Doosan Gas Turbines-0402

Doosan Gas Turbines-0402

Doosan Gas Turbines-0402

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

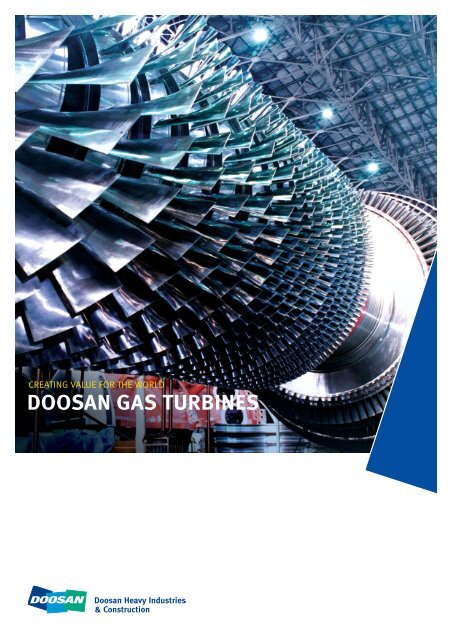

CREATING VALUE FOR THE WORLD<br />

DOOSAN GAS TURBINES

DOOSAN HEAVY INDUSTRIES & CONSTRUCTION<br />

GLOBAL LEADER IN POWER & WATER<br />

<strong>Gas</strong> turbines from <strong>Doosan</strong> have earned global trust for technological advance and performance.<br />

The company has taken on the challenge of developing the industry’s very best gas technology<br />

and know-how for gas turbines, an important source of power that moves the world.<br />

The challenging spirit of <strong>Doosan</strong> is timeless.

CONTENTS<br />

DOOSAN GAS TURBINES<br />

INTRODUCTION 04<br />

GAS TURBINE ADVANTAGES AND APPLICATION 06<br />

SIMPLE CYCLE PERFORMANCE 07<br />

COMBINED CYCLE PERFORMANCE 07<br />

M501F/M701F GAS TURBINE 08<br />

M501G GAS TURBINE 10<br />

M701 GAS TURBINE 12<br />

CASINGS / ROTOR ASSEMBLY 14<br />

COMPRESSOR / TURBINE 15<br />

COMBUSTION SYSTEM / COOLING SYSTEM<br />

CONTROL SYSTEM / TYPICAL GAS TURBINE<br />

16<br />

CONTROL SYSTEM CONFIGURATION 17<br />

SYSTEM DEVICES 18<br />

03

DOOSAN GAS TURBINES<br />

INTRODUCTION<br />

FUJAIRHA Power and Desalination Plant

<strong>Doosan</strong> <strong>Gas</strong> Turbine<br />

DOOSAN HEAVY INDUSTRIES & CONSTRUCTION<br />

It is well known that the <strong>Gas</strong> Turbine has played a leading role in power generation<br />

arising from its high performance, reliability, fuel flexibility, low emissions and its<br />

compactness etc.<br />

Furthermore the <strong>Gas</strong> Turbine stands in a highlighted state of the art technology<br />

with high efficient continuous operation (covering base load operation) as well as<br />

peak load operation.<br />

<strong>Doosan</strong> is capable of producing the heavy duty <strong>Gas</strong> Turbine models of M501G,<br />

M501F, M701F and M701 under Technology License Agreement with Mitsubishi<br />

Heavy Industries.Ltd.<br />

<strong>Doosan</strong> has executed Yeongwol Combined Cycle Power Plant in South Korea by<br />

applying M501F <strong>Gas</strong> Turbine. And also <strong>Doosan</strong> has manufactured full assembled<br />

M501G <strong>Gas</strong> Turbine by Long Term Sourcing Agreement with MHI in <strong>Doosan</strong><br />

