You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

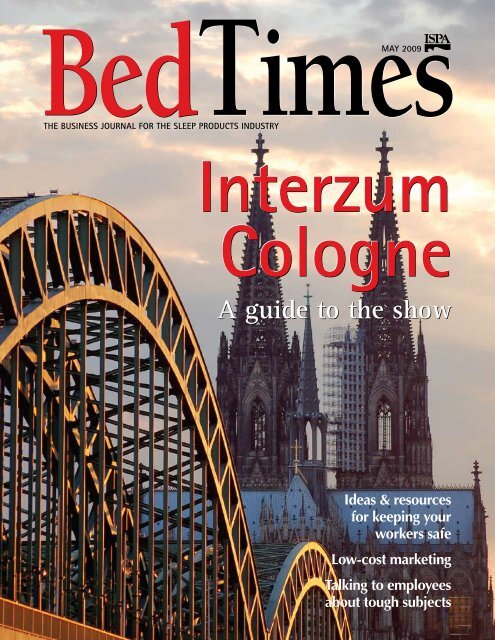

<strong>BedTimes</strong><br />

THE BUSINESS JOURNAL FOR THE SLEEP PRODUCTS INDUSTRY<br />

MAY 2009<br />

Interzum<br />

Cologne<br />

A guide to the show<br />

Ideas & resources<br />

for keeping your<br />

workers safe<br />

Low-cost marketing<br />

Talking to employees<br />

about tough subjects

1344T29A<br />

Build Mattresses with<br />

Walking Foot Mattress Bucket Building<br />

<br />

<br />

requiring only one true tape edge operation (contact sales for details)<br />

<br />

<br />

<br />

puckers or gathers<br />

<br />

<br />

<br />

<br />

<br />

doubling the output of the conventional tape edge machine<br />

<br />

<br />

Website: www.atlatt.com email: sales@atlatt.com<br />

The Sudden Service Company<br />

This equipment is protected by one or more of the following patents:<br />

US patents: 4,280,421; 4,432,294; 4,466,367; 4,644,883; 5,134,947; 5,159,889; 5,203,270; 5,522,332; 5,524,563; 5,562,060;<br />

5,634,418; 5,647,293; 5,657,711; 5,743,202; 5,865,135; 5,899,159; 5,915,319; 5,918,560; 5,979,345; 6,035,794; 6,055,921;<br />

6,202,579; 6,279,869; 6,295,481; 6,494,255; 6,802,271; 6,574,815 B2; 6,834,603 B1; 6,968,794 B1<br />

Foreign patents: 9-520,472; 0,537,323; 92,905,522.6; 96,936,922.2; 2,076,379; 2,084,055.<br />

Other U.S. and Foreign Patents Pending. Copyright 2009 Atlanta Attachment Co. 09018040709<br />

Atlanta Attachment Company<br />

362 Industrial Park Drive<br />

Lawrenceville, GA 30045

One Traditional Tape Edge<br />

We can show you how<br />

to save time and money...<br />

Bucket Build Build your mattresses<br />

Standard Tight Top Euro Top<br />

Euro Pillow Top<br />

Contact a sales representative at 770-963-7369<br />

for machines required or to arrange for a demonstration in our showroom.

Profiles<br />

Non-wovens<br />

Latex Foam<br />

Foam Products<br />

PowerStack Wire Foundations<br />

InnerRest Fabric-Encased Coil Units<br />

InnerACT Alternating Coil Innerspring<br />

Edge Guards<br />

Bonnell and Offset Innersprings<br />

Bed Frames<br />

Memory Foam Toppers<br />

Memory Foam Pillows<br />

Quilting Foam Rolls<br />

IT’S WHAT’S INSIDE<br />

THAT COUNTS<br />

Tradition. Innovation. Performance.<br />

W O R L D W I D E<br />

PO Box 819 • Hickory, NC 28603 • (828) 328-2201<br />

www.hickorysprings.com

MAY 2009<br />

InSide<br />

www.sleepproducts.org/bedtimes<br />

Features<br />

22 For safety’s sake<br />

To create a safe workplace, companies must strive—not just for a low injury<br />

level—but for no injuries. Doing so improves morale, productivity and even the<br />

bottom line. <strong>BedTimes</strong> gives you guidelines, ideas and resources for making your<br />

plant as safe as it can be.<br />

32 Sensitive talk<br />

Given the troubled economy, companies increasingly find themselves having to<br />

break bad news to employees. Human resource and communication consultants<br />

offer tips for telling workers about salary cuts, benefit reductions and other<br />

