiche Galerij“ or poster<br />

gallery.<br />

At the gallery, the historic posters<br />

hang behind a two-meter<br />

high glass wall on a surface of<br />

more than 150 meters. Up to<br />

six times a year, the exhibits,<br />

which were compiled according<br />

to topic by the project director<br />

Wendy Lauw from the<br />

Hague City Archive, are rotated:<br />

„Sixty posters in the illuminated<br />

frames then have to<br />

be changed and hung up<br />

again. Together with <strong>VAHLE</strong>,<br />

the Dutch star architect Rem<br />

Koolhass has developed a<br />

simple and safe system so that<br />

this can be done quickly and<br />

easily. The suspensions of the<br />

frames are threaded in a continuous<br />

guide rail and pushed<br />

into their position by hand. In<br />

order to illuminate the pictures<br />

equally without a glare, the<br />

frames have a built-in indirect<br />

lighting system. Thus, the<br />

electrical current logically has<br />

to be mobile and carried along<br />

with the exhibit.“<br />

Who could have developed a<br />

better solution for this than<br />

<strong>VAHLE</strong>. It’s not for nothing<br />

that the firm’s slogan is:<br />

„<strong>VAHLE</strong> makes electricity mobile“.<br />

While 156 meters of the<br />

S2 carrier were used as guide<br />

rails, the the KSL enclosed<br />

conductors were used to supply<br />

electricity to the illuminated<br />

frames. The collector cables<br />

had to be adjusted to the curves<br />

and bulges of the walls according<br />

to the artists’ preferences.<br />

Flexible to<br />

customers’ wishes<br />

But not only that. The classic<br />

<strong>VAHLE</strong>-green of the conductors<br />

was out of the question<br />

for Koolhaas. Flexibility and<br />

customer service is one of the<br />

great strengths of the firm<br />

from Kamen. This is how VAH-<br />

LE satisfied the needs of the<br />

architect. An eye-catching<br />

orange powder coating was<br />

applied to the carrier rail and<br />

the conductor system was tinted<br />

to match the brown color<br />

of the steel construction. At<br />

any rate Wendy Lauw is highly<br />

Thanks to the bright floors, the openings in the ceiling for daylight and of course the „Affiche<br />

Galerij“ with its 60 illuminated posters, no one will feel trapped in the station at the Spuiplein.<br />

satisfied with the installation:<br />

„It is easy to handle and works<br />

absolutely flawlessly up to<br />

now. I think we will be able to<br />

use it for many more years without<br />

difficulties, not only in<br />

order to relieve the passengers<br />

of that nightmarish feeling<br />

that is often associated with<br />

an underground station, but<br />

also to continue offering them<br />

continually changing art.“<br />

The fact that the people feel<br />

that they are in good hands in<br />

this underground station, certainly<br />

also has to do with the<br />

unusually bright wooden floors<br />

and the daylight slots. However,<br />

the „Affiche Gallerij“ of<br />

the city archive adds an additional<br />

highlight to the highly<br />

successful architecture. The<br />

proof: as soon as the posters<br />

are in their place, the first<br />

photographers are there to<br />

take pictures of them. The<br />

blond archivist director smiles<br />

with satisfaction, when she<br />

points to the picture aficionados<br />

to help her prove her<br />

point: „This is what we experience<br />

every time. You have to<br />

bring art to the people and<br />

then they will take pleasure in<br />

it.“<br />

<strong>VAHLE</strong>’s KSL PVC enclosed<br />

multiple conductor systems are<br />

insulated safety conductors for<br />

crane trolleys and material<br />

handling equipment, suspension<br />

tracks, hoists, electrical<br />

tools, automated storage and<br />

retrieval installations, as well<br />

as many applications in which<br />

electrical current is supplied to<br />

mobile users. They are suitable<br />

for indoor and outdoor facilities.<br />

They distinguish themselves<br />

by the fact that they require<br />

little space, are corrosion-resistant<br />

and easy to install.

