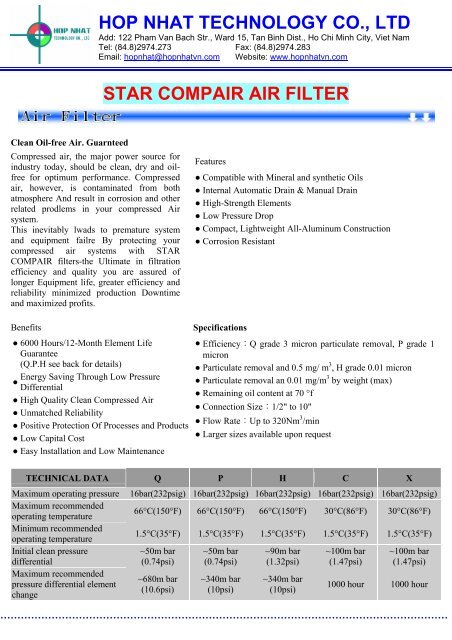

STAR COMPAIR AIR FILTER

STAR COMPAIR AIR FILTER

STAR COMPAIR AIR FILTER

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Clean Oil-free Air. Guarnteed<br />

Compressed air, the major power source for<br />

industry today, should be clean, dry and oilfree<br />

for optimum performance. Compressed<br />

air, however, is contaminated from both<br />

atmosphere And result in corrosion and other<br />

related prodlems in your compressed Air<br />

system.<br />

This inevitably lwads to premature system<br />

and equipment failre By protecting your<br />

compressed air systems with <strong>STAR</strong><br />

<strong>COMP<strong>AIR</strong></strong> filters-the Ultimate in filtration<br />

efficiency and quality you are assured of<br />

longer Equipment life, greater efficiency and<br />

reliability minimized production Downtime<br />

and maximized profits.<br />

HOP NHAT TECHNOLOGY CO., LTD<br />

Add: 122 Pham Van Bach Str., Ward 15, Tan Binh Dist., Ho Chi Minh City, Viet Nam<br />

Tel: (84.8)2974.273 Fax: (84.8)2974.283<br />

Email: hopnhat@hopnhatvn.com Website: www.hopnhatvn.com<br />

<strong>STAR</strong> <strong>COMP<strong>AIR</strong></strong> <strong>AIR</strong> <strong>FILTER</strong><br />

Features<br />

Benefits Specifications<br />

● 6000 Hours/12-Month Element Life<br />

Guarantee<br />

(Q.P.H see back for details)<br />

Energy Saving Through Low Pressure<br />

●<br />

Differential<br />

● High Quality Clean Compressed Air<br />

● Unmatched Reliability<br />

● Positive Protection Of Processes and Products<br />

● Low Capital Cost<br />

● Easy lnstallation and Low Maintenance<br />

● Compatible with Mineral and synthetic Oils<br />

● Internal Automatic Drain & Manual Drain<br />

● High-Strength Elements<br />

● Low Pressure Drop<br />

● Compact, Lightweight All-Aluminum Construction<br />

● Corrosion Resistant<br />

● Efficiency:Q grade 3 micron particulate removal, P grade 1<br />

micron<br />

3<br />

● Particulate removal and 0.5 mg/ m , H grade 0.01 micron<br />

3<br />

● Particulate removal an 0.01 mg/m by weight (max)<br />

● Remaining oil content at 70 °f<br />

● Connection Size:1/2" to 10"<br />

3<br />

● Flow Rate:Up to 320Nm /min<br />

● Larger sizes available upon request<br />

TECHNICAL DATA Q P H C X<br />

Maximum operating pressure 16bar(232psig) 16bar(232psig) 16bar(232psig) 16bar(232psig) 16bar(232psig)<br />