difficult changes.<br />

Departments<br />

16 Management Issues<br />

Learn five ways to empower your<br />

staff—and make yourself a better<br />

leader in the process.<br />

19 Marketing Report<br />

If your marketing funds are in short<br />

supply, concentrate on low-cost<br />

methods of relationship marketing.<br />

39 Interzum Cologne<br />

A special section guides you through<br />

Interzum Cologne, held May 13-16 in<br />

Cologne, Germany. The guide features<br />

extensive exhibitor profiles, maps of<br />

the show venue and more.<br />

5 Editor’s Note<br />

7 Front Matter<br />

13 Company Profile<br />

20 Sales Talk<br />

59 Media Relations<br />

65 Industry News<br />

81 Factory Direct<br />

85 Newsmakers<br />

86 ISPA Advocacy<br />

88 Calendar<br />

89 Classifieds<br />

90 Advertisers Index<br />

92 The Last Word<br />

<strong>BedTimes</strong> | May 2009 | 3

Don’t blow it<br />

Keep your plant clean<br />

& free of overspray<br />

when you use<br />

SABA water-based adhesives<br />

& its clean application technologies<br />

Make your plant a fog-free zone<br />

SABA adhesive application system virtually eliminates overspray<br />

When you use SABA foam bonding adhesives, you can say goodbye<br />

to the hassles, mess and maintenance of your current adhesive<br />

application system.<br />

SABA water-based adhesives are chemically engineered to be shear<br />

stable for hassle-free application when combined with our pressurized<br />

delivery system.<br />

This controls waste, which provides a healthier working environment<br />

for your staff, and a cleaner plant for all.<br />

Between the cleanliness and the cost-savings, the SABA foam bonding<br />

solution is, as we say in the sleep industry, a dream come true.<br />

“<br />

We have been using SABA adhesives and its<br />

delivery and monitoring technologies for more than<br />

18 months across our plants and the results have<br />

been great!<br />

The quality of the adhesive is superior and our<br />

plants are much cleaner due to the reduction in<br />

overspray. Additionally, the service provided by<br />

SABA has been fantastic. I highly recommend<br />

SABA to others in the bedding industry.<br />

”<br />

Dan Hige, Sr. Vice President, Manufacturing<br />

International Bedding<br />

See for yourself first hand how the easy-to-use SABA foam bonding<br />

adhesive system can save you money!<br />

Enjoy 20 to 50% reduction in adhesive costs<br />

All application equipment provided at no cost to you<br />

Highest performing water-based adhesive<br />

Cleaner and safer working environment<br />

Monitor and control adhesive usage<br />

Contact SABA today for a risk-free 30 day testing period.<br />

Call us at 810 824 4964<br />

Email us at sales@saba-adhesives.com<br />

For sales inquiries, please contact:<br />

T 810 824 4964<br />

F 810 824 4986<br />

E sales@saba-adhesives.com<br />

W www.saba-adhesives.com<br />

SABA, dedicated to foam bonding<br />

Est. 1933: 75 years of strong bonds<br />

SABA North America LLC<br />

5426 Lapeer Road<br />

Kimball MI 48074 USA

EDITOR IN CHIEF<br />

Julie A. Palm<br />

336-727-1889<br />

jpalm@sleepproducts.org<br />

SENIOR WRITER<br />

Barbara T. Nelles<br />

336-856-8973<br />

bnelles@sleepproducts.org<br />

CONTRIBUTORS<br />

Lee Froschheiser<br />

Lin Grensing-Pophal<br />

Pam Lontos<br />

Kelley Robertson<br />

Karen Saunders<br />

Dorothy Whitcomb<br />

ART DIRECTOR<br />

Stephanie Belcher<br />

336-201-7475<br />

stephanie@jimmydog.com<br />

VICE PRESIDENT OF SAlES<br />

Kerri Bellias<br />

336-945-0265<br />

kbellias@sleepproducts.org<br />

AD PRODUCTION &<br />

CIRCUlATION mANAgER<br />

Debbie Robbins<br />

336-342-4217<br />

drobbins@sleepproducts.org<br />

COPY EDITOR<br />

Margaret Talley-Seijn<br />

<strong>BedTimes</strong> deadlines<br />

Editorial deadlines for the Industry<br />

News and Newsmakers sections<br />

of the July issue of <strong>BedTimes</strong> are<br />

Monday, June 1.<br />

Volume 137 Number 5<br />

<strong>BedTimes</strong> (ISSN 0893-5556) is published<br />

monthly by the International Sleep Products<br />

Association. Periodicals postage paid at<br />

Alexandria, Va., and additional mailing offices.<br />

Editorial and advertising offices<br />

5603-B W. Friendly Ave. #286<br />

Greensboro, NC 27410<br />

Phone 703-683-8371; Fax 703-683-4503<br />

Administrative and ISPA offices<br />

501 Wythe St., Alexandria, Va. 22314-1917<br />

Phone 703-683-8371; Fax 703-683-4503<br />

Postmaster Send address changes to<br />

<strong>BedTimes</strong>, 501 Wythe St., Alexandria, Va.<br />

22314-1917<br />

Contents © 2009 by the<br />

International Sleep Products<br />

Association. Reprint permission<br />

obtainable through <strong>BedTimes</strong>.<br />

www.sleepproducts.org/bedtimes<br />

Editor’sNote<br />

Interzum Cologne<br />

comes at prime time<br />

many of our readers will be<br />

attending Interzum Cologne,<br />

held May 13-16 in Cologne,<br />

Germany. You might even be reading<br />

this magazine on the show floor: We<br />

have bonus distribution of <strong>BedTimes</strong><br />

at the trade fair.<br />

No one needs to tell you how difficult<br />

the economy is. But shows like<br />

Interzum Cologne—valuable in the<br />

best of times—are invaluable in the<br />

worst of times. Now is when you are<br />

rethinking every part of your business—the<br />

components you’re buying,<br />

the suppliers you’re working with, the<br />

types of mattresses you’re producing.<br />

You’re looking for efficiencies and<br />

ways to gain a competitive edge.<br />

Interzum Cologne allows you to do<br />

all that in one place and in just a few<br />

days.<br />

While putting together this issue of<br />

<strong>BedTimes</strong>, we’ve had a chance to get<br />

a sneak peek at what some exhibitors<br />

will be showing during the fair. They<br />

are rolling out new products and services<br />

designed to make your business<br />

better. Take advantage of what they<br />

have to offer.<br />

And start making plans now to attend<br />

the International Sleep Products<br />

Association’s next EXPO, which will<br />

be March 3-6, 2010, in Charlotte, N.C.<br />

Digital <strong>BedTimes</strong><br />

Last month, I told you that we are<br />

posting the entire magazine online at<br />

www.sleepproducts.org/bedtimes.<br />

The platform we’re using is intuitive,<br />

quick and easy to navigate, allowing<br />

you to flip through the magazine in<br />

much the same way you do the print<br />

<strong>version</strong>.<br />

But the digital <strong>version</strong> does have<br />

some nifty additional features, includ-<br />

ing live email and Web links that allow<br />

you to access further information<br />

from advertisers and others.<br />

We’re posting <strong>BedTimes</strong> online at<br />

the beginning of each month, allowing<br />

all of our readers to see the magazine<br />

earlier than they otherwise might.<br />

We think the digital issue will be<br />

especially useful to our international<br />

readers, who sometimes experience<br />

unavoidable delays in receiving their<br />

copy of the magazine.<br />

Past issues will be archived as we go<br />

forward. Now, no matter where you<br />

are—if you have access to the Internet—you’ll<br />

have access to <strong>BedTimes</strong>.<br />

We’ve had valuable comments<br />

from some readers. If you haven’t<br />

already done so, check it out and tell<br />

us what you think. As always, you<br />

can email me at<br />

jpalm@sleepproducts.org.<br />

In a related note, eventually we’d<br />

like to be able to send all of our readers<br />

a short email reminder when the latest<br />

<strong>BedTimes</strong> has been posted online. We<br />

