BLM Joint Simulator Bench

BLM Joint Simulator Bench

BLM Joint Simulator Bench

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

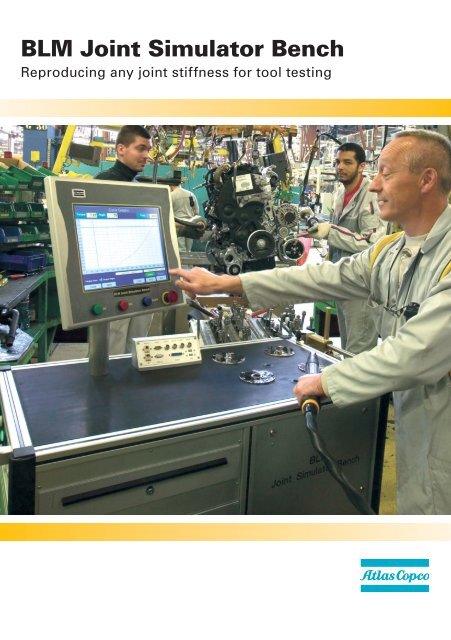

<strong>BLM</strong> <strong>Joint</strong> <strong>Simulator</strong> <strong>Bench</strong><br />

Reproducing any joint stiffness for tool testing

<strong>BLM</strong> <strong>Joint</strong> <strong>Simulator</strong> <strong>Bench</strong> 3860<br />

Flexible quality assurance - fast<br />

The <strong>BLM</strong> <strong>Joint</strong> <strong>Simulator</strong> <strong>Bench</strong> 3860 provides<br />

maximum tool evaluation fl exibility. DC electric,<br />

clutch, impulse and battery tools as well<br />

as torque wrenches are able to be evaluated.<br />

The hydraulic brakes simulate the behaviour<br />

of a real joint reproducing the stiffness from<br />

hard to soft. This allows the tool to be tested in<br />

accordance with VDI/VDE 2647. Machine capability<br />

(Cm, Cmk) can be tested quickly and<br />

easily under real shop fl oor conditions without<br />

the need to run tests on the product on the<br />

line that would interfere with production.<br />

When testing, it is recommended to test the whole<br />

tightening system not just the power tool. That is why<br />

in addition to testing on the shop fl oor, it is also important<br />

to test with the particular sockets and extensions<br />

used in production. There is no need to remove the<br />

socket from the tool.<br />

A complete set of adapters allows the nutrunner<br />

to be tested as it is used on the line. The patented<br />

design of hydraulics brakes, the valves and the oil<br />

pressure accumulator ensure extremely low power<br />

consumption. This allows the test bench to perform<br />

production line tool testing for 16 hours between<br />

charges.<br />

Torque Supervisor installed<br />

on every bench<br />

This software has been specifi cally developed for the<br />

management of plant wide tool operations and allows<br />

machine capability evaluation in addition to periodic<br />

SPC tool testing to ensure the correct performance<br />

of production torque tools (model, class, date of<br />

purchase, tool status, repair history, process history,<br />

<strong>BLM</strong> <strong>Joint</strong> <strong>Simulator</strong> <strong>Bench</strong> on the shop fl oor<br />

etc).<br />

Tool evaluations are fully documented, including the<br />

X bar and R charts with a complete history of the tool,<br />

an important requirement for compliance with the<br />

ISO 9000 standard.<br />

High performance even under<br />

demanding conditions<br />

<strong>Joint</strong> <strong>Simulator</strong> <strong>Bench</strong> advanced technology provides<br />

the best possible linearity when reproducing a joint<br />

rate as a result of three patents. <strong>Joint</strong> <strong>Simulator</strong><br />

<strong>Bench</strong> innovative joint simulation brakes have low<br />

inertia due to brake disc design, smooth actuation as<br />

a result of oil immersed carbon brakes and a unique<br />

cylinder design which allows quick response during<br />

simulation. These features in conjunction with a fast<br />

acting control valve system allow <strong>Joint</strong> <strong>Simulator</strong><br />

<strong>Bench</strong> to deliver exceptional performance even under<br />

demanding conditions such as when testing a multistep<br />

DC electric nutrunner.

