Heat Insulating Material - Wolfshöher Tonwerke

Heat Insulating Material - Wolfshöher Tonwerke

Heat Insulating Material - Wolfshöher Tonwerke

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Approval No.: Z-43.14-128<br />

<strong>Heat</strong> <strong>Insulating</strong> <strong>Material</strong><br />

Prowolf <strong>Heat</strong> <strong>Insulating</strong> Bricks<br />

For heat insulation of extension walls when mounting chimneys in accordance with DIN 18895<br />

Part 1, and also for tiled stoves in accordance with the Specialist Regulations for the Tiled Stove<br />

and Air <strong>Heat</strong>ing Construction Trade.<br />

<strong>Heat</strong> insulating bricks based on the raw materials of calcium silicate and aluminium silicate.<br />

Prowolf heat insulating bricks must be processed with the appropriate DIDOTECT 135-V<br />

fireproof glue.<br />

The Prowolf heat insulation can be heat insulation and brick lining at the same time, see<br />

Diagram 1.<br />

Simple machining of heat insulating bricks with e.g. a gas concrete saw.<br />

Prowolf heat insulating bricks are wear-resistant, additional protection is not statutorily<br />

required. It is possible to seal the surface with DIDOTECT 135-V fireproof glue, however<br />

only for thicknesses of up to 1mm. The glue layer must be sufficiently hardened (a week at<br />

80°C)<br />

Processing Guidelines<br />

<strong>Wolfshöher</strong> <strong>Tonwerke</strong> GmbH &<br />

Co. KG<br />

Wolfshöhe 2<br />

D-91233 Neunkirchen am Sand<br />

Technical Data and Diagrams on Reverse Side <br />

Prowolf bricks are glued together using DIDOTECT 135-V fireproof glue; both the glue and the<br />

yet fresh brickwork should be protected from frost. The glue should be stirred well before being<br />

applied. Any fluid discharged from above may not be drained; it must instead be stirred in. You<br />

should ensure that the glue does not come into contact with the technician’s eyes, skin, etc. In<br />

the event of work stoppages, the glue container should be closed well so as to prevent the<br />

surface from drying out. The glue can be adapted on a small scale by adding water in order to<br />

obtain the desired processing consistency. The bricks to be processed should be dry and only<br />

be slightly humid. Prowolf bricks must be free from dust or other adherences. As a rule, the glue<br />

should be applied to one side of the surfaces to be glued. The glued joint should be 2 – 3 mm<br />

thick; the optimal thickness for the glued joint is two millimetres. The glue drying time is approx.<br />

12 to 48 hours depending on the ambient temperature. Preparation containers and tools should<br />

be cleaned in due time and with care.<br />

General pre-requisites for the assembly of Prowolf bricks in front of walls to be protected are: a<br />

sufficiently adhesive surface for glueing the bricks onto the wall to be protected. It must be level<br />

– unevennesses of up to 4 millimetres can be evened out by the glue on small surfaces – it<br />

must also be statically stable. When glueing onto the wall to be protected, it is recommended to<br />

coat both sides of the surfaces to be glued with DIDOTECT 135-V. The Prowolf bricks must be<br />

screwed together with gypsum plasterboards. They are countersunk 2cm-deep into the Prowolf<br />

bricks in order to avoid too strong thermal bridges or to protect the screw heads. The remaining<br />

recesses are sealed with fibre mortar WT. This type of fastening can only be used for Prowolf<br />

bricks of at least 64mm in thickness; it is only then that a sufficient remaining minimum Prowolf<br />

brick thickness of approx. 40mm between the surface of the gypsum plasterboard and the<br />

screw head can be guaranteed.<br />

Telephone: +49(0)9153/9262-0<br />

Fax.: +49(0)9153/4342<br />

Email: info@wolfshoehe.de<br />

Web www.wolfshoehe.de<br />

Version:<br />

17.06.2006

Technical Specifications:<br />

<strong>Heat</strong> <strong>Insulating</strong> <strong>Material</strong><br />

Prowolf <strong>Heat</strong> <strong>Insulating</strong> Bricks<br />

Gross Density: 435 kg/m 3<br />

Coefficient of <strong>Heat</strong> Conductivity at:<br />

Classification Temperature: 850°C 400°C: 0.12 W/mK<br />

Cold Crushing Strength: approx. 1.2 N/mm 2 600°C: 0.15 W/mK<br />

Thermal Expansion at 700°C: approx. 0.4% 800°C: 0.19 W/mK<br />

<strong>Wolfshöher</strong> <strong>Tonwerke</strong> GmbH &<br />

Co. KG<br />

Wolfshöhe 2<br />

D-91233 Neunkirchen am Sand<br />

Telephone: +49(0)9153/9262-0<br />

Fax.: +49(0)9153/4342<br />

Email: info@wolfshoehe.de<br />

Web www.wolfshoehe.de<br />

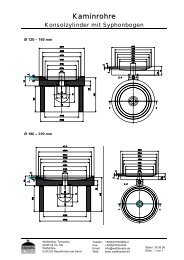

Diagram 1<br />

Working diagram for determining the layer<br />

thickness of “Prowolf“ heat insulating bricks<br />

for use in accordance with DIN 18895-1, as<br />

a replacement for brick lining (BL) and heat<br />

insulation (HI) for inflammable and / or<br />

statically loaded installation walls.<br />

Example:<br />

Necessary heat insulation (HI) in accordance<br />

with manufacturer’s specifications: 10cm<br />

Necessary brick lining in accordance with<br />

DIN 18 895-1, Section 5.6.2.4: 10cm<br />

Total thickness in accordance with DIN 18<br />

895-1, Sections 5.6.2.3 and 5.6.2.4: 20cm<br />

corresponds to 12cm “Prowolf” heat<br />

insulating bricks.<br />

Diagram 2<br />

Working diagram for determining the layer<br />

thickness of “Prowolf” heat insulating bricks<br />

for use in accordance with DIN 18 895-1, as<br />

a replacement for heat insulation (HI) for<br />

non-combustible and/or unstatically loaded<br />

installation walls.<br />

Example:<br />

Necessary heat insulation: 7.0cm<br />

corresponds to 8.0cm “Prowolf” heat<br />

insulating bricks.<br />

Version:<br />

17.06.2006