have emails for many readers but not<br />

all. To make sure we have your email<br />

address, please send it to Debbie Robbins,<br />

our circulation manager, at<br />

drobbins@sleepproducts.org.<br />

(We don’t share email addresses with<br />

outside parties.) BT<br />

Julie A. Palm<br />

<strong>BedTimes</strong> | May 2009 | 5

FrontMatter<br />

Survey<br />

Be cautious before cutting prices<br />

Consumers may<br />

change the way<br />

they think about<br />

your brand<br />

By Julie A. Palm<br />

It’s tempting to slash the price of<br />

your products during a recession,<br />

but companies should carefully<br />

consider the ramifications before<br />

doing so, according to new research<br />

and marketing experts.<br />

A recently released study by The<br />

Futures Company, a global consumer<br />

research firm and consultancy,<br />

shows that lowering prices—even<br />

during an economic downturn—may<br />

cause long-term damage to a brand’s<br />

reputation as consumers wonder<br />

about the reason for the discount: Is<br />

something wrong with the product?<br />

Is it inferior? Is it outdated?<br />

When asked what they think<br />

about a brand when its price is<br />

lowered, 70% of consumers said,<br />

“the brand is overpriced,” according<br />

to the 2009 “Dollars & Consumer<br />

Sense” study. Some 62% of consumers<br />

said they think “the product is<br />

old, about to expire or about to be<br />

updated and the company is trying<br />

to get rid of it to make room for new<br />

stuff.”<br />

Conversely, those companies that<br />

maintain their pricing structure<br />

benefit from positive consumer impressions.<br />

According to the survey,<br />

64% of consumers say they think<br />

“the product is extremely popular”<br />

and 64% say they believe “the product<br />

is already a good value.”<br />

“Drastic price cuts…create a<br />

double-barreled risk for brands.<br />

First, such price cuts generally fail<br />

to generate enough business to pay<br />

for themselves, although clearing<br />

www.sleepproducts.org/bedtimes<br />

inventory is of some value. Second,<br />

they create long-term difficulties in<br />

terms of consumer expectations,”<br />

says J. Walker Smith, president of<br />

the Yankelovich Monitor research<br />

study and executive vice chairman<br />

of The Futures Company, which was<br />

formed through the recent merger<br />

of Yankelovich in Chapel Hill, N.C.,<br />

and London-based Henley Centre<br />

HeadlightVision.<br />

In fact, price cuts can have an unintended<br />

consequence. According to<br />

the survey, the majority of consumers<br />

think that if a company lowers<br />

prices, it will do so again. And they<br />

may delay purchases, just waiting for<br />

additional reductions.<br />

During the past holiday season,<br />

retailers across categories slashed<br />

prices, advertising reductions of as<br />

much as 70%, especially on apparel.<br />

The results were not stellar. As The<br />

Futures Company points out, recently<br />

released quarterly and annual<br />

earnings results from a number of<br />

major retailers showed “that markdowns,<br />

clearance pricing and other<br />

significant price-cutting actions<br />

have negatively impacted gross margins<br />

and other financial results.”<br />

Paul Nunes, executive director of<br />

research at Accenture’s Institute for<br />

High Performance, agrees that automatic<br />

price-cutting isn’t the best<br />

response to the recession.<br />

“Although sales and discounts<br />

seem to be the order of the day,<br />

vendors have more opportunities<br />

to maintain prices than they may<br />

think. For example, there is often a<br />

segment of loyal customers who do<br />

not expect or need to be persuaded<br />

with a discount to purchase. And<br />

although there’s no end of grumbling,<br />

customers can be surprisingly<br />

tolerant of across-the-board<br />

price hikes that they understand are<br />

related directly to increases in raw<br />

input costs, such as fuel for airlines<br />

or milk for ice cream,” Nunes writes<br />

in a Harvard Business blog at<br />

www.harvardbusiness.org. Accenture<br />

is a management consultancy<br />

with operations in 52 countries.<br />

Not only can heavy discounting<br />

encourage consumers to postpone<br />

purchases while they await further<br />

reductions, it also can make it difficult<br />

for companies to raise prices<br />

in the future, Nunes says.<br />

“Aside from the obvious profit<br />

loss caused by hasty discounting,<br />

there is the more pernicious real-<br />

<strong>BedTimes</strong> | May 2009 | 7

FrontMatter<br />

ity that discounting and promotions<br />

condition the buyer to expect lower<br />

prices. This customer mindset makes<br />

it hard to raise prices later when times<br />

are better,” he writes. “In addition, in<br />

what Accenture calls the discount trap,<br />

a reduction in price requires a stiffer<br />

increase just to bring the price back to<br />

par—thus a 30% drop requires a 43%<br />

increase. So customers are likely to<br />

perceive future upward price adjustments<br />

as larger than the discounts.”<br />

Nunes says companies should ask<br />

themselves several questions before<br />

deciding whether to consider price<br />

cuts:<br />

➤ Do customers still need your specific<br />

products? Do they have attractive<br />

alternatives they could purchase<br />

instead?<br />

➤ What benefits do your customers<br />

gain by choosing your products over<br />

8 | <strong>BedTimes</strong> | May 2009<br />

➤ Learn more<br />

The Futures Company’s “Dollars<br />

& Consumer Sense” survey of<br />

1,002 consumers over age 18 was<br />

conducted by phone in January.<br />

To learn more about purchasing<br />

the full results, check<br />

www.yankelovich.com.<br />

(Yankelovich in Chapel Hill, N.C.,<br />

and London-based Henley Centre<br />

HeadlightVision merged recently<br />

to form The Futures Company.)<br />

your competitors?<br />

➤ Do you offer unique services or<br />

delivery capabilities?<br />

The answers will help you segment<br />

customers by their price sensitivity.<br />

If you must discount, Nunes says,<br />

companies can follow a number of<br />

strategies. For instance, he says, “Be<br />

mindful of the customer’s ‘paycheck<br />

cycle.’ The Wall Street Journal recently<br />

reported on how companies are successfully<br />

discounting based on how<br />

close customers are to payday. All buying<br />

power is relative—and it can vary<br />

greatly from week to week and even<br />

from day to day.”<br />

Companies like factory directs<br />

could benefit from Nunes’ suggestion<br />

to offer customers options like<br />

layaway.<br />

“These payment-deferral programs<br />

are back, enjoying a revival<br />

among some retailers like Kmart, for<br />

example,” he writes. “And a new firm,<br />

eLayaway, has updated the concept,<br />

allowing customers to choose products<br />

from about 1,000 local retailers<br />

online.” BT<br />

www.sleepproducts.org/bedtimes

The Strongest Most Reliable<br />

High Speed Quilting Machines<br />

Built Since 1944<br />

The Emco Tack and Jump Embroidery<br />

High Speed Lockstitch Quilter<br />

The Emco 9000 Series High Speed<br />

Double Lock Chainstitch Quilter<br />

Choose the machine that fits your needs. The Emco 9000 Series High Speed Chainstitch Quilter for High Volume Output<br />

or the Emco Tack and Jump Embroidery Lockstitch The Quilter Emco for 9000 the Most Series Versatility. High Speed Whichever you choose you get the<br />

most reliable, strongest, longest lasting machines ever Double built. Lock With parts Chainstitch and service Quilter always available for our customers.<br />

