Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

FUNCTION OF TOOL FEATURES FOR FACE MILLING<br />

<strong>TECHNICAL</strong><br />

<strong>DATA</strong><br />

G018<br />

<strong>TECHNICAL</strong> <strong>DATA</strong><br />

FUNCTION OF TOOL FEATURES<br />

FOR FACE MILLING<br />

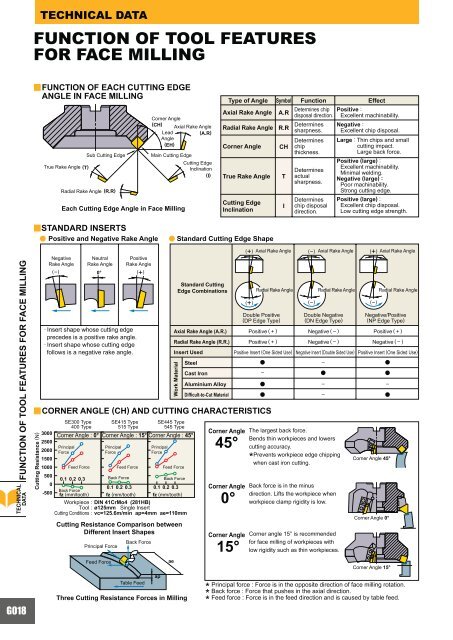

yFUNCTION<br />

OF EACH CUTTING EDGE<br />

ANGLE IN FACE MILLING<br />

Radial Rake Angle (R.R)<br />

Corner Angle<br />

(CH)<br />

Axial Rake Angle<br />

Lead<br />

(A.R)<br />

Angle<br />

(EH)<br />

Sub Cutting Edge Main Cutting Edge<br />

True Rake Angle (T)<br />

Cutting Edge<br />

Inclination<br />

(I)<br />

Each Cutting Edge Angle in Face Milling<br />

ySTANDARD<br />

INSERTS<br />

a Positive and Negative Rake Angle a Standard Cutting Edge Shape<br />

Negative<br />

Rake Angle<br />

Neutral<br />

Rake Angle<br />

(-) 0°<br />

(+ )<br />

· Insert shape whose cutting edge<br />

precedes is a positive rake angle.<br />

· Insert shape whose cutting edge<br />

follows is a negative rake angle.<br />

Positive<br />

Rake Angle<br />

yCORNER<br />

ANGLE (CH) AND CUTTING CHARACTERISTICS<br />

Cutting Resistance (N)<br />

SE300 Type<br />

400 Type<br />

SE415 Type<br />

515 Type<br />

ap<br />

ae<br />

Work Material<br />

Cutting Resistance Comparison between<br />

Different Insert Shapes<br />

Standard Cutting<br />

Edge Combinations<br />

Axial Rake Angle<br />

Radial Rake Angle<br />

Corner Angle<br />

True Rake Angle<br />

Cutting Edge<br />

Inclination<br />

45°<br />

0°<br />

15°<br />

Type of Angle Symbol Function Effect<br />

A.R<br />

R.R<br />

CH<br />

T<br />

I<br />

(+) Axial Rake Angle (-) Axial Rake Angle (+) Axial Rake Angle<br />

(+)<br />

Double Positive<br />

(DP Edge Type)<br />

(-)<br />

Double Negative<br />

(DN Edge Type)<br />

Positive (large) :<br />

Excellent machinability.<br />

Minimal welding.<br />

Negative (large) :<br />

Poor machinability.<br />

Strong cutting edge.<br />

Positive (large) :<br />

Excellent chip disposal.<br />

Low cutting edge strength.<br />

Radial Rake Angle Radial Rake Angle<br />

Radial Rake Angle<br />

(-)<br />

Negative/Positive<br />

(NP Edge Type)<br />

Axial Rake Angle (A.R.) Positive ( + ) Negative (–) Positive ( + )<br />

Radial Rake Angle (R.R.) Positive ( + ) Negative (–) Negative (–)<br />

Insert Used<br />

Positive Insert (One Sided Use) Negative Insert (Double Sided Use) Positive Insert (One Sided Use)<br />

Steel<br />

a – a<br />

Cast Iron<br />

– a a<br />

Aluminium Alloy<br />

a – –<br />

Difficult-to-Cut Material<br />

a – a<br />

SE445 Type<br />

545 Type<br />

3000<br />

2500<br />

Corner Angle : 0° Corner Angle : 15° Corner Angle : 45°<br />

2000<br />

1500<br />

Principal<br />

Force<br />

Principal<br />

Force<br />

Principal<br />

Force<br />

1000 Feed Force<br />

Feed Force<br />

Feed Force<br />

500<br />

0.1 0.2 0.3<br />

Back Force<br />

Back Force<br />

0<br />

-500<br />

Back Force<br />

fz (mm/tooth)<br />

0.1 0.2 0.3<br />

fz (mm/tooth)<br />

0.1 0.2 0.3<br />

fz (mm/tooth)<br />

Workpiece : DIN 41CrMo4 (281HB)<br />

Tool : ø125mm Single Insert<br />

Cutting Conditions : vc=125.6m/min ap=4mm ae=110mm<br />

Principal Force<br />

Feed Force<br />

Back Force<br />

Table Feed<br />

Three Cutting Resistance Forces in Milling<br />

Corner Angle<br />

Corner Angle<br />

Corner Angle<br />

Determines chip<br />

disposal direction.<br />

Determines<br />

sharpness.<br />

Determines<br />

chip<br />

thickness.<br />

Determines<br />

actual<br />

sharpness.<br />

Determines<br />

chip disposal<br />

direction.<br />

The largest back force.<br />

Bends thin workpieces and lowers<br />

cutting accuracy.<br />

* Prevents workpiece edge chipping<br />

when cast iron cutting.<br />

Back force is in the minus<br />

direction. Lifts the workpiece when<br />

workpiece clamp rigidity is low.<br />

Corner angle 15° is recommended<br />

for face milling of workpieces with<br />

low rigidity such as thin workpieces.<br />

Positive :<br />

Excellent machinability.<br />

Negative :<br />

Excellent chip disposal.<br />

Large : Thin chips and small<br />

cutting impact.<br />

Large back force.<br />

Corner Angle 45°<br />

Corner Angle 0°<br />

Corner Angle 15°<br />

* Principal force : Force is in the opposite direction of face milling rotation.<br />

* Back force : Force that pushes in the axial direction.<br />

* Feed force : Force is in the feed direction and is caused by table feed.