Shower Tray Fitting - Aqualux Shower Enclosures

Shower Tray Fitting - Aqualux Shower Enclosures

Shower Tray Fitting - Aqualux Shower Enclosures

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

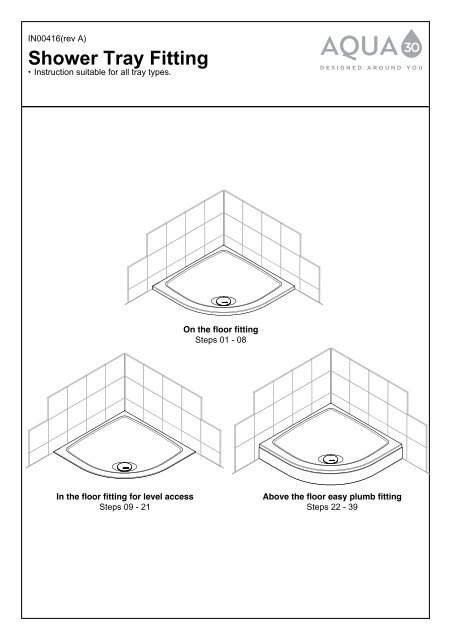

IN00416(rev A)<br />

<strong>Shower</strong> <strong>Tray</strong> <strong>Fitting</strong><br />

• Instruction suitable for all tray types.<br />

In the floor fitting for level access<br />

Steps 09 - 21<br />

On the floor fitting<br />

Steps 01 - 08<br />

Above the floor easy plumb fitting<br />

Steps 22 - 39

Before You Start<br />

• Read the instructions in full before commencing installation.<br />

• Take care of the bottom edges of the tray to avoid chipping of the gelcoat on the corner.<br />

• Check the tray carefully for damage before installation begins. Once installation has begun, the<br />

manufacturer can take no responsibility for damage to the product.<br />

• The tray may be fitted “on the floor” – see steps 1-8, “in the floor” for level access – see steps 9-21 and<br />

“above the floor” for easy plumbing on concrete floors etc. – see steps 22-39. Above the floor fitting<br />

requires the Aqua 30 Top Level Easy Plumb Kit which is available separately.<br />

• Low profile trays require good drainage – ensure that the associated waste pipe runs have a good fall<br />

angle to match the water delivery of the shower unit. We strongly recommend the use of the<br />

Aqua 30 90mm High-Flow Waste, which is available separately.<br />

• Have all the correct tools available – see opposite.<br />

• Ensure that the area is clean, dust free and dry before fitting.<br />

• It is recommended that shower trays are installed before tiling / cladding of the wall surfaces. Ideally the<br />

tile / cladding will overlap the corner radius of the tray such that the mounting surface for the enclosure<br />

will be exactly where the corner radius meets the tray top surface.<br />

During Installation<br />

• Protect the surface of the shower tray with a cloth or cardboard to avoid damage<br />

• In all situations the tray must be bedded on a stiff 5:1 mixture of sand to cement or a ready mixed mortar<br />

product. The void between the underside well surface of the tray and the substrate must be fully filled<br />

to avoid any risk of movement or cracking in use (note that this does not include the space inside the<br />

rim of the tray, which may be left unfilled). Observe the manufacturers recommendations and safety<br />

instructions when handling mortar, particularly with regard to personal protective equipment ie. dust<br />

mask and gloves. Avoid direct skin contact with wet mortar.<br />

• Carefully seal the waste and tray to wall junctions with an anti-fungicidal silicone.<br />

• Wait 24 hours before standing on the tray to ensure that the mortar bed and silicone have fully cured.<br />

Fig.A<br />

Direct Floor Installation:<br />

Refer to Steps 1-8 for<br />

Installation details.<br />

Fig.B<br />

Inset Floor Installation:<br />

Refer to Steps 9 - 21 for<br />

Installation details.<br />

MORTAR BED<br />

SHOWER<br />

TRAY<br />

FLOOR<br />

BOARDS<br />

SHOWER<br />

TRAY<br />

MORTAR BED<br />

FLOOR<br />

BOARDS<br />

PLYWOOD<br />

BOARDS<br />

SILICONE<br />

SILICONE<br />

TILES<br />

TILES<br />

PLASTERBOARD<br />

WALL<br />

PLASTERBOARD<br />

WALL

In-use and care recommendations<br />

• Clean the tray with soapy water and use a soft bristle brush if required for any crevices, then rinse and<br />

dry. Finish off with a soft, clean towel. Avoid all abrasives and harsh detergents.<br />

