You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

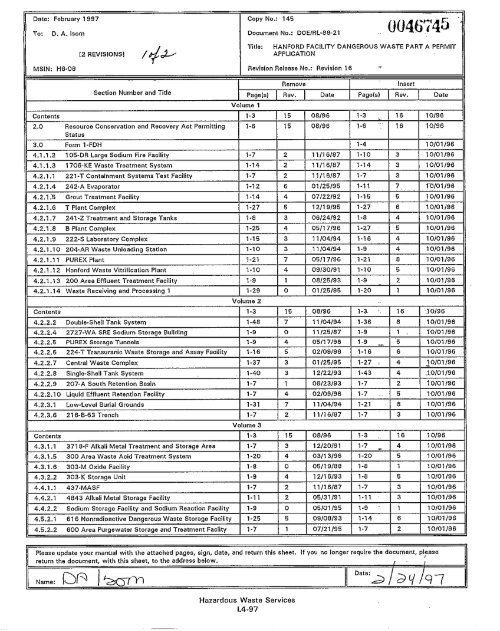

Date: February 1997<br />

To: D. A. Isom<br />

^<br />

[2 REVISIONS) ^P2^<br />

MSIN: H6-08 Y<br />

Copy No.:145<br />

Document No.: DOE/RL-88-21 -<br />

0046"t"40"<br />

Title: HANFORD FACILITY DANGEROUS WASTE PART A PERMIT<br />

APPLICATION<br />

Revision Release No.: Revision 16<br />

Remove Insert<br />

Section Number and Title<br />

Page(s)<br />

Volume 1<br />

Rev. Date Page(s) Rev. Date<br />

Contents 1-3 15 08196 1-3 _ 16 10/96<br />

2.0 Resource Conservation and Recovery Act Permitting 1-6 15 08/96 1-6 _ 16 10/96<br />

Status<br />

—<br />

3.0 Form 1-FDH 1-4 10/01/96<br />

4.1.1.2 105-DR Large Sodium Fire Facility 1-7 2 11/16/87 1-10 3 10/01/96<br />

4.1.1.3 1706-KE Waste Treatment System 1-14 2 11/16/87 1-14 3 10/01/96<br />

4.2.1.1 221-T Containment Systems Test Facility 1-7 2 11/16/87 1-7 3 10/01/96<br />

4.2.1.4 242-A Evaporator 1-12 6 01/25/95 1-11 7 10/01/96<br />

4.2.1:5 Grout Treatment Facility 1-14 4 07/22/92 1-15 5 10/01/96<br />

4.2.1.6 T Plant Complex 1-27 5 12/19/95 1-27 6 10/01/96<br />

4.2.1.7 241-Z Treatment and Storage Tanks 1-8 3 06/24192 1-8 4 10/01/96<br />

4.2.1.8 B Plant Complex 1-25 4 05/17/96 1-27 5 10/01/96<br />

4.2.1.9 222-S Laboratory Complex 1-15 3 11/04/94 1-16 4 10/01 196<br />

4.2.1.10 204-AR Waste Unloading Station 1-10 3 11/04/94 1-9 4 10101/96<br />

4.2.1.11 PUREX Plant 1-21 7 05/17/96 1-21 8 10/01/96<br />

4.2.1.12 <strong>Hanford</strong> Waste Vitrification Plant 1-10 4 09/30/91 1-10 5 10/01/96<br />

4.2.1.13 200 Area Effluent Treatment Facility 1-9 1 08/25/93 1-9 _ 2 10/01/96<br />

4.2.1.14 Waste Receiving and Processing 1 1-29<br />

Volume 2<br />

0 01/25/95 1 1-20 1 10/01/96<br />

Contents 1.3 15 08196 1-3. 16 _70/96<br />

4.2.2.2 Double-Shell Tank System 1-48 7 11/04/94 1-36 8 10/01/96<br />

4.2.2.4 2727-WA SRE Sodium Storage Building 1-9 0 11/25/87 1-9 1 TO/01/96<br />

4.2.2.5 PUREX Storage Tunnels 1-9 4 05/17/96 1-9 5 10/01/96<br />

4.2.2.6 224-T Transuranic Waste Storage and Assay Facility 1-16 5 02/09/96 1-16 .^ 6 10/01/96<br />

4.2.2.7 Central Waste Complex 1-37 3 01/25/95 1-27 4 10/01/96<br />

4.2.2.8 Single-Shell Tank System 1-40 3 12/22/93 1-43 4 _1-0/01 196<br />

4.2.2.9 207-A South Retention Basin 1-7 1 08/23/93 1-7 2 10/01/96<br />

4.2.2.10 Liquid Effluent Retention Facility 1.7 4 02/09/96 1-7 _. 5 10/01/96<br />

4.2.3.1 Low-Level Burial Grounds 1-31 7 11/04/94 1-21 8 10/01/96<br />

4.2.3.6 216-B-63 Trench 1-7 2 11/16/87 1-7 - 3 10/01/96<br />

Volume 3<br />

Contents 1-3 15 08/96 1-3 16 10/96<br />

4.3.1.1 3718-F Alkali Metal Treatment and Storage Area 1-7 3 12/20/91 1-7 4 10/01/96<br />

4.3.1.5 300 Area Waste Acid Treatment System 1-20 4 03/13/96 1-20 5 10/01/96<br />

4.3.1.6 303-M Oxide Facility 1.8 0 05/19/88 1-8 1 10/01/96<br />

4.3.2.2 303-K Storage Unit 1-9 4 12/16/93 1-8 5 10/01/96<br />

4.4.1.1 437-MASF 1-7 2 11/16/87 1-7 3 10/01/96<br />

4.4.2.1 4843 Alkali Metal Storage Facility 1-11 2 05/31/91 1-11 3 10/01/96<br />

4.4.2.2 Sodium Storage Facility and Sodium Reaction Facility 1-9 0 05/01/95 1-9 - 1 10/01/96<br />

4.5.2.1 616 Nonradioactive Dangerous Waste Storage Facility 1-25 5 09/08/93 1-14 6 10/01/96<br />

4.5.2.2 600 Area Purgewater Storage and Treatment Faclity 1-7 1 07/21/95 1-7 2 10/01/96<br />

Please update your manual with the attached pages, sign, date, and return this sheet. If you no longer require the document, please<br />

return the document, with this sheet, to the address below.<br />

Dater ^<br />

I f^r<br />

Name: u-) -n<br />

-7<br />

Hazardous Waste Services<br />

L4-97

Date: February 1997<br />

To: D. A. Isom<br />

MSIN: 1 16-08<br />

[2 REVISIONS)<br />

Section Number and Title<br />

A<br />

Volume 1<br />

Copy No.: 145 - --<br />

Document No.: DOE/RL-88-21 --<br />

Title: HANFORD FACILITY DANGEROUS WASTE PART A PERMIT<br />

APPLICATION<br />

Revision Release No.: Revision 16<br />

Remove - Insert<br />

Page(s) Rev. Date Page(s) Rev. Date<br />

Contents 1-3 15 08/96 1-3 16 10/96<br />

2.0 Resource Conservation and Recovery Act Permitting<br />

Status<br />

1-6 15 08/96 1-6 16 10/96<br />

3.0 Form 1-FDH 1-4 10/01/96<br />

4.1.1.2 105-DR Large Sodium Fire Facility 1-7 2 11/16/87 1-10 3 10101196<br />

4.1.1.3 1706-KE Waste Treatment System 1-14 2 11116/87 1-14 3 10/01/96<br />

4.2.1.1 221-T Containment Systems Test Facility 1-7 2 11/16/87 1-7 3 10/01/96<br />

4.2.1.4 242-A Evaporator 1-12 6 01125/95 1-11 7. 10101/96<br />

4.2.1.5 Grout Treatment Facility 1-14 4 07/22/92 1.15 5 10101/96<br />

4.2.1.6 T Plant Complex 1.27 5 12/19/95 1-27 6 10101/96<br />

4.2.1.7 241-Z Treatment and Storage Tanks 1.8 3 06/24/92 1-8 4 10/01/96<br />

4.2.1.8 B Plant Complex 1-25 4 05/17/96 1-27 5 10/01/96<br />

4.2.1.9 222-S Laboratory Complex 1-15 3 11/04/94 1-16 4 10/01196<br />

4.2.1.10 204-AR Waste Unloading Station 1-10 3 11/04/94 1-9 4 10/01/96<br />

4.2.1.11 PUREX Plant 1-21 7 05117/96 1.21 8 10/01/96<br />

4.2.1.12 <strong>Hanford</strong> Waste Vitrification Plant 1-10 4 09/30/91 1-10 5 10/01196<br />

4.2.1.13 200 Area Effluent Treatment Facility 1-9 1 08/25/93 1-9 _ 2 10/01/96<br />

4.2.1.14 Waste Receiving and Processing 1 1-29 0 01/25195 1.20 1 10/01/96<br />

Volume 2<br />

Contents 1-3 15 08/96 1-3 16 10196<br />

4.2.2.2 Double-Shell Tank System 1-48 7 11/04/94 1.36 8 10/01/96<br />

4.2.2.4 2727-WA SRE Sodium Storage Building .1-9 0 11/25/87 1-9 1 10/01/96<br />

4.2.2.5 PUREX Storage Tunnels 1-9 4 05117/96 1.9 -5 10/01/96<br />

4.2.2.6 224-T Transuranic Waste Storage and Assay Facility 1-16 5 02/09/96 1-16 6 10/01/96<br />

4.2.2.7 Central Waste Complex 1-37 3 01/25/95 1-27 4 10/01/96<br />

4.2.2.8 Single-Shell Tank System 1-40 3 12122/93 1-43 - 4 10/01/96<br />

4.2.2.9 207-A South Retention Basin 1-7 1 08/23/93 1-7 - 2 10/01/96<br />

4.2.2.10 Liquid Effluent Retention Facility 1-7 4 02/09/96 1-7 - 5 10/01/96<br />

4.2.3.1 Low-Level Burial Grounds 1-31 7 11/04/94 1.21 8 10101196<br />

4.2.3.6 216-B-63 Trench 1-7 2 11/16/87 1-7 3 10/01/96<br />

Volume 3<br />

Contents 1-3 15 08196 1-3 16 10/96<br />

4.3.1.1 3718-F Alkali.Metal Treatment and Storage Area 1-7 3 12/20/91 1-7 4 10/01/96<br />

4.3.1.5 300 Area Waste Acid Treatment System 1-20 4 03/13/96 1-20 5 10/01/96<br />

4.3.1.6 303-M Oxide Facility 1-8 0 05/19188 1-8 1 10/01/96<br />

4.3.2.2 303-K Storage Unit 1-9 4 12/16/93 1.8 5 10/01/96<br />

4.4.1.1 437-MASF 1-7 2 11116/87 1.7 - 3 10/01/96<br />

4.4.2.1 4843 Alkali Metal Storage Facility 1-11 2 05/31191 1.11 3 10/01/96<br />

4.4.2.2 Sodium Storage Facility and Sodium Reaction Facility 1-9 0 05/01/95 1-9 - 1 10101/96<br />

4.5.2.1 616 Nonradioactive Dangerous Waste Storage Facility 1-25 5 09/08/93 1-14 6 10101196<br />

4.5.2.2 600 Area Purgewater Storage and Treatment Faclity 1-7 1 07121195 1-7 2 10/01/96<br />

