Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

FUNCTION OF TOOL FEATURES FOR TURNING<br />

<strong>TECHNICAL</strong><br />

<strong>DATA</strong><br />

G014<br />

<strong>TECHNICAL</strong> <strong>DATA</strong><br />

FUNCTION OF TOOL FEATURES<br />

FOR TURNING<br />

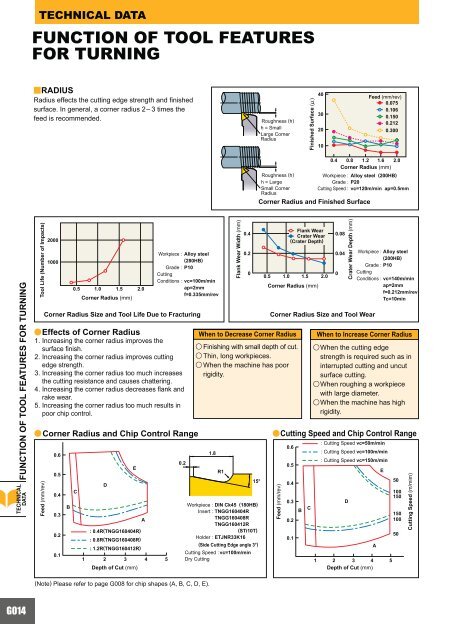

yRADIUS<br />

Radius effects the cutting edge strength and finished<br />

surface. In general, a corner radius 2– 3 times the<br />

feed is recommended.<br />

Tool Life (Number of Impacts)<br />

2000<br />

1000<br />

0.6<br />

0.5<br />

0.4<br />

0.3<br />

0.2<br />

0.1<br />

B<br />

0.5 1.0 1.5 2.0<br />

aEffects<br />

of Corner Radius<br />

1. Increasing the corner radius improves the<br />

surface finish.<br />

2. Increasing the corner radius improves cutting<br />

edge strength.<br />

3. Increasing the corner radius too much increases<br />

the cutting resistance and causes chattering.<br />

4. Increasing the corner radius decreases flank and<br />

rake wear.<br />

5. Increasing the corner radius too much results in<br />

poor chip control.<br />

C<br />

Corner Radius (mm)<br />

D<br />

: 0.4R(TNGG160404R)<br />

: 0.8R(TNGG160408R)<br />

: 1.2R(TNGG160412R)<br />

1 2 3 4 5<br />

E<br />

A<br />

Workpiece :<br />

Grade :<br />

Cutting<br />

Conditions :<br />

0.2<br />

Alloy steel<br />

(280HB)<br />

P10<br />

Corner Radius Size and Tool Life Due to Fracturing<br />

vc=100m/min<br />

ap=2mm<br />

f=0.335mm/rev<br />

1.8<br />

R1<br />

40<br />

30<br />

20<br />

10<br />

Flank Wear<br />

0.4<br />

Crater Wear<br />

0.08<br />

(Crater Depth)<br />

0.2<br />

Workpiece : DIN Ck45 (180HB)<br />

Insert : TNGG160404R<br />

TNGG160408R<br />

TNGG160412R<br />

(STi10T)<br />

Holder : ETJNR33K16<br />

0<br />

15°<br />

Roughness (h)<br />

h = Small<br />

Large Corner<br />

Radius<br />

Roughness (h)<br />

h = Large<br />

Small Corner<br />

Radius<br />

0.5 1.0 1.5 2.0<br />

Corner Radius (mm)<br />

0.6<br />

0.5<br />

0.4<br />

0.3<br />

0.2<br />

0.1<br />

B C<br />

Feed (mm/rev)<br />

0.075<br />

0.106<br />

0.150<br />

0.212<br />

0.300<br />

0.4 0.8 1.2 1.6 2.0<br />

Corner Radius (mm)<br />

Corner Radius and Finished Surface<br />

aCorner Radius and Chip Control Range<br />

aCutting<br />

Speed and Chip Control Range<br />

Feed (mm/rev)<br />

Depth of Cut (mm)<br />

(Note) Please refer to page G008 for chip shapes (A, B, C, D, E).<br />

Flank Wear Width (mm)<br />

When to Decrease Corner Radius<br />

u Finishing with small depth of cut.<br />

u Thin, long workpieces.<br />

u When the machine has poor<br />

rigidity.<br />

(Side Cutting Edge angle 3°)<br />

Cutting Speed : vc=100m/min<br />

Dry Cutting<br />

Finished Surface (!)<br />

Workpiece : Alloy steel (200HB)<br />

Grade : P20<br />

Cutting Speed : vc=120m/min ap=0.5mm<br />

0.04<br />

0<br />

Crater Wear Depth (mm)<br />

Corner Radius Size and Tool Wear<br />

Feed (mm/rev)<br />

D<br />

Workpiece : Alloy steel<br />

(200HB)<br />

Grade : P10<br />

Cutting<br />

Conditions : vc=140m/min<br />

ap=2mm<br />

f=0.212mm/rev<br />

Tc=10min<br />

When to Increase Corner Radius<br />

uWhen<br />

the cutting edge<br />

strength is required such as in<br />

interrupted cutting and uncut<br />

surface cutting.<br />

uWhen<br />

roughing a workpiece<br />

with large diameter.<br />

uWhen<br />

the machine has high<br />

rigidity.<br />

: Cutting Speed vc=50m/min<br />

: Cutting Speed vc=100m/min<br />

: Cutting Speed vc=150m/min<br />

1 2 3 4 5<br />

Depth of Cut (mm)<br />

A<br />

E<br />

50<br />

100<br />

150<br />

150<br />

100<br />

50<br />

Cutting Speed (m/mim)