Kappa 180 V2 - Durst Phototechnik

Kappa 180 V2 - Durst Phototechnik

Kappa 180 V2 - Durst Phototechnik

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

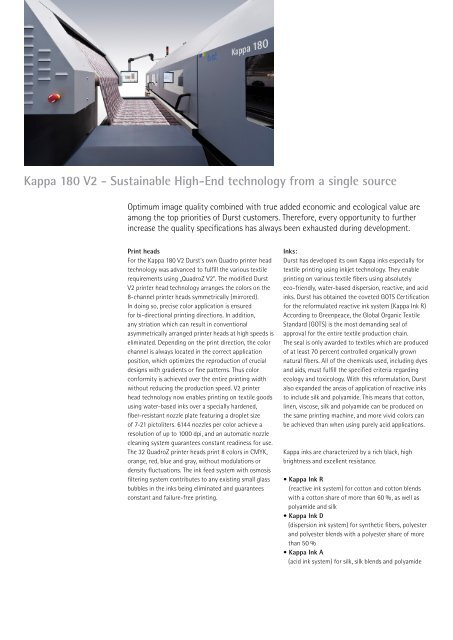

<strong>Kappa</strong> <strong>180</strong> <strong>V2</strong> - Sustainable High-End technology from a single source<br />

Optimum image quality combined with true added economic and ecological value are<br />

among the top priorities of <strong>Durst</strong> customers. Therefore, every opportunity to further<br />

increase the quality specifications has always been exhausted during development.<br />

Print heads<br />

For the <strong>Kappa</strong> <strong>180</strong> <strong>V2</strong> <strong>Durst</strong>‘s own Quadro printer head<br />

technology was advanced to fulfill the various textile<br />

requirements using „QuadroZ <strong>V2</strong>“. The modified <strong>Durst</strong><br />

<strong>V2</strong> printer head technology arranges the colors on the<br />

8-channel printer heads symmetrically (mirrored).<br />

In doing so, precise color application is ensured<br />

for bi-directional printing directions. In addition,<br />

any striation which can result in conventional<br />

asymmetrically arranged printer heads at high speeds is<br />

eliminated. Depending on the print direction, the color<br />

channel is always located in the correct application<br />

position, which optimizes the reproduction of crucial<br />

designs with gradients or fine patterns. Thus color<br />

conformity is achieved over the entire printing width<br />

without reducing the production speed. <strong>V2</strong> printer<br />

head technology now enables printing on textile goods<br />

using water-based inks over a specially hardened,<br />

fiber-resistant nozzle plate featuring a droplet size<br />

of 7-21 pictoliters. 6144 nozzles per color achieve a<br />

resolution of up to 1000 dpi, and an automatic nozzle<br />

cleaning system guarantees constant readiness for use.<br />

The 32 QuadroZ printer heads print 8 colors in CMYK,<br />

orange, red, blue and gray, without modulations or<br />

density fluctuations. The ink feed system with osmosis<br />

filtering system contributes to any existing small glass<br />

bubbles in the inks being eliminated and guarantees<br />

constant and failure-free printing.<br />

Inks:<br />

<strong>Durst</strong> has developed its own <strong>Kappa</strong> inks especially for<br />

textile printing using inkjet technology. They enable<br />

printing on various textile fibers using absolutely<br />

eco-friendly, water-based dispersion, reactive, and acid<br />

inks. <strong>Durst</strong> has obtained the coveted GOTS Certification<br />

for the reformulated reactive ink system (<strong>Kappa</strong> Ink R)<br />

According to Greenpeace, the Global Organic Textile<br />

Standard (GOTS) is the most demanding seal of<br />

approval for the entire textile production chain.<br />

The seal is only awarded to textiles which are produced<br />

of at least 70 percent controlled organically grown<br />

natural fibers. All of the chemicals used, including dyes<br />

and aids, must fulfill the specified criteria regarding<br />

ecology and toxicology. With this reformulation, <strong>Durst</strong><br />

also expanded the areas of application of reactive inks<br />

to include silk and polyamide. This means that cotton,<br />

linen, viscose, silk and polyamide can be produced on<br />

the same printing machine, and more vivid colors can<br />

be achieved than when using purely acid applications.<br />

<strong>Kappa</strong> inks are characterized by a rich black, high<br />

brightness and excellent resistance.<br />

• <strong>Kappa</strong> Ink R<br />

(reactive ink system) for cotton and cotton blends<br />

with a cotton share of more than 60 %, as well as<br />

polyamide and silk<br />

• <strong>Kappa</strong> Ink D<br />

(dispersion ink system) for synthetic fibers, polyester<br />

and polyester blends with a polyester share of more<br />

than 50 %<br />

• <strong>Kappa</strong> Ink A<br />

(acid ink system) for silk, silk blends and polyamide