Please update your manual with the attached pages, sign, date, and return this shoat.<br />

return the document, with this shoat, to the address below.<br />

/<br />

Name: /<br />

Hazardous Waste Services<br />

L4-97<br />

If you no longer require the document, please<br />

-<br />

Data:<br />

a l /

\_J HANFORD FACILITY DANGEROUS WASTE PART A PERMIT APPLICATION<br />

0<br />

E<br />

1.0 INTRODUCTION<br />

CONTENTS<br />

2,0 PERMITTING STATUS FOR DANGEROUS WASTE TREATMENT, STORAGE,<br />

AND/OR DISPOSAL UNITS<br />

3.0 FORM 1 - DANGEROUS WASTE PERMIT APPLICATION<br />

4.0 FORM 3 - DANGEROUS WASTE PERMIT APPLICATION,<br />

4.1 100 AREA FACILITIES<br />

DOE/RL-88-21<br />

Contents<br />

Rev. 16, 02/97<br />

Page 1 of 3<br />

Revision<br />

4.1.1 Treatment Facilities<br />

4.1.1.1 1324-N Surface Impoundment 3 .<br />

4.1.1.2 105-DR Sodium Fire Facility 3<br />

4.1.1.3 1706-KE Waste Treatment System 3<br />

4.1.1.4 183-H Solar Evaporation Basins 4<br />

4.1.2 Disposal Facilities<br />

4.1.2.1 1301-N Liquid Waste Disposal Facility 5<br />

4.1.2.2 1325-N Liquid Waste Disposal Facility 5<br />

4.1.2.3 1324-NA Percolation Pond 3<br />

4.1.2.4 100-D Ponds 4<br />

4.2 200 AREA FACILITIES<br />

4.2.1 Treatment Facilities<br />

♦ = Revised this issue.<br />

4.2.1.5 Grout Treatment Facility 5<br />

4.2.1.6 T Plant Complex 6<br />

4.2.1.7 241-Z Treatment and Storage Tanks 4<br />

4.2.1.8 B Plant Complex 5<br />

4.2.1.9 222-S Laboratory Complex 4<br />

4.2.1.10 204-AR Waste Unloading Station 4 ♦<br />

4.2.1.11 PUREX Plant 8<br />

4.2.1.12 <strong>Hanford</strong> Waste Vitrification Plant 5<br />

4.2.1.13 200 Area Effluent Treatment Facility 2 ♦<br />

4.2.1.14 Waste Receiving and Processing 1<br />

V<br />

0<br />

L<br />

U<br />

M<br />

E<br />

1<br />

0<br />

F<br />

3

i CONTENTS<br />

ur1<br />

4.2.2<br />

(cont)<br />

DOE/RL-88-21<br />

Contents<br />

Rev. 16, 02/97<br />

Page 2 of 3<br />

Revision<br />

4.2.2.2 Double-Shell Tank System 8<br />

4.2.2.3 Hexone Storage and Treatment Facility 3<br />

4.2.2.4 2727-WA SRE Sodium Storage Building 1<br />

4.2.2.5 PUREX Storage Tunnels 5<br />

4.2.2.6 224-T Transuranic Waste Storage and Assay<br />

Facility 6<br />

4.2.2.7 Central Waste Complex 4<br />

4.2.2.8 Single-Shell Tank System 4<br />

4.2.2.9 207-A South Retention Basin 2 •<br />

4.2.2.10 Liquid Effluent Retention Facility 5<br />

4.2.2.11 241-CX Tank System 3<br />

4.2.3 Disposal Facilities<br />

4.2.3.1 Low-Level Burial Grounds 8<br />

4.2.3.5 216-B-3 Main Pond 5<br />

4.2.3.6 216-B-63 Trench 3<br />

4.2.3.7 216-A-10 Crib 3<br />

4.2.3.8 216-U-12 Crib 3<br />

4.2.3.9 216-A-36B Crib 1<br />

11991091011F.11:71:99.013 Ina 110<br />

4.3.1 Treatment Facilities<br />

4.3.1.1 3718-F Alkali Metal Treatment and<br />

Storage Area 4<br />

4.3.1.2 324 Pilot Plant 3<br />

♦ = Revised this issue.<br />

4.3.1.5 300 Area Waste Acid Treatment System 5<br />

4.3.1.6 303-M Oxide Facility 1<br />

4.3.1.7 325 Hazardous Waste Treatment Units 3<br />

4.3.1.8 Biological Treatment Test Facilities 0<br />

V<br />

0<br />

L<br />

U<br />

M<br />

E<br />

^A<br />

0<br />

F<br />

3<br />

—1 V<br />

0<br />

L<br />

U<br />

M<br />

E<br />

3<br />

0<br />

F<br />

3<br />

1

0 CONTENTS<br />

0<br />

0<br />

4.3.2<br />

4.3.2.1 311 Tanks (incorporated into<br />

300 Area Waste Acid Treatment<br />

System, Rev. 3)<br />

4.3.2.2 303-K Storage Unit<br />

4.3.2.3 305-B Storage Facility<br />

4.3.2.4 332 Storage Facility<br />

4.3.3 Disposal Facilities<br />

4.3.3.1 300 Area Process Trenches<br />

4.4 400 AREA FACILITIES<br />

4.4.1 Treatment Facilities<br />

4.4.1.1 437-MASF<br />

4.4.2 Storage Facilities<br />

4.4.2.1 4843 Alkali Metal Storage<br />

Facility<br />

4.4.2.2 Sodium Storage Facility and<br />

Sodium Reaction Facility<br />

4.5 600 AREA FACILITIES<br />

4.5.1 Treatment Facilities<br />

(cont)<br />

4.5.2 Storage Facilities<br />

4.5.2.1 616 Nonradioactive Dangerous Waste<br />

Storage Facility<br />

4.5.2.2 600 Area Purgewater Storage and<br />

Treatment Facility<br />

4.5.3 Disposal Facility<br />

4.5.3.1 Nonradioactive Dangerous Waste<br />

Landfill<br />

4.6 1100 AREA FACILITIES<br />

4.6.1<br />

♦ = Revised this issue.<br />

DOE/RL-88-21<br />

Contents.<br />

Rev. 16, 02/97<br />

Page 3 of 3<br />

Revision<br />

1<br />

5<br />

1<br />

0<br />

rY V<br />

0<br />

L<br />

U<br />

M<br />

3<br />

E<br />

3<br />

1♦<br />

6<br />

2♦<br />

4<br />

3<br />

0<br />

F<br />

3

•<br />

0<br />

•<br />

2.0 PERMITTING STATUS FOR DANGEROUS WASTE TREATMENT, STORAGE,<br />

AND/OR DISPOSAL UNITS<br />

DOE/RL-88-21<br />

Permitting Status<br />

Rev. 16, 02/97<br />

Page 1 of 6<br />

This section contains a permitting status table and an explanation of the contents<br />

of the table.

•<br />

UNIT CD-OP AREA PERMIT TYPE<br />

1324-N SURFACE BHI 100 A/C<br />

IMPOUNDMENT<br />

105-DR SODIUM FIRE FDH 100 A/C<br />

FACILITY<br />

1706-KE WASTE FDH 100 A<br />

TREATMENT SYSTEM<br />

183-H SOLAR BHI 100 A/C<br />

EVAPORATION BASINS<br />

1301-N LIQUID BHI 100 A/C<br />

WASTE DISPOSAL<br />

FACILITY<br />

1325-N LIQUID BHI 100 A/C<br />

WASTE DISPOSAL<br />

FACILITY<br />

1324-NA BHI 100 A/C<br />

PERCOLATION POND<br />

100-D PONDS BHI 100 A/C<br />

221-T CONTAINMENT FDH 2OOW A<br />

SYSTEMS TEST<br />

FACILITY<br />

2Q0 41HST AREA ASH uHG<br />

DEMOLI^iON & - ;<br />

SITE<br />

$OOW :^ A/L^ ;y r . T r<br />

$1'¢ P. 8 SORROW` hI T^T1IH;§C^F^Of7F^ ?' }^ZL4 tom C +. 3^ftS1f85:311,f114194<br />

£ 9Ti<br />

4^^^1^03^^s<br />

s as^aJ2'('19/i ; 1 i 10^'^67^^<br />

DL`fA4^^'EOH :, ^1f. ^...^w .'. ? s , a ,^^:?i cs^.,:>.:.. ^^ v,. ,...: ^..>, ;>x..

