Kappa 180 V2 - Durst Phototechnik

Kappa 180 V2 - Durst Phototechnik

Kappa 180 V2 - Durst Phototechnik

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

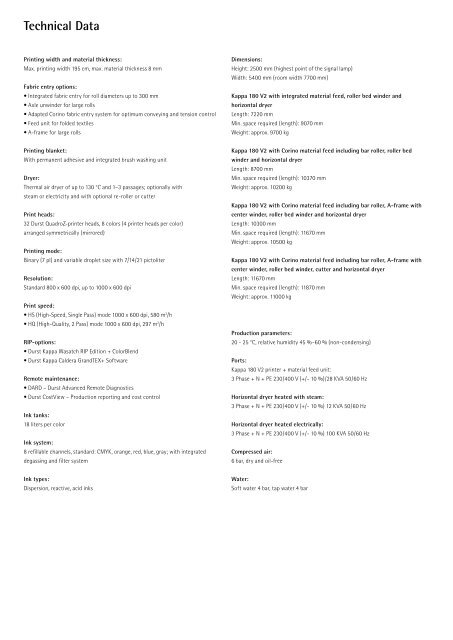

Technical Data<br />

Printing width and material thickness:<br />

Max. printing width 195 cm, max. material thickness 8 mm<br />

Fabric entry options:<br />

• Integrated fabric entry for roll diameters up to 300 mm<br />

• Axle unwinder for large rolls<br />

• Adapted Corino fabric entry system for optimum conveying and tension control<br />

• Feed unit for folded textiles<br />

• A-frame for large rolls<br />

Printing blanket:<br />

With permanent adhesive and integrated brush washing unit<br />

Dryer:<br />

Thermal air dryer of up to 130 °C and 1–3 passages; optionally with<br />

steam or electricity and with optional re-roller or cutter<br />

Print heads:<br />

32 <strong>Durst</strong> QuadroZ-printer heads, 8 colors (4 printer heads per color)<br />

arranged symmetrically (mirrored)<br />

Printing mode:<br />

Binary (7 pl) and variable droplet size with 7/14/21 pictoliter<br />

Resolution:<br />

Standard 800 x 600 dpi, up to 1000 x 600 dpi<br />

Print speed:<br />

• HS (High-Speed, Single Pass) mode 1000 x 600 dpi, 580 m2 /h<br />

• HQ (High-Quality, 2 Pass) mode 1000 x 600 dpi, 297 m2 /h<br />

RIP-options:<br />

• <strong>Durst</strong> <strong>Kappa</strong> Wasatch RIP Edition + ColorBlend<br />

• <strong>Durst</strong> <strong>Kappa</strong> Caldera GrandTEX+ Software<br />

Remote maintenance:<br />

• DARD – <strong>Durst</strong> Advanced Remote Diagnostics<br />

• <strong>Durst</strong> CostView – Production reporting and cost control<br />

Ink tanks:<br />

18 liters per color<br />

Ink system:<br />

8 refillable channels, standard: CMYK, orange, red, blue, gray; with integrated<br />

degassing and filter system<br />

Ink types:<br />

Dispersion, reactive, acid inks<br />

Dimensions:<br />

Height: 2500 mm (highest point of the signal lamp)<br />

Width: 5400 mm (room width 7700 mm)<br />

<strong>Kappa</strong> <strong>180</strong> <strong>V2</strong> with integrated material feed, roller bed winder and<br />

horizontal dryer<br />

Length: 7220 mm<br />

Min. space required (length): 9070 mm<br />

Weight: approx. 9700 kg<br />

<strong>Kappa</strong> <strong>180</strong> <strong>V2</strong> with Corino material feed including bar roller, roller bed<br />

winder and horizontal dryer<br />

Length: 8700 mm<br />

Min. space required (length): 10370 mm<br />

Weight: approx. 10200 kg<br />

<strong>Kappa</strong> <strong>180</strong> <strong>V2</strong> with Corino material feed including bar roller, A-frame with<br />

center winder, roller bed winder and horizontal dryer<br />

Length: 10300 mm<br />

Min. space required (length): 11670 mm<br />

Weight: approx. 10500 kg<br />

<strong>Kappa</strong> <strong>180</strong> <strong>V2</strong> with Corino material feed including bar roller, A-frame with<br />

center winder, roller bed winder, cutter and horizontal dryer<br />

Length: 11670 mm<br />

Min. space required (length): 11870 mm<br />

Weight: approx. 11000 kg<br />

Production parameters:<br />

20 - 25 °C, relative humidity 45 %-60 % (non-condensing)<br />

Ports:<br />

<strong>Kappa</strong> <strong>180</strong> <strong>V2</strong> printer + material feed unit:<br />

3 Phase + N + PE 230/400 V (+/- 10 %)/28 KVA 50/60 Hz<br />

Horizontal dryer heated with steam:<br />

3 Phase + N + PE 230/400 V (+/- 10 %) 12 KVA 50/60 Hz<br />

Horizontal dryer heated electrically:<br />

3 Phase + N + PE 230/400 V (+/- 10 %) 100 KVA 50/60 Hz<br />

Compressed air:<br />

6 bar, dry and oil-free<br />

Water:<br />

Soft water 4 bar, tap water 4 bar