Edgewater Machine Company, Inc.<br />

13-20 131st Street College Point, New York 11356 U.S.A<br />

Phone: 718-539-8200 Fax: 718-358-4648<br />

Email: info@edgewatermachine.com Website: www.edgewatermachine.com

CompanyProfile<br />

OMI lays claim to organic market<br />

Mattress maker sets high manufacturing standards for itself<br />

By Dorothy Whitcomb<br />

At a time when overall bedding<br />

industry sales have slipped by<br />

double digits, Organic Mattresses<br />

Inc., a manufacturer of environmentally<br />

friendly sleep products,<br />

says it is thriving and has high expectations<br />

for continued steady growth.<br />

Capitalizing on an aggressive expansion<br />

program completed in 2008,<br />

the company is opening new sales<br />

territories and preparing to introduce<br />

new products.<br />

“Last year was a crucial year for<br />

us. We doubled our physical size and<br />

revenues and added new equipment<br />

and personnel,” says Walt Bader, the<br />

company’s president and co-owner.<br />

Located in Yuba City, Calif., OMI<br />

produces innerspring and latex mattresses,<br />

foundations and accessories<br />

such as pillows, mattress pads and<br />

comforters. Products are made with<br />

100% organic raw materials, including<br />

wool and cotton sourced in the United<br />

States. To guarantee the purity of its<br />

raw materials, the company limits its<br />

vendors to farmers and producers<br />

whose products have been certified by<br />

recognized third-party organizations.<br />

OMI also imports sustainably<br />

harvested, powdered rubber tree<br />

sap to produce the latex cores for its<br />

mattresses. Because the nonblended,<br />

Talalay-process cores are produced in<br />

the United States, they do not have to<br />

undergo fumigation, a requirement<br />

for imported products, Bader says. In<br />

addition, OMI turns to Forest Stewardship<br />

Council vendors for foundation<br />

lumber from sustainable sources.<br />

“As far as I’m concerned, there<br />

are no grades of organic. Organic is<br />

organic. Kermit only comes in one<br />

color,” Bader says.<br />

Bader goes to great lengths to<br />

www.sleepproducts.org/bedtimes<br />

Sensitive guy Walt Bader, president and<br />

co-owner of Organic Mattresses Inc.,<br />

discovered in the 1990s that his health<br />

problems were caused by chemical sensitivities.<br />

Pristine plant Organic Mattresses Inc. isn’t<br />

just concerned about the components used<br />

in its mattresses. The company maintains a<br />

scrupulously clean manufacturing facility in<br />

Yuba City, Calif.<br />

Retail line The Organicpedic by OMI brand<br />

was launched to be sold by dealers. At the<br />

high end of the line is the Terra, which has a<br />

suggested retail price of about $5,000 for a<br />

queen size.<br />

guarantee the purity of his company’s<br />

finished products by keeping the<br />

50,000-square-foot “eco-factory” free<br />

of outside contaminants. Employees<br />

aren’t allowed to smoke, wear fragrances<br />

or use fabric softeners when<br />

laundering their clothing. They wear<br />

white smocks and booties over their<br />

shoes while they work. Compressed<br />

air, used to clear away lint, is sterilized<br />

to keep pollens and other contaminants<br />

from reaching the mattresses. As<br />

a final measure, an ozone sanitation<br />

chamber is used to eliminate any possible<br />

mold, yeast or bacteria.<br />

Bader has received third-party<br />

certification for OMI’s operations. In<br />

December, it became the first mattress<br />

manufacturer in the United States to<br />

be named a certified organic processor<br />

of fibers and textiles under the Global<br />

Organic Textile Standard. It is the<br />

only mattress manufacturer in North<br />

America to receive GREENGUARD<br />

certification for indoor air quality.<br />

A personal mission<br />

Chemically sensitive his entire life,<br />

Bader began studying the effects of<br />

environmental irritants early. But it<br />

wasn’t until the early 1990s—when a<br />

wide range of personal health issues<br />

were traced to chemical exposures—<br />

that he began an extensive search for<br />

products made with natural ingredients.<br />

A professor of marketing at<br />

Sierra College in northern California<br />

at the time, Bader used his spare time<br />

to find as many ways as possible to<br />

reduce his daily exposure to chemically<br />

laced products.<br />

“Mine was a life of avoidance and<br />

substitution,” he says.<br />

By 1998, he and his wife, Carol, had<br />

identified enough products to found<br />

Lifekind, an online catalog that sells<br />

organic home, pet and personal care<br />

products. When they wanted to add a<br />

mattress line to the e-commerce site,<br />

they couldn’t find what they wanted.<br />

“There was no one out there producing<br />

mattresses to anything like the<br />

standard we required,” he says.<br />

The Baders decided the only way to<br />

<strong>BedTimes</strong> | May 2009 | 13

CompanyProfile<br />

sell the bedding that they sought was<br />

to manufacture it themselves. In 2003,<br />

the pair founded OMI, which initially<br />

produced only for the Lifekind catalog.<br />

Encouraged by response to the<br />

products, the Baders have developed a<br />

new line, Organicpedic by OMI, to be<br />

sold by other retailers.<br />

“We made a choice to follow the<br />

$23 billion health food industry,”<br />

Bader says. “The healthier lifestyle<br />

mindset is firmly entrenched in the<br />

country and organic is a choice for<br />

consumers everywhere except retail<br />

mattress stores.”<br />

According to a 2007 manufacturing<br />

survey by the Greenfield, Mass.based<br />

Organic Trade Association,<br />

U.S. sales of organics—both food<br />

and nonfood<br />

products—<br />

rose 21% in<br />

2006 over<br />

2005, with<br />

continued big<br />

gains forecast.<br />

“Although<br />

the organic<br />

industry has also taken a recessionary<br />

hit, the market is out there, and consumers<br />

are just beginning to realize<br />

that there is now an organic mattress<br />

option,” Bader says.<br />

Bader believes that educating both<br />

consumers and retailers about the<br />

advantages of his product is key to<br />

OMI’s continuing growth.<br />

“Our business model is the same<br />

as every other mattress manufacturer<br />

except for our product. Retailers have<br />

to qualify their customers on price<br />

first. Our mattresses sell on comfort;<br />

purity is a bonus,” Bader says.<br />

Organicpedic mattresses have<br />

suggested retail prices for queen sizes<br />

starting at about $2,000 for the Classic,<br />

a traditional 8-inch, two-sided<br />

mattress with a 660-coil Bonnell innerspring<br />

unit.<br />

At the high end, is the $5,000<br />

Terra. It has a Talalay latex core, latex<br />

comfort layers and a removable, twosided<br />

latex pillow-top that consumers<br />

can flip from the smooth side to the<br />

14 | <strong>BedTimes</strong> | May 2009<br />

‘Although the<br />

organic industry<br />

has also taken a<br />

recessionary hit,<br />

the market is<br />

out there.’<br />

Branching out Organic<br />

Mattresses Inc.’s product line<br />

includes pillows, comforters and<br />

pads, as well as crib mattresses.<br />

sculpted side, depending on their<br />

preference.<br />

Retailers who understand that<br />

organic consumers form a bottomup,<br />

almost grassroots, market see the<br />

potential of the Organicpedic line on<br />

their floors, Bader says.<br />

“Most retailers are used to demand<br />

being created from the top down by<br />

commercials and advertising,” he says.<br />

“In the organic mattress market, however,<br />

the customers are already there<br />

and walk in retailers’ doors every day.<br />

It’s a huge market and retailers who<br />

take the time to educate consumers<br />

and tell them what they’re buying can<br />

take advantage of it.”<br />

Bader thinks the contraction<br />

of bedding sales in North America<br />

may be working to his company’s<br />

advantage.<br />

“Now that sales are tight, retailers<br />

are beginning to think that they<br />

do want that market and are looking<br />

at promoting healthier lifestyles as a<br />

sales tool,” he says.<br />

OMI sells to retailers throughout<br />

the United States and Canada, with<br />

the heaviest concentration of accounts<br />

on the U.S. coasts. Bader includes<br />

ABC Carpet & Home in New York<br />

and a number of high-end furniture<br />

stores among his dealers, but says the<br />

company’s biggest success has been<br />

with sleep chains that have fewer than<br />

10 stores.<br />

Growth plan<br />

Although Bader doesn’t divulge<br />

specific financial information for<br />

the privately held company, he says<br />

that annual sales have been growing<br />

steadily and he predicts continued<br />

gains in 2009, based on the number<br />

of new dealers OMI picked up during<br />

the company’s debut at the Las<br />

Vegas Market in February. Traffic in<br />

the 2,000-square-foot showroom<br />

was brisk and post-market<br />

sales have been strong: “We<br />

were slammed at market with<br />

the majors, the minors and<br />

everything in between,” Bader says.<br />

Bader’s optimism about the future<br />

is tempered by the realities of the difficult<br />

global economic situation.<br />

“The dynamics of the next five<br />

years are pretty hard to forecast,” he<br />

says. “I do believe that the consumer<br />

will start to demand more validity<br />

and, as that happens, the product<br />

mix on retail floors will change.<br />

We’ll be ready for that change.”<br />

Readiness at OMI means offering<br />

retailers and consumers increased<br />

options. Two new mattresses are in<br />

the pipeline, and Bader is working<br />

with his vendors to develop variations<br />

of the organic cotton, wool<br />