1<br />

LJ<br />

UNITCO-OP AREA PERMIT<br />

2727-WA SHE SODIUM FDH 2O0W A<br />

STORAGE BUILDING<br />

PUREX STORAGE FDH 200E A/B<br />

TUNNELS<br />

224-T TRANSURANIC ION 20OW A/B<br />

WASTE STORAGE AND<br />

ASSAY FACILITY<br />

CENTRAL WASTE FDH 2OOW A/B<br />

COMPLEX<br />

SINGLE-SHELL TANK FDH 2OOW -A/C<br />

SYSTEM<br />

207-A SOUTH FDH 200E A/C<br />

RETENTION BASIN<br />

LIQUID EFFLUENT FDH 200E A/B<br />

RETENTION FACILITY<br />

241-CX TANK SYSTEM BHI 200E A/C<br />

LOW-LEVEL BURIAL FDH 2O0EW A/B<br />

GROUNDS<br />

216-5-10 POND AND BHI 20OW A/C<br />

DITCH<br />

2101 M.p,ONt1<br />

NHC 200E ; ..= AIQ<br />

Tt 2'<br />

216-A-29 DITCH BHI 200E A/C<br />

216-B-3 MAIN POND BHI 200E A/C<br />

216-B-63 TRENCH FDH 200E A/C<br />

216-A-10 CRIB BHI 200E A/C<br />

216-U-12 CRIB BHI 20OW A/C<br />

216-A-36B CRIB BHI 200E A/C<br />

216-A-37-1 CRIB BHI 200E A/C<br />

PERMITTING STATUS TABLE<br />

DOE/RL-88-21<br />

Permitting Status<br />

Rev. 16, 02/97<br />

Page 3 of 6<br />

UNIT PART A DATE<br />

TYPE<br />

CLOSURE REV CLOSED COMMENT CLASS<br />

INITIAL LATEST REV PART B<br />

S 12/01/87 10/01/96 1 P/C M<br />

S 12/01/87 10/01/96 5 07/26/96 3 A M<br />

S 12/01/87 10/01/96 6 06/30/92 0 A M<br />

TS 05/01/88 10/01/96 4 10/31/91 0 - A M<br />

TS 02/01/88. 10/01/96 4 09/30/89 Dra A,C M<br />

ft<br />

S 02/26/90 10/01/96 2 C M<br />

S 02/26/90 10/01/96 5 06/26/91 0 A M<br />

S 07/10/90 06/30/94 3 C M<br />

D 11/01/85 10/01/96 8 12/29/89 0 A M<br />

D 02/01/87 06/30194 3 06/01/87 0 C M<br />

TD 08/01/86 06/30/94 3 04/01/87 0 C M<br />

TO 08/01/86 06/30/94 5 _ C_ M<br />

TO 08/01/86 10/01/96 3 04101/87 0 C M<br />

D 08/01/87 06/30/94 3 -- C M<br />

D 08/01/87 06/30/94, 3 _ C_ M<br />

D 02/01/88 06/30/94 1 02/01/88 0 C M<br />

D 02/26/90 06/30/94 2 -- C M<br />

3718-F ALKALI FDH 300 A/C IS 11/01/85 10/01/96 4 11/06/85 11/10/92 1 C M<br />

METAL TREATMENT<br />

AND STORAGE AREA<br />

324 PILOT PLANT PNNL 300 A T 11/01/85 05/19/88 3 11/01/85 0 P/C M<br />

300 AREA WASTE FDH 300 A/C<br />

ACID TREATMENT<br />

SYSTEM<br />

303-M OXIDE FDH 300 A/C<br />

FACILITY<br />

325 HAZARDOUS PNNL 300 A/B<br />

WASTE TREATMENT<br />

UNITS<br />

TS 09/01/87 10/01/96 5 06/29/90 0 C M<br />

T 05/01/88 10/01/96 1 C M<br />

TS 05/01/88 12/02/94 3 06/24/92 0 A M

i<br />

i<br />

PERMITTING STATUS TABLE<br />

DOE/RL-88-21<br />

Permitting Status<br />

Rev. 16, 02/97<br />

Page 4 of 6<br />

UNIT PART A DATE<br />

UNIT CO-OP AREA PERMIT TYPE<br />

CLOSURE REV CLOSED COMMENT CLASS<br />

INITIAL .LATEST REV PART B<br />

BIOLOGICAL PNNL 300 A T 05/01/88 05/19/88 0 P/C M<br />

TREATMENT TEST<br />

FACILITIES<br />

311 TANKS WHC 300<br />

(INCORPORATED INTO<br />

300 AREA WASTE<br />

ACID TREATMENT<br />

SYSTEM, REV. 3)<br />

303-K STORAGE UNIT FDH 300 A/C<br />

305-B STORAGE PNNL 300 A/B<br />

FACILITY<br />

332 STORAGE PNNL 300 A<br />

FACILITY<br />

300 AREA PROCESS BHI 300 A/PC<br />

TRENCHES<br />

437-MASF FDH 400 A<br />

4843 ALKALI METAL FDH 400 A/C<br />

STORAGE FACILITY<br />

SODIUM STORAGE<br />

FACILITY AND<br />

SODIUM REACTION<br />

FDH 400 A/B<br />

FACILITY<br />

9 !'<br />

HAN Olsd1A...OL tJ(fG 60D . AjC:<br />

ACAOEW DEMDUTTD<br />

N<br />

SITES<br />

'-<br />

616 NONRADIOACTIVE FDH 600 A/B<br />

DANGEROUS WASTE<br />

STORAGE FACILITY<br />

600 AREA FDH 600 A/B<br />

PURGEWATER STORAGE<br />

AND TREATMENT<br />

FACILITY<br />

NONRADIOACTIVE BHI 600 A/C<br />

DANGEROUS WASTE<br />

LANDFILL<br />

S 08/01/87 10/01/96 5 12/17/93 2 C M<br />

S 05/01/88 12/20/90 1 04/03/92 2 A M<br />

S 05/01/88 05/19/88 0 P/C M<br />

D 11/01/85 05/25/95 4 11/06/85 0 C M<br />

T 11/01/85 10/01/96 3 11/01/85 0, P/C M<br />

S 09/01/87 10/01/96 3 06/29/91 0 C M<br />

TS 05/01/95 10/01/96 1 A. M<br />

S 11/01/85 10/01/96 6 10/31/91 2 A D<br />

TS 02/20/90 10101/96 2 A M<br />

D 11/01/85 06/30/94 4 11/06/85 09/30/90 0 C D

•<br />

0<br />

EXPLANATION OF PERMITTING STATUS TABLE<br />

DOE/RL-88-21<br />

Permitting Status<br />

Rev. 16, 02/97<br />

Page 5 of 6<br />

UNIT Name of treatment, storage, and/or disposal (TSD) unit that is designated<br />

for permitting as part of the <strong>Hanford</strong> Facility (EPA/State Identification<br />

Number WA7890008967).<br />

CO-OP Co-operator with the U.S. Department of Energy, Richland Operations Office:<br />

BHI -- Bechtel <strong>Hanford</strong>, Inc.<br />

FDH -- Fluor Daniel <strong>Hanford</strong>, Inc.<br />

PNNL -- Pacific Northwest Laboratory.<br />

WHC -- Westinghouse <strong>Hanford</strong> Company.<br />

AREA The area of the <strong>Hanford</strong> Facility in which the unit is located:<br />

100 -- 100 Area<br />

200E -- 200 East Area<br />

20OW -- 200 West Area<br />

200EW -- Parts of a TSD unit are located in both the 200 East and the<br />

200 West Areas<br />

300 -- 300 Area<br />

400 -- 400 Area<br />

500 -- Unused designation<br />

600 -- 600 Area<br />

3000 -- 3000 Area<br />

PERMIT Type of permit application that is required to obtain the desired type of<br />

permit:<br />

A -- Part A<br />

B -- Part B<br />

C -- Closure plan<br />

PC -- Postclosure plan.<br />

UNIT TYPE T -- Treatment<br />

S -- Storage<br />

D -- Disposal.

0<br />

E<br />

INITIAL<br />

EXPLANATION OF PERMITTING STATUS TABLE (cont)<br />

DOE/RL-88-21<br />

Permitting Status<br />

Rev. 16, 02/97<br />

Page 6 of 6<br />

Date the initial Part A permit application was submitted to the Washington<br />

State Department of Ecology:<br />

08/01/88 -- month/day/year.<br />

LATEST Date the latest Part A permit application was submitted to the Washington<br />

State Department of Ecology:<br />

REV Last revision of the Part A permit application.<br />

PART B Date the last Part B permit application was submitted to the Washington<br />

State Department of Ecology:<br />

08/01/88 -- month/day/year.<br />

CLOSURE Date the last closure or postclosure plan permit application was submitted<br />

to the Washington State Department of Ecology:<br />

08/01/88 -- month/day/year.<br />

REV Revision of Part B or closure plan.<br />

COMMENTS. A Active TSD unit.<br />

C TSD unit closing under interim status.<br />

CL Unit is closed.<br />

S Standby.<br />

P/C Procedural closure.<br />

CLASS M Mixed waste TSD unit.<br />

D Dangerous waste TSD unit.

"l<br />

LJ<br />

E<br />

LJ<br />

3.0 FORM 1 - DANGEROUS WASTE PERMIT APPLICATION<br />

This section contains Form is of the Dangerous Waste Permit Application.<br />

DOE/RL-88-21<br />

Form 1<br />

02/97<br />

Page i

0<br />

0<br />

Remove Form 1 for Westinghouse <strong>Hanford</strong> Company.

E<br />

11 B.<br />

WA7890008967<br />

FORM<br />

State of<br />

Washington<br />

Department<br />

of Ecology<br />

WASHINGTON STATE<br />

1. EPA/STATE I.D. NUMBER<br />

DANGEROUS WASTE PERMIT GENERAL INFORMATION IWIAJ<br />

(Read "F. I Inalrvelfone" be)on sI dkw)<br />

DOE/RL-88-21<br />

Form 1-FDH<br />

10/01/96<br />

Page 1 of 4<br />

N IU S ' D ' E ' P ' A ' R ' T ' M'E'N ' 7 'O F' E N E R 6 Y H. A.N.F_O.R_D. _F_A_C_ I. L.I. T Y<br />

P<br />

J,0 H N, D , .,, , M<br />

)RESS<br />

0<br />

A. STREETORP.O.BOX<br />

a. CITYORTOWN C. STATE 1 0.2P CODE<br />

L. A , N. D WA 99352<br />

COMM NAME<br />

C. C IT<br />

Y OR TOWN<br />

E.ZPCODE<br />

NONCLASSIFIABLE 4 REFUSE SYSTEMS<br />

C. THIRD<br />

D. FOURTH<br />

9 5 1 1 r`" ") AIR ANDAWATERNEESOURCE AND 7 3.3 Iw..")<br />

RESEARCH, NONCOMMERCIAL<br />

VII. OPERATOR INFORMATION<br />

A. NAME<br />

B. I. the name Earl<br />

Mem Y1FA e4e U<br />

D E P A R T M E NY. ' O ' F E N E R G Y R I C H L AND OPERATION homy<br />

YES q NO<br />

FLUOR D A N I EL HAN F RO I NC FDH **<br />

C.<br />

0. PHONE fan. cod.&<br />

F. FEDERAL M.P X:(ofdo then (adoe)wanlU F r'o1°")') * 5 0 9 3 7 6 7 3 9 1<br />

S^ STATE O.OTHER(pact%)<br />

P PRNATE<br />

I- STREET OR P.O. BOX ** 5 0 9 3 7 2 2 8 8 E<br />

' P 0 B 0 X! :5 1 5: 0 1 (D OE- **P. 0. BOX 1000 ( FDH)<br />

R I C H L A N D<br />

ECYOiO31<br />

F.CrTYORTOWN O.STATE KZPCODE VIII. INDIAN LAND<br />

W A 9 9 3 5 2 r•rn.r..uiylx.e.d.nwl.nl.na .z<br />

q YES NO<br />

* DOE—RL: OWNER/OPERATOR F DH: CO—OPERATOR FOR CERTAIN UNITS ON THE HANFORD SI E.<br />

COMPLETE BACK PAGE

0<br />

u<br />

WA7890008967 DOE/RL-88-21<br />

Form 1-FDH<br />

10/01/96<br />

Page 2 of 4<br />

IX. MAP<br />

Attach to this application a topographic map of the area extending to at least one mile beyond property boundaries. The map must show the<br />

outline of the facl!44 the location of each of its existing and proposed Intake and discharge st ructures, each of Its hazardous waste treatment,<br />

storage. or disposal facili ties, and each well where it Injects fluids undergound. Include all sp rings, rivers and other surface water bo dies in the<br />

map area. See instruc tions for precise requirements.<br />

X. NATURE OF BUSINESS (provide • brief descri tlon)<br />

NONCLASSIFIABLE - GENERAL<br />

REFUSE SYSTEMS<br />

AIR AND WATER RESOURCE AND SOLID WASTE MANAGEMENT<br />

RESEARCH, NONCOMMERCIAL<br />

XL CERTIFICATION (ace Instruc tions<br />

I certify under poneffy of law that I have personify examined and am IamiGar with the Information MvNifed in this application and all at.<br />

tachments and tha t. based on my k+quiry of those persona Immediafeyreslionsib lo foroblakdag the information contained in the application, I<br />

believe that me lnformallon is true• accurate and complete. tam aware that there are signi fic<br />

ant penalties foraubmiffing (else information, In.<br />

cludi g the possrbilifyof fine and imprisonment.<br />

A1uMEaOfr10N.TfItaDW.wM^+U<br />

SEE ATTACHMENT<br />

ECYD]Gal A'VMe<br />

wunns e.<br />

GDATEf1DNED

0<br />

F-1<br />

LJ<br />

I^<br />

LJ<br />

WA7890008967 DOE/RL-88-21<br />

Form 1-FDH<br />

10/01/96<br />

Page 3 of 4<br />

XI. OPERATOR CERTIFICATION<br />

I certify under penalty of law that I have personally examined and am familiar<br />

with the information submitted in this application and all attachments and<br />

that, based on my; inquiry of those persons immediately responsible for<br />

obtaining the information contained in the application, I believe that the<br />

information is true, accurate and complete. I am aware that there are<br />

significant penalties for submitting false information, including the<br />

possibility of fine and imprisonment.<br />

john D. Wagoner, 7lanager<br />

U.S. Department of Energy<br />

Richland Operations Office<br />

FORM i<br />

DANGEROUS WASTE PERMIT GENERAL INFORMATION<br />

President and Chief Executive Officer<br />

Fluor Daniel <strong>Hanford</strong>, Inc.<br />

^rZ^il'!(O<br />

ate<br />

9/3 %<br />

at

LJ<br />

0<br />

WA7890008967<br />

<strong>Hanford</strong> Facility<br />

DOE/RL-88-21<br />

Form 1-FDH<br />

10/01/96<br />

Page 4 of 4<br />

7960811<br />

1rc

48<br />

E<br />

Pk ue pdrK or type in the unshaded ,roes only<br />

/ fill areas are spaced for eYto type, Le„ 12 ehenmerfinchl.<br />

FORM<br />

3<br />

FOR OFFICIAL USE ONLY<br />

DrA El; V<br />

AAPPP ION .. do &<br />

DANGEROUS WASTE PERMIT APPLICATION<br />

COMMENTS<br />

DOE/RL-88-21<br />

105-DR Large Sodium Fire Facility<br />

Rev. 3, 10101196<br />

Page 1 of 10<br />

1. EPAISTATE I.D. NUMBER<br />

w A T e o 0 0 0 8 .g S T<br />

11, FIRST OR REVISED APP LI CATION<br />

ap for your 1^t^,<br />

i Non * Opp on<br />

pN If Nli i. Yorvr/dust bn cad You ,Imadyknowyour)loca^i EPAISTATE rI D.Number, or H this is^ amvised<br />

app I IC,ttion,<br />

LI). Number in Section 1 above.<br />

A. FIRST APPLICATION 1pkos on 'X' below and provide the appropriate dare!<br />

rl 1. EXISTING FA CILITY !See instructions for defintden of'exkdny' facility. 2. NEW FACILITY ICemplefe Item bdowl<br />

