- Page 1 and 2:

1 : Oct. 24 2008 MODEL NOTE FOR SER

- Page 3 and 4:

NOTE FOR SERVICING MX-5001N 5) Do

- Page 5 and 6:

1 1 : Oct. 24 2008 MX-5001N [1] PR

- Page 7 and 8:

1 1 1 1 : Oct. 24 2008 [2] SPECIFIC

- Page 9 and 10:

D. Scanner section (1) Resolution/G

- Page 11 and 12:

E. Paper feed section (1) Type Type

- Page 13 and 14:

(4) Font Emulation Built-in fonts O

- Page 15 and 16:

(3) Data operation contents Operati

- Page 17 and 18:

D. Middle East/Taiwan/Africa/Israel

- Page 19 and 20:

1 1 : Oct. 24 2008 B. Europe/UK/Aus

- Page 21 and 22:

1 1 1 : Oct. 24 2008 No. Item Conte

- Page 23 and 24:

1 : Oct. 24 2008 MX-5001N [4] EXTE

- Page 25 and 26:

C. Internal operation parts (7) (1)

- Page 27 and 28:

(3) Motors, clutches, solenoids, PW

- Page 29 and 30:

(3) Motor, clutches, solenoids and

- Page 31 and 32:

No. Name function/Operation 1 Touch

- Page 33 and 34:

Signal name Name Function/Operation

- Page 35 and 36:

K. Clutches and solenoids PCSS CPFC

- Page 37 and 38: Signal name Name Type Function/Oper

- Page 39 and 40: O. PWB 26 27 32 14 13 31 8 18 5 25

- Page 41 and 42: Signal name Name Specifications Sec

- Page 43 and 44: MX-5001N [5] ADJUSTMENTS 1. Genera

- Page 45 and 46: 3. Details of adjustment ADJ 1 Adju

- Page 47 and 48: 4) When [EXECUTE] key is pressed, i

- Page 49 and 50: 4-B Adjust the developing bias volt

- Page 51 and 52: 1 1 1 : Oct. 24 2008 4-C Transfer v

- Page 53 and 54: 5-A Color image density sensor (ima

- Page 55 and 56: Mode Display/Item Content Range Def

- Page 57 and 58: 9) If the adjustment result reaches

- Page 59 and 60: 1) Go through the modes specified i

- Page 61 and 62: 8) Loosen the paper feed tray off-c

- Page 63 and 64: A: Rough adjustment pattern B: Fine

- Page 65 and 66: MX-5001N ADJUSTMENTS 5 - 23 -120 12

- Page 67 and 68: 4) Check the rough adjustment and t

- Page 69 and 70: 2) Turn the scanner drive pulley ma

- Page 71 and 72: 5) Change the height balance of the

- Page 73 and 74: 12-B DSPF mode image focus adjustme

- Page 75 and 76: Adjust the section F so that the cl

- Page 77 and 78: 13-B RSPF diagonal adjustment 1) Se

- Page 79 and 80: [Check Method 2] Check that the squ

- Page 81 and 82: 2) Enter the simulation 48-1 mode.

