Third Edition Hot Rolled and Structural Steel Products - CIM

Third Edition Hot Rolled and Structural Steel Products - CIM

Third Edition Hot Rolled and Structural Steel Products - CIM

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

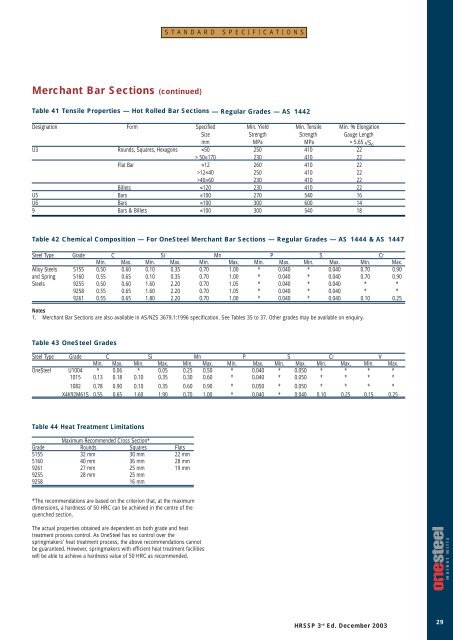

Merchant Bar Sections (continued)<br />

Table 41 Tensile Properties — <strong>Hot</strong> <strong>Rolled</strong> Bar Sections — Regular Grades — AS 1442<br />

Designation Form Specified Min. Yield Min. Tensile Min. % Elongation<br />

Size Strength Strength Gauge Length<br />

mm MPa MPa = 5.65 √S o<br />

U3 Rounds, Squares, Hexagons ≤50 250 410 22<br />

> 50≤170 230 410 22<br />

Flat Bar ≤12 260 410 22<br />

>12≤40 250 410 22<br />

>40≤60 230 410 22<br />

Billets ≤120 230 410 22<br />

U5 Bars ≤100 270 540 16<br />

U6 Bars ≤100 300 600 14<br />

9 Bars & Billets ≤100 300 540 18<br />

Table 42 Chemical Composition — For One<strong>Steel</strong> Merchant Bar Sections — Regular Grades — AS 1444 & AS 1447<br />

<strong>Steel</strong> Type Grade C Si Mn P S Cr<br />

Min. Max. Min. Max. Min. Max. Min. Max. Min. Max. Min. Max.<br />

Alloy <strong>Steel</strong>s 5155 0.50 0.60 0.10 0.35 0.70 1.00 * 0.040 * 0.040 0.70 0.90<br />

<strong>and</strong> Spring 5160 0.55 0.65 0.10 0.35 0.70 1.00 * 0.040 * 0.040 0.70 0.90<br />

<strong>Steel</strong>s 9255 0.50 0.60 1.60 2.20 0.70 1.05 * 0.040 * 0.040 * *<br />

9258 0.55 0.65 1.60 2.20 0.70 1.05 * 0.040 * 0.040 * *<br />

9261 0.55 0.65 1.80 2.20 0.70 1.00 * 0.040 * 0.040 0.10 0.25<br />

Notes<br />

1. Merchant Bar Sections are also available in AS/NZS 3679.1:1996 specification. See Tables 35 to 37. Other grades may be available on enquiry.<br />

Table 43 One<strong>Steel</strong> Grades<br />

<strong>Steel</strong> Type Grade C Si Mn P S Cr V<br />

Min. Max. Min. Max. Min. Max. Min. Max. Min. Max. Min. Max. Min. Max.<br />

One<strong>Steel</strong> U1004 * 0.06 * 0.05 0.25 0.50 * 0.040 * 0.050 * * * *<br />

1015 0.13 0.18 0.10 0.35 0.30 0.60 * 0.040 * 0.050 * * * *<br />

1082 0.78 0.90 0.10 0.35 0.60 0.90 * 0.050 * 0.050 * * * *<br />

X4K92M61S 0.55 0.65 1.60 1.90 0.70 1.00 * 0.040 * 0.040 0.10 0.25 0.15 0.25<br />

Table 44 Heat Treatment Limitations<br />

Maximum Recommended Cross Section*<br />

Grade Rounds Squares Flats<br />

5155 32 mm 30 mm 22 mm<br />

5160 40 mm 36 mm 28 mm<br />

9261 27 mm 25 mm 19 mm<br />

9255 28 mm 25 mm<br />

9258 16 mm<br />

*The recommendations are based on the criterion that, at the maximum<br />

dimensions, a hardness of 50 HRC can be achieved in the centre of the<br />

quenched section.<br />

The actual properties obtained are dependent on both grade <strong>and</strong> heat<br />

treatment process control. As One<strong>Steel</strong> has no control over the<br />

springmakers’ heat treatment process, the above recommendations cannot<br />

be guaranteed. However, springmakers with efficient heat treatment facilities<br />

will be able to achieve a hardness value of 50 HRC as recommended.<br />

STANDARD SPECIFICATIONS<br />

HRSSP 3 rd Ed. December 2003<br />

29