Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

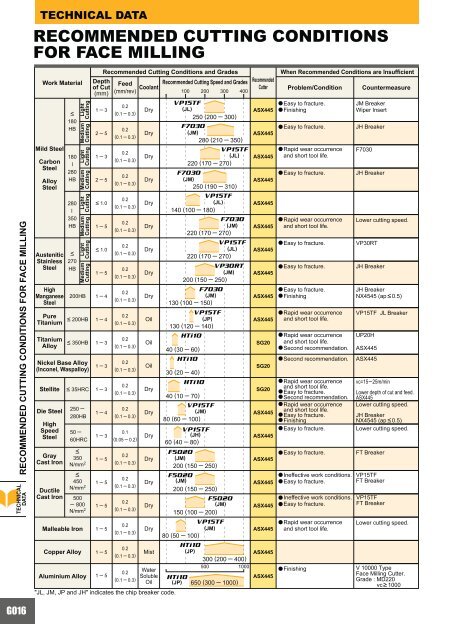

RECOMMENDED CUTTING CONDITIONS FOR FACE MILLING<br />

<strong>TECHNICAL</strong><br />

<strong>DATA</strong><br />

G016<br />

<strong>TECHNICAL</strong> <strong>DATA</strong><br />

RECOMMENDED CUTTING CONDITIONS<br />

FOR FACE MILLING<br />

Work Material<br />

Mild Steel<br />

Carbon<br />

Steel<br />

Alloy<br />

Steel<br />

Austenitic<br />

Stainless<br />

Steel<br />

High<br />

Manganese<br />

Steel<br />

Pure<br />

Titanium<br />

Titanium<br />

Alloy<br />

<<br />

180<br />

HB<br />

180<br />

<br />

280<br />

HB<br />

280<br />

<br />

350<br />

HB<br />

<<br />

270<br />

HB<br />

200HB<br />

< 200HB<br />

< 350HB<br />

Nickel Base Alloy<br />

(Inconel, Waspalloy)<br />

Stellite<br />

Die Steel<br />

High<br />

Speed<br />

Steel<br />

Gray<br />

Cast Iron<br />

Ductile<br />

Cast Iron<br />

< 35HRC<br />

250 <br />

280HB<br />

50 <br />

60HRC<br />

Malleable Iron<br />

Copper Alloy<br />

Light<br />

Cutting<br />

Medium<br />

Cutting<br />

Light<br />

Cutting<br />

Medium<br />

Cutting<br />

Light<br />

Cutting<br />

Medium<br />

Cutting<br />

Light<br />

Cutting<br />

Medium<br />

Cutting<br />

<<br />

350<br />

N/mm 2<br />

<<br />

450<br />

N/mm 2<br />

500<br />

800<br />

N/mm 2<br />

Aluminium Alloy<br />

Recommended Cutting Conditions and Grades When Recommended Conditions are Insufficient<br />