Crane tuning with <strong>VAHLE</strong> in Hong Kong<br />

Space for more containers<br />

Even in the early 18th<br />

century, Europeans had<br />

come to cherish silk, tea, and<br />

spices from China. Once the<br />

English East India Company<br />

had first advanced as far as<br />

Canton in 1699, a flourishing<br />

system of trade with<br />

China quickly developed. This<br />

gave rise to Hong Kong as a<br />

trans-shipment center.<br />

Even today, the logistics industry<br />

of the Chinese special administration<br />

region is considered<br />

to be one of the main pillars<br />

of the economy. Tea, silk<br />

and spices made room for clothing,<br />

electronics, IT and toys a<br />

long time ago. The „nerve system“<br />

of Hong Kong is Victoria<br />

Harbour (located between the<br />

island Hong Kong and the<br />

Kowloon Peninsula), which is<br />

60 km 2 in size. It is among the<br />

most beautiful natural harbors<br />

and – measured by its turnover<br />

– it is at the very top of the<br />

world rankings; its computeroperated<br />

container terminal<br />

„Kwai Chung“ has the highest<br />

turnover on earth, 20.4 million<br />

TEU.<br />

Help in facing<br />

the competition<br />

Hong Kong still maintains a<br />

clear lead, but stiff competition<br />

for the logistics center has<br />

emerged, in particular, in the<br />

neighboring metropolis Shenzhen<br />

with more than a million<br />

residents. The rapidly increa-<br />

sing turnover capacities for<br />

containers in the Chinese special<br />

economic zone are posing<br />

serious difficulties to the Hong<br />

Kong planners. In light of the<br />

competition between these<br />

two rivals, any good idea is<br />

highly welcome. Thus, it is no<br />

surprise that the port operators<br />

of the Hong Kong International<br />

Terminal HIT have willingly<br />

opened their doors to<br />

the crane converter PBI from<br />

Hürth near Cologne with its<br />

latest technical device. The<br />

idea is simple and practical.

Inhospitable environs are no<br />

bother for <strong>VAHLE</strong> professional<br />

solutions.<br />

For conventional cranes, the<br />

stacking height of containers<br />

is limited by the cable loop<br />

hanging down. After all, the<br />

electricity and data cables<br />

need to be able to extend.<br />

The small innovator from the<br />

Rhineland conducted experiments<br />

with the <strong>VAHLE</strong> insulated<br />

conductor U35 with an<br />

aluminum stainless steel de-<br />

sign and the data transmission<br />

system SMG from <strong>VAHLE</strong>, in<br />

order to replace the cables,<br />

which were subject to wear<br />

and tear, with a more modern<br />

solution. By using the U 35 insulated<br />

conductor rail in conjunction<br />

with SMG mobile data<br />

transmission, Hurth Co. was<br />

able to create additional free<br />

space below a container crane.<br />

What does not seem to be so<br />

groundbreaking at first sight<br />

begins to make more sense<br />

when one takes into consideration<br />

how little space is available<br />

in a container port working<br />

at full capacity. If there is<br />

limited room in terms of width,<br />

the solution has to be found<br />

aloft. By removing the cable<br />

carrier assemblies, up to three<br />

meters and more additional<br />

Removing the cable carrier assemblies creates – among<br />

other things – additional space below the crane for more<br />

stacking height in the container port.<br />

stacking height were gained –<br />

enough for a further layer of<br />

containers.<br />

By combining the <strong>VAHLE</strong> products,<br />

it was no longer necessary<br />

to replace the worn out<br />

cables, which otherwise must<br />

be done approximately every<br />

three years, and the crane trolleys<br />

can be driven faster, in order<br />

to bring the containers to<br />

the right position. This entails<br />

further significant benefits besides<br />

the additionally gained<br />

storage space.<br />

Because the „tuning“ of the<br />

test crane went so well, PBI is<br />

already planning on converting<br />

two more cranes. These will<br />

certainly not be the last. More<br />

than 40 cranes are still standing<br />

in this area of the terminal<br />

alone.<br />

The SMG data transmission<br />

system is suitable for interference-free<br />

data transfer at<br />

high data rates in automation<br />

technology. It can be adapted<br />

to nearly all conventional<br />

computers or SPS-interfaces.<br />

Its robust structure also allows<br />

for using the system under<br />

more harsh operational and<br />

environmental conditions. In<br />

combination with the <strong>VAHLE</strong><br />

U35 power conductors, SMG is<br />

a reliable and cost effective<br />

system’s integration.