Industrial PC, Windows based<br />

operating system, dual hard<br />

drives, special suspension,<br />

Ethernet synchronization to<br />

central server provides data<br />

security. WI-FI communication<br />

possible.<br />

Drawer mounted keyboard<br />

provides an additional interface<br />

for large volume data<br />

entry.<br />

Energy saving pressure<br />

accumulator<br />

maintains the hydraulic<br />

test pressure.<br />

This eliminates<br />

battery drain.<br />

Effi cient hydraulic<br />

pump fi lls the pressure<br />

accumulator in<br />

just 15 seconds reducing<br />

battery drain.<br />

Innovative braking system with<br />

three patents for tool joint<br />

simulation. The patents are:<br />

– innovative cylinder/actuator<br />

– thin steel disk for very low inertia<br />

– brakes in carbon and work<br />

in oil for very smooth action<br />

Large LCD touchscreen,<br />

intuitive and easy to use.<br />

Connector panel manages all operator<br />

connections such as external in-line torque<br />

transducers, printers, Ethernet, USB and<br />

serial.<br />

Excellent accuracy realized through single<br />

piece torque transducer eliminating play<br />

and reducing inertia during tool testing.<br />

The brake pressure control valve,<br />

provides fast and accurate pressure<br />

feedback for superior joint simulation.<br />

The smart charging system automatically shuts<br />

down the bench when the batteries are low. Places<br />

the charger in stand-by mode when batteries are<br />

fully charged.<br />

<strong>BLM</strong> <strong>Joint</strong> <strong>Simulator</strong> <strong>Bench</strong> batteries (2 x 80 Ah) allow<br />

over 16 hours of operation on a charge with the<br />

safety of gel cell technology.

Fast and accurate<br />

• Torque tools are tested very quickly on a <strong>Joint</strong><br />

<strong>Simulator</strong> <strong>Bench</strong>. It takes just a few seconds for a<br />

periodic statistical control and three minutes to make<br />

a machine capability test of 30 samples.<br />

• No interference with the production line, torque tools<br />

are tested without having to remove their sockets.<br />

• Pneumatic tools are tested directly on the production<br />

line under real conditions considering air pressure,<br />

hose wear, lubrication, etc.<br />

The joint is always available<br />

• No more problems checking joints with little<br />

clearance.<br />

• No more problems checking joints rarely available<br />

on the line (during the initial production of a new<br />

model or with low volume models or options)<br />

Keeps torque tools under control<br />

Test<br />

Cm, Cmk<br />

Tool in use<br />

on the line<br />

Periodic statistic<br />

testing in a<br />

few seconds<br />

OK<br />

Repair<br />

or adjust<br />

the tool<br />

NOK<br />

Torque tool machine capability (Cm, Cmk) testing should<br />

be performed prior to using a tool in production. If the<br />

tool tests OK, and is placed in production, it should be<br />

periodically checked to make sure that it is performing<br />

correctly. If a tool is out of tolerance all the tightening<br />

done before the test may be inaccurate. Keeping the<br />

tool under control avoids this situation.<br />

<strong>Joint</strong> <strong>Simulator</strong> <strong>Bench</strong> is able to evaluate the tool at<br />

its production line location. The software package on the<br />

test bench provides periodic SPC analysis of the tool’s<br />

performance. If the torque tool needs adjustment or<br />

repair, the SPC software notifi es the operator before the<br />

fastening results are out of specifi cation.<br />

Corrective actions<br />

When <strong>Joint</strong> <strong>Simulator</strong> <strong>Bench</strong> is used to evaluate tools in<br />

the production line, the torque tool is maintained at the<br />

correct level of performance with torque management<br />

software. As the tool is periodically tested an X bar<br />

and R control chart is created and the tool’s results are<br />

evaluated using SPC rules and control limits. If a tool is<br />

found to be not OK, an easy to understand icon will recommend<br />

the appropriate action (repair, adjust + or - ).<br />

.<br />

Remove tool from line<br />

– to be calibrated<br />

At least one measurement<br />

is over the upper tolerance<br />

but repeatability is good.<br />

Set tool to a lower torque.<br />

To be calibrated<br />

Average is over control<br />

limit but no value is out of<br />

tolerance. Set tool<br />

to a lower torque.<br />

Remove tool from line<br />

– to be repaired<br />

At least one measure is<br />

out of tolerance. Bad repeatability<br />

does not allow<br />

to calibrate.<br />

Remove tool from line<br />

– to be calibrated<br />

At least one measurement<br />

is below the lower<br />

tolerance but repeatability<br />

is good. Set tool to a<br />

higher torque.<br />

To be calibrated<br />

Average is below control<br />

limit but no value is out<br />

of tolerance. Set tool to a<br />

higher torque.<br />

To be repaired<br />

No value is out of<br />

tolerance but bad<br />

repeatability does not<br />

allow to set properly.<br />

ISO test fi xture<br />

This optional fi xture can be provided with the <strong>Joint</strong> <strong>Simulator</strong><br />

<strong>Bench</strong> to make torque wrench testing easy and<br />

accurate. With dial indicating or electronic wrenches,<br />

it is easy to maintain the desired torque with this<br />

fi xture. During click wrench testing, the fi xture reduces<br />

operator infl uence and allows the fi nal torque to be<br />

approached slowly and smoothly as recommended in<br />

the ISO 6789. The fi xture can be extended out from<br />

<strong>Joint</strong> <strong>Simulator</strong> <strong>Bench</strong> to match the length of the torque<br />

wrench being calibrated.