• If a bath mat is used in the tray, remove after use to avoid any risk of marking.<br />

Safety<br />

• This product may be heavy and require two people to carry and install it.<br />

• When drilling, check first for hidden pipes and cables.<br />

• Use safety eyewear when drilling.<br />

• Observe precautions when handling cement / mortar.<br />

Disclaimer<br />

• Please notify the retailer immediately of any damage or faults. The manufacturer cannot be held<br />

responsible for installation costs that may arise from damaged or faulty product being installed.<br />

• Please dispose of all packaging with due regard for the environment.<br />

Materials required<br />

• 18mm Marine ply, battens and noggins for “in the floor fit” as required.<br />

• Sand and cement or ready-mixed mortar<br />

•<br />

A dedicated high flow waste and easy plumb kit are available separately<br />

Tools Required (not supplied)<br />

Spirit Level Screwdriver Tape Measure Pencil Utility Knife<br />

Junior hacksaw<br />

Silicone Gun & Sealant Power Drill Suitable Hole Saw Bits<br />

Help Line: 0870 241 6131<br />

Jigsaw<br />

Lines open: 8.30am - 5.00pm Monday to Friday<br />

Standard National call charge rate from BT landlines

Parts & <strong>Fitting</strong>s Supplied<br />

!<br />

Keep small parts away from children<br />

<strong>Tray</strong>*<br />

X1<br />

D2<br />

D1<br />

<strong>Tray</strong> (mm)<br />

Legs Clips Joiners<br />

760 & 800 Square 5 8 1<br />

900 Square<br />

5 10 1<br />

1200 x 760, 800 Rectangle<br />

8 10 1<br />

1200 x 900 Rectangle<br />

8 11 1<br />

800, 900 Quadrant<br />

6 6 NA<br />

Please Note:<br />

*Varies depending on tray / kit type.<br />

Top Level Easy Plumb Kit available separately<br />

!<br />

Please notify the retailer immediately<br />

of any damage or faults. The<br />

manufacturer cannot be held<br />

responsible for any installation costs<br />

that may arise from a damaged or<br />

faulty product being installed.<br />

Waste Cover<br />

X1<br />

Waste<br />

Assembly<br />

X1<br />

Board*<br />

X1<br />

Clips<br />

<strong>Tray</strong> Skirt*<br />

X1<br />

High flow waste -<br />

Available<br />

separately<br />

Skirt Joiner<br />

Square & rectangle<br />

trays only<br />

Legs

D1 D2<br />

A No.8 x ¾” Pan Head Pozi Screws<br />

x1<br />

per skirt<br />

(actual size) clip / foot<br />

B<br />

A<br />

B<br />

Washer<br />

Skirt Fixing<br />

Bracket<br />

X4<br />

Loose Screws & <strong>Fitting</strong>s Supplied<br />

A<br />

B<br />

(actual size)<br />

Qty<br />

Qty<br />

x1<br />

per skirt<br />

clip / foot

Direct to Floor (Finished Floor) Fixing Details only:<br />

For Infloor fitting please refer to steps 9-21 & for Easy Plumb 22-39<br />

1<br />

2<br />

!<br />

Position <strong>Tray</strong> and mark<br />

waste position.<br />

!<br />

!<br />

2.1<br />

2.2<br />

Ensure floor boards are sound<br />

and secure - if not board out<br />

area with 18mm marine ply.<br />

Ensure <strong>Tray</strong> is correctly<br />

positioned and level.<br />

Remove floor boards to gain<br />

access to waste pipe and<br />

fit the Waste Trap fitment.<br />

Cut out floor board to suit<br />

waste hole, (as marked in<br />

previous step). Recommended<br />

diameter 140mm.<br />

Ensure waste is not obstructed as<br />

this may cause leakage

3<br />

<strong>Tray</strong> Preparation:<br />

4<br />

Liberally apply silicone sealant to back of tray.<br />

Mix a stiff 5/1 composition of sand and<br />

cement or use ready-mixed prepared to<br />

manufacturers instructions.<br />

Thoroughly mix and spread with high<br />

spots to contact tray underside - ensure<br />

all of the tray well is fully supported.<br />

Ensure <strong>Tray</strong> is correctly<br />

positioned and level.<br />

5 Apply silicone<br />

sealant and PTFE<br />

tape as required.<br />

!<br />

!<br />

Take precautions when handling<br />

cement / mortar.<br />

4.1<br />

!

