View PDF document - MasonryFirst.com

View PDF document - MasonryFirst.com

View PDF document - MasonryFirst.com

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

20<br />

ASPHALT<br />

Bardon ASHphalt<br />

Bardon ASHphalt is a patent awarded asphalt material that guarantees a minimum content<br />

level of at least 15% of municipal incinerator ash but typically, used in <strong>com</strong>bination with other<br />

secondary or recycled aggregates, uses levels of up to 20% or more. The product can be<br />

formulated to meet most British Standard requirements or design asphalt base and binder<br />

course mixtures.<br />

SUSTAINABILITY CRITERIA<br />

Uses locally available secondary aggregates to reduce reliance on primary aggregate sources and<br />

reduces impact on land fill.<br />

Case Study<br />

A316 at Twickenham in West London, Bardon ASHphalt<br />

The A316 at Twickenham in West London was chosen as a site for trialling Transport for London’s (TfL’s)<br />

Business Procurement Efficiency Programme (BPEP). The BPEP initiative aims to maximise immediate<br />

and ongoing cost savings in road works through the appropriate use of recycled materials to support<br />

the Mayor’s Green Procurement Code.<br />

100mm of existing surfacing was planed off and the area resurfaced with a proprietary 35mm thin<br />

wearing course and 65mm HDBM base course with recycled aggregate. This was laid in the same way<br />

as conventional HDBM. The HDBM mix contained 35% RAP, 10% glass, 10% IBA (total 55% recycled<br />

content), with the remaining aggregate sourced from Bardon Hill Quarry.<br />

Bardon ASHphalt<br />

Call 0845 600 0860 or visit www.bardon-aggregates.<strong>com</strong> for more information about Bardon ASHphalt<br />

Supplied by<br />

Supplied by<br />

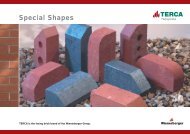

Bardon Forpave Plus<br />

Sustainable solutions that won’t cost the earth<br />

Bardon Forpave Plus counters the problems associated with fuel and oil spillages in bus<br />

stations, taxi ranks, docks etc. Polymer technology provides improved fuel oil resistance<br />

when <strong>com</strong>pared to conventional asphalts and macadams, resisting deformation and crack<br />

propagation, making it ideal for heavy vehicle movement situations. The enhanced<br />

formulation improves fuel oil resistance and provides enhanced workability at higher<br />

temperatures as well as a stiffer product after cooling.<br />

SUSTAINABILITY CRITERIA<br />

Reduced mixing temperature by up to 30ºC resulting in less consumption of fossil fuels in the<br />

production process and subsequently lower CO 2 emissions, reduced exposure to bitumen fumes for<br />

operatives, and increased product life in <strong>com</strong>parison with conventional surfaces. This reduces the long<br />

term requirements for primary aggregate use, transportation of product and disposal of waste asphalt.<br />

Call 0845 600 0860 or visit www.bardon-aggregates.<strong>com</strong> for more information about Bardon Forpave Plus<br />

21<br />

Bardon Forpave Plus