Depth<br />

of Cut<br />

(mm)<br />

Feed<br />

Coolant<br />

(mm/rev)<br />

Recommended Cutting Speed and Grades<br />

100 200 300 400<br />

Recommended<br />

Cutter Problem/Condition Countermeasure<br />

1 3<br />

2 5<br />

1 3<br />

2 5<br />

< 1.0<br />

1 5<br />

< 1.0<br />

1 5<br />

1 4<br />

1 4<br />

1 3<br />

1 3<br />

1 3<br />

1 4<br />

1 3<br />

1 5<br />

1 5<br />

1 5<br />

1 5<br />

1 5<br />

1 5<br />

0.2<br />

(0.1 0.3)<br />

0.2<br />

(0.1 0.3)<br />

0.2<br />

(0.1 0.3)<br />

0.2<br />

(0.1 0.3)<br />

0.2<br />

(0.1 0.3)<br />

0.2<br />

(0.1 0.3)<br />

0.2<br />

(0.1 0.3)<br />

0.2<br />

(0.1 0.3)<br />

0.2<br />

(0.1 0.3)<br />

0.2<br />

(0.1 0.3)<br />

0.2<br />

(0.1 0.3)<br />

0.2<br />

(0.1 0.3)<br />

0.2<br />

(0.1 0.3)<br />

0.2<br />

(0.1 0.3)<br />

0.1<br />

(0.05 0.2)<br />

0.2<br />

(0.1 0.3)<br />

0.2<br />

(0.1 0.3)<br />

0.2<br />

(0.1 0.3)<br />

0.2<br />

(0.1 0.3)<br />

0.2<br />

(0.1 0.3)<br />

0.2<br />

(0.1 0.3)<br />

Dry<br />

Dry<br />

Dry<br />

Dry<br />

Dry<br />

Dry<br />

Dry<br />

Dry<br />

Dry<br />

"JL, JM, JP and JH" indicates the chip breaker code.<br />

Oil<br />

Oil<br />

Oil<br />

Dry<br />

Dry<br />

Dry<br />

Dry<br />

Dry<br />

Dry<br />

Dry<br />

Mist<br />

Water<br />

Soluble<br />

Oil<br />

VP15TF<br />

(JL)<br />

250 (200 300)<br />

F7030<br />

(JM)<br />

280 (210 350)<br />

VP15TF<br />

(JL)<br />

220 (170 270)<br />

F7030<br />

(JM)<br />

250 (190 310)<br />

VP15TF<br />

(JL)<br />

140 (100 180)<br />

F7030<br />

(JM)<br />

220 (170 270)<br />

VP15TF<br />

(JL)<br />

220 (170 270)<br />

VP30RT<br />

(JM)<br />

200 (150 250)<br />

F7030<br />

(JM)<br />

130 (100 150)<br />

VP15TF<br />

(JP)<br />

130 (120 140)<br />

HTi10<br />

40 (30 60)<br />

HTi10<br />

30 (20 40)<br />

HTi10<br />

40 (10 70)<br />

VP15TF<br />

(JM)<br />

80 (60 100)<br />

VP15TF<br />

(JH)<br />

60 (40 80)<br />

F5020<br />

(JM)<br />

200 (150 250)<br />

F5020<br />

(JM)<br />

200 (150 250)<br />

F5020<br />

(JM)<br />

150 (100 200)<br />

VP15TF<br />

(JM)<br />

80 (50 100)<br />

HTi10<br />

(JP) 650 (300 1000)<br />

ASX445<br />

ASX445<br />

ASX445<br />

ASX445<br />

ASX445<br />

ASX445<br />

ASX445<br />

ASX445<br />

ASX445<br />

ASX445<br />

SG20<br />

SG20<br />

SG20<br />

ASX445<br />

ASX445<br />

ASX445<br />

ASX445<br />

ASX445<br />

ASX445<br />

HTi10<br />

(JP)<br />

ASX445<br />

300 (200 400)<br />

500 1000<br />

ASX445<br />

a Easy to fracture.<br />

a Finishing<br />

a Easy to fracture.<br />

a Rapid wear occurrence<br />

and short tool life.<br />

a Easy to fracture.<br />

a Rapid wear occurrence<br />

and short tool life.<br />

a Easy to fracture.<br />

a Easy to fracture.<br />

a Easy to fracture.<br />

a Finishing<br />

a Rapid wear occurrence<br />

and short tool life.<br />

a Rapid wear occurrence<br />

and short tool life.<br />

a Easy to fracture.<br />

a Second recommendation.<br />

a Rapid wear occurrence<br />

and short tool life.<br />

a Easy to fracture.<br />

a Finishing<br />

a Easy to fracture.<br />

a Easy to fracture.<br />

a Rapid wear occurrence<br />

and short tool life.<br />

a Finishing<br />

JM Breaker<br />

Wiper Insert<br />

JH Breaker<br />

F7030<br />

JH Breaker<br />

Lower cutting speed.<br />

VP30RT<br />

JH Breaker<br />

a Rapid wear occurrence<br />

and short tool life.<br />

UP20H<br />

a Second recommendation. ASX445<br />

a Second recommendation. ASX445<br />

JH Breaker<br />

NX4545 (ap