<strong>VAHLE</strong>-Technology closes the giant retractable roof with precision<br />

LTU arena: For any weather<br />

Düsseldorf has a new<br />

stadium of technological<br />

superlatives. The LTU arena<br />

has more than 51,500 seats<br />

and offers space for up to<br />

65,000 spectators including<br />

indoor space at music concerts.<br />

A gigantic home not<br />

only to the American football<br />

team Rheinfire.<br />

The LTU arena has an enormous,<br />

closable roof, which is<br />

235 meters long, 201 meters<br />

wide and 8000 tons when<br />

closed. The roof elements, two<br />

190 meter long steel beams<br />

that weigh 1650 tons each,<br />

are an essential part of the<br />

structure.<br />

With a push of a button, they<br />

open or close the 110 x 70 meter<br />

opening of the roof in just<br />

30 minutes. Thus, rain or snow<br />

cannot disrupt any concert or<br />

football match.<br />

In order to do this, massive<br />

loads must be moved: after all<br />

each of the two halves weighs<br />

630 tons, is 127 meters long,<br />

36 meters wide and nine meters<br />

high. The roof is moved<br />

with the help of electric mo-<br />

tors. The contact surface for<br />

the retractable roof is provided<br />

by the two main carriers of the<br />

roof. As soon as it begins to<br />

move along the toothed wheel<br />

tracks, there is an acoustic<br />

warning signal. The arena can<br />

be completely darkened inside.<br />

The openings below the roof<br />

are then also closed with sunblinds.<br />

Precision demanded<br />

When precision is in demand,<br />

<strong>VAHLE</strong> is never far. The proved<br />

and tested professionals from<br />

Kamen were entrusted with<br />

the task of setting up the electrical<br />

current and the data<br />

transmission system for the<br />

enormous retractable roof. For<br />

its realization, a joint solution<br />

consisting of the SMG data<br />

transmission system and the<br />

LSV aluminum multiple enclosed<br />

conductor system was<br />

installed. Time-tested and reliable.<br />

Both halves of the giant roof<br />

were assembled beforehand.<br />

Each weighing 550 tons, both<br />

In any weather, the LTU arena offers ideal conditions, as<br />

<strong>VAHLE</strong> technology assists in dependably closing the roof.<br />

parts of the retractable roof<br />

for the new Rhine arena in<br />

Stockum were securely anchored<br />

at a height of more than<br />

50 meters. For lifting, two giant<br />

special heavy load cranes<br />

were used, which could each<br />

lift a massive load of 275 tons<br />

with a 25 meter cantilever.<br />

Both halves of the roof were<br />

pre-assembled since February<br />

2003 from around 72 pieces of<br />

steel. The largest pieces had to<br />

be transported to the construction<br />

site by ship.<br />

Heated or open air<br />

The LTU arena possesses a<br />

highly modern and unique heating<br />

system. With a closed<br />

roof, visitors can sit in the<br />

stands in at least 60 F degrees<br />

temperature, even in winter.<br />

Air heating, gas radiators and<br />

floor heating provide for this.<br />

In doing so, 100 ventilators<br />

move 900,000 cubic meters of<br />

air per hour. Overall, the climate<br />

control and ventilation<br />

technology of the LTU arena ca<br />

move 3 million cubic meters of<br />

air per hour. Thus, large events<br />

can be held in the LTU arena<br />

throughout the entire year, independent<br />

of the weather. No<br />

other stadium in Germany can<br />

match that. The 8000 square<br />

meter grass surface for the LTU<br />

arena was delivered from Holland<br />

in „jumbo rolls“ measuring<br />

20 meters long, 1.20 meters<br />

wide and 30 millimeters<br />

thick in a total of 20 truck<br />

loads. Under the grass 42 cm<br />

thick mixture of sand, lava and<br />

peat is found.<br />

The compact LSV aluminum<br />

enclosed multiple conductor<br />

system is suitable for indoor<br />

and outdoor installations. It is<br />

used as a current feed for cranes,<br />

monorails, hoists, electrical<br />

tools, machine tools, automated<br />

storage and retrieval<br />

systems and other mobile consumers<br />

of electrical current,<br />

even at higher temperatures.