<strong>BLM</strong> JOINT SIMULATOR BENCH 3890<br />

Designed for testing torque tools<br />

in the tool crib<br />

The <strong>BLM</strong> <strong>Joint</strong> <strong>Simulator</strong> <strong>Bench</strong> 3890 is specially<br />

designed for heavy duty applications such as testing<br />

production torque tools in the tool crib. It has the same<br />

characteristics as the <strong>BLM</strong> 3860 but is also fi tted with<br />

a cooling system. This effectively removes the heat<br />

produced by continuous testing that can involve several<br />

thousand tests or more. It also enables lifetime tests<br />

to be carried out without problem and with the joint<br />

characteristics remaining constant.<br />

Cooling system<br />

The hydraulic brakes on the <strong>BLM</strong> 3890 have a cooling<br />

system with heat exchanger to avoid overheating when<br />

used continuously for life testing of nutrunners.<br />

Adjustable fi xturing table<br />

The <strong>BLM</strong> JSB 3890 is supplied with an adjustable holding<br />

fi xture for spindles from multi-spindle torque tools.<br />

It is powered for up and down movement to engage<br />

the square drive to the brake and has a sliding function<br />

to keep the working area of the brakes free when<br />

not in use. Four spindles can be fi xed on the table<br />

with adapter fl anges (not supplied with the bench).<br />

The fl anges are fi xed to the table with screws<br />

using the holes provided for this purpose.<br />

The fi xturing table.

TORQUE SUPERVISOR<br />

Torque Supervisor software is required to run the<br />

<strong>BLM</strong> <strong>Joint</strong> <strong>Simulator</strong> <strong>Bench</strong>. Three versions are available<br />

to suit varying needs:<br />

Torque Supervisor Full: for each operation/joint the<br />

software can manage two different types of control:<br />

• controls Cm, Cmk or statistical check related to the<br />

nutrunner in use for the operation/joint.<br />

• controls Cp, Cpk or statistical results of residual<br />

torque checks in conjunction with the LABwrench<br />

or LABwrench Gyro.<br />

The Torque Supervisor Full option is advised when<br />

installed directly on the bench managing the nutrunners<br />

as well as the residual torque checks.<br />

Torque Supervisor Light: for benches utilized in the<br />

tool crib environment, this version manages only Cm,<br />

Cmk as well as periodical SPC testing of the nutrunner.<br />

Torque Supervisor Client/Server. When more<br />

benches are used along the line it is important to keep<br />

one centralized database. In this case Torque Supervisor<br />

Full is installed on a Server for complete data management.<br />

The full list of nutrunners showing status<br />

(on line, off-line, to be checked, OK, NOK) helps the<br />

operator keep the tool under control as well as pro-<br />

TECHNICAL DATA<br />

viding other useful information such as model, class,<br />

date of purchase, presence in line or store, controls,<br />

etc.<br />

Torque Supervisor process statistics creates full SPC<br />

analysis. With separate data collecting capability for<br />

nutrunners in use (Cmk) and residual torque checked<br />

joints (Cpk), it is easy to compare results of nutrunners<br />

with residual torque controls.<br />

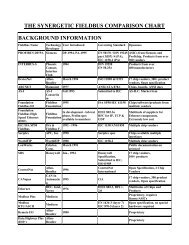

Hydraulic brakes, range Spindle fi xture Dimensions<br />

Model<br />

Mobile benches<br />

Nm lb ft ISO rig holder Length x width x height Ordering No.<br />

JSB 3860-250 1-250 0.8-150 – – 1000 x 550 x 920 8059 0962 00<br />

JSB 3860-250 ISO 1-250 0.8-150 yes – 1150 x 550 x 920 8059 0962 30<br />

JSB 3860-500 ISO 1-500 0.8-365 yes – 1150 x 550 x 920 8059 0962 35<br />

JSB 3860-1000 ISO 1-1000 0.8-735 yes – 1400 x 700 x 950 8059 0962 40<br />

JSB 3860-2000 ISO 1-2000 0.8-1470 yes – 1400 x 700 x 950 8059 0962 50<br />

Fix benches<br />

JSB 3890-500 SH 1-500 0.8-365 – yes 2100 x 850 x 1000 8059 0963 00<br />

JSB 3890-2000 SH 1-2000 0.8-1470 – yes 2300 x 900 x 1000 8059 0963 50<br />

www.atlascopco.com<br />

9833 1698 01 E.C.O Reklambyrå AB. Åtta.45 Tryckeri AB. 2008:1