Changwon Plant.<br />

<strong>Doosan</strong> Heavy Industries & Construction “Changwon Plant”<br />

05

DOOSAN GAS TURBINES<br />

GAS TURBINE ADVANTAGES<br />

AND APPLICATION<br />

<strong>Gas</strong> Turbine Advantages and Application<br />

Low investment cost<br />

Short installation time<br />

High efficiency<br />

Fuel flexibility<br />

Meet emission requirement<br />

High reliability<br />

Operational flexibility<br />

Application<br />

Simple Cycle<br />

Congeneration<br />

Integrated <strong>Gas</strong>ification<br />

Combined Cycle<br />

Combined Cycle<br />

Mechannical Drive

DOOSAN HEAVY INDUSTRIES & CONSTRUCTION<br />

SIMPLE CYCLE PERFORMANCE /<br />

COMBINED CYCLE PERFORMANCE<br />

Simple Cycle Performance<br />

Description<br />

60Hz (3600rpm)<br />

M501F M501G<br />

50Hz (3000rpm)<br />

M701 M701F<br />

Output, MW @ISO 185 267 144 278<br />

<strong>Gas</strong> Turbine Heat Rate, Btu/kWh 9230 8730 9810 8810<br />

Electrical Efficency, % 37.0 39.1 34.8 38.7<br />

No.of Stage<br />

DPCP1(M701)<br />

DPCP2(M701)<br />

DPCP3(M701)<br />

DPCP1(M701F)<br />

DPCP2(M701F)<br />

DPCP1(M501F)<br />

DPCP2(M501F)<br />

DPCP1(M501G)<br />

DPCP2(M501G)<br />

Compressor 16 17 19 17<br />

Turbine 4 4 4 4<br />

Pressure Ratio 16 20 14 17<br />

Exhaust Temp, ℃ 613 600 542 592<br />

Exhaust <strong>Gas</strong> Flow, kg/s 459 599 441 650<br />

No.of Combustor 16 16 18 20<br />

NOTE. 1. PERFORMANCE ARE THE POWER RATINGS AT THE GENERATOR TERMINALS AND ARE BASED ON THE USE OF NATURAL GAS FUEL WITH STANDARD INLET AND<br />