and rubber he uses.<br />

Readiness also means creating a<br />

well-trained, flexible work force—<br />

another focus of his activity over the<br />

past year. BT<br />

www.sleepproducts.org/bedtimes

ManagementIssues<br />

Unlock the potential of your team<br />

5 secrets to empowering your staff and being a better leader<br />

By Lee Froschheiser<br />

As the leader or manager of your<br />

company, do you frequently<br />

feel like things are spinning out<br />

of control? If the answer is yes, you’re<br />

not alone. All too often, employers<br />

find themselves struggling to keep<br />

pace with the day-in, day-out responsibilities<br />

of the job. Yet, it’s usually<br />

their ownership of these responsibilities—and<br />

the fear of letting go of<br />

them—that bogs down the workplace<br />

and stifles overall success.<br />

If letting go has been a challenge<br />

for you, consider the following five<br />

secrets to empowering your people<br />

and becoming a better leader.<br />

1Find an accountability coach<br />

Just as you would consult an<br />

attorney about your company’s<br />

legal issues, you should find someone<br />

impartial to assess and improve<br />

your leadership style and to hold<br />

you accountable. Tough as it may be<br />

to let someone coach you and make<br />

suggestions for change, this person<br />

has one key mission—to help you<br />

achieve your full potential as a leader.<br />

Businesses that fail to see the value<br />

of an accountability coach often have<br />

trouble instigating crucial changes<br />

on their own and are unable to take<br />

their leadership and the company to a<br />

greater level of achievement.<br />

2<br />

Become an empowering leader<br />

To become an empowering<br />

leader, you must first determine<br />

what kind of leader you are today,<br />

using what’s called the empowerment<br />

pendulum. On a scale of 1 to 10, do<br />

you lean toward the control side (1)<br />

of managing your employees or more<br />

toward the empowerment side (10)?<br />

16 | <strong>BedTimes</strong> | May 2009<br />

Ideally, you want to empower others<br />

and that’s accomplished through<br />

training, coaching and supporting<br />

employees by providing them<br />

resources and opportunities to learn<br />

from mistakes. It’s also achieved by<br />

trusting your employees and making<br />

sure their values align with your<br />

company’s values.<br />

Most importantly, you must demonstrate<br />

empowering behavior. All too<br />

often, company owners or managers<br />

say, “Hey, I want to be empowering!”<br />

But when an employee asks for help,<br />

they give her the answers rather than<br />

require her to seek the solutions for<br />

herself. Even worse, they do the employee’s<br />

job for her, wearing a big red<br />

“S” for Supermanager.<br />

If you’re doing everything yourself,<br />

it’s likely that you’re wearing that big<br />

red “S.” Shed this responsibility by<br />

getting the right people around<br />

you so you can delegate to your<br />

team, hold each member<br />

accountable and empower<br />

your staff.<br />

3Establish and maintain fundamental<br />

business practices,<br />

policies and procedures In<br />

everything you say and do, you must<br />

stay focused on practical solutions. Ask<br />

yourself what works and what doesn’t.<br />

The answers to these questions will<br />

uncover the secrets to running your<br />

business effectively. They also will shed<br />

light on six business fundamentals:<br />

leadership, mission, vision, values,<br />

strategies and goals. Ultimately, you’ll<br />

www.sleepproducts.org/bedtimes

need to define, establish, implement,<br />

track and evaluate each of these core<br />

fundamentals. If this sounds like a<br />

massive undertaking, relax: You won’t<br />

be doing all the work. Instead, you’ll be<br />

training and managing your team to<br />

carry out these business fundamentals.<br />

Through this effective leadership approach,<br />

you’ll be able to relinquish unnecessary<br />

control of the company and<br />

turn your attention toward developing<br />

the business instead.<br />

4Focus on the company’s vital<br />

factors You know it’s important<br />

to monitor your body’s health<br />

with regular checkups that measure and<br />

evaluate your vital signs. If you discover<br />

that your weight or blood pressure is<br />

too high, you change your diet and<br />

exercise habits. This often has a domino<br />

effect, improving other vital signs.<br />

When it comes to a company’s<br />

health, an effective leader should focus<br />

on vital signs, or what’s called the company’s<br />

vital factors. These are the crucial<br />

components that must be measured and<br />

accomplished for an efficient system.<br />

As a leader or manager, it’s your job<br />

to define both the company’s and your<br />

employees’ vital factors, determine how<br />

to improve them and then teach your<br />

team to do so, as well. This is most often<br />

done by measuring and then creating<br />

ways to improve. For instance, create a<br />

planning checklist that outlines how to<br />

fix each part of your company’s system.<br />

As you repair the system, you’ll start a<br />

chain reaction of change — the domino<br />

effect that enables overall success.<br />

5Create passion with your<br />

people This is the final secret to<br />

unlocking your team’s power and<br />

potential. Any leader can do this by<br />

motivating and inspiring employees,<br />

but a truly effective leader goes one step<br />

further and requires accountability. As<br />

mentioned, accountability is empowerment<br />

and empowerment breeds<br />

passion. This boils down to measuring<br />

www.sleepproducts.org/bedtimes<br />

employee performance and taking appropriate,<br />

timely action.<br />

Many employers fail to demand<br />

accountability out of fear or because<br />

they view taking action as a negative.<br />

They believe requiring accountability<br />

means pulling the employee aside<br />

to discuss why he isn’t improving.<br />

But accountability also can—and<br />

should—be a positive experience. For<br />

example, when someone is doing a<br />

specific task right, you can give positive<br />

feedback that holds the person<br />

accountable.<br />

Whether you’re delivering negative<br />

or positive feedback, don’t wait until<br />

performance reviews to hold someone<br />

accountable. At that point, your<br />

feedback is usually too late. Instead,<br />

impassion your employees with daily<br />

feedback, whether it’s on the phone,<br />

by email, in the hallway or during<br />

other opportunities. Vital factor<br />

meetings—when you’re discussing the<br />

company’s health—can foster an environment<br />

that’s great for performance<br />

checkups.<br />

Always be on the lookout for ways<br />

to proactively impassion your team.<br />

Accountability is the most underused<br />

tool of mangers, yet it’s probably the<br />

most important. By learning to let<br />

go of the reins a little and pass on<br />

responsibilities to your staff, you will<br />

unlock the power and potential of<br />

your company. BT<br />

Lee Froschheiser, president and chief<br />

executive officer of Map Consulting in<br />

Sherman Oaks, Calif. His consulting<br />

firm specializes in transforming companies<br />

and accelerating the performance<br />

of people, teams and organizations.<br />

Clients include WebEx Communications,<br />

Cold Stone Creamery, Los Angeles<br />

Clippers and KIA Motors. Froschheiser<br />

also co-authored the book, Vital Factors:<br />

The Secret to Transforming Your<br />

Business—And Your Life. For more<br />

information, call 888-834-3040 or visit<br />

www.mapconsulting.com.<br />

One Stop Shopping<br />

for Replacement Parts<br />

Large Extensive Parts Inventory<br />

to Meet Your Requirements<br />

atlantapartsdepot.com<br />

Atlanta Parts Depot <br />

362 Industrial Park Drive<br />

Lawrenceville, GA 30045<br />

1-866-885-5100<br />

Atlanta Parts Depot is a division of<br />

Atlanta Attachment Company, Inc.<br />

© 2009 Atlanta Attachment Company<br />

All rights reserved. 09017040709<br />

<strong>BedTimes</strong> | May 2009 | 17

MarketingReport<br />

Relationship marketing makes connections<br />

You must stay in<br />

constant contact to<br />

build your business<br />

By Karen Saunders<br />

Is the recession the only thing to<br />

blame for your slowing sales? Sara,<br />

a colleague of mine, thought so as<br />

she watched her sales drop, along with<br />

the rest of the economy.<br />

I asked if she had recently cut back<br />

on her advertising and marketing.<br />

“Yes, I’m pulling in the purse<br />

strings and limiting my expenses,”<br />

Sara replied.<br />

I asked if she was meeting new<br />

people and developing relationships.<br />

“No,” she admitted.<br />

Well, that could be part of her<br />

problem. History has shown us that<br />

businesses often reduce—or completely<br />

cut—the money they spend<br />

on marketing and advertising during<br />

economic slowdowns. If you do that,<br />

how do you reach your customers and<br />

end-consumers? One lower cost way is<br />

relationship marketing.<br />

A telling tale<br />

Joe Girard was listed in The Guinness<br />

Book of World Records as the<br />

“World’s Greatest Retail Salesman”<br />

for 12 consecutive years. Joe wasn’t<br />

born with a silver spoon in his mouth.<br />

He was abused as a child, lost jobs<br />

as an adult and even went bankrupt.<br />

He finally landed a job at a Chevrolet<br />

dealership. There, Joe did very well,<br />

personally selling more cars than most<br />

dealerships. In fact, people stood in<br />

line to buy a car from Joe. What was<br />

his secret?<br />

Joe practiced relationship marketing.<br />

Here’s how he did it: He sent<br />

13 handwritten cards to each of his<br />

clients and prospects every year—<br />

