- Page 1 and 2: 01/01/2012 - ProMinent ® Product C

- Page 3 and 4: 01/01/2012 - ProMinent ® Product C

- Page 5 and 6: 01/01/2012 - ProMinent ® Product C

- Page 7 and 8: 01/01/2012 - ProMinent ® Product C

- Page 9: 01/01/2012 - ProMinent ® Product C

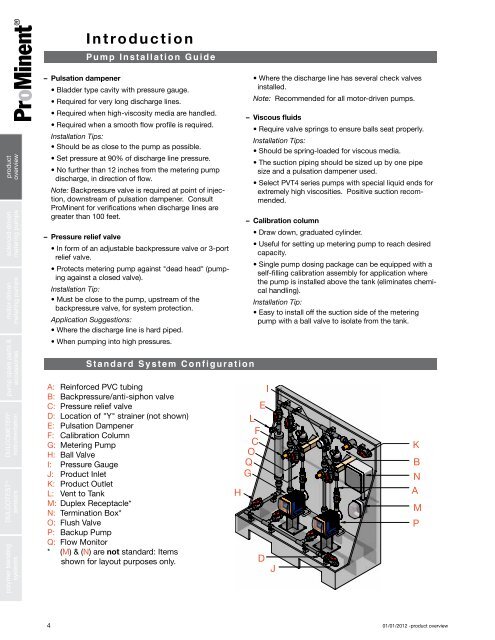

- Page 13: Selection, installation, operation

- Page 17 and 18: Resistance of liquid end materials

- Page 19 and 20: Resistance of liquid end materials

- Page 21 and 22: Resistance of liquid end materials

- Page 23 and 24: Resistance of liquid end materials

- Page 25: 1) WARRANTY, REMEDY, DISCLAIMER: Th

- Page 28 and 29: product overview solenoid-driven me

- Page 30 and 31: product overview solenoid-driven me

- Page 32 and 33: product overview solenoid-driven me

- Page 34 and 35: product overview solenoid-driven me

- Page 36 and 37: product overview solenoid-driven me

- Page 39 and 40: 01/01/2012 - Concept PLUS ProMinent

- Page 41 and 42: 01/01/2012 - Concept PLUS ProMinent

- Page 43 and 44: 01/01/2012 - Beta® pk_1_004_1 ProM

- Page 45 and 46: 01/01/2012 - Beta® ProMinent ® Be

- Page 47 and 48: 01/01/2012 - Beta® ProMinent ® Be

- Page 50 and 51: product overview solenoid-driven me

- Page 52 and 53: product overview solenoid-driven me

- Page 54 and 55: product overview solenoid-driven me

- Page 56 and 57: product overview solenoid-driven me

- Page 58: product overview solenoid-driven me

- Page 61 and 62: 01/01/2012 - delta ® ProMinent ®

- Page 63 and 64: 01/01/2012 - delta ® ProMinent ®

- Page 65 and 66:

01/01/2012 - delta ® ProMinent ®

- Page 67 and 68:

MDLa 01/01/2012 - delta ® ProMinen

- Page 69 and 70:

01/01/2012 - Extronic ProMinent ®

- Page 71 and 72:

01/01/2012 - Extronic ProMinent ®

- Page 73 and 74:

EXBb Enclosure Type: 01/01/2012 - E

- Page 75:

Rp 1/4 pk_1_031 pk_1_032_2 pk_1_029

- Page 79 and 80:

S1Ca A 01/01/2012 - Sigma/ 1 ProMin

- Page 81 and 82:

01/01/2012 - Sigma/ 1 ProMinent ®

- Page 83 and 84:

Sigma/1 Control Version 01/01/2012

- Page 85 and 86:

S1Ba Drive Type: 01/01/2012 - Sigma

- Page 87 and 88:

01/01/2012 - Sigma/ 1 ProMinent ®

- Page 89 and 90:

pk_2_115 A 01/01/2012 - Sigma/ 2 Pr

- Page 91 and 92:

01/01/2012 - Sigma/ 2 ProMinent ®

- Page 93 and 94:

Sigma/ 2 Basic Version 01/01/2012 -

- Page 95 and 96:

S2Ba Drive Type 01/01/2012 - Sigma/

- Page 97 and 98:

6.5 (165) 01/01/2012 - Sigma/ 2 Pro

- Page 99 and 100:

pk_2_006 pk_2_104 pk_2_103 01/01/20

- Page 101 and 102:

01/01/2012 - Sigma HK ProMinent ®

- Page 103 and 104:

S2Ba Drive Type 01/01/2012 - Sigma

- Page 105 and 106:

01/01/2012 - Sigma HK 6.5 (165) Pro

- Page 107 and 108:

pk_2_071 pk_2_104 pk_2_003 A 01/01/

- Page 109 and 110:

Basic Version 01/01/2012 - Sigma/ 3

- Page 111 and 112:

01/01/2012 - Sigma/ 3 ProMinent ®

- Page 113 and 114:

01/01/2012 - Sigma/ 3 ProMinent ®

- Page 115 and 116:

01/01/2012 - ProMus ProMinent ® Pr

- Page 117 and 118:

01/01/2012 - ProMus ProMinent ® Pr

- Page 119:

01/01/2012 - ProMus ProMinent ® Pr

- Page 122 and 123:

product overview solenoid-driven me

- Page 125 and 126:

01/01/2012 - Sigma/ 1 ProMinent ®

- Page 127:

01/01/2012 - Sigma/ 1 ProMinent ®

- Page 131 and 132:

pk_1_008 01/01/2012 - Accessories S

- Page 133 and 134:

pk_1_008 01/01/2012 - Accessories S

- Page 135 and 136:

pk_1_008 01/01/2012 - Accessories b

- Page 137 and 138:

pk_1_008 01/01/2012 - Accessories S

- Page 139 and 140:

01/01/2012 - Accessories Motor Pump

- Page 141 and 142:

01/01/2012 - Accessories Motor Pump

- Page 143 and 144:

01/01/2012 - Accessories Motor Pump

- Page 145 and 146:

Pulse Control Pulse control will al

- Page 147 and 148:

Fig. 1 2165/4 Fig. 2 1521/4 D D 01/

- Page 149 and 150:

Injection valves Fig. 1 A 1447/4 Fi

- Page 151 and 152:

2181/4 1052/4 01/01/2012 - Accessor

- Page 153 and 154:

Gaskets Adapters 01/01/2012 - Acces

- Page 155 and 156:

1/4" FNPT valves Backpressure Press

- Page 157 and 158:

Pulsation dampeners operate on the

- Page 159 and 160:

Pulsation dampeners (cont.) 23.00

- Page 161 and 162:

Calibration columns Borosilicate Gl

- Page 163 and 164:

Adjustable metering monitor “Flow

- Page 165 and 166:

Chemical tanks US gal Litre 100 80

- Page 167 and 168:

Float switches, two stage Float swi

- Page 169 and 170:

Float switches, two stage for Sigma

- Page 171 and 172:

Suction assemblies, single-stage: f

- Page 173 and 174:

Next Generation 01/01/2012 - Access

- Page 175 and 176:

5-1/2" pk_1_092 11" pk_1_092 16" pk

- Page 177 and 178:

Pulse-type water meters for potable

- Page 179 and 180:

Fig. 1 2152/3 Fig. 2 2160/3 01/01/2

- Page 181 and 182:

Valve springs Fig. 1 pk_1_103 Fig.

- Page 183 and 184:

AC Inverter Provides variable motor

- Page 185 and 186:

01/01/2012 - Accessories Pump & Sys

- Page 187 and 188:

Provides variable motor speed with

- Page 189 and 190:

1047_4_1 01/01/2012 - Accessories P

- Page 191:

Introduction 01/01/2012 - Accessori

- Page 195 and 196:

An Introduction to Process Measurem

- Page 197 and 198:

01/01/2012 - DULCOMETER® ProMinent

- Page 199 and 200:

01/01/2012 - DULCOMETER® ProMinent

- Page 201 and 202:

01/01/2012 - DULCOMETER® ProMinent

- Page 203 and 204:

01/01/2012 - DULCOMETER® ProMinent

- Page 205 and 206:

01/01/2012 - DULCOMETER® ProMinent

- Page 207 and 208:

01/01/2012 - DULCOMETER® ProMinent

- Page 209 and 210:

Measuring principle The Perox measu

- Page 211 and 212:

01/01/2012 - DULCOMETER® ProMinent

- Page 213 and 214:

01/01/2012 - DULCOMETER® ProMinent

- Page 215 and 216:

pk_5_001 01/01/2012 - DULCOMETER®

- Page 217 and 218:

pk_5_045 01/01/2012 - DULCOMETER®

- Page 219 and 220:

01/01/2012 - DULCOMETER® ProMinent

- Page 221 and 222:

DXCa Mounting type 01/01/2012 - DUL

- Page 223 and 224:

01/01/2012 - DULCOMETER® ProMinent

- Page 225 and 226:

01/01/2012 - DULCOMETER® ProMinent

- Page 227 and 228:

01/01/2012 - DULCOMETER® ProMinent

- Page 229 and 230:

A Stub cable B Main BUS cable 01/01

- Page 231 and 232:

01/01/2012 - DULCOMETER® ProMinent

- Page 233 and 234:

01/01/2012 - DULCOMETER® ProMinent

- Page 235 and 236:

Sigma/ 1 pk_2_001 P_BE_0002_SW Beta

- Page 237 and 238:

01/01/2012 - DULCOMETER® ProMinent

- Page 239 and 240:

pk_5_021 Mod e 01/01/2012 - DULCOME

- Page 241 and 242:

01/01/2012 - DULCOMETER® ProMinent

- Page 243 and 244:

01/01/2012 - DULCOMETER® ProMinent

- Page 245 and 246:

01/01/2012 - DULCOMETER® ProMinent

- Page 247:

01/01/2012 - DULCOMETER® ProMinent

- Page 251 and 252:

01/01/2012 - DULCOTEST® ProMinent

- Page 253 and 254:

01/01/2012 - DULCOTEST® ProMinent

- Page 255 and 256:

pk_6_016 01/01/2012 - DULCOTEST® P

- Page 257 and 258:

pk_6_018 pk_6_017 01/01/2012 - DULC

- Page 259 and 260:

pk_6_020 pk_6_023 01/01/2012 - DULC

- Page 261 and 262:

pk_6_025 pk_6_027 pk_6_028 pk_6_030

- Page 263 and 264:

pk_6_035 pk_6_034 pk_6_033 01/01/20

- Page 265 and 266:

01/01/2012 - DULCOTEST® ProMinent

- Page 267 and 268:

01/01/2012 - DULCOTEST® ProMinent

- Page 269 and 270:

pk_6_039 pk_6_039 01/01/2012 - DULC

- Page 271 and 272:

CLO_1 CLO_2 01/01/2012 - DULCOTEST

- Page 273 and 274:

pk_6_096 pk_6_040 pk_6_041 01/01/20

- Page 275 and 276:

pk_6_015 pk_6_084 01/01/2012 - DULC

- Page 277 and 278:

BRE_2_CAN CBR_1 01/01/2012 - DULCOT

- Page 279 and 280:

CDE_3mA pk_6_047 01/01/2012 - DULCO

- Page 281 and 282:

pk_6_039 01/01/2012 - DULCOTEST® P

- Page 283 and 284:

pk_6_051 01/01/2012 - DULCOTEST® P

- Page 285 and 286:

01/01/2012 - DULCOTEST® ProMinent

- Page 287 and 288:

LF_1_FE LFT_1FE 01/01/2012 - DULCOT

- Page 289 and 290:

01/01/2012 - DULCOTEST® ProMinent

- Page 291 and 292:

pk_6_054 pk_6_069 pk_6_056 pk_6_055

- Page 293 and 294:

50 ml pk_6_058 pk_6_058 50 ml pk_6_

- Page 295 and 296:

pk_6_066 pk_6_071 01/01/2012 - DULC

- Page 297:

pk_6_063 pk_6_070 01/01/2012 - DULC

- Page 301 and 302:

01/01/2012 - Polymer Blending ProMi

- Page 303 and 304:

01/01/2012 - Polymer Blending ProMi

- Page 305 and 306:

01/01/2012 - Polymer Blending ProMi

- Page 307 and 308:

01/01/2012 - Polymer Blending ProMi