EXHAUST DUCT LOSSES.<br />

Combined Cycle Performance<br />

Model<br />

Net Plant Net Plant Heat Rate GTG STG Number & Type<br />

Output Efficiency (kJ/kWh) Power Power <strong>Gas</strong> Turbine<br />

212,500 kW<br />

426,600 kW<br />

645,000 kW<br />

416,400 kW<br />

835,600 kW<br />

285,100 kW<br />

572,200 kW<br />

398,900 kW<br />

800,500 kW<br />

51.4 %<br />

51.6 %<br />

51.8 %<br />

59.0 %<br />

59.2 %<br />

57.1 %<br />

57.3 %<br />

58.4 %<br />

58.6 %<br />

7,000<br />

6,974<br />

6,947<br />

6,120<br />

6,082<br />

6,305<br />

6,283<br />

6,165<br />

6,144<br />

142,100 kW<br />

284,200 kW<br />

426,300 kW<br />

273,800 kW<br />

547,600 kW<br />

182,700 kW<br />

365,400 kW<br />

264,400 kW<br />

528,800 kW<br />

NOTE. 1. ALL RATINGS ARE BASED ON ISO CONDITIONS.<br />

2. ALL RATINGS ARE BASED ON THE USE OF NATURAL GAS FUEL AT THE GENERATOR TERMINALS.<br />

70,400 kW<br />

142,400 kW<br />

218,700 kW<br />

142,600 kW<br />

288,000 kW<br />

102,400 kW<br />

206,800 kW<br />

134,500 kW<br />

271,700 kW<br />

1 x M701<br />

2 x M701<br />

3 x M701<br />

1 x M701F<br />

2 x M701F<br />

1 x M501F<br />

2 x M501F<br />

1 x M501G<br />

2 x M501G<br />

07

DOOSAN GAS TURBINES<br />

M501F/M701F GAS TURBINE<br />

MULTI-STAGE AXIAL-FLOW AIR COMPRESSOR FEATURING<br />

Variable inlet guide vanes.<br />

Horizontally split casing giving access to internal parts.<br />

Compressor blade rings.<br />

Individually removable stainless steel blading.<br />

Accessible pressure-lubricater, pivoted-pad journal bearing.<br />

Tilting-pad type thrust bearing.<br />

Cold end drive with solid coupling to generator.<br />

COMBUSTION SYSTEM INCLUDING THE FOLLOWING<br />

Multiple can-type combustors in a circular array.<br />

Combustors removable with insulated cylinder cover in place.<br />

Low emissions design.<br />

Optional multiple fuels capability.<br />

Ignition system including retractable igniters.<br />

#2 Journal Bearing<br />

Thrust Bearing<br />

FOUR-STAGE REACTION TYPE TURBINE FEATURING<br />

Advanced cooling technology.<br />

Horizontally split casing giving access to internal parts.<br />

Alloy turbine blades individually removable.<br />

Cooled by air cooler with cooling air filtered.<br />

Individual first stage vanes removable with cylinder cover in place.<br />

Accessible pressure-lubricated, pivoted-pad journal bearing.<br />

Low loss axial exhaust system ideal for waste heat applications.<br />

Compressor Disk<br />

Inlet Guide Vane<br />

Compressor Stationary Blade<br />

Compressor Rotor Blade

Combustor Basket<br />

Transition Piece<br />

Bypass Valve<br />

Turbine Vane<br />

Turbine Blade<br />

Turbine Disk<br />

Trunnion Support<br />

Tangential Strut<br />

#1 Journal Bearing<br />

DOOSAN HEAVY INDUSTRIES & CONSTRUCTION<br />

Model M701F<br />

Model M501F<br />

09

DOOSAN GAS TURBINES<br />

M501G GAS TURBINE<br />

The M501G include a host of long-proven MHI design elements. These<br />

include two-bearing rotor support, cold-end drive with axial exhaust,<br />

tangential exhaust bearing strut support, field-removable blades with<br />

the rotor in position, rotor cooling air taken offboard from the<br />

compressor and cooled prior to reentry into the turbine, and horizontally<br />

split casings throughout. A M501G during assembly. Blades can be changed and the rotor balanced in site.<br />

Thrust Bearing<br />

Inlet Guide Vane<br />

#2 Journal Bearing<br />

Compressor Stationary Vane<br />

Compressor Rotor Blade<br />

Combustor Swirler Assembly<br />

Compressor Disk

Combustor Liner<br />

Bypass Valve<br />

Turbine Disk<br />

Turbine Vane<br />

Turbine Blade<br />

Turbine Support<br />

Tangential Strut<br />

#1 Journal Bearing<br />

DOOSAN HEAVY INDUSTRIES & CONSTRUCTION<br />

Model M501G<br />

11

DOOSAN GAS TURBINES<br />

M701 GAS TURBINE<br />

MULTI-STAGE AXIAL-FLOW AIR COMPRESSOR<br />

Variable inlet guide vanes.<br />

Horizontally split casing giving access to internal parts.<br />

Individually removable stainless steel blading.<br />

Accessible pressure-lubricated, pivoted-pad journal bearing.<br />

Double acting thrust bearing.<br />

Cold-end drive with solid coupling to generatir.<br />

COMBUSTION SYSTEM INCLUDING THE FOLLOWING<br />

Cannular-type combustors in circular array.<br />

Low exhaust emissions level.<br />

Optional multiple fuels capability.<br />

Ignition system with retractable ignitors.<br />

Thrust Bearing<br />

FOUR-STAGE REACTION-TYPE TURBINE FEATURING<br />

Horizontally split casing giving access to internal parts.<br />

Alloy turbine blades individually removable.<br />

Cooled by air cooler, whth cooling air filtered.<br />

Individual first-stage vanes removable with cylinder cover in place.<br />

Accessible pressure-lubricated, pivoted-pad journal bearing.<br />

Low loss axial-exhaust system ideal for waste heat application.<br />

Tangential exhaust casing struts to maintain rotor alignment.<br />

Journal Bearing<br />

Compressor<br />

Combustor

Turbine<br />

Journal Bearing<br />

DOOSAN HEAVY INDUSTRIES & CONSTRUCTION<br />

Model M701D<br />

13

DOOSAN GAS TURBINES<br />

CASINGS /<br />

ROTOR ASSEMBLY<br />

Casings<br />

All engine casings are horizontally split to facilitate maintenance with the rotor in place. Individual inner casings (blade<br />

rings) are used for each turbine stationary stage and can be readily replaced or serviced with the rotor in place. Similar<br />

blade rings have been added in the compressor seventh stage through last stage.<br />

