Enviornmental Assessement report for tiruvarur STP - Municipal ...

Enviornmental Assessement report for tiruvarur STP - Municipal ...

Enviornmental Assessement report for tiruvarur STP - Municipal ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

ENVIRONMENTAL IMPACT<br />

ASSESSMENT REPORT<br />

For Proposed<br />

SEWAGE TREATMENT PLANT<br />

6.92MLD CAPACITY<br />

At<br />

Kekkarai Village, Thiruvarur <strong>Municipal</strong>ity<br />

Thiruvarur District<br />

TamilNadu

CONTENTS<br />

CONTENTS<br />

CONTENTS

Table of Contents<br />

EIA EIA FOR FOR 6.92 6.92 6.92 MLD MLD MLD <strong>STP</strong> <strong>STP</strong> <strong>STP</strong> AT THIRUVARUR<br />

1. INTRODUCTION .............................................................................................................................. 1<br />

1.1 INTRODUCTION ..................................................................................................................... 1<br />

1.2 PREAMBLE ............................................................................................................................... 1<br />

1.3 PROFILE OF THIRUVARUR ................................................................................................ 2<br />

1.4 NEED FOR THE PROJECT.................................................................................................... 2<br />

1.5 THIRUVARUR SEWERAGE SCHEME .............................................................................. 3<br />

1.6 PROJECT BRIEF ...................................................................................................................... 6<br />

1.7 PROPOSED PROJECT SITE .................................................................................................. 6<br />

1.8 NEED FOR EIA ......................................................................................................................... 8<br />

1.9 OBJECTIVES OF THIS REPORT ......................................................................................... 9<br />

1.10 SCOPE OF THE REPORT ................................................................................................... 10<br />

1.11 CATEGORIZATION OF PROJECT ................................................................................... 10<br />

1.12 ENVIRONMENTAL LEGISLATIONS .............................................................................. 11<br />

1.13 WORLD BANK POLICIES .................................................................................................. 13<br />

1.14 LEGAL/REGULATORY CLEARANCES FOR THE PROJECT ................................... 15<br />

1.15 AGENCIES RESPONSIBLE FOR PROJECT IMPLEMENTATION .......................... 16<br />

2. PROJECT DESCRIPTION ............................................................................................................ 17<br />

2.1 PROJECT PROPOSAL ......................................................................................................... 17<br />

2.2 LAND REQUIREMENT ....................................................................................................... 17<br />

2.3 PROCESS DESCRIPTION ................................................................................................... 19<br />

2.4 <strong>STP</strong> PIPELINE AND BYPASS ARRANGEMENT ......................................................... 23<br />

2.5 RAW SEWAGE CHARACTERISTICS .............................................................................. 27<br />

2.6 TREATED EFFLUENT QUALITY .................................................................................... 27<br />

2.7 DISPOSAL OF TREATED EFFLUENT ........................................................................... 27<br />

3. BASELINE ENVIRONMENTAL DATA ................................................................................... 28<br />

3.1 METHODOLOGY .................................................................................................................. 28<br />

3.2 BRIEF DESCRIPTION OF THE PROJECT SITE .......................................................... 28<br />

1

EIA EIA FOR FOR 6.92 6.92 6.92 MLD MLD MLD <strong>STP</strong> <strong>STP</strong> <strong>STP</strong> AT THIRUVARUR<br />

3.3 CONNECTIVITY ................................................................................................................... 31<br />

3.4 LAND USE .............................................................................................................................. 31<br />

3.5 RAINFALL & CLIMATE ...................................................................................................... 33<br />

3.6 GEOLOGY ............................................................................................................................... 33<br />

3.7 AIR ENVIRONMENT ........................................................................................................... 34<br />

3.8 Noise Environment ............................................................................................................ 36<br />

3.9 WATER QUALITY ................................................................................................................ 37<br />

3.10 SOIL QUALITY ...................................................................................................................... 41<br />

3.11 SOCIO-ECONOMIC DATA ................................................................................................. 44<br />

4. PREDICTED IMPACTS AND MITIGATION MEASURES .................................................. 55<br />

4.1 INTRODUCTION .................................................................................................................. 55<br />

4.2 IMPACT EVALUATION ...................................................................................................... 55<br />

4.3 PROPOSED MITIGATION MEASURES ......................................................................... 58<br />

4.4 CONCLUDING REMARKS ................................................................................................. 62<br />

5. PUBLIC PARTICIPATION .......................................................................................................... 63<br />

6. ENVIRONMENTAL MANAGEMENT PLAN ......................................................................... 65<br />

6.1 INTRODUCTION .................................................................................................................. 65<br />

6.2 EMP DURING CONSTRUCTION PHASE ...................................................................... 65<br />

6.3 EMP DURING OPERATION PHASE ............................................................................... 72<br />

6.4 ENVIRONMENTAL MONITORING PROGRAM .......................................................... 73<br />

6.5 GREEN BELT DEVELOPMENT PLAN ........................................................................... 77<br />

6.6 SAFETY TRAINING & HEALTH MONITORING ......................................................... 79<br />

6.7 EMP BUDGETARY ALLOCATION .................................................................................. 87<br />

6.8 PERMISSIONS FROM VARIOUS DEPARTMENTS WITH PRESENT STATUS ......<br />

88<br />

7. CONCLUSION ................................................................................................................................. 98<br />

2

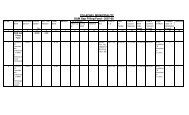

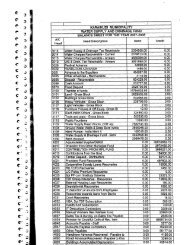

LIST OF TABLES<br />

EIA EIA FOR FOR 6.92 6.92 6.92 MLD MLD MLD <strong>STP</strong> <strong>STP</strong> <strong>STP</strong> AT THIRUVARUR<br />

Table 1-1 Agencies responsible <strong>for</strong> Project Implementation ....................................... 16<br />

Table 2-1 Raw Sewage Characteristics ....................................................................... 27<br />

Table 2-2 Treated Effluent Quality ............................................................................ 27<br />

Table 3-1 Surrounding Features of the Project Site .................................................... 28<br />

Table 3-2 Existing land use of Thiruvarur Town ........................................................ 31<br />

Table 3-3 Land use distribution in Tiruvarur Local Planning Area ............................. 32<br />

Table 3-4 Proposed Land Use Plan ............................................................................ 33<br />

Table 3-5 Mode of collection of Ambient Air Quality Parameters .............................. 35<br />

Table 3-6 Techniques used <strong>for</strong> Ambient Air Monitoring ............................................. 35<br />

Table 3-7 Air Sampling Locations ............................................................................. 36<br />

Table 3-8 Ambient Air Quality Data ......................................................................... 36<br />

Table 3-9 Noise Level Data Sheet .............................................................................. 37<br />

Table 3-10 CPCB standards <strong>for</strong> Noise ......................................................................... 37<br />

Table 3-11 Sampling Locations in the Study Area ...................................................... 38<br />

Table 3-12 Ground Water Quality in Project Site ....................................................... 39<br />

Table 3-13 Soil Sampling Stations ............................................................................. 42<br />

Table 3-14 Soil Quality data ...................................................................................... 44<br />

Table 3-15 Population Statistics ................................................................................ 45<br />

Table 3-16 Literacy Statistics .................................................................................... 46<br />

Table 3-17 Literacy of Thiruvarur District ................................................................. 46<br />

Table 3-18 Literacy Rate of Thiruvarur District......................................................... 46<br />

Table 3-19 Land use Pattern ..................................................................................... 47<br />

Table 3-20 Agriculture in the District ........................................................................ 49<br />

Table 3-21 Livestock Census 2004 ............................................................................. 51<br />

3

EIA EIA FOR FOR 6.92 6.92 6.92 MLD MLD MLD <strong>STP</strong> <strong>STP</strong> <strong>STP</strong> AT THIRUVARUR<br />

Table 3-22 Fishery Production .................................................................................. 51<br />

Table 3-23 Industries in the district ........................................................................... 52<br />

Table 3-24 List of Educational Institutions ................................................................ 53<br />

Table 3-25 Work<strong>for</strong>ce in the District ......................................................................... 53<br />

Table 3-26 Health care facilities in the District .......................................................... 53<br />

Table 6-1 Environmental Monitoring Schedule .......................................................... 75<br />

Table 6-2 Cost <strong>for</strong> Environmental monitoring ........................................................... 77<br />

Table 6-3 Safety Measures <strong>for</strong> the operation of the <strong>STP</strong> ............................................. 80<br />

Table 6-4 Steps to be taken during Trouble shooting .................................................. 83<br />

Table 6-5 Environmental Budget .............................................................................. 88<br />

Table 6-6 Authorities Clearances ............................................................................... 89<br />

Table 6-7 Construction Phase Impacts & Mitigation Measures ................................... 90<br />

Table 6-8 Environmental Enhancement measures ..................................................... 95<br />

