Introduction & Schedule - Constant Contact

Introduction & Schedule - Constant Contact

Introduction & Schedule - Constant Contact

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

KEYNOTE PRESENTATION: EA SIER, BETTER, FA STER AND CHEAPER<br />

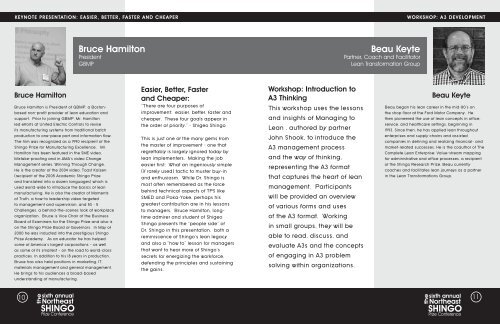

Bruce Hamilton<br />

Bruce Hamilton<br />

President<br />

GBMP<br />

Bruce Hamilton is President of GBMP, a Bostonbased<br />

non-profit provider of lean education and<br />

support. Prior to joining GBMP, Mr. Hamilton<br />

led efforts at United Electric Controls to revise<br />

its manufacturing systems from traditional batch<br />

production to one-piece part and information flow.<br />

The firm was recognized as a 1990 recipient of the<br />

Shingo Prize for Manufacturing Excellence. Mr.<br />

Hamilton has been featured in the SME video,<br />

Mistake-proofing and in AMA’s video Change<br />

Management series, Winning Through Change.<br />

He is the creator of the 2004 video, Toast Kaizen<br />

(recipient of the 2005 Academic Shingo Prize<br />

and translated into a dozen languages) which is<br />

used world-wide to introduce the basics of lean<br />

manufacturing. He is also the creator of Moments<br />

of Truth, a how-to leadership video targeted<br />

to management and supervision, and 5S – 5<br />

Challenges, a behind-the-scenes look at workplace<br />

organization. Bruce is Vice Chair of the Business<br />

Board of Examiners for the Shingo Prize and also is<br />

on the Shingo Prize Board of Governors. In May of<br />

2000 he was inducted into the prestigious Shingo<br />

Prize Academy. As an educator he has helped<br />

some of America’s largest corporations — as well<br />

as some of its smallest — on the road to world-class<br />

practices. In addition to his 18 years in production,<br />

Bruce has also held positions in marketing, IT,<br />

materials management and general management.<br />

He brings to his audiences a broad-based<br />

understanding of manufacturing.<br />

Easier, Better, Faster<br />

and Cheaper:<br />

“There are four purposes of<br />

improvement: easier, better, faster and<br />

cheaper. These four goals appear in<br />

the order of priority.” – Shigeo Shingo<br />

This is just one of the many gems from<br />

the master of improvement – one that<br />

regrettably is largely ignored today by<br />

lean implementers. Making the job<br />

easier first: What an ingeniously simple<br />

(if rarely used) tactic to muster buy-in<br />

and enthusiasm. While Dr. Shingo is<br />

most often remembered as the force<br />

behind technical aspects of TPS like<br />

SMED and Poka-Yoke, perhaps his<br />

greatest contribution are in his lessons<br />

to managers. Bruce Hamilton, longtime<br />

admirer and student of Shigeo<br />

Shingo presents the “people side” of<br />

Dr. Shingo in this presentation, both a<br />

reminiscence of Shingo’s lean legacy<br />

and also a “how to” lesson for managers<br />

that want to hear more of Shingo’s<br />

secrets for energizing the workforce,<br />

defending the principles and sustaining<br />

the gains.<br />

Workshop: <strong>Introduction</strong> to<br />

A3 Thinking<br />

This workshop uses the lessons<br />

and insights of Managing to<br />

Lean , authored by partner<br />

John Shook, to introduce the<br />

A3 management process<br />

and the way of thinking,<br />

representing the A3 format<br />

that captures the heart of lean<br />

management. Participants<br />

will be provided an overview<br />

of various forms and uses<br />

of the A3 format. Working<br />

in small groups, they will be<br />

able to read, discuss, and<br />

evaluate A3s and the concepts<br />

of engaging in A3 problem<br />

solving within organizations.<br />

Beau Keyte<br />

Partner, Coach and Facilitator<br />

Lean Transformation Group<br />

WORKSHOP: A3 DEVELOPMENT<br />

Beau Keyte<br />

Beau began his lean career in the mid-80’s on<br />

the shop floor at the Ford Motor Company. He<br />

then pioneered the use of lean concepts in office,<br />

service, and healthcare settings, beginning in<br />

1993. Since then, he has applied lean throughout<br />

enterprises and supply chains and assisted<br />

companies in defining and realizing financial- and<br />

market-related successes. He is the coauthor of The<br />

Complete Lean Enterprise: Value-stream mapping<br />

for administrative and office processes, a recipient<br />

of the Shingo Research Prize. Beau currently<br />

coaches and facilitates lean journeys as a partner<br />

in the Lean Transformations Group.<br />

10 11