Maximum recommended<br />

operating temperature<br />

66°C(150°F) 66°C(150°F) 66°C(150°F) 30°C(86°F) 30°C(86°F)<br />

Minimum recommended<br />

operating temperature<br />

1.5°C(35°F) 1.5°C(35°F) 1.5°C(35°F) 1.5°C(35°F) 1.5°C(35°F)<br />

Initial clean pressure<br />

~50m bar ~50m bar ~90m bar ~100m bar ~100m bar<br />

differential<br />

(0.74psi) (0.74psi) (1.32psi) (1.47psi) (1.47psi)<br />

Maximum recommended<br />

pressure differential element<br />

change<br />

~680m bar<br />

(10.6psi)<br />

~340m bar<br />

(10psi)<br />

~340m bar<br />

(10psi)<br />

1000 hour 1000 hour

‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧<br />

‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧<br />

Direct interception:<br />

Removes the large particles, this mechanism<br />

tend to take place on the surface of the filter<br />

material affecting mainly the large particles, say<br />

over 1 micron in size.<br />

Diffusion or Brownian Movement:<br />

Which cause the very sera small particles to eventually<br />

collide with and adhere to a fiber.<br />

This usually affects particles below 0.3 micron in size.<br />

Obviously a degree of overlap takes place with the

Inertial impaction:<br />

Removes particles, which are unable to negotiate<br />

the tortuous path between the fibers. Typically<br />

offecting particles in the 0.3 micron - 1 micron size<br />

range.<br />

‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧<br />

<strong>FILTER</strong><br />

GRADE<br />

PARTICLE<br />

REMOVAL DOWN<br />

TO<br />

OIL REMOVAL<br />

DOWN TO(*)<br />

mechanisms, the extent varying on the conditions.<br />

When all mechanisms are combined together and<br />

utilized by a deep bed of the correct grade and type of<br />

filter material, total removal of all particles whether<br />

liquid or solid, is achieved.<br />

NOMINAL<br />

INITIAL<br />

PRESSURE DROP<br />

Q 3 micron -- 0.03 bar g<br />

P 1 micron 0.5 mg/m 3 0.05 bar g<br />

H 0.01 micron 0.01 mg/m 3<br />

0.09 bar g<br />

C -- 0.003 mg/m 3<br />

0.10 bar g<br />

X -- 0.001 mg/m 3<br />

0.10 bar g<br />

(*) Referred to bar and 20 Degrees Celsius<br />

‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧‧<br />

<strong>FILTER</strong><br />

FLOW RATES<br />

@7 bar (100psig)<br />

(mm)<br />

REPLACEMENT<br />

ELEMENTS<br />

WELGHT<br />

PIPE<br />

SIZE<br />

3<br />

scfm Nm /Min A B C D E Type No. Kg<br />

G09 G 1/2 32 0.9 91 25 265 180 EA09 1 1.4<br />

G19 G 3/4 67 1.9 91 25 265 180 EA19 1 1.4<br />

G33 G1 116 3.3 115 30 415 315 EA33 1 2.8<br />

G40 G1 1/2 145 4.0 115 30 415 315 EA40 1 2.8<br />

G60 G1 1/2 176 5.0 115 30 415 315 EA60 1 2.8<br />

G70 G2 250 7.0 160 15 585 350 EA70 1 6.4<br />

G100 G2 353 10 160 15 585 350 EA100 1 6.6<br />

G140 G2 494 14 160 15 585 350 EA140 1 6.8<br />

G200 G2 1/2 706 20 180 45 730 420 EA200 1 11.0<br />

G280 G2 1/2 988 28 180 45 945 550 EA280 1 13.4<br />

G350 G3 1235 35 220 60 760 420 EA350 1 17.4<br />

G420 G3 1482 42 500 60 760 420 EA420 1 18.1<br />

F600 NW100 2117 60 550 230 1000 260 950 EA200 3 95<br />

F800 NW125 2822 80 625 250 1150 260 950 EA200 4 105<br />

F1200 NW150 4234 120 675 260 1300 260 950 EA200 6 120<br />

F1600 NW150 5645 160 730 280 1400 260 950 EA200 8 130<br />

F2000 NW200 7056 200 780 310 1450 260 950 EA200 10 145<br />

F2600 NW200 9173 260 780 310 1450 260 950 EA200 13 155<br />

F3200 NW250 11290 320 840 340 1550 260 950 EA200 16 175<br />

For flow rates at other pressures, apply the correction factor shown.<br />

Line<br />

Bar g 1 2 3 5 7 9 11 13 15 17 20<br />

Pressure Psi g 15 29 44 73 102 131 160 189 218 247 290<br />

Correction factor 0.38 0.53 0.65 0.85 1.0 1.13 1.25 1.36 1.46 1.56 1.7