4

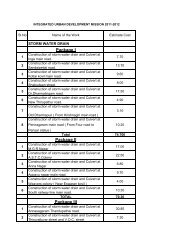

LIST OF FIGURES<br />

EIA EIA FOR FOR 6.92 6.92 6.92 MLD MLD MLD <strong>STP</strong> <strong>STP</strong> <strong>STP</strong> AT THIRUVARUR<br />

Figure 1-1 Thiruvarur Underground Drainage Scheme Plan ........................................ 5<br />

Figure 1-2 Satellite Image of the Site Location ............................................................ 7<br />

Figure 1-3 Current Status of the Site ........................................................................... 7<br />

Figure 1-4 Layout of Sewage Treatment Plant ............................................................. 8<br />

Figure 2-1 Layout of <strong>STP</strong> .......................................................................................... 18<br />

Figure 2-2 Process Flow of <strong>STP</strong> ................................................................................. 20<br />

Figure 2-3 Bypass Arrangement <strong>for</strong> <strong>STP</strong> ................................................................... 25<br />

Figure 2-4 Flow Representation <strong>for</strong> the Proposed <strong>STP</strong> ............................................... 26<br />

Figure 3-1 Surrounding features around Project site .................................................. 29<br />

Figure 3-2 Satellite Imagery of the Project Site - 10 Km Radius ................................. 30<br />

Figure 3-3 Geology Map of Thiruvarur District .......................................................... 34<br />

Figure 3-4 Water Sampling Locations ....................................................................... 41<br />

Figure 3-5 Photographs during field survey ............................................................... 43<br />

Figure 3-6 Population Distribution of Thiruvarur District ......................................... 45<br />

Figure 3-7 Literacy Rate of Thiruvarur District ......................................................... 47<br />

Figure 3-8 Land Utilization Pattern of the Thiruvarur ............................................... 48<br />

Figure 3-9 Cropping Calendar ................................................................................... 50<br />

Figure 6-1 Green Belt Development Plan ................................................................... 79<br />

LIST OF ANNEXURE<br />

Annexure -1 Basic In<strong>for</strong>mation on Proposed project in Thiruvarur<br />

Annexure -2 Consent to Establish<br />

Annexure- 3 Compliance Status of Consent<br />

Annexure-4 List of Activities<br />

Annexure-5 Reply to Query<br />

5

EIA EIA EIA REPORT<br />

REPORT

1.1 INTRODUCTION<br />

1. INTRODUCTION<br />

EIA EIA FOR FOR 6.92 6.92 6.92 MLD MLD MLD <strong>STP</strong> <strong>STP</strong> <strong>STP</strong> AT THIRUVARUR<br />

Tamil Nadu Government made a policy announcement of providing Under<br />

Ground Sewerage scheme in all urban local bodies in a phased manner at<br />

District Head quarter towns. The <strong>Municipal</strong> Sewerage collection network<br />

systems are implemented and the household sewage are collected and moved<br />

to the collection chamber of <strong>STP</strong>.<br />

The <strong>STP</strong> consists of various unit operations and processes to treat the raw<br />

sewage into the final treated effluent quality as per the stipulated standards.<br />

The project will have construction phase and operation phase impacts<br />

which have been assessed and the Environment Impact Assessment has been<br />

prepared.<br />

1.2 PREAMBLE<br />

The proposed sewerage system was designed <strong>for</strong> the targeted population<br />

of about 60,000 people. The project has the following components:<br />

Sewerage network consisting of the main sewer line, branch sewer<br />

line and manholes;<br />

Construction of a sewage pumping station;<br />

A sewage treatment plant<br />

For the purpose of sewage system the project area divided in to 5 zones<br />

each having a separate pumping station. There will be 5 pumping stations and<br />

16 lift stations. The scheme contains provisions <strong>for</strong> sewer laying <strong>for</strong> a total<br />

length of 71.679Km and construction of 2846 manholes.<br />

1

EIA EIA FOR FOR 6.92 6.92 6.92 MLD MLD MLD <strong>STP</strong> <strong>STP</strong> <strong>STP</strong> AT THIRUVARUR<br />

The Sewage Treatment Plant having a capacity of 6.92 MLD is proposed at<br />

Kekarai, Thiruvarur District, Tamil Nadu.<br />

1.3 PROFILE OF THIRUVARUR<br />

Thiruvarur <strong>Municipal</strong>ity is located at a distance of 60 km from East of<br />

Thanjavur town. The latitude of the town is 10〫77” and the longitude of the<br />

town is 79〫15 “. As per 2011 census, the population of Tiruvarur is 1268,094.<br />

Males constitute 49.5 % of the population and females 50.5%. The<br />

decadal growth rate is 8.43%. Tiruvarur has an average literacy rate of 83.26%,<br />

male literacy is 89.65%, and female literacy is 77.02%. 11.98% of the<br />

population is under 6 years of age.<br />

1.4 NEED FOR THE PROJECT<br />

With the rapid growth of the population in Thiruvarur district, the lack of<br />

proper drainage system and sewage treatment facility has become an ever –<br />

larger problem <strong>for</strong> public and from environmental point of view. There<strong>for</strong>e,<br />

Government has decided to provide an Underground Sewerage Scheme with<br />

<strong>STP</strong> at Kekarai as a part of urban development project <strong>for</strong> Thiruvarur<br />

<strong>Municipal</strong>ity.<br />

M/s. Hindustan Dorr-Oliver Limited has been assigned <strong>for</strong> Design,<br />

construction, erection and commissioning, startup and operation of the sewage<br />

treatment by Tamil Nadu Water supply and Drainage Board (TWAD).<br />

In order to assess the impact of the proposed <strong>STP</strong> on the environment,<br />

M/s. Hindustan Dorr-Oliver Limited, Chennai studied the environmental<br />

scenario of the existing situation and the probable impacts that could arise<br />

from the proposed sewage treatment plant at Thiruvarur. Suitable mitigation<br />

measures have also been suggested based on the impact assessment.<br />

2

1.5 THIRUVARUR SEWERAGE SCHEME<br />

EIA EIA FOR FOR 6.92 6.92 6.92 MLD MLD MLD <strong>STP</strong> <strong>STP</strong> <strong>STP</strong> AT THIRUVARUR<br />

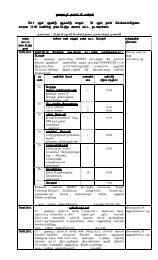

Administrative Sanction was accorded vide G.O No. 16 MAWS dated<br />

1.09.2006 and action was initiated in the year 2007 by TWAD. Sewerage<br />

treatment plant site was selected at Kekkarai Village. (Proposed treatment<br />

plant) About 8.87 Acres of land was identified <strong>for</strong> this purpose. The location of<br />

Sewage Treatment Plant and the underground drainage scheme plan is shown<br />

in Figure 1-1. The pumping Station is divided into 5 zones. Zone I<br />

(Srinivasapuram), Zone II (Chettikulam), Zone III (Kulunthankulam), Zone IV<br />

(Arasankulam) and Zone V (Ramagaye Muni).<br />

The sewage from the residential area is discharged into the corresponding<br />

underground sewerage system. All the sewerage zones are interconnected<br />

with the sewerage network, ultimately collecting into the main pumping station<br />

(Zone V), where sewage will be pumped to the Sewage Treatment Plant. The<br />

treatment system adopted is Activated Sludge Process (ASP).<br />

1.5.1 Zone -I<br />

This pumping station at Srinivasapuram covers an area of 1200 m 2<br />

comprising 1000 housing service connections. The length of sewer is 7398 m<br />

and the sewage from this Zone is pumped to Zone II.<br />

1.5.2 Zone -II<br />

This pumping station at Chettikulam covers an area of 2750 m 2<br />

comprising 3100 housing connections with the sewer length of 16068 m. The<br />

sewage from Zone II is pumped to Zone III which is further pumped to the main<br />

pumping station at Zone V.<br />

1.5.3 Zone III<br />

This pumping station at Kulunthankulam (located in HR & CE land at<br />

Thirumanjana veedhi) covers an area of 1950 m 2 includes 4600 housing service<br />

connection with the sewer length of 17722 m. The sewage from Zone III is<br />

pumped to the main pumping station at Zone V.<br />

3

1.5.4 Zone IV<br />

EIA EIA FOR FOR 6.92 6.92 6.92 MLD MLD MLD <strong>STP</strong> <strong>STP</strong> <strong>STP</strong> AT THIRUVARUR<br />

This pumping station at Arasankulam covers an area of 1240 m 2<br />

includes 3760 housing connections with the length of 19314 m. The sewage<br />

from Zone IV is pumped to the main pumping station at Zone V.<br />

1.5.5 Zone V<br />

This is the main pumping station located at Ramagaye Muni. covers an<br />

area of 1144 m 2 includes 2079 housing connections with the sewer length of<br />

11177 m. All the sewage from this zone is pumped to the Sewage Treatment<br />

Plant at Kekarai village, Thiruvarur <strong>Municipal</strong>ity. The entire treated effluent<br />

will be disposed into Sukkanar drainage canal.<br />

4

Figure 1-1 Thiruvarur Underground Drainage Scheme Plan<br />

EIA EIA FOR FOR 6.92 6.92 MLD MLD <strong>STP</strong> <strong>STP</strong> AT THIRUVARUR<br />

5

1.6 PROJECT BRIEF<br />

Project Town : Kekkarai Village,<br />

<strong>Municipal</strong>ity : Thiruvarur <strong>Municipal</strong>ity<br />

District : Thiruvarur District<br />

State : Tamil Nadu<br />

EIA EIA FOR FOR 6.92 6.92 6.92 MLD MLD <strong>STP</strong> <strong>STP</strong> AT THIRUVARUR<br />

Technology used : Activated Sludge Process (ASP)<br />

Capacity of the Plant : 6.92 MLD<br />

The project involves the construction of Sewage Treatment Plant with an<br />

intermediate capacity of 6.92 MLD and an Ultimate capacity of 8.55 MLD.<br />

Basic In<strong>for</strong>mation on Proposed project in Thiruvarur is enclosed as Annexure-I<br />

1.7 PROPOSED PROJECT SITE<br />

Thiruvarur <strong>Municipal</strong>ity is located at a distance of 60 Km from East of<br />

Thanjavur town. The satellite image and the current status of the project site<br />

are shown in Figures 1.2 and Figure 1.3 respectively. With the rapid<br />

expansion and urbanization of Thiruvarur Town, an underground sewerage<br />

scheme has been <strong>for</strong>mulated <strong>for</strong> the town and the collection system works are<br />

in progress/ nearing completion. The final sewage from the Zone V will be<br />

redirected to the proposed Sewage Treatment Plant <strong>for</strong> final treatment and the<br />

treated effluent will be redirected to the downstream flow of Sukkanar (a<br />

channel <strong>for</strong>med by the drainage of the agricultural lands in the village) which is<br />

about 100 m from the proposed site.<br />

The sewage treatment plant covers an area of 8.87 acres. The <strong>STP</strong> with<br />

selected modern technology has a capacity of 6.92 MLD. The layout of <strong>STP</strong> is<br />

shown in Figure 1.4.<br />

6

Proposed<br />

Project<br />

Site<br />

Figure 1-2 Satellite Image of the Site Location<br />

Figure 1-3 Current Status of the Site<br />

EIA EIA FOR FOR 6.92 6.92 6.92 MLD MLD <strong>STP</strong> <strong>STP</strong> AT THIRUVARUR<br />

7

1.8 NEED FOR EIA<br />

Figure 1-4 Layout of Sewage Treatment Plant<br />

EIA EIA FOR FOR 6.92 6.92 6.92 MLD MLD <strong>STP</strong> <strong>STP</strong> AT THIRUVARUR<br />

Environmental Impact Assessment (EIA) is a study of the possible impacts<br />

that a proposed project may have on the environment, which may affect<br />

natural, social and economic aspects in and around the project area.<br />

The purpose of the assessment is to make the project proponent to<br />

enhance the environmental quality of the project site during planning and<br />

execution of the project. The International Association <strong>for</strong> Impact Assessment<br />

(IAIA) defines an Environmental Impact Assessment as "the process of<br />

identifying, predicting, evaluating and mitigating the biophysical, social, and<br />

8

EIA EIA FOR FOR 6.92 6.92 6.92 MLD MLD <strong>STP</strong> <strong>STP</strong> AT THIRUVARUR<br />

other relevant effects of development proposals prior to major decisions being<br />

taken and commitments made."<br />

As per the World Bank policy, the project is categorized under F1. A<br />

proposed project is classified as Category F1, if it involves investment of Bank<br />

funds through a financial intermediary, in subprojects that may result in<br />

adverse environmental impacts. Hence an assessment study is mandatory as<br />

per the funding agency.<br />

The proposed project is categorized under E1 (as per ESF of Tamil Nadu<br />

Urban Infrastructure Financial Services Limited, Chennai) since it includes<br />

sewerage network, pumping station and sewage treatment plant. Hence an EIA<br />

study is required <strong>for</strong> the proposed work.<br />

This Present <strong>report</strong> elucidates the existing environmental scenario of the<br />

project site and the predicted impacts due to installation of the proposed<br />

Sewage Treatment Plant. It evaluates the impacts during the pre construction,<br />

construction and operation phases of the project. Both positive and negative<br />

impacts are being considered and <strong>report</strong>ed. The Environmental Management<br />

Plan (EMP) is also aimed at mitigating the possible adverse impact of the<br />

project and ensuring the existing environmental quality gets enhanced.<br />

1.9 OBJECTIVES OF THIS REPORT<br />

The objectives of the <strong>report</strong> are<br />

To identify and assess any potential negative environmental and<br />

social impacts and to facilitate the planning of preventive and<br />

remedial measures.<br />

To identify possible environmental enhancements in the project<br />

setting and lay down the action plans.<br />

To develop a set of environmental monitoring and management<br />

plans compliant with the relevant codes, statutes & social norms.<br />

9

1.10 SCOPE OF THE REPORT<br />

EIA EIA FOR FOR 6.92 6.92 6.92 MLD MLD <strong>STP</strong> <strong>STP</strong> AT THIRUVARUR<br />

To assess the baseline of air, water, land, soil and noise environment<br />

around the proposed site in relation to the town by collecting the<br />

samples of air, water, soil and noise in the project setting and<br />

analyzing <strong>for</strong> the recognized parameters as per local statutory<br />

regulations and prepare the baseline document and to predict the<br />

potential impacts<br />

To identify the potential impact by the <strong>STP</strong> on related environmental<br />

issues like wildlife, bird sanctuaries, flora & fauna, public health,<br />

social uplift, archeological monuments, heritage structures and<br />

bring up the appropriate preventive & remedial procedures without<br />

compromising the objective of <strong>STP</strong>.<br />

To develop a set of practices to be followed during preconstruction,<br />

construction and post construction periods in order to avoid the<br />

<strong>for</strong>eseeable negative impacts.<br />

In keeping with the operational policy of the World Bank 4.01, go<br />

through a process of public consultation and transparently<br />

apraising the public of the <strong>for</strong>egoing and securing their concerns,<br />

evolving mutually agreeable measures to all the concerns, document<br />

the same and ensuring a periodic and continual follow up with<br />

project persons and the public.<br />

1.11 CATEGORIZATION OF PROJECT<br />

The proposed project is categorized under E1 since it includes sewerage<br />

network, pumping station and treatment plant as per Tamil Nadu Urban<br />

Infrastructure Financial Services Limited, Chennai.<br />

As per the MoEF Notification S.O. 1533, notification under sub-rule (3) of<br />

Rule 5 of the Environment (Protection) Rules, 1986, dated 14 th September<br />

2006, the Sewage Treatment Plant is not categorized in the schedule.<br />

10

EIA EIA FOR FOR 6.92 6.92 6.92 MLD MLD <strong>STP</strong> <strong>STP</strong> AT THIRUVARUR<br />

As per TNPCB Industrial Categorization, the present project is categorized<br />

as Orange Category.<br />

1.12 ENVIRONMENTAL LEGISLATIONS<br />

below<br />

Salient features of some of the major laws that are applicable are given<br />

1.12.1 Water (Prevention and Control of Pollution) Act, 1974<br />

The basic objective of this Act is to maintain and restore the<br />

wholesomeness of the country's aquatic resources by prevention and control of<br />

pollution. Consequently, the Water Act, a Central law, was enacted under<br />

Article 252(1) of the Constitution, which empowers the Union Government to<br />

legislate in a field reserved <strong>for</strong> the States. All the States have approved<br />

implementation of the Water Act. As during operation, it is likely that the<br />

ground water quality and surface water quality may be altered. There<strong>for</strong>e this<br />

act is applicable to the proposed project.<br />

1.12.2 Air (Prevention and Control of Pollution) Act, 1981<br />

The Union Government under Article 253 of the Constitution passed this<br />

Statute. This Act provides <strong>for</strong> the prevention, control and abatement of air<br />

pollution and confers powers to the Central and State Pollution Control Board<br />

with a view to carry out the a<strong>for</strong>esaid purposes. This act is applicable to the<br />

proposed project.<br />

1.12.3 Environment (Protection) Act, 1986<br />

The Union Government under Article 253 of the Constitution passed this<br />

Statute. The Environment (Protection) Act, 1986 seeks to achieve the objective<br />

of protection and improvement of environment and <strong>for</strong> matters connected<br />

therewith. This legislation enables the co-ordination of activities of the various<br />

regulatory agencies; setting up of an authority or authorities with advocate<br />

powers <strong>for</strong> environmental protection etc., This Act is applicable to the proposed<br />

project.<br />

11

EIA EIA FOR FOR 6.92 6.92 6.92 MLD MLD <strong>STP</strong> <strong>STP</strong> AT THIRUVARUR<br />