Compton, Item bdow.l<br />

FORXISG FACILITIES,<br />

O FOR NEW FACILITIES,<br />

A FOR<br />

EXISTING ACLTIES, CI PROVIDE THE DATE Imo., day, d yl1 PROVIDE THE DATE<br />

OPERATION BEGAN OR eTIHE DATE CONSTRUCTION COMMENCED<br />

coo., I H yd OP RA-<br />

O 3 2 2 4 3<br />

/4FW.et^'AleMnAt'A^n ^E%PECTED R IS<br />

of the <strong>Hanford</strong> Facili ty enrtmlaneed, TO IN<br />

B. REVISED APPLICATION (place an "X' below and complete Sccdon I Iboval<br />

® 1. FACILITY HAS AN INTERIM STATUS PERMIT ® 2. FACILITY HAS A FINAL PERMIT<br />

III. PROCESSES • CODES AND CAPACITIES<br />

A. PROCESS CODE -Enter the code f ro m the Eat of process cedes below that but desc ri bes each p rocess to be used at the }stil7l^ yyTen lines are p ro vided for ente ri ng<br />

codes. if mom lines are needed, enter the code(0 In the space provided. N • process w gl be usod that is not induded in the Nd of codes below, then desc ri be the<br />

p rocess INeludMg its design e^P,ciryl in the space Provided on the 1Seetian li-Q.<br />

B. PROCESS DESIGN CAPACITY -For each co de entered In column A enter the capac ity of the process.<br />

1. AMOUNT - Enter the amount.<br />

2. UNIT OFMEASURE - For each amount entered in column 817 ), enter the code f ro m the list of unit "saw* codes below thit desc ribes the un it of measure used.<br />

Only the u nits of measure that are listed below shou ld be used.<br />

'<br />

PROCESS<br />

PRO-<br />

CESS<br />

CODE<br />

APPROPRIATE UNITS OF<br />

MEASURE FOR PROCESS<br />

DESIGN CAPACITY PROCESS<br />

PRO-APPROPRIATE UNITS OF<br />

CESS . MEASURE FOR PROCESS<br />

CODE DESIGN CAPACITY<br />

iStorage:<br />

Treatment<br />

CONTAINER IbarteL drum• ale)<br />

TANK<br />

WASTE PILE<br />

SURFACE IMPOUNDMENT<br />

Disposal:<br />

S01GALLONS OR LITERS TANK TO1<br />

S02 GALLONS OR LITERS<br />

S03 CUBIC YARDS OR SURFACE IMPOUNDMENT T02<br />

CUBIC METERS<br />

SOe GALLONS OR LITERS INCINERATOR T03<br />

-<br />

GALLONS PER DAY OR<br />

LITERS PER DAY<br />

GALLONS PER DAY OR<br />

LITERS PER DAY<br />

TONS PER HOUR OR<br />

METRIC TONS pER HR;<br />

GALLONS PER HOU OV<br />

INJECTION WELL<br />

LANDFILL<br />

DSO GALLONS OR LITERS<br />

081 ACRE-FEET /the volume that OTHER IUss for pphysical, chemi cal, T04<br />

would cover one acv- to a thermal or bioloolcal t reatment<br />

de th of one foo t)p<br />

R OR<br />

LITERS PER HOUR<br />

GALLONS PER DAY OR<br />

LITERS PER DAY<br />

roce LAND APPLICATION<br />

OCEAN DISPOSAL<br />

SURFACE IMPOUNDMENT<br />

sses not occurring in UOke,<br />

OfHECTAREMETER surface impoundments or in nor-<br />

082 ACRES OR HECTARES - ators, Des cribe the rocoues in<br />

D83 OR th, space provided; g action Io•C.1<br />

LITERS PER DA<br />

D84 GALLONS OR LITERS<br />

UNIT OF MEASURE-<br />

UNIT OF<br />

MEASURE<br />

CODE UNIT OF MEASURE<br />

UNIT OF<br />

MEASURE<br />

CODE UNIT OF MEASURE<br />

UNIT OF<br />

MEASURE<br />

CODE<br />

GALLONS......... .:. ... .. G<br />

LITERS ....................... L<br />

CUBIC YARDS .................. Y<br />

GALLONSPER DAY .............. V<br />

LITERS PER DAY................ V ACRE-FEET.................... A<br />

TONS PER HOUR...............: D 14ECTARE•MEM ............... F<br />

METRIC TONS PER HOUR ........ .. WACRES..e<br />

HECTARESt .................... O<br />

LITERS PER HOUR............. H<br />

EXAMPLE FOR COMPLETING SECTION III /shown in in numbers X-! and X-2 below/: A Lenity has two stews• tanks, one tank can<br />

hold 200 afons and the onion can hold 400 atlons. The faci lity also has an In cinerator Thor can bum to 20 allow per how.<br />

N A. PRO<br />

L U CESS<br />

I M CODE<br />

N e /I/on, liar<br />

E E a6ovel<br />

R<br />

8. PROCESS DESIGN CAPACITY<br />

1, AMOUNT<br />

(iceelfYl<br />

2. UNIT<br />

OF RE<br />

SURE<br />

!corn<br />

cede!<br />

Fop<br />

OFFICIAL<br />

ONLY<br />

USE<br />

N A. PRO•<br />

L U CESS<br />

I M CODE<br />

N e ! Item tut<br />

E E a devel<br />

R<br />

S. PROCESS DESIGN CAPACITY<br />

1. AMOUNT<br />

kpecHYl<br />

2. UNIT<br />

OF MEA-<br />

SURE<br />

lancer<br />

coda!<br />

FOR<br />

OFFICIAL<br />

USE<br />

ONLY<br />

X-1 S 0 2 600<br />

X-2 7-1013 20 f I I I 1 1 6<br />

! S1011 20,000 L T<br />

2 T04 100 V 6<br />

3<br />

4<br />

11a<br />

ECL30 - 300 - ECY 030-31 Forth 3 Rev. 2184 PAGE 1 OF 6 CONTINUE ON REVERSE<br />

6<br />

3<br />

10

E<br />

DOE/RL-88-21<br />

105-DR Large Sodium Fire Facility<br />

Rev. 3, 10/01/96<br />

Page 2 of 10<br />

Continued from the front.<br />

III. PROCESSES (con tinued)<br />

C. SPACE FOR ADD ITIONAL PROCESS CODES OR FOR DESCRIBING OTHER PROCESS Icade'TG4'1. FOR EACH PROCESS ENTERED HERE INCLUDE DESIGN CAPACITY.<br />

Refer to the following page.<br />

IV. DESCRIPTI ON OF DAN G EROUS WASTES<br />

A. DANGEROUS WASTE NUMBER - Enter V four digit number from Chapt er 173-303 WAC for each Read danquoua waste you will hand le . If you handle<br />

dangerous wasps which are not listed In Chapter 173-303 WAD, enter the four digit numbuW that d escribes the charaned erics and/or the toxic con.<br />

to. nts of theta dangerous wanes.<br />

B. ESTIMATED ANNUAL QUANT ITY - For ea ch lend wane entered In cohrmn A estim ate the quantity of the want that will be hand led on an annual bads.<br />

For each characte ri stic or toxic contaminant ente re d In co lu mn A estim ate the total annual quantity of all the twat- listed watt@(a) that win M hand led whkh<br />

pouess th at ehaneteriatla or contaminant.<br />

C. UN IT OF MEASURE- Far ea ch quant it y entered in column B enter the unit of measure coda. Units of measu re which must be used and the app rop riat e co des<br />

are:<br />

ENGLISH UN IT OF MEASURE CODE METRIC UNIT OF MEA SUR E CODE<br />

fPOUNDS .................eras., P KILOGRAMS eras.. K<br />

TONS ....................... T METRIC TONSt . .................M<br />

If faak records use any oth er un it of mature for quantity, the units of measure must be conve rted Wo one of the requ ired units of me asure fairing Into accou nt the .<br />

approp at dens ity or specific gravhy of t he wane.<br />

D.PROCESSES<br />

1. PROCESS CODES:<br />

g Rnad danyrous wane • For each listed dangamus waste entered M co lumn A select the code(t) from the let of p rocess codes co ntained in Station Ill to<br />

lcate hew>M1a want oil( be noted, t re ated, and/or disposed of at t he fa cil it y.<br />

For non-Pated dangerous wastes: For each chenctedstia or toxic contaminant entered In Column A, sele ct the code(n) from the Nn of p rocess codes contained In<br />

Section W W Indica te all<br />

processes th at will be u sed to stars, treat and/or dispose of ale t he rwnained dange rous wastes th at poses. that characteristic or<br />

toxic co ntaminant.<br />

space.<br />

above; (2) Enter '000' In<br />

extreme tight<br />

Iemoting<br />

the<br />

boxof Item Uk and (3)IEnter<br />

the = providedan Pager 4.the Kne number iMtheadditioonal cad.(.)^ecobed<br />

2. PROCESS OESCRIPTION: If a co de Is not "d fore g reater that will be used, descr ib e the P rocter M the space p rovided on the form.<br />

NOTE: DANGEROUS WASTES DESCRIBED BY MORE THAN ONE DANGEROUS WASTE NUMBER - Dange rous wanes that can be deteri lled by more than one Waste<br />

Number • hall be described an the form as follows:<br />

Selma<br />

1' ne and the or Ong ill the protests . to be used to tmap state, ind%or the same complete columns B, q and D by estimating the total snood quantity of<br />

of thee<br />

2. In co lumn A of the next line e nter the oth er Dange ro us Waste Numb er th at ern be used to d esc ribe t he waste. In column D(2) on that line enter ;included with<br />

above' and make no other ent ries on that IM.<br />

3. Repeat stop 2 for ea ch other Dange ro us Wasp Number that can be used to describe the dange ro us wane.<br />

EXAMPLE FOR COMPLETING SECTION IV Itho m In En s, numb er s X-f, X-2, X•3 and X-I below; • A fa cility VAN t re at and diem^., of an estimated 200 pounds per Year<br />

chrome from leather tanning finishing operation. In add WIN<br />

it ion, the fa cility w Rut and dlsyas* of th re of shaviny•<br />

e OorFll$red wastes. Two wastes ate corm.140<br />

on ly and there wlll be an eAlmued 200 pounds per you of each waste. The other wane Is comoslve and Ign it able ant then w il l be an e stimated 100 pounds par Year<br />

of that waste. Treatment w ill be In on In cinerator and d isposal will be in a landfi ll .<br />

