Turbomachinery Coupling Catalog - Emerson Industrial Automation

Turbomachinery Coupling Catalog - Emerson Industrial Automation

Turbomachinery Coupling Catalog - Emerson Industrial Automation

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

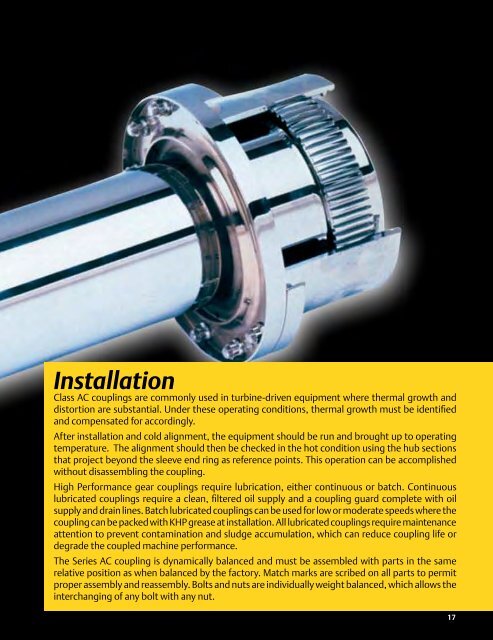

Installation<br />

Class AC couplings are commonly used in turbine-driven equipment where thermal growth and<br />

distortion are substantial. Under these operating conditions, thermal growth must be identified<br />

and compensated for accordingly.<br />

After installation and cold alignment, the equipment should be run and brought up to operating<br />

temperature. The alignment should then be checked in the hot condition using the hub sections<br />

that project beyond the sleeve end ring as reference points. This operation can be accomplished<br />

without disassembling the coupling.<br />

High Performance gear couplings require lubrication, either continuous or batch. Continuous<br />

lubricated couplings require a clean, filtered oil supply and a coupling guard complete with oil<br />

supply and drain lines. Batch lubricated couplings can be used for low or moderate speeds where the<br />

coupling can be packed with KHP grease at installation. All lubricated couplings require maintenance<br />

attention to prevent contamination and sludge accumulation, which can reduce coupling life or<br />

degrade the coupled machine performance.<br />

The Series AC coupling is dynamically balanced and must be assembled with parts in the same<br />

relative position as when balanced by the factory. Match marks are scribed on all parts to permit<br />

proper assembly and reassembly. Bolts and nuts are individually weight balanced, which allows the<br />

interchanging of any bolt with any nut.<br />

17