- Page 83 and 84: 15-B Scan image magnification ratio

- Page 85 and 86: ADJ 16 Scan image off-center adjust

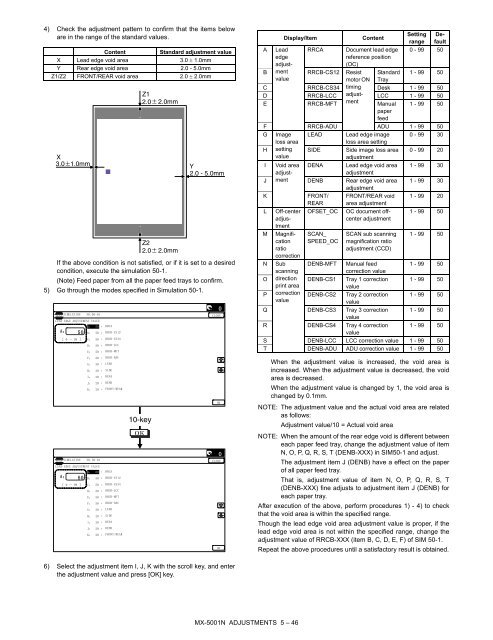

- Page 87: Item Display Content F Image loss a

- Page 91 and 92: NOTE: To execute this adjustment, t

- Page 93 and 94: (Front/rear frame direction image l

- Page 95 and 96: (2) Copy color balance and density

- Page 97 and 98: 4) When [DSPF] button is pressed, i

- Page 99 and 100: c. Adjustment procedure (Auto color

- Page 101 and 102: 6) Check the color balance and dens

- Page 103 and 104: c. Adjustment procedure Copy color

- Page 105 and 106: (Abnormal end (Auto transition))

- Page 107 and 108: • Factory target in the copy colo

- Page 109 and 110: 2) Select the copy mode to be adjus

- Page 111 and 112: Item/Display Density level (Point)

- Page 113 and 114: 20-I Document background density re

- Page 115 and 116: (Adjustment 2) This adjustment is u

- Page 117 and 118: Display/Item (Copy Select Content D

- Page 119 and 120: 2) Select the item A, B with the sc

- Page 121 and 122: Item Button Display Content A OC CO

- Page 123 and 124: 20-T Copy color balance adjustment

- Page 125 and 126: c. Adjustment procedure (Auto color

- Page 127 and 128: 6) Check the color balance and dens

- Page 129 and 130: 1) Enter the SIM 67-25 mode.

- Page 131 and 132: • Relationship between the factor

- Page 133 and 134: 21-C Printer density adjustment (lo

- Page 135 and 136: . Adjustment procedures (Auto color

- Page 137 and 138: 6) Set the color patch image (adjus

- Page 139 and 140:

. Adjustment procedures 1) Enter th

- Page 141 and 142:

1) Go through the modes specified i

- Page 143 and 144:

ADJ 27 Image loss, void area, image

- Page 145 and 146:

6) Press [EXECUTE] key. The f

- Page 147 and 148:

5) After completion of printing, th

- Page 149 and 150:

Standby for entry of SIM sub code E

- Page 151 and 152:

Main Sub Functions Section 23 2 Use

- Page 153 and 154:

Main Sub Functions Section 46 41 Us

- Page 155 and 156:

3. Details of simulation 1 1-1 Purp

- Page 157 and 158:

1 : Oct. 24 2008 3

- Page 159 and 160:

1 : Oct. 24 2008 3-10 Purpose Adjus

- Page 161 and 162:

SIMULATION NO.05-01 5-2 Purpose

- Page 163 and 164:

6-6 Purpose Operation test/check Fu

- Page 165 and 166:

1 1 1 : Oct. 24 2008 8-2 Purpose Op

- Page 167 and 168:

9 9-2 Purpose Operation test/check

- Page 169 and 170:

22 22-1 Purpose Adjustme

- Page 171 and 172:

22-6 Purpose Adjustment/Setting/Ope

- Page 173 and 174:

DRUM DAY K Number of day that used

- Page 175 and 176:

24-2 Purpose Data clear Function (P

- Page 177 and 178:

PRINT BW Print counter (B/W) PRINT

- Page 179 and 180:

26 26-1 Purpose

- Page 181 and 182:

26-10 Purpose Setting Function (Pur

- Page 183 and 184:

(*2) Item B: COLOR MODE set value (

- Page 185 and 186:

Set value Destination Toner prepara

- Page 187 and 188:

Item/Display Content A FSS MODE NEB

- Page 189 and 190:

27-10 Purpose Data clear Function (

- Page 191 and 192:

1 1 : Oct. 24 2008 30 30-1 Purpose

- Page 193 and 194:

1 1 : Oct. 24 2008 41-2 Purpose Adj

- Page 195 and 196:

1 1 : Oct. 24 2008 P HL_UM OHP PAPE

- Page 197 and 198:

1 1 : Oct. 24 2008 [50-sheet machin

- Page 199 and 200:

1 1 : Oct. 24 2008 AB HL_LM E-STAR

- Page 201 and 202:

1 1 : Oct. 24 2008 TH_UM Fusing up

- Page 203 and 204:

1 1 : Oct. 24 2008 [50-sheet machin

- Page 205 and 206:

1 1 1 : Oct. 24 2008 [41-sheet mach

- Page 207 and 208:

1 1 : Oct. 24 2008 Item/Display Con

- Page 209 and 210:

TH_UM Fusing upper thermister main

- Page 211 and 212:

Item/Display Content G PCS_K BELT M

- Page 213 and 214:

Mode Item/Display (*: Correction va

- Page 215 and 216:

44-16 Purpose Operation data displa

- Page 217 and 218:

Category Item/Display Content For p

- Page 219 and 220:

Mode Item/Display Content Setting r

- Page 221 and 222:

1 1 : Oct. 24 2008 Item/Display Con

- Page 223 and 224:

44-61 Purpose Adjustment Function (

- Page 225 and 226:

46-8 Purpose Adjustment (Color scan

- Page 227 and 228:

46-19 Purpose Setting Function (Pur

- Page 229 and 230:

46-26 Purpose Adjustment Function (

- Page 231 and 232:

46-38 Purpose Adjustment/Setup Func

- Page 233 and 234:

Item/Display Content Setting range

- Page 235 and 236:

To check the adjustment density lev

- Page 237 and 238:

46-60 Purpose Adjustment/Setup Func

- Page 239 and 240:

Item/Display Content S MODE0_UNDER

- Page 241 and 242:

1 : Oct. 24 2008 48

- Page 243 and 244:

Item/Display Content FINM Inner fin

- Page 245 and 246:

Item/Display Description C Image lo

- Page 247 and 248:

D Image loss amount setting SIDE1 F

- Page 249 and 250:

50-12 Purpose Adjustment Function (

- Page 251 and 252:

1 1 : Oct. 24 2008 50-22 Purpose Ad

- Page 253 and 254:

Main scanning adjustment error Erro

- Page 255 and 256:

Item classific ation Sampling statu

- Page 257 and 258:

Item classific ation Sampling statu

- Page 259 and 260:

[RSPF] FAX send When image send mod

- Page 261 and 262:

51-2 Purpose Adjustment/Setup Funct

- Page 263 and 264:

1 1 : Oct. 24 2008 Display/Item Con

- Page 265 and 266:

55 55-1 Purpose (Do not use this fu

- Page 267 and 268:

60 60-1 Purpose Operation test/chec

- Page 269 and 270:

1 1 : Oct. 24 2008 Mode Item/Displa

- Page 271 and 272:

62-6 Purpose Operation test/check F

- Page 273 and 274:

[RSPF] Item/ Display Content NOTE G

- Page 275 and 276:

63-8 Purpose Adjustment/Setup Funct

- Page 277 and 278:

64-2 Purpose Operation test/check F

- Page 279 and 280:

64-5 Purpose Operation test/check F

- Page 281 and 282:

64-7 Purpose Operation test/check F

- Page 283 and 284:

67-26 Purpose Adjustment/Setup Func

- Page 285 and 286:

67-34 Purpose Adjustment/Setup Func

- Page 287 and 288:

[7] SELF DIAG AND TROUBLE MX-5001N

- Page 289 and 290:

Kind of trouble General PCU color s

- Page 291 and 292:

1 1 : Oct. 24 2008 Trouble code Mai

- Page 293 and 294:

Trouble code Main code Sub code U6

- Page 295 and 296:

E7-08 MFP memory compatibility erro

- Page 297 and 298:

E7-80 MFP-SCU PWB communication err

- Page 299 and 300:

F1-32 Finisher - Punch unit communi

- Page 301 and 302:

1 : Oct. 24 2008 F2-41 Toner densit

- Page 303 and 304:

F2-72 Improper toner cartridge dete

- Page 305 and 306:

H3-04 Fusing section high temperatu

- Page 307 and 308:

H7-14 Recovery error from low fuser

- Page 309 and 310:

L4-45 Toner cooling fan trouble (To

- Page 311 and 312:

U2-24 MFP PWB SRAM memory user auth

- Page 313 and 314:

U6-09 LCC lift trouble Trouble cont

- Page 315 and 316:

A0-21 Conflict firmware and EEPROM

- Page 317 and 318:

Fusing section (Others) Part name L

- Page 319 and 320:

2. Details A. Photoconductor sectio

- Page 321 and 322:

4) Insert the MC cleaner rod into t

- Page 323 and 324:

16) Remove the side seal F/R. Maint

- Page 325 and 326:

(Note for servicing the DV roller)

- Page 327 and 328:

11) Remove the DV side seal F/R. Ma

- Page 329 and 330:

D. LSU section ✕: Check (Clean, r

- Page 331 and 332:

E. Transfer section ✕: Check (Cle

- Page 333 and 334:

(Note for servicing the transfer un

- Page 335 and 336:

10) Remove the screws, and remove t

- Page 337 and 338:

22) Remove the secondary belt trans

- Page 339 and 340:

19 18 17 15 (1) Fusing paper exit r

- Page 341 and 342:

2) Remove the web roller (on the wi

- Page 343 and 344:

4) Remove the screw, disconnect the

- Page 345 and 346:

3) Disengage the hook of the lower

- Page 347 and 348:

1 : Oct. 24 2008 NOTE: When install

- Page 349 and 350:

H. Paper feed section ✕: Check (C

- Page 351 and 352:

I. Paper transport section ✕: Che

- Page 353 and 354:

1) Clean the paper exit roller 2 (D

- Page 355 and 356:

L. Scanner section ✕: Check (Clea

- Page 357 and 358:

1) Open the paper feed unit. 2) Rem

- Page 359 and 360:

1) Open the upper door. Remove the

- Page 361 and 362:

16) Remove the connector from the D

- Page 363 and 364:

3. Maintenance and disassembly A. M

- Page 365 and 366:

(1) Firmware update procedure from

- Page 367 and 368:

D. Emergency update (incase of an H

- Page 369 and 370:

1 1 : Oct. 24 2008 (2) MX-4100N/500

- Page 371 and 372:

C. PCU PWB (1) MX-4101N/4100N FAN P

- Page 373 and 374:

D. Scanner control PWB INV PWB 8.5

- Page 375 and 376:

F. Serial communication RxD[1] P.U.

- Page 377 and 378:

1 1 : Oct. 24 2008 (2) MX-5001N/500

- Page 379 and 380:

1 1 : Oct. 24 2008 (2) MX-5001N/500

- Page 381 and 382:

1 1 : Oct. 24 2008 J. DC power line

- Page 383 and 384:

(2) DSPF CNT PWB section 2/2 SPPD2

- Page 385 and 386:

B. RSPF 179228-3(BLACK) RSPF DRIVER

- Page 387 and 388:

(2) Front section (P2) INTCNT DSW-R

- Page 389 and 390:

1 1 : Oct. 24 2008 b. Fusing unit s

- Page 391 and 392:

(5) Process drive unit section 1/2

- Page 393 and 394:

(7) DL and DV section (P7) PCU PWB

- Page 395 and 396:

(9) Paper feed unit section (P9) PH

- Page 397 and 398:

(11) PS unit and Process control un

- Page 399 and 400:

(13) Paper exit unit section (P13)

- Page 401 and 402:

(15) DESK and LCC (P15) (DC main ha

- Page 403 and 404:

MX-5001N ELECTRICAL SECTION 10 - 36

- Page 405 and 406:

(19) FAX section (P19) MFP PWB CN18

- Page 407 and 408:

(21) USB section (P21) KEY PWB SRA-

- Page 409 and 410:

Signal name CSS12 Tray 1 paper size

- Page 411 and 412:

Signal name POFM_ LD2 Name [Type] F

- Page 413 and 414:

[11] OTHERS MX-5001N Item 1. Syst

- Page 415 and 416:

Item Factory default setting Setti

- Page 417 and 418:

Item Factory default setting ◆ Le

- Page 419 and 420:

3. MFP substrate replacement proced

- Page 421 and 422:

(4) Upper cabinet right/Upper cabin

- Page 423 and 424:

MX-5001N [B] OPERATION PANEL 1. El

- Page 425 and 426:

3) Remove the screw, remove the ear

- Page 427 and 428:

MX-5001N [C] DSPF SECTION 1. Elect

- Page 429 and 430:

D. Optical section E. Peper exit se

- Page 431 and 432:

3. Disassembly and assembly A. DSPF

- Page 433 and 434:

1) Remove the front cabinet. 2) Rem

- Page 435 and 436:

(3) DSPF No.2 resist roller clutch

- Page 437 and 438:

(1) DSPF transport motor 1) Remove

- Page 439 and 440:

MX-5001N [D] RSPF SECTION 1. Elect

- Page 441 and 442:

B. Paper feed transport operation (

- Page 443 and 444:

11) Resist operation (First sheet b

- Page 445 and 446:

7) Stop at the stamping position/St

- Page 447 and 448:

(1) SPF document with sensor 1) Rem

- Page 449 and 450:

D. Reversing section Parts a Docume

- Page 451 and 452:

MX-5001N [E] SCANNER SECTION 1. El

- Page 453 and 454:

3. Disassembly and assembly A. Scan

- Page 455 and 456:

(5) Document detection light emitti

- Page 457 and 458:

Signal name Name Function/Operation

- Page 459 and 460:

Signal name Name Function/Operation

- Page 461 and 462:

3) Remove the lock block. Disengage

- Page 463 and 464:

6) Remove the MF upper base paper g

- Page 465 and 466:

MX-5001N [G] PAPER TRANSPORT SECTIO

- Page 467 and 468:

MX-5001N [H] LSU SECTION 1. Electr

- Page 469 and 470:

1 : Oct. 24 2008 (Writing position

- Page 471 and 472:

B. Others Parts a LSU shutter solen

- Page 473 and 474:

Signal name Name Function/Operation

- Page 475 and 476:

1 1 : Oct. 24 2008 Signal name Name

- Page 477 and 478:

5) Pinch the knob and remove the de

- Page 479 and 480:

2. Operational descriptions When th

- Page 481 and 482:

Signal name Name Function/Operation

- Page 483 and 484:

MX-5001N [L] TRANSFER SECTION 1. E

- Page 485 and 486:

2. Operational descriptions A. Tran

- Page 487 and 488:

5) Hold the specified position, and

- Page 489 and 490:

Signal name Name Function/Operation

- Page 491 and 492:

(1) Upper thermostat 1) Remove the

- Page 493 and 494:

1 : Oct. 24 2008 NOTE: When install

- Page 495 and 496:

Signal name Name Function/Operation

- Page 497 and 498:

2. Operational descriptions A. Dupl

- Page 499 and 500:

B. Paper exit unit c Unit Parts (1)

- Page 501 and 502:

1 1 1 : Oct. 24 2008 [O] DRIVE SECT

- Page 503 and 504:

1 1 1 1 : Oct. 24 2008 (7) C drum m

- Page 505 and 506:

5) Disconnect the connector, and re

- Page 507 and 508:

[P] PWB SECTION MX-5001N A. Contr

- Page 509 and 510:

c) Raise the memory PWB until the c

- Page 511 and 512:

3) Remove the screw and disconnect

- Page 513 and 514:

(6) Primary transfer PWB 1) Remove

- Page 515 and 516:

4) Disconnect the connector and rem

- Page 517 and 518:

[R] SENSOR/SWITCH SECTION MX-5001N

- Page 519 and 520:

Memo

- Page 521 and 522:

Memo

- Page 523 and 524:

CAUTION FOR BATTERY REPLACEMENT (Da