one card every month and an extra<br />

at Christmas. Some were cards of<br />

www.sleepproducts.org/bedtimes<br />

appreciation and others offered tips<br />

or giveaways, but they never pushed a<br />

sale or discount. During his 15 years<br />

with the dealership, Joe sent 13,000<br />

handwritten cards. Recipients began<br />

to anticipate getting a card from Joe<br />

every month and he was the first<br />

person on their mind when they were<br />

ready to buy a car.<br />

What can we learn from this story<br />

and how can we expand upon it? Here<br />

are a few strategic objectives we can<br />

put in place now, so our businesses<br />

can better withstand the impact of<br />

economic downturns.<br />

Develop strong relationships People<br />

do business with people they know,<br />

like and trust. It’s our job to make<br />

this connection happen. To do that,<br />

we must go beyond the superficial<br />

and become genuinely interested in<br />

our prospects and customers. For<br />

instance, we can meet customers at<br />

a coffee shop and get to know them<br />

personally, without the usual business<br />

discussions. I often do that. I make<br />

mental notes about what is going on<br />

in their lives, so I can refer to it the<br />

next time we talk. Then I nurture<br />

those relationships by consistently<br />

staying in touch.<br />

Consistency is the key We can stay<br />

connected to our customers and dealers<br />

by sending heartfelt cards like Joe<br />

did or through phone calls, emails or<br />

newsletters. We lose 10% of our influence<br />

every month that we don’t have<br />

contact with our customers. Just a 5%<br />

increase in customer loyalty could add<br />

20% to 80% to your bottom line. A<br />

disappointing statistic shows that 91%<br />

of all real estate agents are forgotten<br />

by clients within one to two years after<br />

they close or represent a buyer on a<br />

home because they did not stay in<br />

touch.<br />

Commit to staying in touch Here<br />

are a few ideas: Set up campaign<br />

postcards to go out once a month<br />

or develop a system for remembering<br />

birthdays or other significant<br />

days. I use an online service that has<br />

a phenomenal system for managing<br />

my contacts, as well as printing and<br />

mailing postcards and greeting cards.<br />

I customize and personalize the cards<br />

with my own handwriting-style font,<br />

signature and photos. I have found<br />

that a simple and sincere card can<br />

make a huge impression on someone.<br />

When we build strong networks<br />

and nurture meaningful relationships<br />

with the people we serve, we<br />

will garner unlimited contacts and be<br />

less affected by economic slowdowns.<br />

Start making relationship marketing<br />

part of your efforts and watch your<br />

company grow. BT<br />

© 2008 Karen Saunders<br />

Karen Saunders is owner of the design<br />

firm MacGraphics Services in Aurora,<br />

Colo., and an expert in graphic design<br />

and relationship marketing. For more<br />

information, call her at 303-680-2330<br />

or check www.macgraphics.net.<br />

<strong>BedTimes</strong> | May 2009 | 19

SalesTalk<br />

New strategies for a changing economy<br />

Hone your skills<br />

& narrow your<br />

list of prospects<br />

By Kelley Robertson<br />

Companies are cutting back,<br />

people are tightening their<br />

belts and many decisionmakers<br />

are holding off on major<br />

purchases. But, chances are,<br />

your company hasn’t reduced<br />

your sales quotas. Selling in a<br />

difficult economy requires a<br />

different approach than selling<br />

during a robust one. Let’s look<br />

at what you need to do to compete<br />

and keep your sales afloat.<br />

Don’t believe everything<br />

you hear: The slide in the<br />

economy doesn’t mean that<br />

your own sales have to sink.<br />

Your mindset plays a tremendous<br />

role in your success.<br />

While it’s difficult to maintain<br />

a positive perspective during<br />

times like these, it’s essential to<br />

keep focused on your main objective.<br />

Associate with positive,<br />

like-minded people and avoid<br />

naysayers like the plague.<br />

1. Tighten your prospecting<br />

Too many salespeople cast a<br />

wide net when prospecting,<br />

with the hope of catching<br />

anything that comes their way. This<br />

approach isn’t a good use of your<br />

time. Instead of cold calling dozens<br />

and dozens of businesses, determine<br />

your ideal customer and target dealers<br />

that most closely match that description.<br />

If you don’t know who your<br />

ideal customer is, look at your existing<br />

customers. Who generates high revenue<br />

with high profit margins? What<br />

problems do you help them solve?<br />

Why do they do business with you? If<br />

20 | <strong>BedTimes</strong> | May 2009<br />

you don’t know, ask.<br />

And don’t, under any circumstances,<br />

say “…and I will sell to anyone.”<br />

This is the equivalent of selling to no<br />

one. Sales guru Lee Salz recommends<br />

that you limit your prospecting efforts<br />

to no more than 25 new customers<br />

with an additional 10 on the<br />

back butner.<br />

Too many salespeople cast a<br />

wide net when prospecting,<br />

with the hope of catching<br />

anything that comes their way.<br />

This approach isn’t a good<br />

use of your time.<br />

2. Broaden your campaign Jill<br />

Konrath, author of Selling to Big<br />

Companies, suggests that you use a<br />

multitouch campaign after you identify<br />

your top prospects. Use a combination<br />

of emails, phone calls, targeted<br />

letters, trigger events and networking<br />

to connect with key decision-makers.<br />

This takes planning and time—another<br />

reason you can’t effectively prospect<br />

more than 25 companies at a time.<br />

Once again, this reinforces the importance<br />

of narrowing your prospect list<br />

instead of using a shotgun approach.<br />

3. Focus your presentations Anytime<br />

you meet with a prospect or<br />

even existing customer, make sure<br />

that your presentation is focused on<br />

his problem. Skip the nonsense about<br />

how long you’ve been in business,<br />

blah, blah, blah. Instead,<br />

concentrate on showing your<br />

prospect exactly how his business<br />

will benefit from selling your<br />

mattress brand. If your product<br />

will improve margins, tell them<br />

by exactly how much. If you have<br />

additional services that improve<br />

their sales efforts, show your<br />

prospect exactly how. Decisionmakers<br />

don’t stop making<br />

purchases in difficult economic<br />

times, but they do expect more.<br />

4. Get closer to your customers<br />

Ideally, you already have a<br />

great relationship with your existing<br />

customers. Now is the time<br />

to further strengthen those ties.<br />

Aggressively look for ways you<br />

can help them solve problems<br />

they may be experiencing in their<br />

business. This doesn’t necessarily<br />

mean selling more of your products.<br />

It could mean connecting<br />

them with experts in different<br />

fields, helping them on a project<br />

or recommending other resources.<br />

5. Become more visible Resist<br />

the temptation to crawl into a cave<br />

and hide until the economy recovers.<br />

Your customers may well forget<br />

about you. Now is the time to increase<br />

your networking activities at<br />

appropriate events. For instance, if<br />

you’re attending Interzum Cologne<br />

May 13-16 in Cologne, Germany,<br />

make a point of going out to din-<br />

www.sleepproducts.org/bedtimes

ner each night with some industry<br />

colleagues you may not know very<br />

well. And start making plans now to<br />

attend the International Sleep Products<br />

Association’s Industry Conference<br />

and Exhibition, which will be<br />

Nov. 4-6 in Bonita Springs, Fla.<br />

(You can find details later this year<br />

at www.sleepproducts.org/<br />

industryconference.)<br />

6. Fine-tune your sales skills As<br />

a sales trainer, I always come back<br />

to this and with good reason. The<br />

skills you currently possess got you<br />

where you are today but they won’t<br />

get you much further. During times<br />

of economic uncertainty, it’s essential<br />

to refine your questioning skills. How<br />

have your customers’ buying processes<br />

changed? What new challenges are<br />

they facing? What needs must your<br />

customers have satisfied now?<br />

www.sleepproducts.org/bedtimes<br />

In addition to death and taxes, one<br />

thing you can count on is that the<br />

economy will fluctuate. Right now, it’s<br />

more challenging than it was just two<br />

years ago. That doesn’t mean you can’t<br />

reach your sales targets. Get smarter.<br />

Get focused. Get busy. Get ready to<br />

succeed in a tough economy. BT<br />

© 2009 Kelley Robertson. All rights<br />

reserved.<br />

Kelley Robertson, author of The<br />

Secrets of Power Selling, helps sales<br />

professionals and businesses discover<br />

new techniques to improve their sales<br />

and profits. Receive a free copy of 100<br />

Ways to Increase Your Sales by subscribing<br />

to his free newsletter at<br />

www.kelleyrobertson.com. Robertson<br />

conducts workshops and speaks<br />

at sales meetings and conferences.<br />

Contact him at 905-633-7750 or<br />

kelley@robertsontraininggroup.com.<br />

Resist the<br />

temptation to<br />

crawl into a cave<br />

and hide until the<br />

economy recovers.<br />

…Now is the time<br />

to increase your<br />

networking<br />

activities at<br />

appropriate events.<br />

<strong>BedTimes</strong> | May 2009 | 21

22 | <strong>BedTimes</strong> | May 2009<br />

Safety First<br />

Creating an injury-free plant<br />

According to the U.S. Bureau of Labor Statistics,<br />

safety at mattress manufacturing plants has steadily<br />

