Optimetrics: Parametrics and Optimization Using Ansoft HFSS

Optimetrics: Parametrics and Optimization Using Ansoft HFSS

Optimetrics: Parametrics and Optimization Using Ansoft HFSS

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

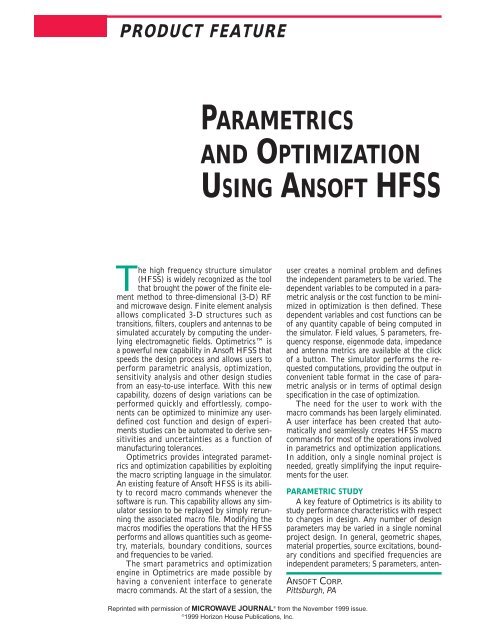

PRODUCT FEATURE<br />

The high frequency structure simulator<br />

(<strong>HFSS</strong>) is widely recognized as the tool<br />

that brought the power of the finite element<br />

method to three-dimensional (3-D) RF<br />

<strong>and</strong> microwave design. Finite element analysis<br />

allows complicated 3-D structures such as<br />

transitions, filters, couplers <strong>and</strong> antennas to be<br />

simulated accurately by computing the underlying<br />

electromagnetic fields. <strong>Optimetrics</strong> is<br />

a powerful new capability in <strong>Ansoft</strong> <strong>HFSS</strong> that<br />

speeds the design process <strong>and</strong> allows users to<br />

perform parametric analysis, optimization,<br />

sensitivity analysis <strong>and</strong> other design studies<br />

from an easy-to-use interface. With this new<br />

capability, dozens of design variations can be<br />

performed quickly <strong>and</strong> effortlessly, components<br />

can be optimized to minimize any userdefined<br />

cost function <strong>and</strong> design of experiments<br />

studies can be automated to derive sensitivities<br />

<strong>and</strong> uncertainties as a function of<br />

manufacturing tolerances.<br />

<strong>Optimetrics</strong> provides integrated parametrics<br />

<strong>and</strong> optimization capabilities by exploiting<br />

the macro scripting language in the simulator.<br />

An existing feature of <strong>Ansoft</strong> <strong>HFSS</strong> is its ability<br />

