DC GD69# 6I H:6# - Wallenius Wilhelmsen Logistics

DC GD69# 6I H:6# - Wallenius Wilhelmsen Logistics

DC GD69# 6I H:6# - Wallenius Wilhelmsen Logistics

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

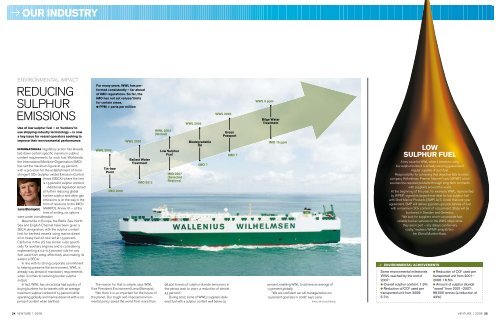

hese new vessels will certainly move us into<br />

the next decade and beyond,” predicted Geir<br />

Fagerheim, the head of Fleet Management<br />

for WWL.<br />

The four 76,500-gross-tonne vessels, which will<br />

bring about the next technological leap forward for<br />

WWL are currently being built at the Mitsubishi Heavy<br />

<br />

<br />

<br />

<br />

Industries shipyard in Nagasaki, Japan, and<br />

they will be delivered in 2011 and 2012.<br />

WWL has a long history of successful<br />

newbuildings from the world-renowned<br />

Mitsubishi yard. The vessels will be NIS<br />

flagged and certified by Det Norske Veritas.<br />

They will be 265 metres long, have<br />

a beam of 32.26 metres and a cruising<br />

speed of 20 knots. Schedule speed is assumed<br />

at 18 knots given various weather<br />

conditions.<br />

will be ideal for<br />

carrying combined loads of; Cars, High<br />

& Heavy and Non Containerised Cargo<br />

(NCC).. The configuration of the vessels<br />

has been “optimised for different types of<br />

cargo”, hence liftable decks.<br />

Fagerheim told Venture: “We have always<br />

had a special focus on the high and heavy cargo<br />

segment and these new vessels will, for sure, help<br />

optimise our effectiveness in this sector.”<br />

Major design criteria for the four vessels<br />

are to meet the demands of our customers:<br />

maximum flexibility, more efficiency through<br />

larger vessels, lower fuel consumption,<br />

good transport economies, efficient cargo<br />

handling, minimum impact on the environment,<br />

good form stability and thus a<br />

reduced need for water ballast. Also the<br />

main deck will be strengthened for Samson<br />

heavy-lift trailers and three liftable decks<br />

will provide flexibility and maximum<br />

utilisation for the vessels.<br />

deck of these stateof-the-art<br />

vessels will be strengthened<br />

and equipped to accommodate project<br />

cargoes such as yachts, windmill blades<br />

and other cargo suitable for on-deck shipments.<br />

All cargoes, except weather deck cargo, will<br />

be loaded and discharged via a high-capacity<br />

12-metre wide stern ramp. For extra safe watertight<br />

<br />

closure there will also be a separate watertight door.<br />

Fuel oil will be stored in protected deep tanks forward<br />

and aft. With these very advanced specifications these<br />

vessels will be among the safest and most environmentally<br />

friendly afloat the seven seas.<br />

Conscientious WWL is always looking to, wherever<br />

possible, reduce its carbon footprint. Fagerheim<br />

says the four new arrivals will be “more fuelefficient”<br />

than those of previous generations and this<br />

will allow WWL to bring down fuel consumption and<br />

reduce emissions. The exhaust gas energy will also<br />

be recovered to generate the entire electrical need at<br />

sea,” adds Fagerheim. Fuel-efficient vessels will be<br />

even more important in the future as the oil prices<br />

look set to remain stubbornly high for the foreseeable<br />

future.<br />

On top of this the vessels will have a special bilge<br />

water separator and use biodegradable stern tube oil,<br />

thereby reducing emissions into the sea.<br />

Fagerheim concludes, ”We will definitely be at the<br />

forefront of shipping technology when these vessels<br />

come out.”