SFA-5.16

SFA-5.16

SFA-5.16

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>SFA</strong>-<strong>5.16</strong> 1998 SECTION II<br />

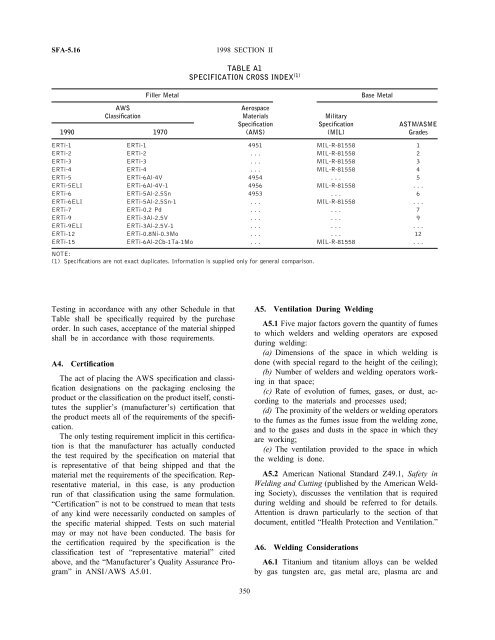

TABLE A1<br />

SPECIFICATION CROSS INDEX (1)<br />

Filler Metal Base Metal<br />

AWS Aerospace<br />

Classification Materials Military<br />

Specification Specification ASTM/ASME<br />

1990 1970 (AMS) (MIL) Grades<br />

ERTi-1 ERTi-1 4951 MIL-R-81558 1<br />

ERTi-2 ERTi-2 . . . MIL-R-81558 2<br />

ERTi-3 ERTi-3 . . . MIL-R-81558 3<br />

ERTi-4 ERTi-4 . . . MIL-R-81558 4<br />

ERTi-5 ERTi-6Al-4V 4954 . . . 5<br />

ERTi-5ELI ERTi-6Al-4V-1 4956 MIL-R-81558 . . .<br />

ERTi-6 ERTi-5Al-2.5Sn 4953 . . . 6<br />

ERTi-6ELI ERTi-5Al-2.5Sn-1 . . . MIL-R-81558 . . .<br />

ERTi-7 ERTi-0.2 Pd . . . . . . 7<br />

ERTi-9 ERTi-3Al-2.5V . . . . . . 9<br />

ERTi-9ELI ERTi-3Al-2.5V-1 . . . . . . . . .<br />

ERTi-12 ERTi-0.8Ni-0.3Mo . . . . . . 12<br />

ERTi-15 ERTi-6Al-2Cb-1Ta-1Mo . . . MIL-R-81558 . . .<br />

NOTE:<br />

(1) Specifications are not exact duplicates. Information is supplied only for general comparison.<br />

Testing in accordance with any other Schedule in that<br />

Table shall be specifically required by the purchase<br />

order. In such cases, acceptance of the material shipped<br />

shall be in accordance with those requirements.<br />

A4. Certification<br />

The act of placing the AWS specification and classification<br />

designations on the packaging enclosing the<br />

product or the classification on the product itself, constitutes<br />

the supplier’s (manufacturer’s) certification that<br />

the product meets all of the requirements of the specification.<br />

The only testing requirement implicit in this certification<br />

is that the manufacturer has actually conducted<br />

the test required by the specification on material that<br />

is representative of that being shipped and that the<br />

material met the requirements of the specification. Representative<br />

material, in this case, is any production<br />

run of that classification using the same formulation.<br />

“Certification” is not to be construed to mean that tests<br />

of any kind were necessarily conducted on samples of<br />

the specific material shipped. Tests on such material<br />

may or may not have been conducted. The basis for<br />

the certification required by the specification is the<br />

classification test of “representative material” cited<br />

above, and the “Manufacturer’s Quality Assurance Program”<br />

in ANSI/AWS A5.01.<br />

350<br />

A5. Ventilation During Welding<br />

A5.1 Five major factors govern the quantity of fumes<br />

to which welders and welding operators are exposed<br />

during welding:<br />

(a) Dimensions of the space in which welding is<br />

done (with special regard to the height of the ceiling);<br />

(b) Number of welders and welding operators working<br />

in that space;<br />

(c) Rate of evolution of fumes, gases, or dust, according<br />

to the materials and processes used;<br />

(d) The proximity of the welders or welding operators<br />

to the fumes as the fumes issue from the welding zone,<br />

and to the gases and dusts in the space in which they<br />

are working;<br />

(e) The ventilation provided to the space in which<br />

the welding is done.<br />

A5.2 American National Standard Z49.1, Safety in<br />

Welding and Cutting (published by the American Welding<br />

Society), discusses the ventilation that is required<br />

during welding and should be referred to for details.<br />

Attention is drawn particularly to the section of that<br />

document, entitled “Health Protection and Ventilation.”<br />

A6. Welding Considerations<br />

A6.1 Titanium and titanium alloys can be welded<br />

by gas tungsten arc, gas metal arc, plasma arc and