6<br />

7<br />

5mm<br />

8<br />

5mm<br />

!<br />

!<br />

!<br />

Ensure <strong>Tray</strong> is correctly<br />

positioned and level.<br />

Thoroughly Seal <strong>Tray</strong><br />

to Wall.<br />

Tile down to <strong>Tray</strong><br />

surface leaving a 5mm<br />

gap for sealing.<br />

Ensure Silicone Sealant<br />

thoroughly seals junction of<br />

tiles and tray.<br />

!<br />

Once silicone and mortar<br />

is dry water test the<br />

waste for drainage.

Inset Floor Fixing Details only:<br />

For On the floor fitting please refer to steps 1-8. For easy Plumb 22-39<br />

9<br />

!<br />

10<br />

Cut out tray footprint to the depth<br />

of the floorboards & remove.<br />

Beware of concealed pipework &<br />

electrical cables.<br />

Position tray and mark position<br />

!<br />

11<br />

!<br />

Ensure <strong>Tray</strong> is correctly<br />

positioned.<br />

Check the tops of the joist are<br />

level.

!<br />

12<br />

13<br />

14<br />

18mm<br />

Place battens 18mm from the top of<br />

perimeter noggins & joists.<br />

!<br />

!<br />

12.1<br />

Add noggins as additional support as<br />

required.<br />

13.1<br />

Fit the Waste Trap fitment.<br />

Align waste with tray. Do not drill the<br />

joists as this may compromise their<br />

strength.<br />

14.1<br />

Wall<br />

Wall<br />

Battens<br />

Joists<br />

Floor<br />

Battens<br />

Joists<br />

Floor<br />

Noggins<br />

Plan View<br />

Plan View

15<br />

16<br />

<strong>Tray</strong> Preparation:<br />

17<br />

Liberally apply silicone sealant to back of tray.<br />

!<br />

!<br />

Infill with 18mm marine ply cutting<br />

a hole for the waste. Recommended<br />

diameter 140mm.<br />

Mix a stiff 5/1 composition of sand and<br />

cement or use ready-mixed prepared to<br />

manufacturers instructions.<br />

! Take precautions when handling<br />

!<br />

Thoroughly mix and spread with high<br />

spots to contact tray underside - ensure<br />

all of the tray well is fully supported.<br />

cement / mortar.<br />

17.1<br />

Ensure <strong>Tray</strong> is correctly positioned &<br />

levelled.

18 Apply a silicone<br />

sealant and PTFE<br />

tape as required.<br />

19<br />

!<br />

Ensure tray is correctly<br />

positioned and level.<br />

Thoroughly seal tray to wall.

20 Tile down to tray<br />

surface leaving a 5mm ! gap for sealing.<br />

5mm<br />

21<br />

5mm<br />

!<br />

!<br />

Ensure silicone sealant<br />

thoroughly seals junction<br />

of tiles and tray.<br />

Once silicone and mortar<br />

is dry water test the<br />

waste for drainage.

Easy Plumb <strong>Fitting</strong> Details only:<br />

For On the floor fitting please refer to steps 1-8. For In the floor fitting 9-21<br />

Fig. A: Board layouts and Leg positions are unique to each kit size & type.<br />

It is recommended that the waste is situated at the front of the tray when installed for easy access.<br />

Fig. B: Skirt Layouts<br />

22<br />

!<br />

Quadrant Square<br />

Rectangle<br />

Quadrant Square Rectangle<br />

Square & rectangle boards require a 4mm clearance from the wall.<br />

Quadrant tray boards may butt against the wall.<br />

Offer Board into position.

Adjustable foot preparation<br />

!<br />

23.1<br />

23.2<br />

Locking Key<br />

Foot Body<br />

Foot Base<br />

Please Note: Adjustable<br />

Foot is supplied assembled,<br />

disassemble as shown.<br />

Position Adjustable<br />

Foot base into foot<br />

holes in Board.<br />

Refer to Fig. A for<br />

foot positions.<br />

Mark fixing hole<br />

positions.<br />

23<br />

!<br />

IMPORTANT NOTE:<br />

Ensure board and adjustable foot<br />

bases are correctly positioned.

!<br />

* Drill pilot hole to suit floor type, if<br />

required use wall plugs (not supplied &<br />

if necessary).<br />

24.1* 24.2<br />

25.1<br />

Ensure the waste is not obstructed<br />

as this may cause leakage.<br />

A<br />

B<br />

24<br />

!<br />

25<br />

!<br />

For accuracy fit feet bases in<br />

conjunction with board.<br />

Route waste pipe as required<br />

ensuring foot clearance.