Contractless power supply line CPS® in compressor production<br />

Kaeser is on the road to<br />

success with <strong>VAHLE</strong> quality<br />

In road construction, even<br />

laymen are quick to recognize<br />

mobile compressors<br />

from Kaeser. Still, that is<br />

only one application area<br />

where compressed air is used.<br />

Wherever compressed air<br />

must be generated, produced<br />

or distributed, one can encounter<br />

the bright yellow<br />

power plants of the Franconian<br />

manufacturer.<br />

Today, Kaeser is a world-wide<br />

leading manufacturer of compressors<br />

and products for compressed<br />

air technology, employing<br />

more than 3000 people<br />

and is represented in over 70<br />

countries and on all continents<br />

through a competent marketing<br />

and service organization.<br />

The company operates one of<br />

the largest fully automated<br />

plants for the production of<br />

compressors of all types at its<br />

German headquarters in Coburg.<br />

In order to satisfy the high demand<br />

which the Franconian<br />

company places on internal<br />

transport, AFT, an automizati-<br />

on and materials handling<br />

technology company based in<br />

Schopfheim uses components<br />

from <strong>VAHLE</strong>.<br />

More effective<br />

production<br />

To make production at the<br />

main facility in Coburg even<br />

more effective, a section for<br />

driverless floor transportation<br />

vehicles was installed, which is<br />

distributed over two floors.<br />

On a stretch of 510 meters in<br />

length (310 m in the ground<br />

floor, 200 m in the upper level),<br />

ten vehicles transported<br />

the compressors after completion<br />

to stations such as weight<br />

and contour control and to the<br />

transfer stations for the storage<br />

and retrieval facility,<br />

which is located in a separate<br />

building.<br />

The track system consists of<br />

two parallel tracks on which<br />

the vehicles travel fully automatically,<br />

both forwards and<br />

backwards. Four elevators<br />

(hoists from the ground floor<br />

to the upper floor) and 15<br />

track switches connect the<br />

track sections.<br />

High flexibility<br />

The tracks can be changed at<br />

any time to achieve higher flexibility.<br />

The electrical current<br />

for the vehicles is transmitted<br />

inductively via the contactless<br />

power supply CPS® manufactured<br />

by <strong>VAHLE</strong>.<br />

The entire installation is supplied<br />

by a <strong>VAHLE</strong> primary inverter<br />

P145 with 45 kW, which<br />

is located on the ground floor.<br />

Each vehicle carries one pallet,<br />

which is loaded and unloaded<br />

from the side. It is equipped<br />

with steerable axles as well as<br />

with two <strong>VAHLE</strong> track guidance<br />

sensors for each direction<br />

of travel and two Ultra Caps<br />

(24V) with a 500 farad load<br />

volume (a type of quick loading<br />

battery or „large“ capacitor).<br />

These are supplied with electrical<br />

current (up to 125A/<br />

24V0 by a <strong>VAHLE</strong> flat pickup<br />

PU09 (3 kW) with control electronic,<br />

mounted on the carria-<br />

As if driven by a ghost, the floor transport carriers precisely deliver components to the next<br />

assembly station – the contactless current supply CPS® <strong>VAHLE</strong> makes it possible.<br />

ge. Each vehicle has its own<br />

„intelligence“ on board and receives<br />

the destination instructions<br />

via RF transmission;<br />

transponders in the floor assure<br />

local accuracy<br />

This <strong>VAHLE</strong> CPS installation<br />

was designed and developed to<br />

meet specific design criteria<br />

postulated by Kaeser. The system<br />

has operated trouble free<br />

for over a year with the <strong>VAHLE</strong><br />

products. Therefore, Kaeser is<br />

contemplating an expansion to<br />

achieve even faster transport<br />

of goods because of increased<br />

volumes.<br />

CPS® is the <strong>VAHLE</strong> system for<br />

contractles power supply. In<br />

contrast to customary methods<br />

of supplying electrical current<br />

to moveable equipment CPS®-<br />

Technology offers the following<br />

advantages: low maintenance<br />

due to a lack of wear parts,<br />

clean and noiseless operation,<br />

unlimited travel speed, utilization<br />

is also possible with complex<br />

track layouts and under<br />

adverse environmental conditions,<br />

high track guidance tolerance,<br />

the possibility of integrated<br />

battery charging function,<br />

integrated inductive track<br />

guidance and data communication,<br />

high degree of efficiency.