D. PROCESSES<br />

I N AN EROUS<br />

O NO. G. ESTIMATED ANNUAL<br />

OF MEA<br />

N STE<br />

QUANTITY OF WASTE WASURE<br />

E<br />

car ter 1. PROCESS CODES 2. PROCESS DESCRIPTION<br />

(amereodal code; l-nnr; Ilya code Is not en tered A Dill)<br />

X-1 K 0 5< Soo P T O J D 8 0<br />

X-2 D 0 0 2 400 P T 0 3 D 3 0<br />

X-3 D 0 0 1 too P T 0 3 D Q O<br />

X-f 0 0 0 2 T 0 3 D 0 0 included wile above<br />

ECL30 - 271 - ECY 030-31 Fenn 3 PAGE 2 OF 6 CONTINUE ON PAGE 3

u<br />

Section III.C.. Description of Process Codes Listed in Section III.A.<br />

DOE/RL-88-21<br />

105-DR Large Sodium Fire Facility<br />

Rev. 3, 10/01/96<br />

Page 3 of 10<br />

The 105-DR Large Sodium Fire Facility (105-DR), which began waste management<br />

operations in 1972, was a research laboratory located in the 105-DR Reactor Building<br />

in the 1007D Area. The unit was used to conduct experiments for studying the<br />

behavior of molten alkali metals and alkali metal fires. This unit also had been<br />

used for the storage and treatment of alkali metal dangerous waste. The 105-DR<br />

operated between 1972 and 1986. In 1995, closure activities were initiated at the<br />

unit for Areas 1, 3, and 7, as defined in Part V, Chapter 10, of the <strong>Hanford</strong><br />

Facility Resource Conservation and Recovery Act (RCRA) Permit (Permit Number<br />

WA7890008967).<br />

In 1996, Ecology (Letter, M. W. Wilson, Ecology to J. E. Rasmussen, U.S.'Department<br />

of Energy, and E. F. Loika, Westinghouse <strong>Hanford</strong> Company, dated July 16; 1996)<br />

accepted clean closure of Areas 1, 3, and 7 and released these areas from the<br />

requirements of RCRA and Washington Administrative Code (WAC) 173-303 Dangerous<br />

Waste Regulations. Also, the letter identified that Area 6, as defined by Part V,<br />

Chapter 10 of the <strong>Hanford</strong> Facility RCRA Permit, is believed not to have received<br />

dangerous waste and is considered closed for the purposes of WAC 173-303. Areas 2,<br />

4, and 5, as defined by Part V, Chapter 10 of the <strong>Hanford</strong> Facility RCRA Permit,<br />

remain regulated by RCRA and WAC 173-303. Closure of these areas is expected to<br />

® occur during decommissioning and decontamination of the 105-DR Reactor.<br />

LJ<br />

SO1 T04<br />

Treatment.of alkali metal dangerous waste consisted of heating the waste to<br />

the point of oxidation. Any offgases from treatment were processed through an<br />

offgas system that used portions of the 105-DR Reactor exhaust system.<br />

The maximum storage process design capacity was 20,000 liters (5,284 gallons).<br />

The maximum treatment process design capacity was 100 liters per day<br />

(26 gallons per day).

1I<br />

Continued (ram papa 2.<br />

NOTE. Photocopy thisi hefnre comeletine N von have more than 26 wastes to list.<br />

I.D. NUMBER lentued ficm page !1<br />

W I A 1 7 1 8 9 0 0 0 8 9 6 7<br />

IV. DESCRIPTION OF DANGEROUS WASTES tcontlnued)<br />

A •<br />

N ANGE ND!<br />

N O WASTE NO.<br />

E .<br />

(enter code)<br />

B. ESTIMATED ANNUAL<br />

QUANTITY OF WASTE<br />

C. UNIT<br />

OSURE<br />

/entu<br />

eodd<br />

1. PROCESS CODES<br />

/enter/<br />

D. PROCESSES<br />

2. PROCESS DESCRIPTION<br />

fit. code is not entered in D711)<br />

1 D1010 1 20,'000 K SO1 T04 Sto a e =Tank Treatment-Other<br />

2 D 010 3 (Thermal Treatment)<br />

3 W SIC 2 Included With Above<br />

4<br />

s'<br />

s<br />

7<br />

a<br />

9<br />

10<br />

ii<br />

12<br />

13<br />

14<br />

15 '<br />

16'<br />

17<br />

18 '<br />

19<br />

20<br />

21<br />

22<br />

23<br />

24<br />

25<br />

26<br />

DOE/RL-88-21<br />

105-DR Large Sodium Fire Facility<br />

Rev 3, 10/01/96<br />

Page 4 of 10<br />

ECL30 - 271 - ECY 03031 P.nn 3 PAGE 3 ' OF 5 CONTINUE ON REVERSE<br />

(enter 'A. 'B . 'C', etc. behind the '3'to feentify photo copied pages)

Ell<br />

Cominued from the from.<br />

IV. DESCRIPTION OF DA NGEROUS WASTES Icentinu.dl<br />

E. USE THIS SPACE TO LIST ADDI TI<br />

ONAL PROCESS CODES FROM SECTION Dill ON PAGE 3.<br />

The 105-DR was used for the storage and treatment of alkali metal dangerous<br />

waste with the associated dangerous waste characteristics of ignitibility<br />

(D001), reactivity (D003), and corrosivity (WSC2 state-only, corrosive,<br />

dangerous waste). The waste consisted of metallic sodium, lithium, and<br />

sodium-potassium alloy. Approximately 20,000 kilograms (44,100 pounds) were<br />

managed at this unit each year.<br />

V. FACILITY DRAWING Refer to attached drawing(s).<br />

Ad exi sting fadlMse must Include in the apace provided on page 6 a scale d,avAng of the facllhy Teas Mstmerions for more detsrl.<br />

vi. PHOTOGRAPHS Refer toattachedphotograph(s).<br />

Ai exirtinv facllMu must In cl ude photognphe l^.riJ or yrovndLwp that clearly delineate dl existing eWstvm; existing steppe, treatment and disposal mu; an d<br />

rhea Cf<br />

future treatment<br />

or dispou1.... (a.. nstn,.e .. fermors dar.M.<br />

VII. FACILITY GEOGRAPHIC LOCATI ON Tras infarrnahon IS provided on the attached drawing (s) and photograph(s).<br />

A e rev nv d ec.odW ICNR04Dg d re M<br />

Vlll. FACILITY OWNER<br />

rxl A. If the facility owner Is also the faalhy operator ss li sted in Section VII on Farm 1. 'General Information', pla ce an ' X* M the box to the left and clip to Section IX<br />

below.<br />

a. N the facility owner is north* facility operator as sated In Section Va on Form 1, Comp le te the feliawing hems:<br />

i A A N no<br />

S OR P 4 R 6 6 O<br />

IX. OWNER CERTIFICATION<br />

/eertNyundeepenalry oflew that lhavc poison N/y s.minedand•m/m,T.rw/th Ma M/ormdon submi tted M thkand ♦d•rtscheddoeuma ts, and tharbasedon my<br />

»yu•ya/Noss indNiduefa immedl.talyr apongii lorabwnTnyy f aeon,/Aalisve e tthat le subMttad»lermaWnla Wa, eeeur•re,•odaompkte. /am •w^u fhd<br />

65

i<br />

11<br />

X.' OPERATOR CERTIFICATION<br />

DOE/RL-88-21<br />

105-DR Large Sodium Fire Facility<br />

Rev. 3,.10/01/96<br />

Page-6 of 10<br />

I certify under penalty of law that I have personally examined and am familiar<br />

with the information submitted in this and all attached documents, and that<br />

based on my inquiry of those individuals immediately responsible for obtaining<br />

the information, I believe that the submitted information is true, accurate,<br />

and complete. I am aware that there are significant penalties for submitting<br />

false information,-including the possibility of fine and imprisonment.<br />

0 r Operator<br />

J n D. Wagoner, Ma ager<br />

.S. Department of Energy<br />

Richland Operations Office<br />

Co- pei for<br />

H. J. Hatch,<br />

President and Chief Executive Officer<br />

Fluor Daniel <strong>Hanford</strong>, Inc.<br />

f?z6 ^QG<br />

Da e<br />

`9 9^<br />

e

• • e<br />

46'41'24^<br />

1 05-DR Large Sodium Fire Facility - <strong>Site</strong> Plan<br />

I ..^<br />

105-DFi<br />

Large Sodium<br />

Fire Facility<br />

L— 10 Large<br />

Sodium Fire Facility<br />

190-DR q ^/<br />

100-D<br />

Area $<br />

Q Be<br />

200 200<br />

' west •East<br />

— I <strong>Hanford</strong><br />

_ l <strong>Site</strong> Richland<br />

119.32'08"<br />

H96070109.1<br />

V DO<br />

to<br />

CD.<br />

0CO<br />

1,<br />

0<br />

LTI I<br />

t<br />

0<br />

r<br />

w<br />

LQ<br />

CD<br />

CD<br />

N<br />

O<br />

C-<br />

J.<br />

C<br />

CD 3<br />

• T<br />

-o J•t7<br />

ww-so<br />

CD m m<br />

m<br />

^-nz vow r<br />

n i<br />

0 o J. 00<br />

h 00<br />

J.<br />

^-• to N

0 0<br />

105-DR Large Sodium Fire Facility TSD Unit Boundary<br />

® Building not part of the 105-DR<br />

^-- N ^- -<br />

0 100 Feet<br />

0 30 Meters<br />

Large Sodium Fire Facility<br />

Treatment, Storage and/or Disposal<br />

(TSD) Unit<br />

Filter Bldg<br />

117-DR<br />

TSD Unit Bounda ry (10 ft<br />

from Structures Unless<br />

Otherwise Shown)<br />

Underground<br />

Exhaust Tunnel<br />

/Soil Clean<br />

Closed;<br />

II /<br />

Spray Scrubber in Exhaust<br />

Tunnel (Non-Operational) 119-DR Building<br />

(For conversion, apply the following:<br />

feet to meters -multiply by 0.3848)<br />

13.5 ft I I ..<br />

T<br />

IF<br />

S1iil Clean ^f<br />

Closed<br />

^.w.<br />

Supply Fan Room<br />

Sodium<br />

Handling<br />

\<br />

3uilding<br />

ExhaustSmall Large<br />

^7I -- Fan Fire Fire<br />

'T<br />

_-_ '= Room Room Room<br />

TSD Unit<br />

Boundary<br />

(Interior Walls)<br />

Room<br />

^1^//<br />

DR Reactor<br />

Building<br />

Upper Exhaust Tunnel WYZJLV////K/ //X<br />

E<br />

H96070109.3<br />

0 DVCo<br />

to O000C)<br />

rn<br />

V<br />

0<br />

t<br />

0<br />

z<br />

r—<br />

n<br />

CD<br />

CD<br />

N<br />

0<br />

a<br />

zc<br />

mB<br />

• T<br />

v ^- O<br />

W S O<br />

to m- m m<br />

(D<br />

C ' T 7J<br />

ca r<br />

0<br />

-h<br />

00<br />

C3 0) N<br />

O Old 1-.

