brilliant debut of The First schifflihead embroidery Machine

brilliant debut of The First schifflihead embroidery Machine

brilliant debut of The First schifflihead embroidery Machine

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

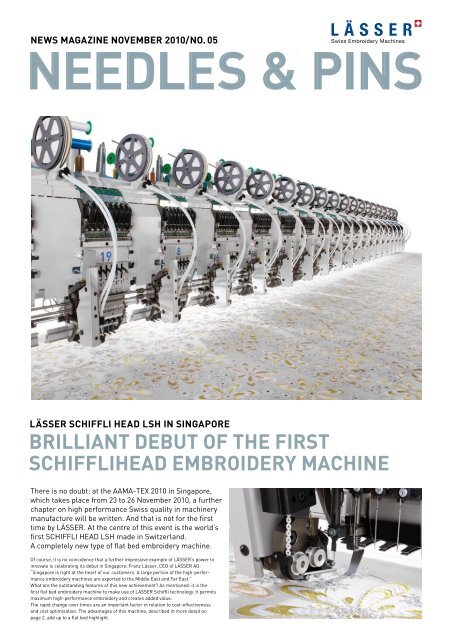

News MagaziNe NoveMber 2010/No. 05<br />

Needles & PiNs<br />

lÄsser sCHiFFli Head lsH iN siNgaPore<br />

brilliaNT debUT oF THe FirsT<br />

sCHiFFliHead eMbroiderY MaCHiNe<br />

<strong>The</strong>re is no doubt: at the AAMA-TEx 2010 in Singapore,<br />

which takes place from 23 to 26 November 2010, a further<br />

chapter on high performance Swiss quality in machinery<br />

manufacture will be written. And that is not for the first<br />

time by LÄSSER. At the centre <strong>of</strong> this event is the world’s<br />

first SCHIFFLI HEAD LSH made in Switzerland.<br />

A completely new type <strong>of</strong> flat bed <strong>embroidery</strong> machine.<br />

Of course, it is no coincidence that a further impressive example <strong>of</strong> LÄSSER’s power to<br />

innovate is celebrating its <strong>debut</strong> in Singapore. Franz Lässer, CEO <strong>of</strong> LÄSSER AG:<br />

“Singapore is right at the heart <strong>of</strong> our customers. A large portion <strong>of</strong> the high-performance<br />

<strong>embroidery</strong> machines are exported to the Middle East and Far East.”<br />

What are the outstanding features <strong>of</strong> this new achievement? As mentioned: it is the<br />

first flat bed <strong>embroidery</strong> machine to make use <strong>of</strong> LÄSSER Schiffli technology. It permits<br />

maximum high-performance <strong>embroidery</strong> and creates added value.<br />

<strong>The</strong> rapid change-over times are an important factor in relation to cost-effectiveness<br />

and cost optimisation. <strong>The</strong> advantages <strong>of</strong> this machine, described in more detail on<br />

page 2, add up to a flat bed highlight.

lÄsser sCHiFFli Head lsH<br />

aMaziNg diMeNsioNs<br />

iN TeCHNologY aNd earNiNgs<br />

only minimal structural preparations are necessary<br />

for the installation <strong>of</strong> the lÄsser sCHiFFli Head lsH.<br />

<strong>The</strong> installation <strong>of</strong> the machine is uncomplicated<br />

and quick. <strong>The</strong> machine stands out with above-average<br />

flexibility, fast changeover and reaction times –<br />

immediate adaptation to specific requirements. <strong>The</strong><br />

users <strong>of</strong> the lÄsser sCHiFFli Head lsH can enjoy<br />

longer <strong>embroidery</strong> times without a thread change.<br />

<strong>The</strong> machine is setting new standards: technologically,<br />

commercially and in a wide range <strong>of</strong> details.<br />

request the completely new<br />

schiffli Head lsH brochure.<br />

We will start with the head. <strong>The</strong> LÄSSER SCHIFFLI HEAD<br />

LSH can be equipped with three different head systems.<br />

<strong>The</strong> user can set-up the head to suit the solution:<br />

With either five, six or eight needles and one borer.<br />

<strong>The</strong> number <strong>of</strong> heads and the selected head distance<br />

define the different length measurements on the<br />

LÄSSER SCHIFFLI HEAD LSH.<br />

Potent inner workings<br />

<strong>The</strong> inner workings open up advantages for the user that<br />

are crucial in a business orientated on efficiency and<br />

success. Hardy Lipp, LÄSSER Sales Director: “It is the<br />

details which matter here. For instance the thread roller<br />

drive, thanks to which the tension <strong>of</strong> the <strong>embroidery</strong> thread<br />