The trench conductor systems installed in the wharf have proven themselves for years.<br />

Valencia claims its place at the top with <strong>VAHLE</strong> quality<br />

Higher output for the „City of the Sea“<br />

Valencia lies on the Spanish<br />

Mediterranean<br />

coast, approximately 350 km<br />

south of Barcelona at the<br />

mouth of the Turia river. As<br />

an old port city on the Mediterranean,<br />

Valencia is full of<br />

maritime stories. It is therefore<br />

often called „the City of<br />

the Sea“. In 2007, the legendary<br />

American’s Cup of sailing<br />

is slated to start here.<br />

With 746,000 residents, the<br />

provincial capital of Valencia is<br />

the third largest city in Spain<br />

after Madrid and Barcelona. In<br />

addition to the traditional consumer<br />

goods industries such as<br />

textiles, wood, ceramics and<br />

footwear, large multinational<br />

companies have settled in the<br />

economic region of Valencia<br />

that are specialized in the ma-<br />

nufacture of automobiles, automobile<br />

accessories, engineering,<br />

iron and steel extraction,<br />

glass, plastic and petrochemicals.<br />

In addition, the region<br />

also has a large number of<br />

technology based companies,<br />

which provide the multinational<br />

companies with supplies<br />

and services.<br />

Top place in Spain<br />

In addition, Valencia companies<br />

also export a wide array<br />

of agricultural products and<br />

the traditional local goods like<br />

ceramic tiles, footwear and<br />

textiles.<br />

Valencia is the second largest<br />

exporter in Spain. For that purpose,<br />

a high-capacity port is a<br />

logical requirement. The port<br />

of Valencia transacts 20% of<br />

Spanish exports and is the largest<br />

container port in Spain<br />

overall with 28 million tons of<br />

freight per year.<br />

The port never sleeps<br />

In order to achieve this accomplishment,<br />

the container<br />

cranes are utilized around the<br />

clock. The port never sleeps.<br />

The requirements on technology<br />

are continuously subjected<br />

to a difficult test in this raw<br />

environment. Salt water and<br />

dirt afflict the cranes and their<br />

power train components. It is<br />

therefore not surprising that<br />

only proven products can survive<br />

here in the long run.<br />

Such products include the<br />

trench conductor system from<br />

<strong>VAHLE</strong>. Since 1997, a 1.5 kilo-<br />

The <strong>VAHLE</strong> slotless trench<br />

conductor system has been<br />

manufactured since 1925. It is<br />

used for dock side cranes, loading<br />

bridges, locomotive transversers,<br />

etc., where an above<br />

ground conductor system<br />

would be obstructive. The<br />

trench conductor system is installed<br />

below ground parallel<br />

to the dockside and can<br />

follow all incidental curves of<br />

the crane rail.<br />

The conductor trench is normally<br />

laid in concrete. The<br />

trench conductor system is<br />

covered over the entire length<br />

with steel plates supported on<br />

both sides by edge steel<br />

profiles.The plates are hinged<br />

with an above or below ground<br />

hinges.<br />

meter long trench is in use<br />

with the proven U30 conductors.<br />

Eleven giant container<br />

cranes are supplied with electrical<br />

current from under the<br />

ground.<br />

Due to the reliability of the<br />

system, another 500 meters<br />

were installed in the past year,<br />

in order to expand the reach of<br />

the cranes to an additional<br />

loading wharf.<br />

An additional 720 meters of<br />

below-ground trenches will be<br />

constructed this year. Due to<br />

the higher capacity requirements,<br />

the larger type U40 U<br />

conductors are being used.<br />

Moreover, high voltage of<br />

11,000 Volts will be utilized.<br />

Thus, Valencia will also be able<br />

to claim its top position in<br />

Spain in the future.

The world’s<br />

largest copper<br />

mine<br />

Back to<br />

its origins<br />

At first sight, the mind re<br />

fuses to understand what<br />

the eyes see in the thin air of<br />

the high mountains of Chuquicamata:<br />

the largest open<br />

pit copper mine in the world<br />

located nearly 3000 meters<br />

high in the north of Chile<br />

can be identified even dozens<br />

of kilometers away.<br />

„Pies“ are what the natives call<br />

the giant mining dumps, which<br />

push up like lower mountain<br />

ranges from the pre-Andes<br />

into the withered landscape.<br />

Not until houses and cars enter<br />

the scene can the sheer<br />

magnitude of this mine of superlatives<br />

be fathomed, which<br />

evidently can be recognized<br />

from space with the naked eye.<br />

The pride of Chile produces<br />

600,000 tons of copper per<br />

year and belongs to the stateowned<br />

copper company Codelco,<br />

which generates eight percent<br />

of the state budget alone.<br />

Since 1915 1.6 trillion tons of<br />

stone have been blasted out of<br />

the mountains in Chuquicamata<br />

approximately 1600 kilometers<br />

to the north of the capital<br />

of Santiago and dumped<br />

into the mining dumps after<br />

removing the copper.<br />

Like an excessively large football<br />

stadium, the mine today is<br />

4.3 kilometers long, 3 kilometers<br />

wide, and 835 meters<br />

deep. At the bottom of the<br />

mine, mechanical diggers,<br />

which are hardly recognizable<br />

with the naked eye, load the<br />

blasted stone onto giant<br />

trucks, which then transport it<br />

to the surface on serpentines.<br />

The giant trucks in the enormous strip mine of Chuquicamata look like toy cars.<br />

Raw materials<br />

for <strong>VAHLE</strong><br />

For many years, the state copper<br />

manufacturer has relied on<br />

<strong>VAHLE</strong> products for mining activities.<br />

These products then<br />

return as finished products to<br />

where their copper core has its<br />

origins. Even today, insulated<br />

U40 solid copper conductor<br />

rails provide for the reliable<br />

supply of electricity to the<br />

processing facilities. They are<br />

especially equipped for the difficult<br />

conditions in the melting<br />

plants and have a good reputation<br />

among Chileans due to<br />

their robustness and because<br />

they are easy to handle. This<br />

reliability is also in demand for<br />

the coming years.<br />

2.5 billion tons of reserves are<br />

still stuck in the earth, which<br />

are enough for thirty more years.<br />

And then? The Escondida<br />

mine is already in the process<br />

of surpassing the Chuquicamata<br />

mine, because „Chuqui“,<br />

as it is affectionately called is<br />

only a part of the state copper<br />

company Codelco. It supplies<br />

twenty percent of the copper<br />

produced worldwide and – like<br />

saltpeter once was – it is the<br />

lifeline of the Chilean state<br />

budget: in the sixties and seventies<br />

the Frei and Allende<br />

governments put the copper<br />

industry under state control<br />

and the military government<br />

under General Pinochet kept it<br />

that way.<br />

No longer normal<br />

All numbers and figures concerning<br />

this mine are almost<br />

surreal. Every shovel for the gigantic<br />

mechanical diggers –<br />

priced at 10 million Euros a piece<br />

– grabs 110 tons of boulders.<br />

The trucks have a load<br />

capacity of 400 tons. At 3300<br />

horse-power, the 110 vehicles<br />

hum around the clock with<br />

their precious cargo up to the<br />

rock grinders and furnaces at<br />

the surface. Every one of the<br />

four tires costs as much as a<br />

mid-sized car and the diesel<br />

consumption of 400 liters per<br />

100 kilometers is also somewhat<br />

higher than normal.<br />

From ore to metal<br />

First the stone is grinded<br />

down. Then the grinded stone<br />

is chemically treated in a basin:<br />

this is where the iridescent<br />

green broth with black air<br />

bubbles simmers. Coppery mud<br />

settles at the bottom and<br />

flows into the foundry. There<br />

the mud is heated in a giant<br />

furnace. The fire glows in a<br />

turquoise color. The glowing<br />

metal is poured into molds and<br />

cooled off with running water.<br />

The product is called „Blister“<br />

and consists of 99 percent<br />

copper. The still steaming bullions<br />

are piled onto containers<br />

and then driven from here to<br />

the port.<br />

Codelco is already drawing up<br />

plans for an even much more<br />

gigantic mine, next to which<br />

the existing excavation would<br />

look like a mid-sized dent. In<br />

the next 20 years Chuquicamata<br />

is supposed to be expanded<br />

to a length of 20 kilometers.<br />

Until then, as much rock<br />

is supposed to be moved as in<br />

the past 90 years together.<br />

Insulated U40 conductor rails<br />

provide electricity for many<br />

TECHNIKDETAILS<br />

applications such as heavy<br />

cranes and container bridges<br />

(crane Auch das and crane Bild steht trolleys), stell-<br />

high-performance vertretend für ein monorails, anderes<br />

coking Foto. Dies plant ist machinery Blindtext. among Er<br />

others. hat keinerlei The insulating Bezug shroud zum<br />

in Inhalt, both the sondern standard stellt and allein heatresistant<br />

die Textmenge, design is Schriftart resistant to<br />

gasoline, und -größe, mineral Zeilenabstand<br />

oil, grease,<br />

sodium hydroxide 50%, con-<br />

und Umbrauch dar.<br />

centrated salt acid and sulfuric<br />

acid 50%.

„Kai zen“ with <strong>VAHLE</strong>:<br />

Taking small steps<br />

towards success<br />

There are many ways for<br />

small and mid-sized businesses<br />

to increase their competitiveness,<br />

for example by<br />

creating their own company<br />

profile and by designing their<br />

products attractively.<br />

Special attention in this regard<br />

should be given to the<br />

employees’ creative potentials<br />

and diverse ideas. Many<br />

small and mid-sized companies<br />

can find „hidden reserves“<br />

here.<br />

Through its workshops, <strong>VAHLE</strong><br />

has begun a „kai zen“ process<br />

this year. The driving force behind<br />

this form of management<br />

is Michael Pavlidis, <strong>VAHLE</strong><br />

Technical Director.<br />

? Mr. Pavlidis, what does kai<br />

zen mean in German?<br />

! The Japanese word kai zen<br />

consists of the two terms KAI<br />

= change and ZEN = for the<br />

better. This thus describes the<br />

aim of the process – the<br />

endeavor to constantly scrutinize<br />

and improve products, activities,<br />

business processes and<br />

customer relations. According<br />

to the kai zen philosophy it is<br />

not so much about „great<br />

ideas“, rather the multitude of<br />

small and simple suggestions.<br />

? Where are these ideas supposed<br />

to come from?<br />

! These suggestions for improvement<br />

are expected from all<br />

the employees of the firm, so<br />

that the products and working<br />

processes are continually further<br />

developed within the framework<br />

of a so-called<br />

„Continual Improvement Process“<br />

(CIP).<br />

One might exaggerate a bit<br />

and describe it as follows: a<br />

one-percent improvement of<br />

one hundred things in the<br />

business is better than a 100<br />

percent improvement of one<br />

thing.<br />

? What is your understanding<br />

of a creative employee?<br />

! A creative employee is someone<br />

who continually thinks<br />

while he or she is doing what<br />

he or she does. Someone who<br />

doesn’t let the things just run,<br />

but also feels responsible for<br />

the quality that he or she manufacturers,<br />

someone who becomes<br />

active and doesn’t just<br />

say: „I know that that is bad,<br />

but we have a quality assurance<br />

system. They will figure it<br />

out“.<br />

? How can <strong>VAHLE</strong> use the creativity<br />

of its employees?<br />

Michael Pavlidis discusses the concrete implementation of the<br />

results on site with two participants of the workshop.<br />

! We have already set our<br />

sights on several areas this<br />

year and brought the employees<br />

together in small groups<br />

in order to bundle together<br />

ideas and put them into<br />

practice directly.<br />

? Why small groups?<br />

! Better suggestions are frequently<br />

made in small groups.<br />

More sensible and practicable<br />

suggestions can be reached<br />

when they are drawn up by<br />

working groups and discussed<br />

within them.<br />

? What do you pay particular<br />

attention to with regard to the<br />

improvements?<br />

! The primary goal is the reduction<br />

of muda (waste).<br />

Muda refers to everything that<br />

is unnecessary. Unused storage<br />

space, unnecessary trips, friction<br />

loss when working together<br />

and much more.<br />

The main goal is not correcting<br />

errors, rather avoiding errors<br />

and striving for zero-defect-<br />

solutions. The motto here is:<br />

quality is when the customer<br />

comes back, and not the product.<br />

? What do you hope to achieve<br />

with the „running process“?<br />

! The benefits are obvious: lower<br />

costs, reducing allowable<br />

defects, reducing stock, saving<br />

space, improved quality and<br />

maintenance during production.<br />

For the employees I expect<br />

an improved business climate,<br />

better communication,<br />

self reliant colleagues and improved<br />

work ethic.<br />

? Are there any first results?<br />

! Yes, as a result of the workshop,<br />

we were able to avoid<br />

moving into a new hall by<br />

using space more optimally. I<br />

have to clearly emphasize one<br />

thing here: these successes<br />

would not have been possible<br />

if our employees had not cooperated<br />

excellently and adapted<br />

to the new approach so<br />

well.<br />

Representatives from all over the world met at the <strong>VAHLE</strong> international conference to gain insights on current developments<br />

in the firm. The main focus was placed on the intensive training of the sales force as well as the presentation of innovations and<br />

further developed products. While exchanging professional information with one another, the German and international guests also visited<br />

several cultural sites in the Ruhr region, where they had extra time to enjoy each others’ company.