0 C] •<br />

Schematic of the 105-DR Large Sodium Fire Facility Identifying Clean Closed Structures<br />

and Structures Containing Dangerous Waste.Residues<br />

MM<br />

® May Contain Dangerous<br />

® Clean<br />

Contains Dangerous<br />

Waste Residue<br />

Waste Residue<br />

Closed<br />

Note: All Solis Cleaned Closed<br />

Sealed<br />

Openings<br />

Underg round<br />

Exhaust Tunnel<br />

117-DR Filler<br />

Building<br />

Underg round<br />

ExhaustTunnal<br />

Spray Scrubber<br />

(Non•Opsrational)<br />

Upper Exhaust<br />

Tunnel<br />

Lower Exhaust<br />

Tunnel<br />

H90070109.2<br />

nV<br />

0 0to<br />

to<br />

CA<br />

V<br />

C)<br />

0 i0<br />

z rc+naCD<br />

N<br />

O<br />

n<br />

zc<br />

m a<br />

.D T<br />

o<br />

(D 3 (D p<br />

m m<br />

ooc r<br />

^ni<br />

0 co<br />

-h I<br />

r+ to 1- N<br />

O olt

i<br />

WA7890008967<br />

DOE/RL-88-21<br />

105-DR Large Sodium Fire Facility<br />

Rev. 3, 10/01/96<br />

Page 10 of 10<br />

105-DR LARGE SODIUM FIRE FACILITY<br />

46°41'24" 96070232-02CN<br />

119°32'08" (PHOTO TAKEN 1996)<br />

r ^

i CONTAINER<br />

L-A<br />

Plesse p ri nt or type in the unshaded are as only<br />

lt,lz areas are spaced Nor alit, type, L-., 12 chomatorlbrch).<br />

FORM<br />

DOE/RL-88-21<br />

1706-KE Waste Treatment System<br />

Rev. 3, 10/01/96<br />

Page 1 of 14<br />

1. EPA/STATE LD, NUMBER<br />

3 DANGEROUS WASTE PERMIT APPLICATION w A TTB g O O o 1 B 1 o 1 B 17<br />

FOR OFFICIAL USE ONLY<br />

APPLICATION 4&I EO<br />

,A,a, d,<br />

COMMENTS<br />

II. FIRST OR REVISED APPLICATION<br />

boxA, of<br />

Place an 'X- In the appropriate hex in A or 8 babes Mark om ho%amyl to Indicate whether this is the lint a bea0on you aro submitting for your facili or a rovited<br />

Place<br />

a 11 the Is your First application and you • ady know your faelliry s EPAISTATE I.D. Number, or II rl. Is s mvued applicat ion. enter your tae@ty'a EPAISTATE<br />

I.D. Number in Section I above.<br />

A. FIRST APPLICATION (place an -X- below and provide the appropr ia te doml<br />

p1. EXISTING FACILITY (So,<br />

e llMian of -existho - IaclFly,<br />

irom belowj<br />

02. NEW FACILITY /Complete Item balewl<br />

MO<br />

3<br />

DA<br />

2 2<br />

YR<br />

4 3<br />

FOR EXISTING FACILITIES, PROVIDE THE DATE Imo. dayy, & yyrr^))<br />

OPERATION BEGAN OR THE DATE CONSTRUCTION L'OMMENCED<br />

(ut tha ozss to the Into<br />

eThe date conatnletron of the <strong>Hanford</strong> Facility commenced.<br />

DA YR FOR NEW FACILITIES.<br />

PROVIDE THE DATE,<br />

Imo. day, & yri OpERA-<br />

7IOf( BEGAN OR IS<br />

EXPECTED TO BEGIN<br />

S. REVISED APPLICATION /place en -X- balawand complete Steven ! above)<br />

® 1. FACILITY HAS AN INTERIM STATUS PERMIT ® 2. FACILITY HAS A F INAL PERMIT<br />

111. PROCESSES - CODES AND CAPAC ITIES<br />

A. PROCESS CODE • Enter the code f rom the list of p roce ss codes be low that best deserlbm each p rocess to be wad at the facility. Ton lines am provided for ente ri ng<br />

code., If more Onus am needed, enter the codes) In the space p rovided. It a process will be wad that M riot included N the gat of codes be low, then desc ribe the<br />

Propos e llncludlno Its daslpn capacity! in the space p rovided an the (Section Al-Q.<br />

S. PROCESS DESIGN CAPACITY- For each cede ente re d In column A enter the capacity of the p rocess.<br />

1. AMOUNT - Enter the amount.<br />

2. UN IT OF MEASURE - For each amount entered In column e(1), enter the code f rom the list of unit moon. cod e, below that d escribes the unit of m ea sure wad.<br />

Only the unite of measu re that ate listed below should be used.<br />

PRO. APPROPRIATE UN IT<br />

S OF PRO- APPROPRIATE UN IT<br />

PROCESS<br />

CESS<br />

CODE<br />

MEASURE FOR PROCESS<br />

DESIGN CAPACITY PROCESS<br />

CESS<br />

CODE<br />

S OF<br />

MEASURE FOR PROCESS<br />

DESIGN CAPACITY<br />

Storage: TroatmanC<br />

(bana l, drum, etc)<br />

TANK<br />

WASTE PILE<br />

S01<br />

502<br />

503<br />

GALLONS OR LITERS<br />

GALLONS OR LfTER3<br />

R<br />

TANK<br />

SURFACE IMPOUNDMENT<br />

T01<br />

T02<br />

GALLONS PER DAY OR<br />

LITERS PER DAY<br />

GALLONS PER<br />

SURFACE IMPOUNDMENT 504<br />

CUBIC METERS<br />

GALLONS OR LITERS INCINERATOR T03<br />

YOR<br />

DA<br />

TONS PER HOUR OR<br />

Disposal:<br />

INJECTION WE LL 080 GALLONS OR L<br />

GA^LLRONSPER<br />

PPE R ORR<br />

LITERS PER HOUR<br />

IT<br />

LANDFILL D81<br />

ERS<br />

ACRE-FEET [the volume that<br />

would cover one sue to a<br />

OTHER (Uxe for pphysical, chemical, T04<br />

thermal or hlologlcal t<br />

GALLONS PER DAY OR<br />

re<br />

atment LITERS PER DAY<br />

depth of one loo t] p rocesses not occ urri ng in tanks,<br />

OR HECTARE-METER surface Impoundments or Inciner<br />

LAND APPLICATION 082 ACRES OR HECTARES atom. Desc ribe the pproaesse. h<br />

R DAY OR the apt" p rovided: Saetlon 10-C.)<br />

OCEAN DISPOSAL D83 GALLONS<br />

S<br />

SURFACE IMPOUNDMENT D84 GALLONS OR LITERS<br />

UN IT<br />

OF<br />

UN IT<br />

OF UN IT<br />

MEASURE MEASURE<br />

OF<br />

MEASURE<br />

UN IT<br />

OF MEASURE CODE UN IT OF MEASURE CODE UN IT OF MEASURE CODE<br />

GALLONS..................... G LITERS PER DAY................ V ACRE-FEET................... A<br />

LITERS ....................... L TONS PER HOUR.....:........,. D HECTARE-METER .............F.,.<br />

CUBIC YARDS .................. Y METRIC TONS PER HOUR.......... W ACRES....................... e<br />

H HECTARES<br />

.................... NS<br />

O<br />

GALLON S HOUR.....<br />

PEROAY .............. ..... ....<br />

. U<br />

LITER E<br />

EXAMPLE FOR COMPLETING SECTION 111 Ishown An Arno numbers X-! and X-2 below): A lociliry has two storage tanks, one tank pen<br />

hold 200 gallon end the other can hold 400 pa/lone. The faci lity also has an Inc inerator that can bum up to 2 Colons par hour.<br />

B. PROCESS DESIGN CAPACITY<br />

B. PROCESS DESIGN CAPACITY<br />

N PRO-<br />

L U A. CESS<br />

FOR<br />

N A. PRO-<br />

2. UNIT OFFICIAL<br />

L U CESS<br />

2. UNIT<br />

I M CODE 1. AMOUNT<br />

OF MEA-<br />

SURE<br />

USE I M CODE<br />

N 6 lliam list 1. AMOUNT OF MEA-<br />

N e #rem list<br />

SURE<br />

E E *bowl<br />

lspacityl War<br />

ONLY E E ahoy.) /rpeci/Yl<br />

Ionian<br />

R code) R code!<br />

X• 1 S 0 1 600<br />

X4 T 0 3 20 E<br />

I S 0 2 2,461 L<br />

2 7 0 4 5,678 V<br />

4<br />

G 6<br />

i--<br />

FOR<br />

OF<br />

USE<br />

ONLY<br />

rm in. nnn - FCY 03n-31 Form 3 Rev. 2184 PAGE 1 OF 6 CONTINUE ON REVERSE

u<br />

E<br />

Centimmel from the front.<br />

III. PROCESSES (continued)<br />

C. SPACE FOR ADDITIONAL PROCESS CODES OR FOR DESCRIBING OTHER PROCESS load. "TG4"1. FOR EACH PROCESS ENTERED HERE INCLUDE DESIGN CAPACITY.<br />

S02. T04<br />

The 1706-KE Waste Treatment System (1706-KE) intended to begin waste management operations in July of 1986. This unit was<br />

intended to treat mixed waste generated in the laboratories of the 1706-KE Building. The 1706-KE consisted of a 2,082-liter<br />

(550-gallon) waste accumulation tank, a 0.14-cubic meter (5-cubic foot) mixed-bed.resin ion exchan.;a column, a 114-liter<br />

(30-gallon) evaporation unit, and a 363-liter (96-gallon) condensate collection tank.<br />

Waste generated in the 1706-KE Building was to have been transferred from the waste accumulation tank to the ion exchange<br />

column and then continuously recirculated to remove the ionic constituents from the waste stream. The waste would then have<br />

been transferred to the evaporation unit. The evaporation Unit would have heated and boiled the liquid waste to steam. The<br />

steam would then have been condensed and collected in the e63-titer (96-gallon) condensate collection tank with the exhaust<br />

frog the evaporation unit being passed through a HEPA filter prior to discharge.<br />

The 1706-KE never managed mixed wasteand a procedural closure under interim status is being pursued. The maximum process<br />

design capacity for tank storage is 2,461 liters (650 gallons). The maximum process design capacity for tank treatment is<br />

5,678 liters (1,500 gallons) per day.<br />

IV. DESCRIPTION OF DANGEROUS WASTES<br />

A. DANGEROUS WASTE NUMBER- Enter the four digit number from Chapter 173 . 303 WAC for each gated dangerous waste you will handle. If you handle<br />

dangerous wastes which am net listed in Chapter 173.303 WAC, enter the four digit number(,) that describes the characteristics and/or the toxic contaminants<br />

of these dangerous wastes.<br />

'B. ESTIMATED ANNUAL QUANTITY - For each gated waste entered In column A ..times the quantity of that waste that will be handled onan annual basis.<br />