can be specifically controlled via the LSH-Cockpit. It is not<br />

necessary to adjust the thread brake as on conventional<br />

machines. A clear plus for the user.” On the other hand,<br />

the thread take-<strong>of</strong>f can be adjusted to suit the size <strong>of</strong> the<br />

spools (cones). Large <strong>embroidery</strong> spools can also be used.<br />

<strong>The</strong> borer system is extremely powerful with 12 step depth<br />

regulation and equipped with changeable borer points.<br />

<strong>The</strong> height <strong>of</strong> user friendliness<br />

Here the potential is shown in particular, which will be<br />

highly appreciated by the customers. A machine with such<br />

dimensions must be easy to control and always remain<br />

clear. <strong>The</strong> LÄSSER SCHIFFLI HEAD LSH is extremely userfriendly.<br />

<strong>The</strong> LSH-Cockpit is clearly arranged. <strong>The</strong> <strong>embroidery</strong><br />

field is very simple to manage.<strong>The</strong> <strong>embroidery</strong><br />

positions are easily accessible. Because user friendliness<br />

has the highest priority, the s<strong>of</strong>tware is written specifically<br />

in-house at LÄSSER. Result: precise and perfect <strong>embroidery</strong><br />

results.<br />

Three-dimensional and s<strong>of</strong>ter<br />

With the LÄSSER SCHIFFLI HEAD LSH widely varying yarn<br />

thicknesses such as cotton, rayon, polyester, wool, gimp<br />

and many more are highly efficiently processed.<br />

<strong>The</strong> result <strong>of</strong> the <strong>embroidery</strong> process is more three-dimensional<br />

and s<strong>of</strong>ter. Less stitches are required. <strong>The</strong> Schiffli<br />

bobbins have the unique advantage <strong>of</strong> running three times<br />

longer than round bobbins. <strong>The</strong> frame with its new type<br />

<strong>of</strong> LSH spanning system ensures guaranteed fabric tension<br />

and better quality. <strong>The</strong> user can enjoy fully balanced,<br />

even fabric tension. Support fabrics as used in the past are<br />

no longer necessary.<br />

New opportunities, new markets<br />

More and more applications. <strong>The</strong> enrichment <strong>of</strong> the range<br />

with glamorous double sequins and sequins has no<br />

limits. Even cord and thermocut are possible in various<br />

configurations. Also effect yarns or cords can be embroidered.<br />

Multilayer applications are possible.<br />

<strong>The</strong> LÄSSER SCHIFFLI HEAD LSH opens the way for<br />

elegant evening attire and formal attire, seductive<br />

lingerie, sophisticated swimwear, chic accessories, silk<br />

scarves and ornate traditional garments with sequins.<br />

New opportunities, new markets, new success stories.

lÄsser Md5<br />

a geNTle giaNT is CaUsiNg<br />

a seNsaTioN worldwide<br />

request the<br />

documentation.<br />

It is quiet. It is powerful. And it is a major success worldwide. <strong>The</strong> LÄSSER MD5<br />

represents the latest technology that is decisively improving <strong>embroidery</strong><br />

performance. Easy to operate, it addresses multidimensional needs. Worldwide<br />

more than 100 MD5 machines have already been sold.<br />

Ergonomic design. Easy access to the stitching field, the latest user-friendly machine control system. Patented LÄSSER<br />

single thread control system STG. Frame drive with highly dynamic servo motors. <strong>The</strong>se and other merits improve processing,<br />

increase convenience and provide for economical work process steps, easier handling, more speed and increased<br />

cost-effectiveness.

lÄSSer MeeTS SWAroVSKI<br />

co-oPerATIon WITH THe GlITTerInG<br />

FlAIr oF A GloBAl BrAnD<br />

Based on a co-operation with Swarovski, we are able to <strong>of</strong>fer new applications that<br />

will massively expand the scope <strong>of</strong> your range. lÄSSer crYSTAl STone HeAD is the<br />

solution, lochrose art. 3129 the crucial component that you can integrate into your<br />

<strong>embroidery</strong> machine.<br />

LÄSSER CRYSTAL STONE HEAD was developed for textile processing and the fashion<br />

industry. <strong>The</strong> application is based on an innovative technology that <strong>of</strong>fers a unique combination<br />

<strong>of</strong> <strong>embroidery</strong> and the application <strong>of</strong> crystals in one step. Possible applications are<br />

curtains, textile wall coverings and decorative accessories. Inspire individuality. Set trends<br />

with Crystal Stone Head. <strong>The</strong> basis for creativity and innovative opulence. Treasures<br />

that make up that special chic for the fashion world. With the automatic application <strong>of</strong><br />

the Swarovski Elements Lochrose art. 3129 you have an excellent option for obtaining<br />

a competitive edge on the market.<br />

CRYSTAL STONE hEAd<br />

developed in collaboration with<br />

request the brochure. request the brochures.<br />

THerMocUT<br />

PrecISe, GenTle ProceSSInG. MUlTIlAYer<br />

APPlIcATIon ProceSSInG.<br />

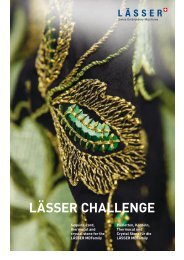

LÄSSER CHALLENGE<br />

Sequins, cord,<br />

thermocut and<br />

crystal stone for the<br />

LÄSSER MDFamily<br />

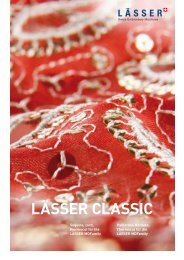

LÄSSER LÄSSER CLASSIC CLASSIC<br />

ITMA BArcelonA 2011<br />

lÄSSer AT THe leADInG TrADe FAIr For<br />

THe TeXTIle AnD cloTHInG InDUSTrY<br />

“Master the Art <strong>of</strong> Innovation”, says<br />

the hanger for the ITMA, which takes<br />

place from 22 to 29 September 2011<br />

in Barcelona. <strong>The</strong> trade fair has an<br />

impressive history. It is held every four<br />

years and is considered the “olympics”<br />

<strong>of</strong> the textile machine industry.<br />

In this accelerated environment for change, LÄSSER AG is<br />

exhibiting its globally successful products. Visitors must<br />

be pleased. As a present they receive a top quality gift, a Swiss<br />

Army knife. It is so-to-speak a symbol <strong>of</strong> the Swiss quality<br />

that LÄSSER has set itself. If you choose LÄSSER high-<br />

performance <strong>embroidery</strong> machines, you are deciding for a<br />

clear advantage.<br />

lÄSSer THerMocUT lTc is becoming established in the fashion world. More than a<br />

hundred machines are in use worldwide and they are here to stay.<br />

Why this success? <strong>of</strong> course, a feeling for the market is needed. An innovative spirit is<br />

needed. And ideas.<br />

However, at the end <strong>of</strong> the day it is tangible advantages that impress customers. <strong>The</strong><br />

precise, gentle processing. <strong>The</strong> multi-layer application processing. <strong>The</strong> higher cutting performance<br />

compared to laser systems or manual applications is also crucial. However,<br />

the biggest advantage is that the cut edges are sealed and therefore protected against<br />

fraying. And that very special advantage: sequins and cord can be combined. <strong>The</strong> LÄSSER<br />

THERMOCUT LTC is suitable for all LÄSSER <strong>embroidery</strong> machines. Cutting is independent<br />

<strong>of</strong> the repeat. <strong>The</strong> cutting patterns are fabricated elegantly and without major effort<br />

(thanks to the proven punch s<strong>of</strong>tware). You integrate these patterns directly into the<br />

<strong>embroidery</strong> program. With the LÄSSER THERMOCUT LTC cost-effectiveness is a strong<br />

point. And: the best convenience is combined with easy handling!<br />

World-leading developer and manufacturer <strong>of</strong><br />

high-performance <strong>embroidery</strong> machines<br />

Security after the purchase<br />

Ground-breaking technologies<br />

Swiss quality<br />

optimal cost-benefit ratio<br />

Pailletten, Kordeln,<br />

<strong>The</strong>rmocut und<br />

Crystal Stone für die<br />

LÄSSER MDFamily<br />

Sequins, Sequins, cord, cord,<br />

thermocut thermocut for for the the<br />

LÄSSER LÄSSER MDFamily MDFamily<br />

Pailletten, Kordeln,<br />

<strong>The</strong>rmocut für die<br />

LÄSSER MDFamily<br />

renowned international<br />

<strong>embroidery</strong> collections carry<br />

our signature<br />

Innovative, flexible, solution-orientated<br />

DACHCOM