PZ004 - KEK

PZ004 - KEK

PZ004 - KEK

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

4 HIGH POWER TEST<br />

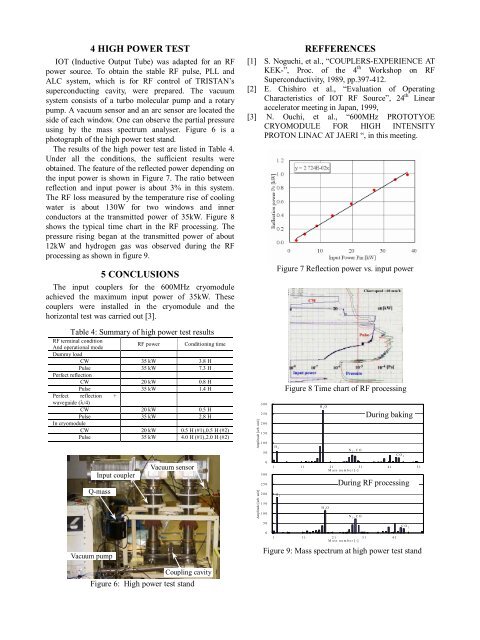

IOT (Inductive Output Tube) was adapted for an RF<br />

power source. To obtain the stable RF pulse, PLL and<br />

ALC system, which is for RF control of TRISTAN’s<br />

superconducting cavity, were prepared. The vacuum<br />

system consists of a turbo molecular pump and a rotary<br />

pump. A vacuum sensor and an arc sensor are located the<br />

side of each window. One can observe the partial pressure<br />

using by the mass spectrum analyser. Figure 6 is a<br />

photograph of the high power test stand.<br />

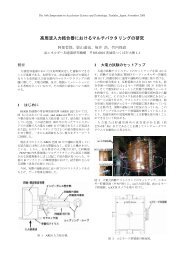

The results of the high power test are listed in Table 4.<br />

Under all the conditions, the sufficient results were<br />

obtained. The feature of the reflected power depending on<br />

the input power is shown in Figure 7. The ratio between<br />

reflection and input power is about 3% in this system.<br />

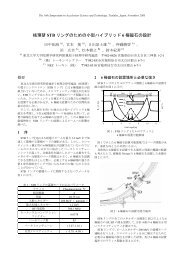

The RF loss measured by the temperature rise of cooling<br />

water is about 130W for two windows and inner<br />

conductors at the transmitted power of 35kW. Figure 8<br />

shows the typical time chart in the RF processing. The<br />

pressure rising began at the transmitted power of about<br />

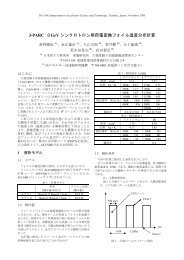

12kW and hydrogen gas was observed during the RF<br />

processing as shown in figure 9.<br />

5 CONCLUSIONS<br />

The input couplers for the 600MHz cryomodule<br />

achieved the maximum input power of 35kW. These<br />

couplers were installed in the cryomodule and the<br />

horizontal test was carried out [3].<br />

Table 4: Summary of high power test results<br />

RF terminal condition<br />

And operational mode<br />

Dummy load<br />

RF power Conditioning time<br />

CW 35 kW 3.8 H<br />

Pulse<br />

Perfect reflection<br />

35 kW 7.3 H<br />

CW 20 kW 0.8 H<br />

Pulse 35 kW 1.4 H<br />

Perfect reflection +<br />

waveguide (λ/4)<br />

CW 20 kW 0.5 H<br />

Pulse<br />

In cryomodule<br />

35 kW 2.8 H<br />

CW 20 kW 0.5 H (#1),0.5 H (#2)<br />

Pulse 35 kW 4.0 H (#1),2.0 H (#2)<br />

Input coupler<br />

Q-mass<br />

Vacuum pump<br />

Vacuum sensor<br />

Coupling cavity<br />

Figure 6: High power test stand<br />

REFFERENCES<br />

[1] S. Noguchi, et al., “COUPLERS-EXPERIENCE AT<br />

<strong>KEK</strong>-”, Proc. of the 4 th Workshop on RF<br />

Superconductivity, 1989, pp.397-412.<br />

[2] E. Chishiro et al., “Evaluation of Operating<br />

Characteristics of IOT RF Source”, 24 th Linear<br />

accelerator meeting in Japan, 1999,<br />

[3] N. Ouchi, et al., “600MHz PROTOTYOE<br />

CRYOMODULE FOR HIGH INTENSITY<br />

PROTON LINAC AT JAERI “, in this meeting.<br />

Amplitude [arb. unit]<br />

Amplitude [arb. unit]<br />

300<br />

250<br />

200<br />

150<br />

100<br />

50<br />

0<br />

300<br />

250<br />

200<br />

150<br />

100<br />

50<br />

0<br />

H 2<br />

Figure 7 Reflection power vs. input power<br />

Figure 8 Time chart of RF processing<br />

H 2 O<br />

N 2 ,CO<br />

CO 2<br />

1 11 21 31 41 51<br />

M ass number [-]<br />

H 2<br />

H 2 O<br />

N 2 ,CO<br />

During baking<br />

During RF processing<br />

1 11 21 31 41<br />

M ass number [-]<br />

Figure 9: Mass spectrum at high power test stand<br />

CO 2