For each chaotaristie ra or Lode contaminant entered In column A estimate the total annual quantity of all the inn-Homd<br />

waate(s) that will be handled which<br />

possess that characteristic or contaminant.<br />

C. UNIT OF MEASURE - For each quantity entsred In column S enter the unit of measure code. Unite of measure which must be used and the appropriate codas<br />

are:<br />

ENGLISH UNIT OF MEASURE CODE METRIC UNIT OF MEASURE CODE<br />

POUNDS................... .. P KILOGRAMS......:............ K<br />

TONS ....................... T METRICTONS ........ ........ ..M<br />

It f.cIl meards use any other unit of measure for quantity, the units of measure must be converted Into ens of the required units of measure taking into account the<br />

appropriate density or specific gravity of the waste.<br />

O.PRocesses<br />

1. PROCESS CODES:<br />

For listed dangerous waste: For each listed dangerous waste entered In cokimn A select the code(,) from the list of process codes contained In Section III to<br />

Indicate how the waste will.be stored, treated, and/or disposed of at the facility. -<br />

For non-listed dangerous wastes: For each characteristic or toxic contaminant entered In Column A, select the code(,) from the Hit of process codes contained In<br />

Section ill to Indicate all the processes that will be used to store, treat and/or dispose of all the non-listed dangerous wastes that possess that characteristic or<br />

toxic contaminant.<br />

Nob: Few spaces am provided for entering procea, codes. If mom are needed: 111 Enter the first throe as described above; (2) Enter 1000" In the extreme right<br />

box of Item IV-DV 1; and (3) Enter in the space provided on page 4, the line number and the additlonal code(s). -<br />

2. PROCESS DESCRIPTION: If • code Is not listed Ter a procaes that VA be used, describe the procass M the space provided on the form.<br />

NOTE: DANGEROUS WASTES DESCRIBED BY MORE THAN ONE DANGEROUS WASTE NUMBER- Dangerous waste. that can be described by more than one Waste<br />

Number ,hall be described an the form as follows:<br />

1. Select one of the Dangerous Waste Numbers and enter It In wkmmn A. On the same Inn. complete columns B, C. and D by estimating the total annual quantity of<br />

the waste and describing all the processec to be used to gnat, store, and/or dispose of the waste.<br />

2. In column A of the next line enter the other Dangerous Waste Number that can be used to describe the waste. In column D(2) on that line enter "Included with<br />

above' and make no other entries on that line.<br />

3. Repeat step 2 for each other Dangerous Waste Number that can be used to deserbe the dange ro us waste.<br />

EXAMPLE FOR COMPLETING SECTION IV /shown In line number X4, X-2, X-3, and X-4 below/ - A facility will treat and dispose of an estimated 900 pounds per year<br />

of chrome ,havingg. from leather tanning and finishing operation. In addition, the facility will treat and dispose of throe non-Feted wastes• Two wastes are corrosive<br />

only<br />

eand The other waste is conceiv ignitable and them VIII be 100 pounds per year<br />

be he<br />

an estimated and them<br />

pounds year eachwill<br />

atedn uCuna<br />

ofr waste. Treatment be wig 00 ntand o of st in<br />

D. PROCESSES<br />

A.<br />

C. UNIT<br />

N DANGEROUS B, ESTIMATED ANNUAL<br />

OF MEA.<br />

S<br />

N O WASTE NO. QUANTITY OF WASTE tenter 1. PROCESS CODES 2. PROCESS DESCRIPTION<br />

E * lento coda! "del tented of a code is not entered /a DIIII<br />

X-I X 01514 900 P T O 3 D if 01 1<br />

X-2 D 0 O 2 400 P T O 3 D 8 O<br />

X3 D 0 0 1 100 P T D 3 D 8 G<br />

DOE/RL-88-21<br />

1706-KE Waste Treatment System<br />

Rev. 3, 10/01/96<br />

Page 2 of 14<br />

X-4 D 0 0 2 T 0 3 D a 0 1 Included with above<br />

ECL30 . 271 - ECY 030.31 Form 3 PAGE 2 OF 5 CONTINUE ON PAGE 3

ContlAwd<br />

Co from pale 2 •n. w Fw/ a mmn/wNnn H wu hev. mere Man 1R wares m Hrt.<br />

NUMBER<br />

. .<br />

IV. DESCRIMON OF DANGEROUS WASTES (.ntinuod)<br />

DOE/RL-88-21<br />

1706-KE Waste Treatment System<br />

Rev. 3, 10/01/96<br />

Page 3 of 14<br />

ESTIMATED ANh<br />

&UANTITY OF WAN 1. PROCESS CODES 2. PROCESS DESCRIPTION<br />

MIMI 011MI-10.<br />

©1111 IIIYIIIIIIIIII<br />

©1111 ^IIIIYIYIYYI<br />

01111 IIIWIi1W1Y<br />

01111^^1IIIIIIYIIIYI<br />

milli^^ii11YY11Ylii<br />

01111 IIIYIYIfYYI<br />

OIIII^^IIIIYWYIIY<br />

01111 IIIWIYYIYI<br />

mill) IIIYIIYYIW<br />

m1111^^111Y1IYW111<br />

®1111 IIIIIiWWY1<br />

®1111 IIIYIIYYIYI<br />

®1111 IIIIYIYWW<br />

mllil IIIYIIYIYYI<br />

mull IIIIIIIYIIIYI<br />

mull IIIIIIIYIYYI<br />

mill) IIIYIWWYI<br />

mull 1111YIYWIi1<br />

Will IIIIilIYWli1<br />

milli lllw Yww<br />

®1111 IIIWYIWYI<br />

©1111 IIIYIYIIYW<br />

m1111 IIIWIYIillil<br />

. , ' a<br />

mjwl^ ^^^WWWW<br />

EGL30 • ill CGS wa•a^ ^o,m u<br />

(enter A','B•,'C; etc. baAlnd Ne -3- to ldentlfypheto rnpled pegol<br />

( , .

0<br />

I 1<br />

1<br />

u<br />

! 1<br />

1<br />

Co ki d fmm the fm.<br />

N- DESCRIPTION OF DANGEROUS WASTES IccnOnwd)<br />

E. USE THIS SPACE TO UST AODRIGNAL PROCESS CODES FROM SECTION DO) ON PAGE 3,<br />

DOE/RL-88-21<br />

1706-KE Waste Treatment System<br />

Rev. 3, 10/01/96<br />

Page 4 of 14<br />

The 1706-KE Building was intended to treat a wide variety of laboratory waste.<br />

The majority of this waste was expected to be acidic or caustic solutions<br />

(D002, characteristic, corrosive, dangerous waste). Approximately<br />

6,804 kilograms (15,000 pounds) of waste could have been treated in the<br />

1706-KE per year.<br />

V. FACRRY DRAWING ReferW attached drawn s .<br />

.<br />

AN e.d trop facDlW s must induda M tlw epaoo pnvWed an page 6 a sca le dr"ng of the fa cility Is" FMbpndpw far mess daroX.<br />

W. PHOTOGRAPHS Reter to atteehed photograph(s).<br />

Ag eldstina facilit»s mot induda otwtoom pha M.Wor pmmd4,Y*# thatakat1Y all d+Dneab abating struan+na: eaiadno staraps, tmatment and disposal amar; and<br />

she. of fYmm storage, beatmem or dl+pnsal auras /see n+Ouctlone felmom demo!.<br />

VII. FACILITY GEOGRAPHIC LOCATION'this intomation is providedon unit attacheddraw ng s and pROtograph(s).<br />

VIII. FACILITY OWNER<br />

Qx A. It the fleft owner Is slw the'faclnty operator as gated M Section VII on Foma 1, 'General Infa matlan', plat y an'X' in tM box to the left and skip to Section IX<br />

below.<br />

o, It the IaaHlty owner N not the faenhy ePVator as letN In Section VII on Farm 1, complete LM teaswbq Name:<br />

IX. OWNER CERTIFICATION<br />

l eI/d/Y YndI/Pent/(L'O//IW mIt /AaW Pe/IOn N/ enMMIMeM ear l//)d//N w/M tbI b1I1/Illeda111VbI1JttM (n drk+ 4la sneebad dOW/M/IG, and that b..d all my<br />

nnxn4armaWn4tlfwa, anweb, elr/lah. eamp lam .were that<br />

ro/subm/mny Hba "o—abe ncN hDM pattIDWtye//be ti%J,to<br />

'ONAME<br />

/pint or type!<br />

5 N 7U IDATE IGNED<br />

John D. Vegoner, Manager<br />

U.S. Department of Energy'<br />

7./<br />

tiehtend O eretitxu Office<br />

(/ll<br />

X. OPERATOR CERwICATION<br />

l oamYY unJw pn+//ryry of law Met /haw par+onrly sranrJrW dam laMWr w/M tea Mf . subMttd h Mh and ae sRacAed d.wft, ale Matbud on my<br />

irplLy•/Moe b,dir7du 46wrnadiefdyrvpon+lAH law obteLailp Ma A/emrWn,tbeGw Mat saubmiMad itf m di nL WO. oeewsfe, end eampkfe. /em ewaro Mat<br />

Mara AM w+!!../ dtpenddee hraubm/rdn0 tetra h/ImuWn, ncAtdlwrl MepaaalbAity elites an/bNxtronm+nc<br />

NAME Ipint of type/<br />

SIGNATURE DATE SIGNED<br />

SEEATTACHMENT<br />

ECL3o • 271 - ECY 03001 Form 3 rAOE 4 OF 6 CONTINUE ON PAGE 6

0<br />

X. OPERATOR CERTIFICATION<br />

1706-KE Waste<br />

I certify under penalty of law that I have personally examined and am<br />

familiar with the information submitted in this and all attached documents,<br />

and that based on my inquiry of those individuals immediately responsible<br />

for obtaining the information, I believe that the submitted information is<br />

true, accurate, and complete. I am aware that there are significant<br />

penalties for submitting false information, including the possibility of<br />

fine and imprisonment.<br />

•W1,4, LG (Q^<br />

'oh wn e p a ^<br />

to<br />

Wagoner, Manage<br />

U.S. Department of Energy<br />

Richland Operations Office<br />

C ator Vate<br />

H. J. Hatch,<br />

President and Chief Executive Officer<br />

Fluor Daniel <strong>Hanford</strong>, Inc.<br />

DOE/RL-88-21<br />

Treatment System<br />

Rev. 3, 10/01/96<br />

Page 5 of 14

0<br />

170,6-KE Waste Treatment System<br />

S<br />

4<br />

1706-KE Waste<br />

Treatment System =J<br />

3.6 Metric^0<br />

Ton Crane<br />

TSD Unit*<br />

105-KE<br />

17064KE<br />

Boundary - 4 1706-KEF7<br />

0 [1<br />

TSD Un it<br />

Boundary Is defined as the room<br />

containing the 1706-KE Waste Treatment<br />

System, which is 9 meters below grade. 1<br />

115 KE<br />

0 1.00 Feet H96070161.7<br />

i --3 I<br />

0 30 0 Meters<br />

46°36'58"<br />

V 011<br />

rn<br />

E<br />

ya+N(+<br />

!<br />

m<br />

A-1<br />

CD -1<br />

< m 'v a p<br />

W 3 O<br />

to m- m rn<br />

CD = \ . C+ ;0<br />

rn . r<br />

\N I<br />

OO 00<br />

h ^ w C pp<br />

\ t+ 1<br />

^-' lD a) N<br />

4-01 a N

0<br />

0<br />

WA7890008967<br />

1706-KE WASTE<br />

TREATMENT SYSTEM<br />

WASTE STORAGE TANK WITH HEPA VACUUM FILTER<br />

SYSTEM INCLUDING WASTE FEED SHUTOFF<br />

46 0 38'58" 132285-1CH<br />

119°35'48"<br />

DOE/RL-88-21<br />

1706-KE Waste Treatment System<br />

Rev. 3, 10/01/96<br />

Page 7 of 14

0<br />

r<br />

0<br />

WA7890008967<br />

DOE/RL-88-21<br />

1706-KE Waste Treatment System<br />

Rev. 3, 10/01/96<br />

Page 8 of 14<br />

1706-KE WASTE TREATMENT SYSTEM<br />

ION EXCHANGE COLUMN AND WASTE ACCUMULATION TANK<br />

46°38'58"<br />

119°35'48"<br />

8700734-7CN<br />

(PHOTO TAKEN 1987)