Objective of this Act is to provide the protection and improvement of<br />

environment (which includes water, air, land, human being, other living<br />

creatures, plants, microorganism and properties) and <strong>for</strong> matters connected<br />

therewith.<br />

1.12.4 Public Liability Insurance Act, 1991<br />

The Act, provides public liability insurance <strong>for</strong> the purpose of providing<br />

immediate relief to the persons affected by accident occurring while handling<br />

hazardous substances. Hazardous substance means any substance or<br />

preparation which is defined as hazardous substance under the Environment<br />

(Protection) Act 1986, and exceeding such quantity as may be specified by<br />

notification by the Central Government.<br />

1.12.5 <strong>Municipal</strong> Solid Waste (Management & Handling) Rules, 2000<br />

This notification by Ministry of Environment & Forest lay down the<br />

methods of handling <strong>Municipal</strong> Solid Waste (MSW) and its scientific disposal. It<br />

bans incineration of MSW.<br />

<strong>Municipal</strong> Solid Waste (Management & Handling) Rules, 2000 are<br />

applicable to every municipal authority responsible <strong>for</strong> collection, segregation,<br />

storage, transportation, processing and disposal of <strong>Municipal</strong> Solid Waste. The<br />

Rules contains four Schedules namely;<br />

Schedule Activity<br />

I Relates to implementation schedule<br />

II Specifications relating to collection, segregation, storage, transport,<br />

processing and disposal of <strong>Municipal</strong> Solid Waste<br />

III Specifications <strong>for</strong> land filling, indicating site selection, facilities at site,<br />

specifications <strong>for</strong> and filling, Pollution prevention, water quality<br />

monitoring, ambient air quality monitoring, Plantation at landfill site,<br />

closure of landfill site and post care.<br />

IV Indicate waste processing options including; standards <strong>for</strong> composting,<br />

treated lactates and incinerations<br />

12

1.12.6 The Noise Pollution (Regulation And Control) Rules, 2000<br />

EIA EIA FOR FOR 6.92 6.92 6.92 MLD MLD <strong>STP</strong> <strong>STP</strong> AT THIRUVARUR<br />

The Union Government has laid down statutory norms to regulate and<br />

control noise levels to prevent their adverse effects on human health and the<br />

psychological well being of the people. Under the new regulation, different<br />

areas and zones are to be identified as industrial, commercial, and residential<br />

or silence areas and anyone exceeding the specified noise level would be liable<br />

<strong>for</strong> action. In industrial areas, the noise level limit during the day time (6 am to<br />

10 pm) is 75 decibels and during night (10 pm to 6 am) 70 decibels.<br />

Similarly, <strong>for</strong> commercial areas day time limit is 65 decibels and night<br />

limit is 55 decibels. In the case of residential areas, the limits are respectively<br />

55 and 45 decibels and <strong>for</strong> the silence zones, 50 and 40 decibels<br />

1.13 WORLD BANK POLICIES<br />

Following are the Operation Policy & Directorate of the World Bank.<br />

1.13.1 Environmental Assessment OP/BP 4.01<br />

This requires the borrower to screen projects upstream in the project<br />

cycle <strong>for</strong> potential impacts. Thereafter, an appropriate EA approach to assess,<br />

minimize / enhance and mitigate potentially adverse impacts is selected<br />

depending on nature and scale of project. The EA needs to be integrated in the<br />

project development process such that timely measures can be applied to<br />

address identified impacts. The policy requires consultation with affected<br />

groups and NGOs to recognize community concerns and the need to address<br />

the same as part of EA.<br />

1.13.2 Cultural Property - OP 11.03<br />

Requirements - World Bank’s Operational Policy Note 11.03 which aims<br />

at preserving and avoiding the elimination of structures having archaeological<br />

(prehistoric), paleontological, historical, religious and unique natural values.<br />

Projects that could significantly damage non-replicable cultural properties are<br />

declined <strong>for</strong> funding and the Bank will in turn assist protection and<br />

13

EIA EIA FOR FOR 6.92 6.92 6.92 MLD MLD <strong>STP</strong> <strong>STP</strong> AT THIRUVARUR<br />

enhancement of cultural properties encountered in the project rather than<br />

leaving that protection to chance.<br />

1.13.3 Natural Habitats – OP/BP 4.04<br />

This policy sets out the World Bank’s policy on supporting and<br />

emphasizing the precautionary approach to natural resource management and<br />

ensuring opportunities <strong>for</strong> environmentally sustainable development. As per<br />

this policy, projects that involve significant conversion or degradation of critical<br />

natural habitats are not supported by the Bank.<br />

1.13.4 Forests – OP/BP 4.36<br />

This sets out specific policy on protection of <strong>for</strong>ests through<br />

consideration of <strong>for</strong>est related impacts of all investment operations, ensuring<br />

restrictions <strong>for</strong> operations affecting critical <strong>for</strong>est conservation areas, and<br />

improving commercial <strong>for</strong>est practice through use of modern certification<br />

systems. The policy requires consultation with local people, the private sector<br />

and other stakeholders in <strong>for</strong>est area.<br />

Pest<br />

1.13.5 Pest Management - OP 4.09<br />

This policy supports environmentally sound pest management, including<br />

integrated pest management, but does not prohibit the use of highly hazardous<br />

pesticides. Pest Management is the borrower/s responsibility in the context of a<br />

project’s EA.<br />

1.13.6 Involuntary Resettlement - OP/BP 4.12<br />

This policy is implemented in projects which displace people. It requires<br />

public participation in resettlement planning as part of EA <strong>for</strong> projects. It is<br />

intended to restore or improve income earning capacity of displaced<br />

populations.<br />

14

1.13.7 Indigenous Peoples –OP/BP 4.20<br />

EIA EIA FOR FOR 6.92 6.92 6.92 MLD MLD <strong>STP</strong> <strong>STP</strong> AT THIRUVARUR<br />

The purpose of this policy is to ensure indigenous peoples benefit from<br />

Bank financed developed and to avoid or mitigate adverse affects on indigenous<br />

peoples. Applies to projects that might adversely affect indigenous peoples or<br />

when they are targeted beneficiaries. Requires participation of indigenous<br />

peoples in creation of “indigenous people development plans”<br />

1.14 LEGAL/REGULATORY CLEARANCES FOR THE PROJECT<br />

The following are the list of approvals required <strong>for</strong> the implementation of<br />

proposed project.<br />

Land approval<br />

Consent from Pollution Control Board<br />

Permission <strong>for</strong> laying of pipelines <strong>for</strong> disposal<br />

1.14.1 Land Approval<br />

The land belongs to the Thiruvarur <strong>Municipal</strong>ity. It was handed over to<br />

TWAD <strong>for</strong> the construction of <strong>STP</strong> in Kekkarai, Thiruvarur District. Hence, the<br />

land is ready <strong>for</strong> the construction of <strong>STP</strong>.<br />

1.14.2 Consent from Pollution Control Board<br />

The project has obtained the Consent to Establish from Tamil Nadu<br />

Pollution Control Board vide Proceedings No. AEE/TNPCB/NGT/F.MIS-<br />

438/O/L/W/2010/dt.12.08.2010, which is enclosed as Annexure II. The<br />

compliance status of the special conditions, additional conditions and general<br />

conditions issued by TNPCB are enclosed in Annexure III.<br />

1.14.3 Permission <strong>for</strong> laying of pipelines <strong>for</strong> disposal<br />

The treated effluent will be within the prescribed standards. The treated<br />

effluent from the <strong>STP</strong> will be discharged through 100m pipe line laid from site<br />

15

EIA EIA FOR FOR 6.92 6.92 6.92 MLD MLD <strong>STP</strong> <strong>STP</strong> AT THIRUVARUR<br />

leading to Sukkanar drainage canal which is adjacent to the site. The<br />

Sukkanar drainage canal leads to Vettar river.<br />

1.15 AGENCIES RESPONSIBLE FOR PROJECT IMPLEMENTATION<br />

The agencies responsible <strong>for</strong> the successful execution of the Project are<br />

shown in Table 1.1.<br />

Table 1-1 Agencies responsible <strong>for</strong> Project Implementation<br />

S.No Agency Responsibility<br />

1 Thiruvarur <strong>Municipal</strong>ity Project proponent.<br />

2 Tamilnadu Water Supply and Drainage Project implementing<br />

Board<br />

agency.<br />

3 Hindustan Dorr-Oliver Limited Executing the Project<br />

Plan.<br />

16

2.1 PROJECT PROPOSAL<br />

2. PROJECT DESCRIPTION<br />

EIA EIA FOR FOR 6.92 6.92 6.92 MLD MLD <strong>STP</strong> <strong>STP</strong> AT THIRUVARUR<br />

Name of the Project : Designing, Providing, Constructing, Erection and<br />

Commissioning, startup of Sewage treatment<br />

plant with selected modern Technology at<br />

Thiruvarur <strong>Municipal</strong>ity of Thiruvarur District in<br />

Tamilnadu on DBOT Basis.<br />

Project Town : Kekkarai Village, Thiruvarur District, Tamil Nadu.<br />

<strong>STP</strong> Capacity : 6.92 MLD<br />

Technology used : Activated Sludge Process (ASP)<br />

Project cost : 5.9 crores .<br />

Land Available : 8.87 Acres<br />

2.2 LAND REQUIREMENT<br />

The total land available <strong>for</strong> the project is about 8.87 Acres. The proposed<br />

Sewage Treatment Plant will have an intermediate capacity of 6.92 MLD. Based<br />

on statistical analysis, in future, due to urbanization of the project area, the<br />

incoming sewage will be higher. Hence the ultimate capacity will be 8.55 MLD.<br />

The remaining land area will be occupied <strong>for</strong> storage and provision of<br />

chemicals, sludge, laboratory, employees shed houses and restrooms,<br />

remaining areas will be used <strong>for</strong> developing green belt in and around the site<br />

premises. The <strong>STP</strong> layout is given in Figure 2-1.<br />

17

Figure 2-1 Layout of <strong>STP</strong><br />

EIA EIA FOR FOR 6.92 6.92 MLD MLD <strong>STP</strong> <strong>STP</strong> AT THIRUVARUR<br />

18

2.3 PROCESS DESCRIPTION<br />

EIA EIA FOR FOR 6.92 6.92 6.92 MLD MLD <strong>STP</strong> <strong>STP</strong> AT THIRUVARUR<br />

Sewage is collected from all the sources in the receiving chamber. The<br />

sewage is sent through a series of bar screens. Materials which are greater<br />

than 20 mm in size are removed from the sewage. Screening prevents the<br />

clogging of pumps and pipelines.<br />

First, the sewage is sent through the coarse screen chamber / mechanical<br />

coarse screen chambers. Here materials greater than 20 mm & 15 mm are<br />

removed respectively. Then the sewage is sent through operated / automatic<br />

fine screens to remove materials sized 15 mm & 10 mm.<br />

From here the sewage is sent to the grit chamber where fine particles like<br />

sand are removed through sedimentation. The sand being heavier than sewage<br />

settles down and can be removed. From the grit chamber the sewage is sent to<br />

the parshall flume chamber. Parshall flumes are used to check the flow in the<br />

plant. The Screened sewage is then led to the Primary Clarifier tank. The<br />

excess sludge is sent to the sludge digester tank. The sewage from the primary<br />

clarifier is then led to the aeration tank. Biological treatment takes place in the<br />

aeration tank. Air is diffused through air blowers to oxidize organic matters.<br />

The overflow from the aeration tank is sent to the secondary clarifier. The<br />

underflow clarifier sludge is returned to the aeration tank <strong>for</strong> mixing and the<br />

excess sludge from the secondary clarifier is sent to the Sludge digestor tank.<br />

The recirculation of the sludge will takes place effectively. In the Sludge<br />

digestor tank, air is diffused through the sludge <strong>for</strong> the proper digestion and<br />

the digested sludge is dosed by poly dosing system. The digested sludge is then<br />

pumped into the centrifuge through screw pump to separate the solids from<br />

the treated effluent. The drain out from the Centrifuge is collected in the<br />

filtrate sludge sump which is then sent back to the receiving chamber through<br />

filtrate pump.<br />

The overflow from the secondary clarifier is sent to Chlorine Contact tank<br />

where Chlorine is dozed through gas chlorinator. The treated effluent from the<br />

19

EIA EIA FOR FOR 6.92 6.92 6.92 MLD MLD <strong>STP</strong> <strong>STP</strong> AT THIRUVARUR<br />

Chlorine contact tank is led to the Sukkanar drainage Channel. The schematic<br />

representation of the process flow is shown in Figure 2.2.<br />

2.3.1 Sewage Receiver<br />

Figure 2-2 Process Flow of <strong>STP</strong><br />

Raw Sewage will be delivered through pipe lines at a hydraulic head of<br />

6.0 m into a receiving chamber from where it will be taken into downstream<br />

screens. The function of the receiving chamber is to reduce the incoming<br />

velocity. Receiving chamber shall be of adequate size to meet the requirements<br />

of workability inside it. The flow from the receiving chamber will lead to screen<br />

Chamber.<br />

2.3.2 Primary Treatment<br />

In primary treatment, a portion of the suspended solids and organic<br />

matter is removed from the wastewater. The liquid effluent from primary<br />

treatment, often contains a large amount of suspended organic materials, and<br />

has a high BOD (about 60% of original). Sometimes, the preliminary as well as<br />

primary treatments are classified together, under primary treatment.<br />

The organic solids, which are separated out in the sedimentation tanks<br />

in the primary treatment, are often stabilized by anaerobic decomposition in a<br />

digestion tank or incinerated. The residue is used <strong>for</strong> landfills or as a soil<br />

conditioner. The principal function of primary treatment is to act as a<br />

precursor to secondary treatment.<br />

20

2.3.2.1 Fine Screening<br />

EIA EIA FOR FOR 6.92 6.92 6.92 MLD MLD <strong>STP</strong> <strong>STP</strong> AT THIRUVARUR<br />

Fine screens are to be provided <strong>for</strong> the removal of fine floating material<br />

coming with the sewage. One is mechanically operated and the other screen is<br />

provided as standby. The fine screens should be capable to screen out most of<br />

the medium & fine floating and material such as hair, debris, weeds, paper,<br />

rags etc. which could clog the downstream units. The Fine screen shall be<br />

inclined with bar screen. It should be of sturdy design and the bar screen shall<br />

be of stainless steel flats. The screenings shall be dropped on conveyor above<br />

the top of the screen channel. A conveyor system of suitable width shall be<br />

provided which shall be adjacent to the screens. The screening materials as<br />

collected will drop automatically into a wheelbarrows <strong>for</strong> its disposal.<br />

2.3.2.2 De-gritting<br />

Screened sewage will be gravitable to minimum two numbers of Grit<br />

separator tank <strong>for</strong> the removal of grit and small inorganic particulars matter of<br />

specific gravity above 2.65 and particle size above 150 microns. One is<br />

mechanically operated and the other is provided as standby. The Grit<br />

separator tank shall be of RCC construction complete with mechanical<br />

internals and square in size. The grit separated shall be properly collected and<br />

be transferred <strong>for</strong> disposal. The degritted sewage shall flow through open<br />

channels from the grit separators and confluence into a single channel of<br />

suitable width.<br />

2.3.2.3 Flow Measurement<br />

A Flow measurement unit in the <strong>for</strong>m of ultrasonic flow transmitter<br />

shall be provided in the common header of the raw sewage Pumps.<br />

The mechanical screen chamber, mechanical fine screen chamber and<br />

grit chamber are mechanically operated and the other screens are provided as<br />

standby.<br />

21

2.3.3 Secondary Treatment Process<br />

EIA EIA FOR FOR 6.92 6.92 6.92 MLD MLD <strong>STP</strong> <strong>STP</strong> AT THIRUVARUR<br />

Screened, de-gritted sewage shall be fed into the Activated Sludge<br />

Treatment system to meet the treated effluent quality prescribed in Table 2-1.<br />

The effluent from the secondary biological treatment will usually contain BOD<br />

of 5 to 10%. The organic solids/ sludge separated out in the primary as well as<br />

in the secondary settling tanks are disposed of by stabilizing under aerobic<br />

conditions in a Sludge digestion tank. Any problem in aeration tank will be due<br />

to diffusers provided in the tank. This can be rectified by lifting the diffusers<br />

and manually cleaning the blockages. If the blower has any problem, a<br />

standby blower is also provided in aeration tank.<br />

2.3.4 Tertiary Treatment<br />

Tertiary treatment is used to further purify the water contaminants,<br />

especially pathogens. The level of tertiary treatment per<strong>for</strong>med depends on the<br />

quality of effluent desired. This is determined by the size of the receiving body<br />

of water, and the intended use of that water.<br />

2.3.4.1 Chlorination<br />

This is the most widely practiced means of disinfecting water. The strong<br />

oxidizing capacity of chlorine destroys or inhibits the growth of pathogens,<br />

reduces the BOD, reduces odour, water color and oxidizes metal ions.<br />

2.3.5 Sludge Handling System<br />

The sludge from the Treatment Plant shall be collected in a sludge sump<br />

where it is aerated continuously <strong>for</strong> mixing. Then the aerated sludge shall be<br />

passed through mechanical dewatering system. The sludge cake shall be<br />

transported to the compost yard of Thiruvarur municipality in a safe manner.<br />

22

2.4 <strong>STP</strong> PIPELINE AND BYPASS ARRANGEMENT<br />

EIA EIA FOR FOR 6.92 6.92 6.92 MLD MLD <strong>STP</strong> <strong>STP</strong> AT THIRUVARUR<br />

The necessary bypass arrangement is provided in the above process as<br />

follows. Coarse screen chamber, Fine screen chamber & Grit chamber are<br />

provided with 2 units. Two numbers of shutter arrangements are provided in<br />

the outlet of the fine screen chamber to grit chamber. This arrangement is<br />

provided so that the sewage from fine screen chamber moves to either of the<br />

grit chamber. When one grit chamber is under fault, the other one will operate<br />

and vice versa.<br />

When the primary clarifier is under fault, the outlet from the grit chamber<br />

is taken to the inlet of the aeration tank. Aeration tank is provided with the<br />

enough cushion to take the load and the sludge settling will be taken care by<br />

the secondary clarifier. Generally the problem in aeration tank will be due to<br />

the blockage in diffusers. This will be rectified by cleaning the diffuser by<br />

washing. The bypass arrangement is made to use when any failure occur<br />

during the <strong>STP</strong> functioning.<br />

In aeration tank, the partition provided will split the aeration tank as two<br />

parts. If any problem occurs in any one part of the aeration tank, the other part<br />

will be in full operation. Two lines from the bottom of the aeration tank are<br />

taken to the sludge tank. The sludge <strong>for</strong>med in the partition portion under<br />

failure will be pumped to the sludge digester tank during the rectification<br />

period.<br />

When the secondary clarifier unit is under fault, aeration arrangement in<br />

one of the partition in the aeration tank will be stopped so that the settling of<br />

sludge will take place in that particular partition. Two lines from the bottom of<br />

the aeration tank is taken to the sludge tank. A portion of sludge settled<br />

(activated sludge) as indicated above, will be recycled through pumping to<br />

common inlet of aeration unit <strong>for</strong> maintain the plant efficiency. The balance<br />

sludge will be drawn to sludge digester tank with necessary pumping<br />

arrangements. The supernatant or treated effluent will be bypassed to the<br />

23

EIA EIA FOR FOR FOR 6.92 6.92 MLD MLD <strong>STP</strong> <strong>STP</strong> AT THIRUVARUR<br />

chlorination tank. After rectification of secondary clarifier, this aeration tank<br />

will be working as usual. This may be helpful to send supernatant from<br />

aeration tank to chlorine contact tank until the secondary clarifier is made in<br />

ready condition. In chlorine Contact tank where Chlorine is dozed through the<br />

water through gas chlorinator. The treated effluent from the Chlorine contact<br />

tank is led to the Sukkanaru.<br />

Thus, the bypass arrangement provided in <strong>STP</strong> will be operated without<br />

shutting down the <strong>STP</strong> during the failure situation. All the faults can be<br />

attended in few hours time. In such cases, the above points can be carried out<br />

<strong>for</strong> the treatment. The <strong>STP</strong> is designed to take a peak factor of 2.25 and the<br />

flow diagram of <strong>STP</strong> provide with all bypass arrangements is shown in Figure<br />

2.2.<br />

.<br />

24

Figure 2-3 Bypass Arrangement <strong>for</strong> <strong>STP</strong><br />

EIA EIA FOR FOR 6.92 6.92 MLD MLD <strong>STP</strong> <strong>STP</strong> AT THIRUVARUR<br />

25

Figure 2-4 Flow Representation <strong>for</strong> the Proposed <strong>STP</strong><br />

EIA EIA EIA FOR FOR 6.92 6.92 MLD MLD <strong>STP</strong> <strong>STP</strong> AT THIRUVARUR<br />

26

2.5 RAW SEWAGE CHARACTERISTICS<br />

EIA EIA FOR FOR FOR 6.92 6.92 MLD MLD <strong>STP</strong> <strong>STP</strong> AT THIRUVARUR<br />

The sewage collected from the various chambers is almost of same type.<br />

The domestic wastewater from the local residential area constitutes the raw<br />

sewage. The wastewater characterization is presented in Table 2.1.<br />

Table 2-1 Raw Sewage Characteristics<br />

S.No. Parameter Values<br />

1 pH 6 to 6.95 -<br />

2 Total suspended solids 6.92 mg/l<br />

3 Bio-chemical Oxygen Demand 180 to 300 mg/l<br />

4 Chemical Oxygen demand 385 to 600 mg/l<br />

2.6 TREATED EFFLUENT QUALITY<br />

Unit of measurement<br />

The <strong>STP</strong> is designed in such a way that the treated effluent quality attains<br />

the limits or even better so as to attain the standards well below given by the<br />

Pollution control board.<br />

The parameters to be monitored and to maintain within limits are<br />

presented in Table 2.2.<br />

Table 2-2 Treated Effluent Quality<br />

S.No Parameter Values Unit of measurement<br />

1 pH 5.5-9.0 -<br />

2 Total suspended solids 30 mg/l<br />

3 Bio-chemical Oxygen Demand20 mg/l<br />

4 Chemical Oxygen demand 250 mg/l<br />

2.7 DISPOSAL OF TREATED EFFLUENT<br />

Finally the treated effluent shall be disposed through pipeline of about<br />

100m to link canal leading to Sukkanar drainage canal. The grit and waste<br />

from the screens and sludge will be stored in the project site and will be<br />

disposed to Thiruvarur <strong>Municipal</strong> Compost Yard at regular intervals.<br />

27

3.1 METHODOLOGY<br />

EIA EIA FOR FOR FOR 6.92 6.92 MLD MLD <strong>STP</strong> <strong>STP</strong> AT THIRUVARUR<br />

3. BASELINE ENVIRONMENTAL DATA<br />

The baseline environmental status with respect to various environmental<br />

components like air, noise, water, land, flora & fauna and socio-economic,<br />

being integral part of an EIA, <strong>for</strong>ms the basis <strong>for</strong> predicting/assessing the<br />

environmental impacts of the proposed project. Field monitoring at site was<br />

per<strong>for</strong>med <strong>for</strong> the month of April 2010, representing the post-monsoon season.<br />

Various environmental components were monitored and samples were<br />

analyzed. Apart from this, additional data were also collected from secondary<br />

sources like Government/Non-Governmental Agencies, Universities, Irrigation<br />

Department, India Meteorology Department, Ground Water Board, etc.<br />

3.2 BRIEF DESCRIPTION OF THE PROJECT SITE<br />

The Thiruvarur Sewerage scheme plan is shown in Figure 3.1. The<br />

satellite imagery of 10 Km radius is shown in Figure 3.2. The nearby<br />

residences are located with a distance of about 2 km from the site. The<br />

surrounding features in and around the project site is shown in Table 3.1.<br />

Table 3-1 Surrounding Features of the Project Site<br />

S.NO Surrounding Features Distance from<br />

Project Site<br />

Direction with<br />

respect to<br />

project site<br />

1 Government Boys School 2.8 Km SW<br />

2 Palani Andavar Temple 2 Km S<br />

3 Ox<strong>for</strong>d Convent 3.5Km SW<br />

4 Thiyagaraja Temple 2.5 Km SW<br />

5 NH 83 5.9 Km S<br />

6 SH 202 20 Km SW<br />

7 State Highway 23 5.6 Km N<br />

8 Residences 2 Km SW<br />

28

PS III<br />

Kulundankula<br />

m<br />

Figure 3-1 Surrounding features around Project site<br />

EIA EIA FOR FOR 6.92 6.92 MLD MLD <strong>STP</strong> <strong>STP</strong> AT THIRUVARUR<br />

29

Thiruvarur-kodavasal-kumbakonam road<br />

Thruvarur-Mannagudi road<br />

Ox<strong>for</strong>d convent<br />

Thiruvarur Thiyagarajar<br />

State Highway 23<br />

Palani Andarar Temple<br />

Govt Boys School<br />

State Highway 148<br />

Nagappattinam-Trichy-Karur-Coimbatore-Mettupalayam-Ooty-Gundlupet road<br />

Figure 3-2 Satellite Imagery of the Project Site - 10 Km Radius<br />

EIA EIA FOR FOR 6.92 6.92 MLD MLD <strong>STP</strong> <strong>STP</strong> AT THIRUVARUR<br />

C oa rse Scre en<br />

C ha m ber (T102A/B)<br />

G rit Ch am b er<br />

(T1 0 4A )<br />

Mec ha nica l<br />

M anu al Man u al<br />

Me chan ical<br />

Fin e Scree n<br />

C ha mb er (T1 0 3A /B) Sc rew Pu mp<br />

Re ceiving<br />

Cha mbe r (T101)<br />

Grit C ha m ber ( T10 4 B)<br />

Primary<br />

Clarifier tank<br />

(T105)<br />

Administration Block<br />

3'0" x 7'0 "<br />

(0 .9 0 x 2.1 m)<br />

230 wall<br />

Primary Sludge<br />

Pump - 2 nos<br />

Aeration tank (T106)<br />

Size: 15.0m x 6.0 m x 4.5m ht<br />

D<br />

D<br />

W<br />

Admin Building<br />

W<br />

Cum<br />

Lab<br />

E lectrical R oom<br />

Air Blower - 3 nos<br />

1 0 # @ 150 c/c<br />

10 # @ 150 c/c<br />

Secondary Clarifier tank (T107)<br />

Air Blo wer - 2 nos<br />

INTERNAL<br />

ROAD<br />

Screw Pump - 3 nos<br />

Chlorine Contact<br />

tank (T109)<br />

Sludge<br />

digestor tank<br />

(T108)<br />

Secondary Sludge<br />

Pump - 2 nos<br />

Filtrate<br />

Slu d ge Su mp<br />

Cen trifug e<br />

H ou se<br />

INTERNAL<br />

ROAD<br />

ROAD<br />

W<br />

Filtrate Pump - 2 nos<br />

Size: 6m x 6m x 5m ht<br />

Chlorine T onner Room<br />

W W<br />

D<br />

INTERNAL<br />

ROAD<br />

30

3.3 CONNECTIVITY<br />

120 km.<br />

EIA EIA FOR FOR 6.92 6.92 MLD MLD MLD <strong>STP</strong> <strong>STP</strong> AT THIRUVARUR<br />

Airport - The nearest airport to the town is in Trichy at a distance of<br />

Railway – The town is well connected with railways. It serves as a<br />

railway junction <strong>for</strong> Thanjavur- Nagapattinam and Chidambaram-<br />

Pattukkottai railway sections.<br />

Roads<br />

National Highways State Highways<br />

NH 45 A - Villupuram-Tiruvarur SH 23 Mayiladuthurai -<br />

NH 67 - Tiruvarur-Coimbatore-<br />

Mysore Road<br />

NH 68 - Nagapattinam-<br />

Coimabtore- Gudalur-Mysore<br />

Road<br />

3.4 LAND USE<br />

Thiruthuraipoondi Road<br />

SH 63 Thanjavur - Mannargudy -<br />

Thiruthuraipoondi - Vedaranyam -<br />

Kodiakkarai Road<br />

SH 65 Thiruvarur - Kodavasal -<br />

Kumbakonam Road<br />

SH 66 Kumbakonam - Mannargudi<br />

- Athirampattinam Road<br />

SH 67 Nagoore-Nanilam-Nachiyar<br />

Koil Road<br />

SH 146 Mannargudi - Pattukkottai<br />

- Sethubhavachatram Road<br />

SH 147 Kumbakonam - Karaikal<br />

Road<br />

SH 151 Kilvelur - Katchanam Road<br />

Existing land use in Tiruvarur town, as per Master Plan 2001, is given<br />

in the table below<br />

Table 3-2 Existing land use of Thiruvarur Town<br />

Land use Developed % to Total<br />

Area (in Ha) Area<br />

Residential 436.75 38.5<br />

Commercial 55.90 5.0<br />

Industrial 14.43 1.5<br />

Educational 16.09 1.5<br />

Public & Semipublic<br />

5.60 0.5<br />

31

Transportation 80.51 7.0<br />

Total<br />

Developed Area<br />

609.29 54.0<br />

Agriculture 393.09 34.5<br />

Water Bodies 132.05 11.50<br />

Total area 1134.43 100<br />

EIA EIA FOR FOR 6.92 6.92 MLD MLD MLD <strong>STP</strong> <strong>STP</strong> AT THIRUVARUR<br />

Developed area constitutes around 54% of the total area of the town. Of<br />

total developed area of the town, about 72% of the land is under residential<br />

use and 14% under public and semi-public uses, which includes land under<br />

transportation also. Land under industrial use constitutes only 2.4%<br />

reflecting that there are no major industrial activities in the town. 34% of<br />

the total area of the municipality is under agriculture.<br />

Existing land use in Tiruvarur Local Planning Area (excluding Tiruvarur<br />

town), as per Master Plan 2001, is given in the table below<br />

Table 3-3 Land use distribution in Tiruvarur Local Planning Area<br />

Land use Developed % to Total LPA<br />

area (in Ha) area<br />

Residential 769.31 10.00<br />

Commercial 4.85 0.06<br />

Industrial 93.89 1.00<br />

Educational 4.70 0.04<br />

Public & Semi-public 102.58 1.20<br />

Transportation 119.59 1.50<br />

Developed Area 1094.74 13.80<br />

Agriculture 6292.80 79.60<br />

Water Bodies 510.87 6.60<br />

Total area 7898.41 100<br />

Developed area constitutes around 14% of the total planning area.<br />

Residential use constitutes 70% of the total developed area of LPA, excluding<br />

town. Land under industrial use <strong>for</strong>ms 8.5% of the total developed area of<br />

LPA, excluding town. The proportion under industrial use is high due to<br />

presence of ONGC establishments in the Planning Area. Land under<br />

agriculture is about 80% and under water bodies is 6.6%.<br />

Tiruvarur town being district headquarters is expected to grow at a<br />

rapid pace in the future. There are possibilities <strong>for</strong> setting up of more public<br />

offices in this town. Trend of migration is expected to go up. Keeping all<br />

32

EIA EIA FOR FOR 6.92 6.92 MLD MLD MLD <strong>STP</strong> <strong>STP</strong> AT THIRUVARUR<br />

these considerations in mind, vacant lands within developed area and dry<br />

lands are drawn under residential use zone.<br />

Table 3-4 Proposed Land Use Plan<br />

Land use Tiruvarur Town Tiruvarur LPA<br />

(excluding Town)<br />

Requirement<br />

(in Ha)<br />

% to<br />

Total<br />

Area<br />

Requirement<br />

(in Ha)<br />

% to<br />

Total<br />

Area<br />

Tiruvarur LPA<br />

Requirement<br />

(in Ha)<br />

% to<br />

Total<br />

Area<br />

Residential 664.80 58.00 1385.00 17.50 2049.00 23.00<br />

Commercial 65.50 6.00 6.30 0.10 71.80 0.80<br />

Industrial 11.50 1.00 135.00 1.70 146.50 1.60<br />

Educational 17.00 1.50 4.70 0.05 21.70 0.20<br />

Public &<br />

Semi-public<br />

(including<br />

Transportati<br />

on)<br />

90.00 8.00 308.40 3.80 390.40 4.20<br />

Agriculture 285.63 25.50 6067.01 76.85 6353.34 70.20<br />

Total 1134.43 100.00 7898.41 100.00 9032.84 100.00<br />

3.5 RAINFALL & CLIMATE<br />

The district receives rainfall from both during southeast and northeast<br />

monsoons. The normal annual rainfall in the district ranges from 1100 to<br />

1260 mm. It gradually increases towards east and south and attains a<br />

maximum around Thiruvarur in the eastern part. It is observed that the<br />

chances of receiving normal annual rainfall vary from 40% at<br />

Needamangalam to 51 % at Thiruthuraipoondi. These changes are the<br />

highest (50-55 percentage) in a small area around Thiruthuraipoondi in the<br />

eastern part. In the rest of the district these chances are in the range 40-50<br />

percentages.<br />

The district has a hot tropical climate the summer season, which is very<br />

oppressive, is from March to about the end of May. The humidity is<br />

generally high in the coastal region throughout the year and exceeds 70<br />

percentages during period from August to May. It is much drier towards the<br />

interior of the district.<br />

3.6 GEOLOGY<br />

Thiruvarur district is made up of tertiary and alluvial deposits. The<br />

cuddalore sand stones of tertiary age are well developed as seen near<br />

33

EIA EIA FOR FOR 6.92 6.92 MLD MLD MLD <strong>STP</strong> <strong>STP</strong> AT THIRUVARUR<br />

mannargudi. These sand stones are covered by a thin layer of windblown<br />

sandy clays, unconsolidated sands, clay bound sands and mottled clays<br />

with liginite seams. This tertiary <strong>for</strong>mation is invariably capped by laterite.<br />

The alluvial deposits of the river cauvery and its tributaries lie over the<br />

tertiary sand stone. They consist of medium to firm sands, clays and sandy<br />

clays. The thickness of these <strong>for</strong>mations range from 30m to 400m.<br />

3.7 AIR ENVIRONMENT<br />

Figure 3-3 Geology Map of Thiruvarur District<br />

Pollutants / contaminants discharged into the atmosphere with<br />

consequent impact on air environment have to be taken into consideration<br />

<strong>for</strong> the review of the present and future impact study. It governs the<br />

concentration of pollutants and varies with time and location with respect to<br />

their sources.<br />

3.7.1 Sampling Location and Rationale<br />

The identification of the sampling stations is based on the sensitivity<br />

of the location, distance and direction with respect to the proposed project<br />

site. The location of sampling stations are given in Table 3-7.<br />

34

EIA EIA FOR FOR 6.92 6.92 MLD MLD MLD <strong>STP</strong> <strong>STP</strong> AT THIRUVARUR<br />