to record macro comm<strong>and</strong>s whenever the<br />

software is run. This capability allows any simulator<br />

session to be replayed by simply rerunning<br />

the associated macro file. Modifying the<br />

macros modifies the operations that the <strong>HFSS</strong><br />

performs <strong>and</strong> allows quantities such as geometry,<br />

materials, boundary conditions, sources<br />

<strong>and</strong> frequencies to be varied.<br />

The smart parametrics <strong>and</strong> optimization<br />

engine in <strong>Optimetrics</strong> are made possible by<br />

having a convenient interface to generate<br />

macro comm<strong>and</strong>s. At the start of a session, the<br />

PARAMETRICS<br />

AND OPTIMIZATION<br />

USING ANSOFT <strong>HFSS</strong><br />

user creates a nominal problem <strong>and</strong> defines<br />

the independent parameters to be varied. The<br />

dependent variables to be computed in a parametric<br />

analysis or the cost function to be minimized<br />

in optimization is then defined. These<br />

dependent variables <strong>and</strong> cost functions can be<br />

of any quantity capable of being computed in<br />

the simulator. Field values, S parameters, frequency<br />

response, eigenmode data, impedance<br />

<strong>and</strong> antenna metrics are available at the click<br />

of a button. The simulator performs the requested<br />

computations, providing the output in<br />

convenient table format in the case of parametric<br />

analysis or in terms of optimal design<br />

specification in the case of optimization.<br />

The need for the user to work with the<br />

macro comm<strong>and</strong>s has been largely eliminated.<br />

A user interface has been created that automatically<br />

<strong>and</strong> seamlessly creates <strong>HFSS</strong> macro<br />

comm<strong>and</strong>s for most of the operations involved<br />

in parametrics <strong>and</strong> optimization applications.<br />

In addition, only a single nominal project is<br />

needed, greatly simplifying the input requirements<br />

for the user.<br />

PARAMETRIC STUDY<br />

A key feature of <strong>Optimetrics</strong> is its ability to<br />

study performance characteristics with respect<br />

to changes in design. Any number of design<br />

parameters may be varied in a single nominal<br />

project design. In general, geometric shapes,<br />

material properties, source excitations, boundary<br />

conditions <strong>and</strong> specified frequencies are<br />

independent parameters; S parameters, anten-<br />

ANSOFT CORP.<br />

Pittsburgh, PA<br />

Reprinted with permission of MICROWAVE JOURNAL ® from the November 1999 issue.<br />

© 1999 Horizon House Publications, Inc.

na parameters, eigenmode data or<br />

other <strong>HFSS</strong>-computed quantities are<br />

dependent parameters. Users can<br />

create compound parameters, which<br />

are a function of both dependent <strong>and</strong><br />

independent parameters. Such a<br />

compound parameter can be used for<br />

better visualization <strong>and</strong> underst<strong>and</strong>ing<br />

of the project or as a cost function<br />

to be used in the optimizer. The<br />

number of independent or dependent<br />

parameters is unlimited. All dependencies,<br />

such as boundary conditions,<br />

are restored intelligently including<br />

face picks, impedance,<br />

calibration lines, gap source lines <strong>and</strong><br />

the UV coordinate system of periodic<br />

boundaries. For example, if an impedance<br />

line has been created that is<br />

one-third wavelength from the end of<br />

a port face, this line will always be<br />

one-third wavelength for the parametric<br />

projects.<br />

Fig. 1 An H-plane reactive T-junction with<br />

inductive septum. ▼<br />

Fig. 2 <strong>Optimetrics</strong> table for organizing <strong>and</strong> simulating<br />

parameters. ▼<br />

PRODUCT FEATURE<br />

Consider the problem of computing<br />

the power division produced by an<br />

inductive septum in a waveguide Tjunction<br />

at 10 GHz, as shown in Figure<br />

1. To solve this problem as a<br />

function of the septum offset, the<br />

nominal problem is entered <strong>and</strong><br />

solved. With <strong>Optimetrics</strong>, a table is<br />

set up for sweeping the offset with<br />

each row of the table corresponding<br />

to a specific offset value. (There is no<br />

limit on the number of rows users can<br />

enter.) Taking into account the parameters<br />

specified for the row, solving<br />

the table creates an <strong>HFSS</strong> project for<br />

every row of the table. <strong>Optimetrics</strong><br />

supports automatic seeding for each<br />

parametric setup. In the case where<br />

no geometry parameter is changed,<br />

the refined nominal mesh is used as<br />

the starting mesh for all solutions.<br />

Dependent <strong>and</strong> compound parameters<br />

can be added as columns of a table.<br />

In this case, the original dependent parameters<br />

of interest are the magnitude<br />

of the scattering parameters. Upon execution,<br />

the value of the dependent parameter<br />

computed for this row’s solution<br />

fills the far right columns as shown<br />

in Figure 2. In this case, the problem<br />

size was 8000 unknowns <strong>and</strong> required<br />

three minutes <strong>and</strong> five seconds per row<br />

using a 360 MHz Pentium III processor.<br />

If the user is not satisfied with the<br />

accuracy of the solution, it is possible to<br />

perform additional refinement <strong>and</strong> obtain<br />

a higher accuracy solution for<br />

every row. Users can also add frequency<br />

sweeps if single frequency<br />

information is insufficient.<br />

<strong>Optimetrics</strong> offers users the choice<br />

of either saving or deleting the para-<br />

metric field solutions. Turning off the<br />

field-saving feature saves disk space,<br />

but the parametric field solutions are<br />

not available for later viewing. The<br />

values of the dependent parameters<br />

are always retained.<br />

Table postprocessing enables users<br />

to plot one column against another, as<br />

shown in Figure 3. Parametric projects<br />

can be viewed in the same detail<br />

as the nominal project. A macro file<br />

created in the nominal project to<br />

generate plots can be run for any<br />

parametric setup with the click of a<br />

button. The saved plots for every row<br />

can be plotted together to view the<br />

effect of changing parameter values<br />

on the plots.<br />

Even after the solution is completed,<br />

the user may add new solution<br />

columns to the table. In this case, the<br />

left-to-right power ratio vs. offset is<br />

evaluated <strong>and</strong> plotted. Within seconds,<br />

<strong>Optimetrics</strong> creates new columns <strong>and</strong><br />

fills them by deriving the newly requested<br />

data from the existing solutions<br />

in the corresponding rows. The results<br />

are shown in Figure 4.<br />

Fig. 3 S parameters vs. septum position<br />

for the reactive T-junction. ▼<br />

Fig. 4 New plots of derived quantities. ▼

▲ Fig. 5 A four-post microstrip filter.<br />

▲ Fig. 6 The optimized filter’s frequency response.<br />

Fig. 7 The modeled microstrip<br />

patch antenna. ▼<br />

OPTIMIZATION<br />

<strong>Optimetrics</strong> contains a powerful<br />

internal optimization algorithm to<br />

help users achieve optimal designs.<br />

This optimizer employs a constrained<br />

superlinearly convergent active set algorithm.<br />

To restrict the search region<br />

<strong>and</strong> prevent the optimizer from creating<br />

physically meaningless designs<br />

(such as overlapping geometry), <strong>Optimetrics</strong><br />

supports simple bounds as<br />

well as linear constraints. The optimized<br />

design is guaranteed to be<br />

within the feasible domain.<br />

<strong>Optimetrics</strong> also provides users<br />

with unlimited freedom in defining<br />

cost functions for optimization. Any<br />

algebraic expression may be defined<br />

as the cost function <strong>and</strong> any solution<br />

quantity (such as field strength, far-<br />

PRODUCT FEATURE<br />

field values or circuit parameters that<br />

can be computed in the simulator)<br />

may be used as a variable in this cost<br />

function. <strong>Optimetrics</strong> searches the<br />

design space to minimize the cost<br />

function. To accommodate maximization<br />

or compound objectives, the user<br />

may construct partial cost functions<br />

<strong>and</strong>/or apply appropriate weights.<br />

To simplify cost function definition<br />

for st<strong>and</strong>ard tasks, <strong>Optimetrics</strong> provides<br />

a graphical user interface that<br />

allows the user access<br />

to commonly<br />

used quantities<br />

(such as circuit parameters)<br />

with the<br />

push of a button. A<br />

special panel for filter<br />

optimization is<br />

also provided. The<br />

user may choose an<br />

arbitrary number of<br />

frequency b<strong>and</strong>s<br />

<strong>and</strong> specify the requested<br />

filter characteristics.<br />

Expert<br />

users can even create<br />

their own macro<br />

scripts. The cost functions in the<br />

macro script may contain loops <strong>and</strong><br />

conditional statements.<br />

By default, optimization starts from<br />

the nominal settings for the design.<br />

However, if a parametric table is available,<br />

<strong>Optimetrics</strong> will first scan the<br />

table, analyze all designs that are feasible<br />

<strong>and</strong> start optimization from the design<br />

of least cost. Hence, the user may<br />

manually create parameter settings for<br />

one or more c<strong>and</strong>idates as the starting<br />

point for the optimization, or even begin<br />

with a parametric sweep. Beginning<br />

with a parametric sweep is particularly<br />

attractive when the user chooses to inspect<br />

the response surface over a wide<br />

range of parameters <strong>and</strong> may also help<br />

to avoid local optima.<br />

FINE-TUNING A DESIGN<br />

To illustrate some of the productivity<br />

gains afforded by <strong>Optimetrics</strong>,<br />

consider the problem of fine-tuning<br />

the product design. It often happens<br />

that a designer has the basic parameters<br />

for a microwave component but<br />

needs to fine-tune these parameters<br />

to deliver a precision product. <strong>Using</strong><br />

cut-<strong>and</strong>-try methods, such fine-tuning<br />

can require weeks of prototyping<br />

<strong>and</strong> tweaking; using <strong>Optimetrics</strong>, it<br />

can be performed overnight.<br />

Consider the four-post microstrip<br />

b<strong>and</strong>pass filter shown in Figure 5.<br />

This filter was designed 1 in an attempt<br />

to meet a design goal of an 8 to<br />

9 GHz passb<strong>and</strong> with less than 1 dB<br />

ripple. <strong>Using</strong> traditional filter design<br />

techniques, a filter was designed, fabricated,<br />

tested <strong>and</strong> published with a<br />

7.6 to 9 GHz passb<strong>and</strong> <strong>and</strong> 1.5 dB<br />

ripple. <strong>Using</strong> the published dimensions<br />

as the nominal design, this filter<br />

was entered into <strong>Optimetrics</strong>. The<br />

optimization problem consists of four<br />

parameters: the diameter of the end<br />

posts, the diameter of the center<br />

posts, the spacing between the end<br />

<strong>and</strong> center posts, <strong>and</strong> the spacing between<br />

the center posts. As shown in<br />

Figure 6, <strong>Optimetrics</strong> improved this<br />

design considerably; the optimized<br />

design has a passb<strong>and</strong> from 8 to 9<br />

GHz with less than 0.6 dB ripple, exceeding<br />

the design specifications.<br />

CREATING A DESIGN<br />

FROM SCRATCH<br />

In some cases, <strong>Optimetrics</strong> is able<br />

to create an excellent design even<br />

though the user has little initial<br />

knowledge of a good design. This capability<br />

is not foolproof; complex designs<br />

often have many parameters<br />

<strong>and</strong> many local minima that can confound<br />

direct optimization. A designer<br />

is advised to perform a parametric<br />

sweep first <strong>and</strong> must use his or her<br />

judgment to create an initial good design.<br />

Nevertheless, in some simple<br />

cases, the optimizer works surprisingly<br />

well in creating designs with minimal<br />

user design input.<br />

Consider the microstrip patch antenna<br />

in Figure 7. The design goal for<br />

this antenna is to produce an antenna<br />

resonant at 2 GHz <strong>and</strong> the lowest possible<br />

return loss at resonance. The design<br />

parameters are the length of the<br />

patch <strong>and</strong> the feed location on the side<br />

of the patch. The nominal patch <strong>and</strong><br />

the optimized patch are shown in Figure<br />

8; the corresponding return loss vs.<br />

frequency plots are shown in Figure 9.<br />

In this case it can be seen that the<br />

nominal patch is very far from an acceptable<br />

design while the optimized<br />

patch provides good performance.<br />

OPTIMIZATION USING<br />

EXTERNAL OPTIMIZERS<br />

Since <strong>Optimetrics</strong> is based on the<br />

<strong>HFSS</strong> macro scripting language, it is<br />

possible to drive <strong>Ansoft</strong> <strong>HFSS</strong> from

▲ Fig. 8 The microstrip patch antenna’s geometry.<br />

Fig. 9 The antenna’s nominal <strong>and</strong> optimized return loss<br />

vs. frequency. ▼<br />

start to finish from an outside program.<br />

This outside program may be<br />

used to adjust design parameters until<br />

particular postprocessing results are<br />

achieved. The outside program may<br />

be written in C, C++, FORTRAN or<br />

any other language. Unlike the automated<br />

procedures available in an internal<br />

optimizer, using an outside<br />

computer program for optimization<br />

requires a significant programming effort<br />

on the part of the user. In the example<br />

described here, MatLab supplies<br />

the optimization algorithm <strong>and</strong><br />

controls the input to <strong>Ansoft</strong> <strong>HFSS</strong>.<br />

Consider the three-element Yagi-<br />

Uda antenna shown in Figure 10. A<br />

typical Yagi-Uda antenna should have<br />

a high directivity, narrow beamwidth,<br />

low sidelobes <strong>and</strong> a high front-to-back<br />

ratio. In this example, the goal was to<br />

optimize the variables to achieve a directivity<br />

<strong>and</strong> front-to-back ratio of 8<br />

dB or greater. The antenna consists of<br />

a director, driven element <strong>and</strong> reflector.<br />

The distance between the driven<br />

element <strong>and</strong> reflector is denoted by S1<br />

while the distance between the direc-<br />

PRODUCT FEATURE<br />

tor <strong>and</strong> driven element<br />

is denoted by<br />

S2. In order to<br />

achieve their functions,<br />

the reflector<br />

should be longer<br />

than the driven elements<br />

<strong>and</strong> the director<br />

should be shorter.<br />

(Constraints in<br />

the optimization<br />

were used to enforce<br />

these conditions.)<br />

Two cost<br />

functions were used:<br />

one to measure the<br />

directivity, the other<br />

to measure the<br />

front-to-back-ratio.<br />

The MatLab multiobjective<br />

goal attainment<br />

algorithm<br />

(fgoalattain.m) was<br />

also used.<br />

The cross-sectional<br />

radius of the<br />

antenna elements is<br />

assumed to be<br />

0.003369λ (ln λ/2a =<br />

5). A search was performed<br />

to determine<br />

a combination of element<br />

lengths <strong>and</strong><br />

separation distances<br />

such that the directivity <strong>and</strong> front-toback<br />

ratio are greater than 8 dB. Figure<br />

11 shows the directivity <strong>and</strong> frontto-back<br />

ratio vs. number of iterations.<br />

During the first few iterations, the optimizer<br />

was able to achieve a front-toback<br />

ratio greater than 8 dB, but the<br />

directivity was approximately 5 dB. After<br />

34 iterations, the software found its<br />

goal at 8.05 <strong>and</strong> 8.46 dB. Figure 12<br />

shows the initial <strong>and</strong> optimized dimensions<br />

as well as how they changed vs.<br />

optimization cycle.<br />

CONCLUSION<br />

<strong>Optimetrics</strong> is a powerful new feature<br />

in <strong>Ansoft</strong> <strong>HFSS</strong> that provides<br />

parametric <strong>and</strong> optimization capabilities<br />

for 3-D RF <strong>and</strong> microwave design<br />

problems. The approach used is<br />

very general <strong>and</strong> allows any design<br />

quantity to be parameterized <strong>and</strong> optimized.<br />

It even allows outside programs<br />

such as MatLab to be used to<br />

drive the optimization. The examples<br />

shown indicate the ease with which<br />

parametric solutions may be set up<br />

<strong>and</strong> the power of the new optimiza-<br />

▲ Fig. 10 The three-element Yagi-Uda<br />

array antenna.<br />

▲ Fig. 11 Directivity <strong>and</strong> front-to-back<br />

ratio vs. optimization cycle.<br />

Fig. 12 The antenna’s dimensions<br />

vs. optimization cycle. ▼<br />

tion capability. Significant applications<br />

of <strong>Optimetrics</strong> include fine-tuning<br />

preliminary designs, searching the<br />

design space for acceptable designs<br />

<strong>and</strong> the possibility of creating excellent<br />

designs from scratch. All of these<br />

applications provide good productivity<br />

improvements for designers <strong>and</strong> allow<br />

precision designs to be created<br />

with minimal cost <strong>and</strong> time.<br />

References<br />

1. MatLab Version 5.3 is a registered trademark<br />

of the Mathworks Inc., Natick, MA<br />

01760, USA.<br />

2. K.L. Wu, C. Wu <strong>and</strong> J. Litva, “Characterizing<br />

Microwave Planar Circuits <strong>Using</strong> the<br />

Coupled Finite-Boundary Element<br />

Method,” IEEE Transactions on Microwave<br />

Theory <strong>and</strong> Techniques, Vol. 40,<br />

October 1992, pp. 1963–1966.<br />

<strong>Ansoft</strong> Corp.<br />

Pittsburgh, PA (412) 261-3200