improved since 2001. U.S. mattress manufacturers’<br />

total case incidence rate*, as defined by the<br />

Occupational Safety and Health Administration, dropped<br />

from 13 in 2001 to 6.2 in 2008.<br />

The industry’s improved record is reflective of an overall<br />

trend toward better safety management, says Jesse Brazzell,<br />

manager of safety services at the Safety Management Group<br />

consultancy in Indianapolis.<br />

“When I first started consulting 12 years ago, safety inspections<br />

in workplaces used to raise surprised, even hostile,<br />

responses,” he says. “Now people seem to expect inspections<br />

and that safe procedures will be in place.”<br />

Mattress makers and safety experts <strong>BedTimes</strong> spoke<br />

with agree that companies must strive—not for low levels<br />

of injury—but for zero injuries. They cite an ethical duty<br />

to create a “safety culture” within a company. The results<br />

positively impact morale, product quality and—especially<br />

By Barbara T. Nelles<br />

important in times like these—the bottom line.<br />

Simmons’ safety turnaround story is a case in point.<br />

The Atlanta-based mattress maker had an OSHA incidence<br />

rate of 17.6 in 2001—4.6 points higher than the mattress<br />

industry’s average for that year. In 2008, Simmons’ total case<br />

incidence rate was just 3.2—half the current industry average.<br />

(See story on Page 28.)<br />

“The Simmons safety program has made good business<br />

sense with what it has returned to our bottom line.<br />

For example, we brought our total incurred workers’<br />

compensation costs down from $3.5 million in 2001 to<br />

just $300,000 in 2008,” says Jonathan Dawe, Simmons<br />

director of human resources for safety, health, wellness<br />

and workers’ compensation.<br />

What are the costs of on-the-job injuries and illnesses? In<br />

addition to workers’ compensation, they can include higher<br />

insurance premiums, medical bills, property damage, time<br />

required to hire and train replacements, and overtime paid<br />

to the injured employee’s co-workers.<br />

www.sleepproducts.org/bedtimes

www.sleepproducts.org/bedtimes<br />

* The total case incidence rate<br />

is the number of OSHA recordable<br />

incidents (any occupational<br />

injury or illness that requires<br />

medical treatment beyond simple<br />

first aid) in a given year. It is<br />

determined by multiplying the<br />

recordable incidents by 200,000<br />

and dividing that number by the<br />

total hours worked that year. (The<br />

200,000 hours in the formula<br />

represents the equivalent of 100<br />

employees working 40 hours per<br />

week, 50 weeks per year, and<br />

provides the standard base for<br />

incidence rates.)<br />

<strong>BedTimes</strong> | May | May 2009 2009 | 23<br />

| 23

Build a safety culture<br />

Becoming a zero-accident or zeroillness<br />

workplace requires much more<br />

than training supervisors in safety<br />

regulations and handing out safety<br />

booklets to employees. That was the<br />

old way—and it wasn’t very effective,<br />

safety experts say.<br />

Company leadership, from the top<br />

executives on down, must be committed<br />

to safety management and practices.<br />

Each supervisor and employee<br />

must be on board. If a company appoints<br />

a safety leader, he or she must<br />

be empowered—and motivated—to<br />

get everyone else involved.<br />

“Just like a good marriage, communication<br />

and involvement are key,”<br />

Brazzell says. “A one-person safety<br />

initiative never works.”<br />

When safety becomes ingrained<br />

in your company’s culture, “it will<br />

work its way into all phases of your<br />

manufacturing, with positive impacts<br />

on your efficiency, quality, housekeeping<br />

and employee morale,” says Joe<br />

Schmoeller, senior vice president of<br />

operations at Kingsdown, a bedding<br />

manufacturer based in Mebane, N.C.<br />

“You’ll want to put your safety<br />

programs in writing<br />

and support and<br />

enforce them at every<br />

level,” says professor<br />

Thomas Schneid,<br />

director of Eastern<br />

Kentucky University’s<br />

online and on-campus<br />

graduate program<br />

in safety, security and<br />

emergency management<br />

in Richmond,<br />

Ky. “You need to go<br />

far above OSHA standards if you<br />

want to reduce injuries, create a better<br />

workplace and increase your profitability.”<br />

OSHA has rigorous voluntary regulatory<br />

assessment programs in which<br />

companies can choose to participate.<br />

The Safety and Health Achievement<br />

Recognition Program and the more<br />

stringent Voluntary Protections<br />

Programs require one to three years of<br />

advance preparation. But involvement<br />

in such programs isn’t a necessity if<br />

you want to build an exemplary safety<br />

management program.<br />

24 | <strong>BedTimes</strong> | May 2009<br />

It’s all in the timing<br />

An e c d o t A l A n d even s o m e statistical<br />

evidence shows that certain times<br />

of the week are more dangerous.<br />

Here are some ways to mitigate:<br />

➤ Monday morning It may be a<br />

perfect time for a safety pep talk<br />

to refocus employees who may<br />

be distracted by the weekend’s<br />

activities.<br />

➤ Friday afternoon This is a good<br />

time for a safety walk-through to<br />

check up on housekeeping—and<br />

make sure minds are on the tasks<br />

at hand, not weekend plans.<br />

➤ Operating on Saturdays? Think<br />

twice. Fatigued employees may<br />

be suffering the after-effects of the<br />

previous night’s activities.<br />

‘Do a daily walk-through. Then do<br />

documented weekly walk-throughs.<br />

You are looking for trip hazards, poor<br />

housekeeping, machine guards removed,<br />

employees not wearing personal protective<br />

equipment, missing fire extinguishers, etc.’<br />

“You can take your company to the<br />

next level by sending a staff member<br />

back to school for a safety degree,” Schneid<br />

says. “There are programs of study<br />

available from the community college<br />

level right through graduate school.”<br />

Workplace safety regulations are<br />

complex and constantly changing.<br />

Bringing in an outside safety consultant<br />

makes sense for many smaller<br />

manufacturers. They offer a different<br />

perspective and a “new set of eyes” to<br />

spot unnoticed safety issues.<br />

Englander licensees have relied on<br />

safety compliance consultants, says Ed<br />

Ciolkosz, president of Chicago-based<br />

Englander Midwest and chairman of<br />

Englander’s manufacturing committee.<br />

“I highly recommend that small<br />

and mid-size manufacturers work<br />

with an outside company,” he says.<br />

“It’s the only way to keep up with<br />

regulations and make sure all your<br />

paperwork is in order, too.”<br />

Run a safer plant<br />

“Controlling hazards” is a key phrase<br />

in safety management. And those<br />

hazards can change from day to day<br />

or week to week. Is a new employee<br />

flouting the safety code? Is a piece of<br />

equipment malfunctioning, causing<br />

employees to take dangerous shortcuts?<br />

“A hazard can be an unguarded<br />

machine, a shortage of personal<br />

protection equipment or an employee<br />

or supervisor whose attitude is that<br />

it’s OK to break safety rules to get a<br />

job done,” says Carl Potter, a certified<br />

safety adviser and an advocate for<br />

zero-injury workplaces in Tulsa, Okla.<br />

It’s important to engineer physical<br />

hazards out of your facilities, which<br />

may mean bringing in a qualified<br />

safety engineer to<br />

“machine guard”<br />

older equipment.<br />

“We’ve guarded<br />

spinning fly wheels on<br />

quilt machines and<br />

open rollers that feed<br />

fabric stock into quilters,”<br />

Simmons’ Dawe<br />

says. “We’ve put lots<br />

of interlocks on safety<br />

stops and changed<br />

factory equipment design<br />

and layout—all sorts of things to<br />

literally keep the hazards from coming<br />

into contact with employees.”<br />

Back strains and sprains are the<br />

most common occupational injury in<br />

mattress plants, according to manufacturers.<br />

“We believe prevention is key. For<br />

instance, for the past two years, we’ve<br />

brought in a safety consultant to<br />

coach employees on back safety,” says<br />

Sirina Jacobson, director of quality<br />

and safety at Hoffman Estates, Ill.based<br />

Serta.<br />

Englander Midwest tries to limit<br />

www.sleepproducts.org/bedtimes

strenuous lifting, pushing and tugging<br />

through better plant design and the<br />

use of conveyor belt systems, Ciolkosz<br />

says.<br />

His 95,000-square-foot plant has<br />

rubber floor coverings in work areas<br />

to decrease foot, leg and back strain<br />

and he purchases precut components<br />

when possible to reduce the use of<br />

electric cutting equipment.<br />

Forklift accidents are another<br />

potential plant mishap. Supervisors<br />

should enforce safe driving rules<br />

and formally train all operators in<br />

maneuvering and backing up within<br />

the facility.<br />

When feasible, rotating workers’<br />

assignments can help fend off carpal<br />

Safety resources<br />

Associations<br />

Nonprofit Risk Management Center<br />

Free fact sheets, forms and training checklists for workplace<br />

safety, including Lockout/Tag-out Procedures, Fleet<br />

Safety Checklist and Accident Analysis Fact Sheet<br />

www.nonprofitrisk.org<br />

American Society of Safety Engineers<br />

www.asse.org<br />

Canadian Association of Provincial Safety Councils<br />

Offers safety information and training<br />

www.nationalsafetycouncils.ca<br />

National Safety Council<br />

A safety research, education and advocacy group<br />

www.nsc.org<br />

Online<br />

Free safety checklists and a laundry list of safety<br />

discussion guides<br />