WA7890008967 DOE/RL-88-21<br />

1706-KE Waste Treatment System<br />

Rev. 3, 10101196<br />

Page 9 of 14<br />

0 1706-KE WASTE<br />

TREATMENT SYSTEM<br />

ION EXCHANGE COLUMN AND<br />

ASSOCIATED PIPING<br />

46 0 38'58" 870 073 4-3CN<br />

® 119°35'48" (PHOTO TAKEN 1987)

WA7890008967<br />

i 1706-KE WASTE<br />

TREATMENT SYSTEM<br />

0<br />

46°38'58"<br />

119°35'48"<br />

U<br />

SOLIDIFICATION UNIT SHOWN IN UP POSITION<br />

1706-KE Waste<br />

132285-6CN<br />

(PHOTO TAKEN 1986)<br />

DOE/RL-88-21<br />

Treatment System<br />

Rev. 3, 10/01/96<br />

Page 10 of 14

0<br />

u<br />

WA7890008967<br />

46°38'58"<br />

119°35'48"<br />

•<br />

1706-KE Waste<br />

1706-KE WASTE TREATMENT SYSTEM<br />

SHOWN IN DOWN POSITION EVAPORATING WASTE<br />

DOE/RL-88-21<br />

Treatment System<br />

Rev. 3, 10/01/96<br />

Page 11 of 14<br />

8700734-8CN<br />

(PHOTO TAKEN 1986)

0<br />

E<br />

Is<br />

WA7890008967 DOE/RL-88-21<br />

1706-KE Waste Treatment System<br />

Rev. 3, 10/01/96<br />

Page 12 of 14<br />

1706-KE WASTE<br />

TREATMENT SYSTEM<br />

SYSTEM CONTROL PANEL<br />

46 0 38'58" 132285-2CH<br />

119 0 35'48" (PHOTO TAKEN 1986) -

0<br />

nL^<br />

•<br />

WA7890008967<br />

1706-KE WASTE<br />

TREATMENT SYSTEM<br />

CONDENSATE'TANK<br />

46°38'58" 132285-3CN<br />

119°35'48" (PHOTO TAKEN 1986)<br />

DOE/RL-88-21<br />

1706-KE Waste Treatment System<br />

Rev. 3, 10/01/96<br />

Page 13 of 14

^J<br />

WA7890008967<br />

DOE/RL-88-21<br />

1706-KE Waste Treatment System<br />

Rev. 3, 10/01/96<br />

Page 14 of 14<br />

1746-KE WASTE TREATMENT SYSTEM<br />

EXHAUST FILTER SYSTEM<br />

46°38'58"<br />

8700734-6CN<br />

119°35'48" (PHOTO TAKEN 1987)<br />

•

a<br />

r 1<br />

,<br />

u<br />

Please p rint or type In the unshaded areas only<br />

IrMHn m os s ale spaced for elite type, La., 12 chmacterAnchl.<br />

FOAM<br />

$ DANGEROUS WASTE PERMIT APPLICATION<br />

FOR OFFICIAL USE ONLY<br />

A LICATIO CAT E EIVED COMMENTS<br />

APPROVED mo. de a t.<br />

DOE/RL-88-21<br />

221-T Test Facility<br />

Rev. 3, 10/01/96<br />

Page 1 of 7<br />

1. EPAISTATE I.D. NUMBER<br />

w A T e a o 0 o a s 6 T<br />

It. F IRST OR REVISED APPLICA TI ON<br />

Place an'X' [nth* app ro p riate box M A cr B below mark one box only) to ind este whether this is the first application you are submit ti ng for your facllitV or a revised<br />

e plication. If this Is your first application and you a ready know your faciliry'a EPA/STATE I.D. Number, or It this Is a re vised application, enter your f eGIIM's EPAISTATE<br />

1.1'). Number in Settle" I above.<br />

A. FIRST APPLICA TION fphce an 'X' below and provide the appmedits data)<br />

rl i, EXISTI NG FACILIT' Com ofimdan of'existing' t-olvr e. 2. NEW FACILITY IComplere hem below)<br />

p stohemb ar c<br />

MO V VR * FOR EXIS TING FACILITIES. PROVIDE THE DATE Imo., day, b yr.l 1,Y y FOR NEW FACILITIES,<br />

PROVIDE THE DATE.<br />

O 3 2 2 4 3 OPERATION BEGAN OR THE DATE CONSTRUCTION COMMENCED Inn. M 8 yr) OPERA-<br />

( the xes to rrhh• 1 fa TIOtf BEGAN Oq<br />

` ile dale Coniftelon of the <strong>Hanford</strong> Facility Corrlmeneed.<br />

IS<br />

EXPECTED TO BEGIN<br />

B. REVISED APPLICATK)N !place an 'X' below and Complete Seetlon I above/<br />

® 1. FACILITY HAS AN INTERIM STATUS PERM IT® 2. FACILITY HAS A FWAL PERMIT<br />

III. PROCESSES . CODES AND CAPACITIES<br />

A. PROCESS CODE - Enter the code f ro m the list of p ro cess codes below that best desc ribes each p ro cess ro be used at the faeilky. Ten line. aro provided for ente ri ng<br />

mdes. 1/ men 0", we needed, en te r the code/.) in the space It a pImcaas w il l be used that a not Included In the psi o1 aodsa bebw, then describe the<br />

1,10"29 Ifnektding hs design eapacityl In the space p rovided on the (Ssozian 11 Ch.<br />

B. PROCESS DESIGN CAPACITY - For each code e nte re d M column A enter the cepaelty of the p rocess.<br />

1. AMOUNT• Enter the amount.<br />

2. NI OF M<br />

amountentered<br />

-t<br />

In Column nter th. Co de fo he Bit of unit measure Codes below that desc ribes the unit of me as u re S For<br />

used.<br />

8 of iRE F that e be used.<br />

PROCESS<br />

PRO-<br />

CESS<br />

CODE<br />

APPROPRIATE UNITS OF<br />

MEASURE FOR PROCESS<br />

DESIGN CAPACITY PROCESS<br />

PRO-<br />

CESS<br />

CODE<br />

APPROPRIATE UNITS OF<br />

MEASURE FOR PROCESS<br />

DESIGN CAPACITY<br />

S torage:<br />

Treatment:<br />

CONTAINER (barrel, drum, ate)<br />

TANK<br />

WASTE PILE<br />

S01 GALLONS OR LITERS<br />

S02 GALLONS OR LITERS<br />

S03 CUBIC YARDS OR<br />

CUBIC METERS<br />

TANK T01 GALLONS PER DAY OR<br />

- LITERS,,ER DAY<br />

SURFACE IMPOUNDMENT T02 GALLONS PER DAY OR<br />

L IT SURFACE IMPOUNDMENT<br />

D isposal:<br />

INJECTION WELL<br />

LANDFILL<br />

504 GALLONS OR LITERS<br />

DOD GALLONS OR LITERS<br />

Gat ACRE-FEET Ithe volume that<br />

would cover one acre to s<br />

do of loud<br />

ERS PER DAY<br />

INCINERATOR T03 OR<br />

MOETWC TONSPER<br />

GALLONS PER HOUR OR<br />

LITERS PER HOUR<br />

OTHER (Use for physical, chemical, T04 GALLONS PER DAY.OR<br />

themul or biotog4Cal t reatment LITERS PER DAY<br />

p ro cess es not oc cu Ofi HECTARE-METER<br />

rring In tanks,<br />

surfa ce LAND APPLICA<br />

Impoundments at bdn.r<br />

TI ON<br />

OCEAN DISPOSAL<br />

D82 ACRES OR HECTARES<br />

D83 PER DAY OR<br />

PER<br />

atre. Describe the roee ... a In<br />

the sp<br />

gaction 0C.)<br />

a<br />

r<br />

L<br />

ce o id<br />

p v ed.<br />

IT SURFACE IMPOUNDMENT<br />

ERS<br />

D04 GALLONS OR L IT ERS<br />

UN IT OF UNIT OF _ UN IT UNIT OF MEASURE<br />

MEASURE<br />

CODE UNIT OF MEASURE<br />

OF<br />

MEASURE- MEASURE<br />

CODE UNIT Of MEASURE CODE<br />

GALLONS..................... 0<br />

LITERS ....................... L<br />

CUBICYARDS .................. Y<br />

CUBICMETERS ................. C<br />

GALLONS PER DAY .............. U<br />

LITERS PER DAY ................ V<br />

TONS PER HOUR................ D<br />

METRIC TONS PER HOUR.......... W<br />

GALLONS PER HOUR............. E<br />

LITERS PER HOUR............... H<br />

ACRE-FEET........... A<br />

HECRARE-ME'TEFi ........... .. .. F<br />

ACRES.......................B<br />

HECTARES.................... 0<br />

-<br />

EXAMPLE FOR COMPLETING SECTION III Ishown In fi<br />

ne numbers X-1 and X-2 below): A facility has two stra^pa Units, and tank can<br />

hold 200 Mons and the other cm hold 400 slons. The fa cility also has an Incinerator that can bum up to 20 gallons per hour.<br />

N A. PRO.<br />

L U CESS<br />

I M<br />

N B<br />

B. PROCESS DESIGN CAPACITY<br />

2 UNIT<br />

O^ MEA-<br />

FOR<br />

OFFICIAL<br />

N<br />

L U<br />

I M<br />

A. PRO-<br />

CESS<br />

CODE<br />

B. PROCESS DESIGN CAPACITY<br />

2. UNIT<br />

OF MEA•<br />

FOR<br />

OFFICIAL<br />

CODE<br />

/noire list<br />

E E above)<br />

R<br />

t. AMOUNT<br />

(speG1Y)<br />

SURE<br />

(enter<br />

I code!<br />

USE<br />

ONLY<br />

N BE<br />

E E<br />

R<br />

Thom list<br />

above)<br />

1. AMOUNT<br />

I:peciry)<br />

SURE<br />

fentet<br />

code!<br />

USE<br />

ONLY<br />

I<br />

X-1 S 0 2 600<br />

X-2 T 0 .7 1 20<br />

G 6<br />

El I 11<br />

1 0141 100 V 7<br />

2<br />

6<br />

0<br />

4 10<br />

ECL30 • 300 . ECY 030.31 Form 3 Rev. 2184 PAGE 1 OF 5 CONTINUE ON REVERSE<br />

6<br />

g

I<br />

is Continued fro m the f ro nt.<br />

a<br />

DOE/RL-88-21<br />

221-T Test Facility<br />

Rev. 3, 10101196<br />

Page 2 of 7<br />

III. PROCESSES (continued)<br />

C. SPACE FOR ADDITIONAL PROCESS CODES OR FOR DESCRIBING OTHER PROCESS (code 'TOV). FOR EACH PROCESS ENTERED HERE INCLUDE DESIGN CAPACITY.<br />

T04<br />

The 221-T Containment Systems Test Facility (221-T) was a research laboratory<br />

intended to perform experiments with alkali metal compounds. It was<br />

anticipated that operations were to begin in 1977. This unit also was<br />