The aft-end bearing housing is supported by six tangential struts. Airfoil support the inner and outer-diffuser cones.<br />

Tangential struts maintain alignment of the bearing housing by rotating it as required to accommodate thermal expansion.<br />

Rotor Assembly<br />

3D modeling for Turbine Cylinder<br />

Compressor Combustor Cylinder<br />

Similar to all past 501/701 series designs, the single rotor is made up of the compressor and turbine components. The<br />

M501/M701 rotor is a bolted construction supported by two tilting-pad bearings. The thrust bearing is a tilting pad type.<br />

The compressor rotor is comprised of a number of elements that are spigotted and bolted together by twelve through bolts.<br />

Rotor Disc manufacturing by applying Curvic & Broaching Machine

COMPRESSOR /<br />

TURBINE<br />

Compressor<br />

Turbine<br />

DOOSAN HEAVY INDUSTRIES & CONSTRUCTION<br />

The compressor blade path is designed using a three-dimensional flow-field analysis computer program. Rotor blades are<br />

double circular arc designs in the first four stages. Stationary blading, fabricated into two 180。diaphragms per stage for<br />

easy removal, maintains the highly efficient inner-shroud sealing system.<br />

These seals are supported by machined seal rings, which can be removed to facilitate inspection and maintenance of<br />

shrouds and seals.<br />

The turbine design of the M501/M701 maintains moderate aero-dynamic loadings in spite of the increased inlet<br />

temperature by choosing a 4-stage turbine. Furthermore, improvements in aero-dynamic airfoil shapes have been made<br />

possible by utilization of a fully three dimensional flow analysis computer code. The first and second stages on the turbine<br />

rotor are the free-standing type. The third and fourth stages use integral shrouds.<br />

Each row of vane segments is supported in a separate blade ring, which is keyed and supported to permit radial and axial<br />

thermal response independent of possible external cylinder distortions.<br />

Turbine Blade<br />

5 axle High Speed Milling Machine<br />

Turbine Vane<br />

15

DOOSAN GAS TURBINES<br />

COMBUSTION SYSTEM /<br />

COOLING SYSTEM<br />

Combustion System<br />

The M501/M701 combustion system consists of 16 and 20 can-annular combustors, respectively. The combustion system is<br />

a dual-fuel (natural gas and No. 2 distillate oil) system, which has provisions for steam or water injection for emissions control<br />

and power augmentation. A new premix lean-burn hybrid combustor is to be applied to meet the existing and new NOx<br />

emission limitations around the world. The hybrid combustor features a two-stage burner assembly and a bypass valve which<br />

directs a portion of the compressor delivery air directly into the transition piece to enhance flame stability during starting and<br />

to maintain desired fuel/air ratio during loading. This unique valving system then is modulated to full closed at full load.<br />

“F” TYPE<br />

COMBUSTOR<br />

“G” TYPE<br />

COMBUSTOR<br />

Cooling System TURBINE ROTOR COOLING<br />

The cooling circuits for the turbine section connsist of a rotor cooling<br />

circuit and four stationary cooling circuits. Rotor cooling air is provided<br />

by compressor discharge air extracted from the combustor shell.<br />

Direct compressor discharge air is used to cool the row 1 vane.<br />

Compressor bleed air from HP, IP and LP stages are used to provide<br />

cooling air to turbine blade ring cavities at stages 2, 3, and 4<br />

respectively. This suppply of bleed air also cools the stage 2, 3, and 4<br />

vane segments and ring segments and provides cooling air for the<br />

turbine interstage disc cavities.<br />

#4 Stage<br />

#3 Stage<br />

#2 Stage<br />

Filiter Cooler<br />

Rotor Cooling<br />

ESR

DOOSAN HEAVY INDUSTRIES & CONSTRUCTION<br />

CONTROL SYSTEM / TYPICAL GAS TURBINE<br />

CONTROL SYSTEM CONFIGURATION<br />

Control System<br />

Operation of the M501/M701 gas turbine and its combined cycle plant is supported by Mitsubishi plant control system<br />

“DIASYS Series”. DIASYS Netmation is the latest gas turbine control system, which is Mitsubishi Heavy Industries’ total<br />

plant control system also. It is a product that unites state-of-the-art info-com technology, MHI’s rich experience as a plant<br />

manufacturer, and control technology for maximum satisfaction of such customer demands as high reliability, economy,<br />

advanced automation, and easy maintenance.<br />

Typical <strong>Gas</strong> Turbine Control System Configuration<br />

1<br />

2<br />

Site OPS(Operator Station)<br />

Human I/F for monitoring & Ope.<br />

Graphic, Trend, Alarm<br />

Control Plate<br />

Control Logic Monitoring<br />

MPS(Multiple Process Station)<br />

I/O processing to the field<br />

Control logic Execution<br />

Short term data preservation<br />

Unit Network<br />

100M-Ethernet<br />

4<br />

Internet<br />

Firewall<br />

EMS(Eng. & Maint. Station)<br />

Maintenance of whole system<br />

by DIASYS-IDOL++<br />

System configuration<br />

HMI setting<br />

Graphic creation<br />

Object data base modification<br />

Drawing management<br />

3<br />

5<br />

Browser OPS<br />

Internet based CRT operation<br />

Graphic, Trend, Alarm<br />

Control Plate<br />

Control Logic Monitoring<br />

ACS(Accessory Station)<br />

Data store & management,<br />

and Web server, Gateway<br />

Reports, Trip log, Event log,<br />

Ope. Action log, Flight<br />

Recorder<br />

17

DOOSAN GAS TURBINES<br />

SYSTEM DEVICES<br />

■ MULTIPLE PROCESS STATION(MPS)<br />

The Multiple Process Station used to perform<br />

automatic turbine Control by I/O processing. It<br />

features advanced arithmetic processing<br />

capabilities that enable it to support a wide range<br />

of applications that require high-speed processing,<br />

such as turbine governor control as well as<br />

automatic plant start/stop control.<br />

■ OPERATOR STATION(OPS)<br />

Operator station is a human-machine interface for<br />

monitoring and operating a plant. Adoption of the<br />

latest, most powerful, Windows XP based PCs<br />

enables plant operator personnel to perform power<br />

plant operations and monitoring with a minimal use<br />

of time. Moreover, since screen configuration<br />

elements have been implemented as components<br />

based on Microsoft’s Active X component<br />

technology, users can customize the OPS by<br />

themselves.<br />

■ ENGINEERING MAINTENANCE STATION(EMS)<br />

Engineering Maintenance Station is an engineering<br />

tool for performing maintenance of control system.<br />

EMS provides the functions to perform a host of<br />

operations, modification and creation of control<br />

logic on Multiple Process Stations, design of<br />

graphic displays, trends and control loop plates on<br />

Operator Stations, and configuration of GT Control<br />

systems. These operations are performed using<br />

software named DIASYS-IDOL++. DIASYS-IDOL++<br />

eliminates the need for burdensome programming<br />

of a must of control and arithmetic processing.

GLOBAL NETWORK<br />

Overseas Branches<br />

DOOSAN HEAVY INDUSTRIES<br />

AMERICA CORP.<br />

Parker Plaza, 10th Floor<br />

400 Kelby Street<br />

Fort Lee, NJ 07024, U.S.A.<br />

Tel 1-201-944-4554<br />

Fax 1-201-944-5022, 5053<br />

NEW JERSEY OFFICE<br />

Parker Plaza, 10th Floor<br />

400 Kelby Street<br />

Fort Lee, NJ 07024, U.S.A.<br />

Tel 1-201-944-4554<br />

Fax 1-201-944-5022, 5053<br />

PITTSBURGH OFFICE<br />

C/O Westinghouse Electric<br />

Company Room 2X18,<br />

Building F<br />

P.O. Box 158<br />

Madison, PA 15663 U.S.A.<br />

Tel 1-724-722-5215<br />

Fax 1-724-722-5668<br />

SCHENECTADY OFFICE<br />

General Electric Building 33, Room<br />

202A One River Road<br />

Schenectady, NY 12345, U.S.A.<br />

Tel 1-518-385-5218, 2629<br />

Fax 1-518-385-4984<br />

WINDSOR OFFICE<br />

20 International Drive<br />

Windsor, CT 06095, U.S.A.<br />

Tel 1-860-731-6479, 6482<br />

Fax 1-860-731-6478<br />

DOOSAN HEAVY INDUSTRIES<br />

JAPAN CORP.<br />

Mita Kokusai Building, Room 2410<br />

1-4-28, Mita, Minato-gu,<br />

Tokyo 108-0073, Japan<br />

Tel 81-3-3452-5451~3<br />

Fax 81-3-3452-5624<br />

BANGKOK OFFICE<br />

M-Thai Tower, 10th Floor<br />

All Seasons Place,<br />

87 Wireless Road<br />

Phatumwan, Bangkok 10330,<br />

Thailand<br />

Tel 66-2-654-0690, 2<br />

Fax 66-2-654-0693<br />

BEIJING OFFICE<br />

Gateway Plaza, Tower B, 19th Floor<br />

No. 18 Xiaguangli, North Road,<br />

East Third Ring, Chaoyang District,<br />

Beijing 100027, China<br />

Tel 86-10-8454-7131, 7133<br />

Fax 86-10-8484-7139<br />

HANOI OFFICE<br />

Daeha Business Center, #1101<br />

360 Kim Ma Street<br />

Ba Dinh District, Hanoi, Vietnam<br />

Tel 84-4-823-2501, 5<br />

Fax 84-4-843-2302<br />

HYDERABAD OFFICE<br />

White House, #119, Block 3<br />

6-3-1192/1/1, Kundan Bagh<br />

Begumpet<br />

Hyderabad 500 016, India<br />

Tel 91-40-6613-2444/5<br />

Fax 91-40-6613-2447<br />

KOLKATA OFFICE<br />

Trinity Building, 3G<br />

226/1 AJC Bose Road<br />

Kolkata 700 020, India<br />

Tel 91-33-4003-3018<br />

Fax 91-33-2289-0576<br />

MUMBAI OFFICE<br />

Maker Chambers-V, 1109~1110<br />

Nariman Point, Mumbai 400 021,<br />

India<br />

Tel 91-22-2202-6504<br />

Fax 91-22-2202-6557<br />

NEW DELHI OFFICE<br />

Lotus Towers 2A, Community Centre<br />

New Friends Colony<br />

New Delhi 110 065, India<br />

Tel 91-11-5132-8031<br />

Fax 91-11-5132-8039<br />

SHANGHAI OFFICE<br />

City Center of Shanghai,<br />

Room 2802, 100 Zunyi Road,<br />

Changning District<br />

Shanghai 200051, China<br />

Tel 86-21-6237-2485~6<br />

Fax 86-21-6237-2487<br />

TAIPEI OFFICE<br />

51 Keelung Road, Room 704<br />

Section 2, Taipei, Taiwan,<br />

R.O.C.<br />

Tel 886-2-2739-2255(ARS)<br />

Fax 886-2-2739-2266<br />

FRANKFURT OFFICE<br />

Arabella Center, 9th Floor<br />

Lyoner Strasse 44-48<br />

Frankfurt am Main 60528,<br />

Germany<br />

Tel 49-69-69-5004-0<br />

Fax 49-69-69-5004-10<br />

ABU DHABI OFFICE<br />

P.O. Box 27767<br />

Al Ghaith Tower, Suite 508<br />

Hamdan Street, Abu Dhabi,<br />

U.A.E.<br />

Tel 971-2-627-6273<br />

Fax 971-2-627-6274<br />

DUBAI OFFICE<br />

P.O. Box 11859<br />

Al Serkal Building, Office No. 308<br />

Airport Road, Dubai, U.A.E.<br />

Tel 971-4-294-4699<br />

Fax 971-4-294-9930<br />

KUWAIT OFFICE<br />

Villa 15, Street 24, Block 4<br />

Sabah Al-Salem Area, Kuwait<br />

Tel 965-551-8436<br />

Fax 965-551-8453<br />

RIYADH OFFICE<br />

P.O. Box 9656<br />

Riyadh 11423, Saudi Arabia<br />

Tel 966-1-419-1920, 1696<br />

Fax 966-1-419-1995<br />

TRIPOLI OFFICE<br />

P.O. Box No. 7780<br />

Tripoli, Libya<br />

Tel 218?21?360?8451<br />

Fax 218-21-361-0563<br />

DOOSAN WATER R&D CENTER<br />

Gold & Diamond Park<br />

Building No. 6, Office 112<br />

Sheikh Zayed Road<br />

P.O. Box 282350, Dubai, U.A.E.<br />

Tel 971-4-347-7051<br />

Fax 971-4-347-7142<br />

Overseas Subsidiaries<br />

DOOSAN BABCOCK ENERGY LTD.<br />

11 The Boulevard, Crawley<br />

West Sussex, RH10 1UX, U.K.<br />

Tel 44-1293-612-888<br />

Fax 44-1293-584-816<br />

DOOSAN HYDRO TECHNOLOGY, INC.<br />

912 Chad Lane Tampa, FL 33619 ,<br />

U.S.A.<br />

Tel 1-813-549-0182<br />

Fax 1-813-549-0183<br />

DOOSAN HF CONTROLS CORP.<br />

1624 West Crosby Road, Suite 124<br />

Carrollton, Texas 75006, U.S.A.<br />

Tel 1-469-568-6526, 6557<br />

Fax 1-469-568-6589<br />

DOOSAN IMGB<br />

104 Berceni Road Bucharest 4, Romania<br />

Tel 40-21-301-2602<br />

Fax 40-21-301-2701<br />

DOOSAN BABCOCK ENGINEERING &<br />

SERVICES INDIA PVT. LTD.<br />

DLF Building No. 8, 3rd Floor<br />

DLF Cyber City Phase II<br />

Gurgaon 122 002, Haryana, India<br />

Tel 91-124-439-8200<br />

Fax 91-124-414-7006<br />

DOOSAN PROJECTS INDIA PVT. LTD.<br />

322 Solitaire Corporate Park, Chakala<br />

Andheri Kurla Road, Andheri (East)<br />

Mumbai 400 093, India<br />

Tel 91-22-4097-0500<br />

Fax 91-22-4097-0599<br />

DOOSAN HEAVY INDUSTRIES<br />

VIETNAM CO., LTD. [DOOSAN VINA]<br />

No. 1 An Duong Vuong Street<br />

Quangngai City, Quangngai Province<br />

Vietnam<br />

Tel 84-55-713-001~7<br />

Fax 84-55-713-008<br />

HAN-VIET HEAVY INDUSTRY &<br />

CONSTRUCTION CORP. [HANVICO]<br />

933 Ton Duc Thang Street<br />

Hong Bang District, Hai Phong,<br />

Vietnam<br />

Tel 84-31-371-2720<br />

Fax 84-31-712-714~5<br />

CEYLON HEAVY INDUSTRIES &<br />

CONSTRUCTION CO., LTD. [CHICO]<br />

Oruwala Athurugiriya, Sri Lanka<br />

Tel 94-114-440031~2<br />

Fax 94-114-440030<br />

HANJUNG POWER LTD.<br />

P.O. Box 2803, Boroko, NCD<br />

Port Moresby, Papua New Guinea<br />

Tel 675-320-0529<br />

Fax 675-321-2984

<strong>Doosan</strong> Heavy Industries & Construction Co., Ltd. www.doosanheavy.com<br />

SEOUL OFFICE HEAD OFFICE AND CHANGWON PLANT<br />

1303-22, Seocho-Dong, Seocho-Gu. Seoul 137-920, 555, Guigok-dong, Changwon,<br />

Korea (C.P.O Box 1826, Seoul Korea) Gyeongsangnam-do, 641-792, Korea<br />

Tel. 82-2-513-6114, Fax. 82-2-513-6200 Tel. 82-55-278-6114, 7114 Fax. 82-55-264-5551,5552