WEILER DZ45/65: An ergonomic innovation

WEILER DZ45/65: An ergonomic innovation

WEILER DZ45/65: An ergonomic innovation

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

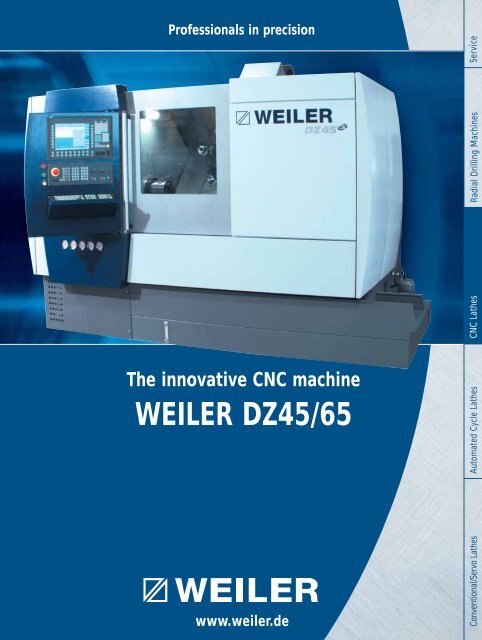

Professionals in precision<br />

The innovative CNC machine<br />

<strong>WEILER</strong> <strong>DZ45</strong>/<strong>65</strong><br />

www.weiler.de<br />

Service<br />

Conventional/Servo Lathes Automated Cycle Lathes CNC Lathes<br />

Radial Drilling Machines

<strong>WEILER</strong> <strong>DZ45</strong>/<strong>65</strong>: <strong>An</strong> <strong>ergonomic</strong> <strong>innovation</strong><br />

Leading edge design for easy<br />

handling and short set-up times<br />

Version T<br />

Working area<br />

Precision<br />

Rigid substructure filled with concrete<br />

Linear measuring scale on x-axis<br />

High quality, heavily ribbed grey cast iron bed<br />

ensures extreme rigidity<br />

Linear guides for the highest possible dynamics<br />

and precision<br />

Precisely borne work spindle<br />

High positioning accuracy<br />

High thermostability<br />

Productivity<br />

High rapid traverse speeds minimize<br />

non-productive times<br />

Short turret indexing times<br />

Fast start up through innovative drive concept<br />

Digital drive technology<br />

Dynamic and powerful axis and spindle drives<br />

High operational fail-safety<br />

• Working spindle lubricated for life<br />

• Fully automated centralized lubrication<br />

• Long service intervals<br />

• Spindle motor air/water cooled<br />

Electrically monitored safety interlocks<br />

on all axes<br />

Tailstock can be program driven along<br />

its own axis<br />

Fast clamping pressure adjustment through<br />

pressure regulating valves with integrated<br />

pressure switch setting

SIEMENS SINUMERIK 810D/840D Control<br />

12,1“ TFT flat panel screen<br />

Floppy disk drive<br />

CNC full-range keyboard<br />

PCU 50 module with 1 Gigabyte<br />

user memory<br />

Network interface to enable<br />

optional tele-diagnosis<br />

Operator Friendly<br />

Generously dimensioned sliding proctective cover<br />

ensures best possible access (easy-running,<br />

large safety glass window)<br />

Ergonomic operating controls with full-scale<br />

PC keyboard<br />

Removable coolant device<br />

Control with easy-to-use text editor and<br />

powerful contour processor<br />

Operating panel can be swivelled 90°<br />

Tool turret<br />

with Y-axis

Version H<br />

Working area<br />

Working area of version with<br />

tool turret version T<br />

106<br />

(110)<br />

160<br />

(200)<br />

145.5<br />

(160)<br />

150<br />

50.5<br />

Ø 25<br />

479<br />

(464)<br />

730<br />

(715)<br />

770<br />

70.5<br />

75<br />

15<br />

Diameter max. 560 mm<br />

135<br />

200<br />

7.5<br />

190<br />

SW 300<br />

160<br />

145.5<br />

155<br />

106<br />

160<br />

145.5<br />

260<br />

Version H working area with<br />

16 station turret and Y-axis<br />

15<br />

685<br />

476<br />

676<br />

796<br />

530<br />

60<br />

Diameter max. 560 mm<br />

120<br />

87<br />

Version H working<br />

area with subspindle<br />

and 16 station turret<br />

(DZ <strong>65</strong> dimensions<br />

in brackets)<br />

560<br />

45 Y-stroke<br />

35 Y-stroke<br />

45<br />

300<br />

Ø 300<br />

6/6

2200<br />

1130<br />

Dimensions<br />

1012<br />

R 660<br />

2900 2050<br />

3180<br />

454

Service<br />

Conventional/Servo Lathes Automated Cycle Lathes CNC Lathes<br />

Radial Drilling Machines<br />

<strong>DZ45</strong> CNC DZ<strong>65</strong> CNC<br />

Working Range T1 T2 T3 T4 H1 H2 H3 H4 H1 H2 H3 H4<br />

Maximum swing over bed mm 560 560 560 560 560 560 560 560 560 560 560 560<br />

Maximum travel X-axis mm 207.5 207.5 207.5 207.5 207.5 207.5 205 205 207.5 207.5 205 205<br />

Maximum travel Z-axis mm 530 530 530 530 530 530 525 525 530 530 525 525<br />

Turning diameter mm 240 240 240 240 240 240 240 240 240 240 240 240<br />

Main Drive Belt Drive Spindle Motor Spindle Motor<br />

Power at 100 %/60 % duty cycle kW 9/11 9/11 9/11 9/11 17/21.5 17/21.5 17/21.5 17/21.5 21/27 21/27 21/27 21/27<br />

Spindle speed range rpm 5-6000 5-6000 5-6000 5-6000 5-6000 5-6000 5-6000 5-6000 5-5000 5-5000 5-5000 5-5000<br />

Torque at main spindle Nm 57/70 57/70 57/70 57/70 100/128 100/128 100/128 100/128 200/260 200/260 200/260 200/260<br />

Main Spindle<br />

Spindle nose according<br />

to DIN 55026 size 5 5 5 5 5 5 5 5 6 6 6 6<br />

Chuck diameter mm 160 160 160 160 160 160 160 160 200 200 200 200<br />

Spindle bore mm 53 53 53 53 53 53 53 53 77 77 77 77<br />

Spindle diameter in front bearing mm 85 85 85 85 85 85 85 85 120 120 120 120<br />

Bare capacity in draw/thrust tube mm 42 42 42 42 42 42 42 42 66 66 66 66<br />

Feed Drive<br />

Feed force X/Z/Q, Q H-types only daN 340 340 340 340 530 530 530 530 530 530 530 530<br />

Rapid traverse X/Z/Q m/min 30/30 30/30 30/30/6 30/30/6 30/30/30 30/30/30 30/30/30 30/30/30 30/30/30 30/30/30 30/30/30 30/30/30<br />

Tailstock Hydraulic NC NC<br />

Center pixture MK 4 4 4 4 4 4<br />

Supporting force daN 340 340 530 530 530 530<br />

Subspindle<br />

Spindle nose according<br />

to DIN 55026 size 5 5 5 5<br />

Maximum chuck diameter mm 160 160 160 160<br />

Spindle diameter in front bearing mm 85 85 85 85<br />

Bare capacity in draw/thrust tube mm 42 42 42 42<br />

Power at 100 %/60 % duty cycle kW 13.5/17 13.5/17 13.5/17 13.5/17<br />

Spindle speed range rpm 5-6000 5-6000 5-6000 5-6000<br />

Torque 100 %/60 % duty cycle Nm <strong>65</strong>/85 <strong>65</strong>/85 <strong>65</strong>/85 <strong>65</strong>/85<br />

Tool Turret<br />

Number of tool stations<br />

(not live/live) 12 12/12 12 12/12 12 12/12 16/16 16/16 12 12/12 16/16 16/16<br />

Reverence circle diameter mm 300 300 300 300 300 300 300 300<br />

Reverence circle diameter SW 300 300 300 300<br />

Tool shank section mm 20 x 20 20 x 20 20 x 20 20 x 20 20 x 20 20 x 20 16 x 16 16 x 16 20 x 20 20 x 20 16 x 16 16 x 16<br />

Shank dia. acc. to DIN 69880 mm 30 30 30 30 30 30 25 25 30 30 25 25<br />

Power at 100 % duty cycle kW 4.5 4.5 4.5 4.5 4.5 4.5 4.5 4.5<br />

Tool Turret with Y-axis<br />

Y-axis travel mm +45/–35 +45/–35<br />

Control Sinumerik 810 D 810 D 810 D 810 D 840 D 840 D 840 D 840 D 840 D 840 D 840 D 840 D<br />

Dimensions<br />

Technical Data<br />

Length/width/height mm 3180 x 2050 x 2200 3180 x 2050 x 2200 3180 x 2050 x 2200<br />

Center line above floor mm 1130 1130 1130 1130 1130 1130 1130 1130 1130 1130 1130 1130<br />

Weight kg 5900 5900 6100 6100 6100 6100 <strong>65</strong>00 <strong>65</strong>00 6300 6300 6700 6700<br />

www.weiler.de<br />

<strong>WEILER</strong> Werkzeugmaschinen GmbH<br />

Mausdorf 46 • D-91448 Emskirchen<br />

Telefon +49 (0)9101-705-0<br />

Fax +49 (0)9101-705-122<br />

info@weiler.de • service@weiler.de<br />

Right to make technical modifications reserved · 09/06 · 5.0915.07.01.00.02