The fine samplers PM 10 were placed at height of 2.5 m above the<br />

ground level, free from obstructions. Samples were collected <strong>for</strong> various<br />

parameters at hourly intervals. The collected samples were shifted to HECS<br />

laboratory through standard chain of custody norms and practices and they<br />

are analyzed according to the Standards prescribed by Indian Standards<br />

(IS).<br />

S.<br />

No.<br />

Table 3-5 Mode of collection of Ambient Air Quality Parameters<br />

S.No Parameters Absorbing solutions/<br />

Filter paper<br />

1 PM 10 Whattman glass fiber<br />

filter paper<br />

2 SO2 Sodium tetra chloromercurate<br />

3 NOx Sodium Hydroxide<br />

Instrument<br />

Fine sampler PM 10<br />

Respirable dust<br />

sampler/Enviro Tech<br />

Respirable dust<br />

sampler/Enviro Tech<br />

Table 3-6 Techniques used <strong>for</strong> Ambient Air Monitoring<br />

Parameters Technique Technical Protocol Minimal<br />

Detectable<br />

Limit (µg/ m3 )<br />

IS: 5182 part 3 1970 >1<br />

method<br />

IS: 5182 part 2 2001 0.1<br />

1 PM 10 Gravimetric<br />

2 SO2 p-Rosaniline<br />

method<br />

3 NOx NEDA method IS: 5182 part VI<br />

1975<br />

3.7.2 Data Inference<br />

0.01 to 1.5<br />

All the Ambient Air quality monitoring is under the category of<br />

commercial and industrial zone. The locations were selected based on the<br />

wind direction, taking into the consideration of one location in the up wind<br />

direction and 5 locations in the down wind direction. In all the locations the<br />

observed values of PM 10, SO2, & NOX are within the prescribed limits of<br />

CPCB. The detailed air quality data are given in the Table 3-8.<br />

35

Table 3-7 Air Sampling Locations<br />

EIA EIA FOR FOR 6.92 6.92 MLD MLD MLD <strong>STP</strong> <strong>STP</strong> AT THIRUVARUR<br />

Location<br />

Code<br />

Location<br />

Distance w.r.to project<br />

site (km)<br />

L1 Project site ---<br />

L2<br />

Bore well near the proposed<br />

site<br />

0.05 E<br />

L3<br />

Near Keekarai Govt.<br />

Elementary School<br />

2.8 SW<br />

L4 Near Keekarai Post Office 1.5 SW<br />

L5 Near Keekarai Railway Gate 2.5 SW<br />

L6<br />

Near Keekarai Pumping<br />

Station<br />

3 SW<br />

Table 3-8 Ambient Air Quality Data<br />

Date Location Gaseous Pollutants,<br />

µg/m 3<br />

PM10 SO2 NOx<br />

12.04.10 Project Site 16 9.6 12<br />

12.04.10 Bore well near <strong>STP</strong> 42 11<br />

14<br />

12.04.10 Near Keekarai Govt.<br />

Elementary School<br />

35 10 13<br />

12.04.10 Near Keekarai Railway Gate 56 9.6 12<br />

6.2.2010 Near Keekarai Post Office 55 9 10<br />

6.2.2010 Near Keekarai Pumping<br />

Station<br />

60 11 12<br />

NAAQ Norms* 100 80 80<br />

Legend: PM10 –Particulate Matter 10; SO2- Sulphur dioxide; NOx- Oxides of Nitrogen<br />

* NAAQ Norms-National Ambient Air Quality Norms Stipulated by CPCB<br />

The PM10 concentration was found between 16 – 60 µg/m3. The SO2<br />

concentration was between 9 – 11 µg/m3 and the NOx concentration was<br />

observed between 10 – 14 µg/m3. The observed AAQ values in the study<br />

area are found to be within the limits of CPCB norms.<br />

3.8 Noise Environment<br />

The main objective of noise monitoring in the study area is to establish<br />

the baseline noise levels and assess the impact of the total noise generated<br />

by the operation of the proposed project activities around it. The noise level<br />

has been monitored from 12.00 hours to 18.00 hours and their results are<br />

shown in Table 3-9.<br />

36

Date: 15.12.09<br />

Table 3-9 Noise Level Data Sheet<br />

HOURS NOISE LEVEL (dB)<br />

EIA EIA FOR FOR 6.92 6.92 MLD MLD MLD <strong>STP</strong> <strong>STP</strong> AT THIRUVARUR<br />

10 20 30 40 50 60 Average<br />

min min min min min min<br />

12.00 45.3 43.6 45.2 48.2 45.6 48.2 46.2<br />

13.00 40.2 41.5 46.9 45.9 40.5 41.9 42.8<br />

14.00 40 55.4 51.2 46.3 54.2 54.2 50.8<br />

15.00 42.6 50.2 49.5 41.2 56.2 54.2 50.1<br />

16.00 41.2 42.5 43.2 50.2 42.5 46.2 44.5<br />

17.00 46.3 41 43.3 51.2 41 41.3 44.0<br />

18.00 42.6 42.2 54.9 57.5 45.2 54.9 50.1<br />

The project site is classified under residential zone. The noise level in<br />

the project site shows that the area is void of any noise. The noise level is<br />

well within the permissible standards prescribed by TNPCB. The maximum<br />

noise level is 50.8 dB (A).<br />

Table 3-10 CPCB standards <strong>for</strong> Noise<br />

Limits in dB (A) Leq<br />

Category of Area Day Time Night Time<br />

Industrial Zone 75 70<br />

Commercial Zone 65 55<br />

Residential Zone 55 45<br />

Silence Zone 50 40<br />

3.9 WATER QUALITY<br />

3.9.1 Selection of Sampling Locations<br />

The assessment of present status of water quality within the study<br />

area was conducted by collecting water samples from ground water sources<br />

(Hand Pumps) during the period of April 2010. The sampling locations have<br />

been identified on the basis of their importance. The identification of the<br />

sampling stations is based on the sensitivity of the location, distance and<br />

direction with respect to the proposed project site.<br />

Details of ground water locations, their distance and direction from<br />

the proposed plant site are presented in Table 3-11. The locations were<br />

37

EIA EIA FOR FOR 6.92 6.92 MLD MLD MLD <strong>STP</strong> <strong>STP</strong> AT THIRUVARUR<br />

selected based on the vicinity of the treatment plant, to establish the<br />

existing base line water quality.<br />

Table 3-11 Sampling Locations in the Study Area<br />

Location<br />

Code<br />

Location<br />

Distance w.r.to project<br />

site (km)<br />

W1 Proposed site <strong>for</strong> <strong>STP</strong> ---<br />

W2 Borewell Near <strong>STP</strong><br />

Near <strong>STP</strong> (Kekkarai)Bridge<br />

0.05 E<br />

W3 (Downstream point of<br />

Sukkanar)<br />

0.5 NE<br />

W4<br />

Near Kekkarai Govt. Elementary<br />

School<br />

2.8 SW<br />

W5 Near Kekkarai Post Office 1.5 SW<br />

W6 Near Kekkarai Railway Gate 2.5 SW<br />

W7 Near Kekkarai Pumping Station 3 SW<br />

3.9.2 Methodology<br />

The samples were analyzed <strong>for</strong> selected physico-chemical parameters<br />

to establish the existing water quality of the study area. Samples were<br />

collected, preserved and analyzed as per the methods given in Standard<br />

Methods <strong>for</strong> the Examination of Water and Wastewater (APHA and WPCF<br />

2000).<br />

38

Table 3-12 Ground Water Quality in Project Site<br />

EIA EIA FOR FOR 6.92 6.92 MLD MLD MLD <strong>STP</strong> <strong>STP</strong> AT THIRUVARUR<br />

S.No Parameters Units W1 W2 W3 W4 W5 W6 W7<br />

1 Color Hazen

EIA EIA FOR FOR 6.92 6.92 MLD MLD MLD <strong>STP</strong> <strong>STP</strong> AT THIRUVARUR<br />

S.No Parameters Units W1 W2 W3 W4 W5 W6 W7<br />

19 Manganese mg/l as Mn

W4<br />

3.9.3 Observations<br />

EIA EIA FOR FOR 6.92 6.92 MLD MLD MLD <strong>STP</strong> <strong>STP</strong> AT THIRUVARUR<br />

The analysis of the results indicates that the average pH ranges<br />

between7.13 - 8.02. TDS ranges from 1030 to 1480 mg/L. Total hardness<br />

ranges from 57 to 67 mg/L. The chloride values ranges from 176 to 514<br />

mg/L. The ground water quality data is given in Table 3-12. The sampling<br />

locations of water are shown in Figure 3.3.<br />

3.9.4 Inference<br />

The water analysis shows that the quality of the water in the study<br />

area is fine and free from contaminants.<br />

W7<br />

3.10 SOIL QUALITY<br />

W5<br />

W6<br />

W3<br />

Project Site<br />

W1 W2<br />

Figure 3.3 Satellite Image showing sampling locations <strong>for</strong> water<br />

Figure 3-4 Water Sampling Locations<br />

The soil sampling locations were identified to assess the fertility and<br />

agricultural characteristics of the soil and also to assess the impact of the<br />

sludge leachate in the immediate surroundings. The sampling location has<br />

W8<br />

41