www.toolboxtopics.com<br />

Safety Training Lesson Plans<br />

www.safetylessonplans.com<br />

SAFESTART/SAFETRACK<br />

Industry- and job-specific training materials<br />

and workshops<br />

www.safestart-safetrack.com<br />

Coastal Training Technologies Corp.<br />

An international, multilingual<br />

online training resource covering<br />

all health and safety topics<br />

www.coastal.com<br />

26 | <strong>BedTimes</strong> | May 2009<br />

tunnel syndrome and other repetitive<br />

stress injuries. It also may alleviate<br />

feelings of boredom and monotony,<br />

which can lead to accidents.<br />

Supervisors must enforce consequences<br />

when workers neglect to wear<br />

personal protection equipment, such<br />

as gloves, eyewear, hearing protection,<br />

masks, hard hats and steel-toe boots.<br />

“Because it always comes around<br />

to your people,” Potter says. “You can<br />

retrofit old equipment with safety<br />

guards, but if someone puts tape over<br />

a switch or a chip of wood in a machine<br />

to keep it running, you have a<br />

horrendous injury waiting to happen.”<br />

Serta encourages give-and-take at<br />

its facilities with an open-door policy<br />

on safety matters.<br />

“Communication is No. 1 when it<br />

comes to safety,” Jacobson says.<br />

Supervisors can’t look the other<br />

way or cut someone a break when a<br />

safety rule is broken—the practice will<br />

lead to more rule breaking. Strive to<br />

use positive reinforcement instead of<br />

resentment-causing punitive measures.<br />

“We use a progressive discipline<br />

process,” Dawe says. “You try to coach<br />

and improve those who are not performing<br />

and you recognize, reinforce<br />

and reward good safety behaviors in<br />

others.”<br />

Make sure fully stocked first aid<br />

kits are readily available and employees<br />

know where they are located.<br />

Publications<br />

EHS Today<br />

The latest news about health and safety in office and<br />

industrial settings<br />

www.ehstoday.com<br />

Industrial Safety & Hygiene News<br />

www.ishn.com<br />

Occupational Health & Safety<br />

www.ohsonline.com<br />

Legal Liability: A Guide for Safety and Loss Prevention<br />

Professionals<br />

By Thomas D. Schneid and Michael S. Schumann<br />

Zero! Responsible Safety Management by Design<br />

By Deb Potter with Carl Potter<br />

www.safetybooks.com<br />

U.S. government<br />

OSHA<br />

Detailed information about federal workplace safety<br />

regulations in the United States is available at the U.S.<br />

Department of Labor’s Occupational Safety and Health<br />

Administration Web site, www.osha.gov.<br />

There, you’ll also find:<br />

➤ An easy-to-use alphabetical listing of safety and health<br />

topics, including all workplace hazards and how to<br />

mitigate them<br />

➤ Job Hazard Analysis white paper with complete<br />

information on how to conduct a workplace hazard<br />

assessment and safety audit<br />

➤ OSHA Hazard Awareness Advisor tool<br />

Department of Labor<br />

The U.S. Department of Labor’s Bureau of Labor Statistics<br />

has an online tool for computing an injury incidence<br />

rate, www.bls.gov/iif/osheval.htm.<br />

www.sleepproducts.org/bedtimes

When an accident or near miss<br />

happens at a facility, communicate<br />

it throughout the company and do<br />

a thorough investigation to find out<br />

why it happened.<br />

“You need to educate employees<br />

that most accidents are caused<br />

by rushing, fatigue, frustration or<br />

complacency—by critical errors such<br />

as your eyes not being on the task or<br />

putting yourself in the line of fire,<br />

losing your traction, your balance or<br />

your grip,” Dawe says.<br />

It’s smart to have the head of the<br />

company or someone in upper management<br />

sit down with an injured employee<br />

to discuss the accident, experts<br />

say. It shows concern for the employee<br />

and demonstrates that the company<br />

really cares about safety.<br />

Take whatever corrective measures<br />

are necessary to prevent similar accidents<br />

and communicate your actions<br />

to all employees.<br />

Regular inspections<br />

Safety audits, inspections and walkthroughs<br />

must be part of any effective<br />

safety management program.<br />

“Do a daily walk-through. Then do<br />

documented weekly walk-throughs,”<br />

28 | <strong>BedTimes</strong> | May 2009<br />

consultant Brazzell<br />

says. “You are<br />

looking for trip<br />

hazards, poor<br />

housekeeping,<br />

machine guards<br />

removed, employees<br />

not wearing<br />

personal protective<br />

equipment, missing<br />

fire extinguishers, etc. Generate<br />

a list of items to fix by the following<br />

week. And identify people who need<br />

retraining.”<br />

In addition to regular inspections<br />

and audits conducted by each plant<br />

administrator, Serta conducts twiceyearly<br />

surprise inspections at each of<br />

its facilities, Jacobson says. Englander’s<br />

safety consultants conduct monthly<br />

walk-throughs or safety audits at its<br />

facilities.<br />

“They’re bilingual, which is important<br />

since a majority of our work force<br />

is Hispanic,” Ciolkosz says. “We began<br />

conducting emergency evacuation<br />

drills. They check fire extinguishers<br />

and all safety equipment. They even<br />

examine air quality and noise levels<br />

and hold regular safety meetings with<br />

employees.”<br />

Simmons plants receive OSHA recognition<br />

In recent m o n t h s, sIx sIm m o n s m A n u f A c t u r I n g fAcIlItIes have been recognized by the<br />

U.S. Occupational Safety and Health Association for their workplace safety<br />

and health efforts.<br />

The company’s plant in Aurora, Colo., achieved OSHA’s Voluntary Protection<br />

Program Merit status. Facilities in Honolulu; Kansas City, Kan.; and<br />

Waycross, Ga., earned placement in OSHA’s Safety and Health Achievement<br />

Recognition Program, while a plant in Agawam, Mass., earned SHARP<br />

recertification. A Simmons facility in Los Angeles received the Golden Gate<br />

Partnership Recognition Award for Safety.<br />

“Safety is a huge priority at Simmons at every level,” says Steve Fendrich,<br />

president and chief operating officer of the Atlanta-based bedding manufacturer.<br />

“It is budgeted and planned for and woven into all that we do. There is<br />

a direct correlation between our dedication to safety and the overall quality<br />

of our product.”<br />

“It has been a nine-year journey to get where we are today,” says Jonathan<br />

Dawe, Simmons director of human resources for safety, health, wellness and<br />

workers’ compensation.<br />

Dawe credits the company’s record on safety to a complete overhaul of its<br />

safety systems, as well as its widespread involvement in OSHA’s cooperative<br />

safety programs: All 18 of its domestic manufacturing plants participate. Facilities<br />

in Charlotte, N.C.; Phoenix; San Juan, Puerto Rico; and San Leandro,<br />

Calif., have received special OSHA certifications in the past.<br />

Create a committee<br />

Forming a safety committee<br />

at every facility<br />

is a cornerstone of<br />

safety management.<br />

Choose representatives<br />

from all departments<br />

and levels—but<br />

keep the group small<br />

enough to be effective—<br />

and select an odd number to<br />

aid in decision-making. The committee<br />

should include employees from<br />

the factory floor, an individual with<br />

safety training and a management<br />

representative.<br />

Keep the safety committee’s assignments<br />

simple and focused.<br />

“For example, if you’ve had a recurrence<br />

of a hand injury in the plant,<br />

the committee can examine the problem<br />

and come up with a solution,”<br />

Brazzell says. “Or they can review and<br />

revise policies on something like the<br />

use of personal protective equipment.”<br />

Ongoing training<br />

Companies need to put everything<br />

in writing and make employees<br />

familiar with safety rules during<br />

orientation and ongoing training.<br />

“We try to inject elements of fun<br />

and real-life stories into our ongoing<br />

face-to-face training,” Jacobson<br />

says. “It includes open dialogue,<br />

feedback and a variety of teaching<br />

materials.”<br />

Many companies break safety<br />

training into monthly sessions that<br />

are repeated year to year.<br />

“We hold monthly safety meetings<br />

at each plant covering a different<br />

OSHA topic, such as hazardous<br />

communication, blood-borne<br />

pathogens, Lockout/Tag-out training<br />

and many other safety issues,”<br />

Schmoeller says.<br />

Short topics can be highlighted<br />

each week, for instance, at a Monday<br />

safety briefing on the plant floor.<br />

Review an accident or incident from<br />

the previous week at one of your facilities<br />

or go over some safety rules.<br />

Insurance companies are a good<br />

resource for safety training. They<br />

may offer videos on a number of<br />

topics, as well as provide OSHA<br />

training certifications. Insurers also<br />

www.sleepproducts.org/bedtimes

will perform periodic<br />

safety walkthroughs<br />

to help<br />

identify hazards.<br />

Management’s aim<br />

should be to constantly<br />

remind employees<br />

about the importance of<br />

following all safety rules<br />

and to reinforce safe<br />

behaviors.<br />

Kingsdown adds a financial<br />

incentive by tracking each<br />

facility’s safety record and considering<br />

the results when rating plants<br />

for year-end bonuses, Schmoeller says.<br />

One way to help employees recognize<br />

their stake in a safe, healthy work<br />

Are you prepared for an OSHA inspection?<br />

The National Federation of Independent Business advises<br />

companies to take the following steps to ready themselves<br />

for a possible inspection by the U.S. Occupational<br />