26<br />

!<br />

Screw skirt clips onto underside<br />

of board using holes provided, as<br />

required<br />

Foot Body preparation:<br />

Choose four feet at the<br />

extremities of the board &<br />

set to the high position.<br />

A<br />

B<br />

Set all others at the low position.

27<br />

28<br />

!<br />

27.1<br />

28.1<br />

Position feet into board.<br />

Push hard to ensure foot is fully<br />

located.<br />

Position feet bodies and board into<br />

foot base.

Square & Rectangular boards<br />

!<br />

!<br />

!<br />

29<br />

*<br />

Assemble skirt if required.<br />

Trim with a junior hacksaw at each<br />

end to match the wall.<br />

Skirt Joiner<br />

When using the corner junction use the factory cut ends<br />

at the junction for best finish<br />

Inside view<br />

Ensure skirt snaps securely into<br />

fixing clips.<br />

Work progressively from one end, if the skirt should kink this is due to the board being<br />

slightly out of flat and can be compensated for by final adjustment of the legs.<br />

!

Fig. C: Positioning locking key into ADJUSTABLE POSITION:<br />

30<br />

i)*<br />

* Please Note: Top of foot body is not shown for legibility only.<br />

You do not need to disassemble foot body at this stage.<br />

Locate locking key onto depth stops<br />

on the inside of the leg body so that it<br />

sits in a proud position.<br />

ii)*<br />

!<br />

Ensure that the locking key is set<br />

in a proud position, as shown in<br />

Fig.C (above).

*<br />

31<br />

i)<br />

*<br />

ii)<br />

iii)<br />

Ensure that the tray skirt is clear of<br />

the floor.<br />

Adjustable Foot: Adjustment Details<br />

Twist locking key as required to adjust<br />

board height to suit.<br />

For simple adjustment:<br />

Using the extremity legs only, level the tray from front to back on the one side. Then<br />

level the opposite side. Next level from side to side across the tray. This can be done by<br />

adjusting both legs an equal amount together. Check the skirt clearance whilst proceeding<br />

to get a good flush fit with the floor. If necessary the skirt can be trimmed by scoring with<br />

a sharp knife and breaking along the score line. Finally lower the central legs ensuring the<br />

board is fully level & will bear weight without deflection.

Fig. D: Positioning locking key into FIXED POSITION:<br />

i)*<br />

iii)<br />

* Please Note: Top of foot body is not<br />

shown for legibility only. You do not need<br />

to disassemble foot body at this stage.<br />

Remove locking key and twist around<br />

one detent.<br />

ii)*<br />

Ensure top of locking key lines up with<br />

fixing teeth on foot body.<br />

iv)

33<br />

33<br />

!<br />

!<br />

Ensure that Locking Key is set in<br />

a fixed position, as shown in Fig.D<br />

(on previous page).<br />

Locking key should be flush with<br />

top of the board.<br />

Check fit of tray<br />

& skirt match.<br />

! Remove skirt.<br />

!<br />

Mix a stiff 5/1 composition of sand and<br />

cement or use ready-mixed prepared to<br />

manufacturers instructions.<br />

!<br />

Do not mix cement on board itself to<br />

prevent excess moisture ingress. Take<br />

! precautions when handling cement /<br />

mortar.<br />

Thoroughly mix and spread with high<br />

spots to contact tray underside - ensure<br />

all of the tray well is fully supported.

<strong>Tray</strong> Preparation:<br />

34<br />

Liberally apply silicone sealant to back<br />

of tray. Only apply to the area where<br />

is it positioned against the wall.

35<br />

36<br />

!<br />

Apply a silicone<br />

sealant and PTFE<br />

tape as required.<br />

Ensure tray is correctly<br />

positioned and level.<br />

Thoroughly seal tray<br />

to wall.

37<br />

5mm 5mm<br />

Ensure silicone sealant thoroughly<br />

seals junction of tiles and tray.<br />

5mm 5mm<br />

!<br />

!<br />

Tile down to <strong>Tray</strong> surface leaving a<br />

5mm gap for sealing.<br />

!<br />

Once silicone & mortar is<br />

dry water test the waste<br />

for drainage.

39 Refit skirt & silicone seat skirt to<br />

!<br />

floor, tray & walls for security

Notes: