IQ-Analog - EEWeb

IQ-Analog - EEWeb

IQ-Analog - EEWeb

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

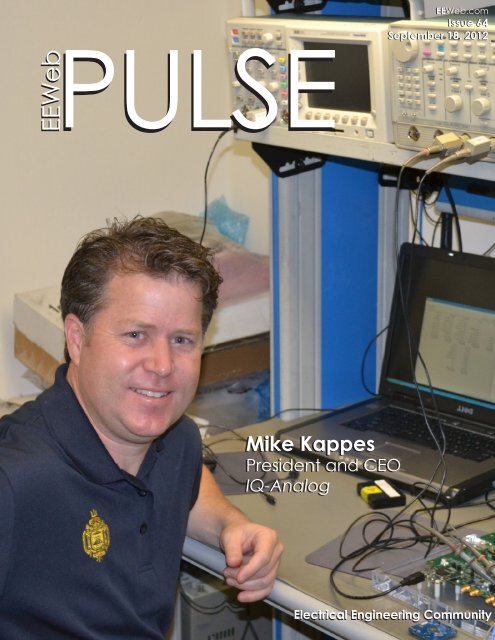

<strong>EEWeb</strong><br />

PULSE<br />

Mike Kappes<br />

President and CEO<br />

<strong>IQ</strong>-<strong>Analog</strong><br />

INTERVIEW<br />

<strong>EEWeb</strong>.com<br />

<strong>EEWeb</strong>.com<br />

Issue 64<br />

September September 18, 2012<br />

Electrical Engineering Community<br />

Visit www.eeweb.com 1

Experts<br />

Exchanging<br />

Ideas<br />

Every Day.<br />

VISIT DIGIKEY.COM/TECHXCHANGE TODAY!<br />

Digi-Key is an authorized distributor for all supplier partners. New products added daily. © 2012 Digi-Key Corporation, 701 Brooks Ave. South, Thief River Falls, MN 56701, USA

<strong>EEWeb</strong> PULSE TABLE OF CONTENTS<br />

Mike Kappes<br />

<strong>IQ</strong>-ANALOG<br />

Interview with Mike Kappes - Founder, President and CEO of <strong>IQ</strong>-<strong>Analog</strong><br />

Featured Products<br />

Preparing Our Next Generation of Young<br />

Engineers for Success<br />

BY STEVE DARROUGH WITH ZILOG<br />

The importance of teaching students the relationship between specialized micro-elements and<br />

the total process of product design.<br />

Homemade Tools - Part 1<br />

BY PAUL CLARKE WITH EBM-PAPST<br />

An outline of how to design your own tools that will help you pursue your own unique task.<br />

RTZ - Return to Zero Comic<br />

Visit www.eeweb.com<br />

4<br />

9<br />

12<br />

18<br />

22<br />

3

<strong>EEWeb</strong> PULSE<br />

49<br />

<strong>EEWeb</strong> | | Electrical Engineering Community<br />

Mike<br />

Kappes<br />

<strong>IQ</strong><strong>Analog</strong> <strong>IQ</strong>-<strong>Analog</strong>

How did you get into electrical<br />

engineering and when did you<br />

start?<br />

My uncle is an MIT graduate in<br />

Mechanical Engineering and he<br />

sparked an interest in gadgetry at an<br />

early age. My wish list for birthdays<br />

was always loaded with items from<br />

Edmund Scientific. I had a natural<br />

curiosity about how things worked<br />

and the fact that my parents could<br />

provide no clear answers made<br />

electronics all the more interesting.<br />

I had several science projects in my<br />

youth culminating in the permanent<br />

dismantling of a personal computer.<br />

What have been some of your<br />

influences that have helped<br />

you get to where you are<br />

today?<br />

My mom was a former biochemist<br />

from NASA who would take me on<br />

field trips to science labs at local<br />

universities. I realized there was<br />

still a lot of mystery as to how things<br />

worked and that electronics in<br />

particular was an exciting field with<br />

a lot of mystery. While other kids<br />

may have liked Captain Kirk, I was<br />

a fan of Spock. He knew everything<br />

about everything. Kirk was just<br />

bumbling around in the darkness.<br />

How did you decide to start<br />

your own company?<br />

I have worked in multiple chip<br />

companies— several of them<br />

start-ups—and I developed a lot<br />

experience in analog circuit design<br />

for communications. Along the<br />

way, I developed an emphasis on<br />

data-converter technology, which<br />

was becoming more and more<br />

important in these systems. As an<br />

engineer, I’ve always aspired to<br />

change the world in some small<br />

way. I decided I wanted to start a<br />

group that developed a new class<br />

of data converters that leveraged<br />

digital signal processing to enhance<br />

performance with greater efficiency.<br />

When I first started out, it was a little<br />

bit of a shock because I went from<br />

having a stable salary to no income<br />

with only a few months of cushion.<br />

I was lucky to find a short-term<br />

project with a local company as a<br />

design engineer working on-site for<br />

them. After that project was done, I<br />

had a technology component that I<br />

owned which I could leverage for<br />

the next project. From there, it was<br />

one project after the other until I<br />

had licensed enough intellectual<br />

property to other companies to afford<br />

to build our team. It has steamrolled<br />

in the last 3-4 years to where we have<br />

the critical mass to balance our IP<br />

licensing business with advanced<br />

research and development of the<br />

technology need to roll out our own<br />

integrated circuit product line.<br />

How many employees do<br />

you have at <strong>IQ</strong>-<strong>Analog</strong> and<br />

how you would describe the<br />

culture?<br />

We currently have seven employees.<br />

It’s a fun place to work. We are<br />

addressing client problems that<br />

are difficult to solve. We are very<br />

service-oriented and we all interact<br />

with our customers. As a result of the<br />

personal relationships we develop,<br />

we have heightened responsibility<br />

and ownership of our engineering<br />

activities. If the customer’s<br />

expectations are not fully met, then<br />

there is a personal consequence to<br />

that. The oppposite is also true that<br />

their is a great sense of satisfaction<br />

in solving complex problems for our<br />

clients.<br />

What particular technologies<br />

are you licensing to other<br />

companies?<br />

We develop intellectual property (IP)<br />

that is used to perform some form of<br />

Visit www.eeweb.com<br />

INTERVIEW<br />

analog interface or data converter<br />

function on a client’s integrated<br />

circuit product. It is all analog hard<br />

macro circuit design. We develop<br />

the circuit architectures, perform<br />

the circuit design and layout and<br />

package the IP as a software bundle<br />

ready for integration. We are a very<br />

hardware-focused company and we<br />

like to take our own test-chips into<br />

the lab and do testing to validate our<br />

performance expectations.<br />

Engineering prowess<br />

has created the<br />

largest corporation<br />

in the world out of<br />

humble beginnings<br />

in a garage. I<br />

don’t think we<br />

give [America]<br />

enough credit for<br />

our contributions<br />

to society.<br />

Our company is currently working<br />

on the advancement of analog<br />

interface technologies, in particular<br />

data converters, for 4G base station<br />

equipment. Data converters are<br />

marching up the signal chain<br />

replacing RF components while<br />

enhancing data rates and system<br />

performance. We are working<br />

to provide more advanced data<br />

converters to enable higher<br />

performance and lower cost cellular<br />

networks.<br />

5

<strong>EEWeb</strong> PULSE<br />

What kinds of companies are<br />

buying your IP?<br />

We have licensed our IP around<br />

the globe for a myriad of<br />

applications. The trend lately has<br />

been toward servicing femtocell<br />

and picocell products which are<br />

essentially consumer-grade cellular<br />

basestations. We have also seen<br />

a lot of attention from companies<br />

developing semiconductors for<br />

wireless transceivers that provide<br />

data back-haul from base-station<br />

to base-station. Integration has<br />

historically been the pathway<br />

to enable lower cost wireline<br />

communications systems (ethernet,<br />

DSL, etc) and the same is holding<br />

true for wireless communications. It<br />

is a natural evolution enabled both<br />

by advances in process technology<br />

and the the ingenuity of creative<br />

engineers doing more with the<br />

transistors made available to them.<br />

Do you have any note-worthy<br />

engineering experiences?<br />

I have over 20 patents in analog<br />

circuit designs. My greatest<br />

accomplishment to date has been<br />

building <strong>IQ</strong>-<strong>Analog</strong> into a company<br />

that enabled me to attract worldclass<br />

engineering talent. Our<br />

greatest accomplishment together<br />

is yet to come.<br />

What challenges do you<br />

foresee in our industry?<br />

The biggest issue I see as an<br />

entrepreneur is the scarcity of other<br />

emerging start-up semiconductor<br />

businesses. This is not a good sign<br />

but is indicative of the vacuum left<br />

behind when venture capitalists<br />

vacated semiconductors about 5<br />

years ago. There has been no source<br />

of capital to fill this void. I would like<br />

to see a federal government initiative<br />

to keep our edge in semiconductors<br />

over emerging countries who are<br />

6<br />

<strong>EEWeb</strong> | Electrical Engineering Community<br />

My greatest accomplishment to date<br />

has been building <strong>IQ</strong>-<strong>Analog</strong> into a<br />

company that enabled me to attract<br />

world-class engineering talent.<br />

Our greatest accomplishment<br />

together is yet to come.

investing state dollars and creating<br />

an uneven global playing field.<br />

Is there anything that you<br />

have not accomplished yet,<br />

that you have your sights on<br />

accomplishing in the near<br />

future?<br />

That’s a big question. Obviously,<br />

I want to take my company to new<br />

heights and reward our employees<br />

for all of the hard work we have<br />

invested over the last 7 years. After<br />

that I’d like to contribute to our local<br />

community. Qualcomm has been<br />

a fantastic corporate role model in<br />

the San Diego community. I’d like to<br />

follow their lead in an appropriately<br />

smaller way.<br />

Do you have any advice for<br />

the electrical engineering<br />

community?<br />

I believe that America is still the<br />

leader in creative and independent<br />

thinkers. Engineering prowess has<br />

created the largest corporation in<br />

the world out of humble beginnings<br />

Visit www.eeweb.com<br />

INTERVIEW<br />

in a garage. I don’t think we give<br />

ourselves enough credit for our<br />

contributions to society. It is an<br />

honorable profession and I think we<br />

need to be sure this message gets<br />

across to the next generation. ■<br />

Visti <strong>IQ</strong>-<strong>Analog</strong>’s website:<br />

7

Technology You Can Trust<br />

Avago Technologies Optocouplers<br />

A Superior Technology<br />

for High Voltage Protection!<br />

IEC 60747-5-5 Certifi ed<br />

Optocouplers are the only isolation devices that meet or exceed the IEC 60747-5-5<br />

International Safety Standard for insulation and isolation. Stringent evaluation tests show Avago’s<br />

optocouplers deliver outstanding performance on essential safety and deliver exceptional High Voltage protection<br />

for your equipment. Alternative isolation technologies such as ADI’s magnetic or TI’s capacitive isolators do not deliver<br />

anywhere near the high voltage insulation protection or noise isolation capabilities that optocouplers deliver.<br />

For more details on this subject, read our white paper at: www.avagoresponsecenter.com/672

FEATURED PRODUCTS<br />

-36V, -200mA, Low-Dropout Linear Regulator<br />

The TPS7A30xx series of devices are negative, high-voltage (–36V),<br />

ultralow-noise (15.1µVRMS, 72dB PSRR) linear regulators capable of<br />

sourcing a maximum load of 200mA. These linear regulators include a<br />

CMOS logic-level-compatible enable pin and capacitor-programmable<br />

soft-start function that allows for customized power-management<br />

schemes. Other features available include built-in current limit and<br />

thermal shutdown protection to safeguard the device and system during<br />

fault conditions. For more information, please click here.<br />

First NFC Wireless Charging Solution<br />

Renesas Electronics Corporation, a supplier of semiconductor solutions,<br />

has developed the near field communication (NFC) wireless charging<br />

system to eliminate the power cable for charging and increase efficiency<br />

of those systems. Renesas supplies the essential components needed<br />

to build a system: the NFC microcontroller (MCU) RF20, the power<br />

transmitter IC R2A45801, and the power receiver IC R2A45701. Renesas<br />

also provides the total kit including peripheral general-purpose devices<br />

(e.g. power semiconductor devices) as a system solution. For more<br />

information, please click here.<br />

Isolated 1W DC-DC Converter<br />

Murata Power Solutions announced the MEE1 series, a 1 Watt single<br />

output PCB mounted DC-DC converter designed for a broad range of<br />

industrial, automation and instrumentation applications that require an<br />

isolated low-power distributed supply. These highly efficient converters<br />

are available in a variety of models accommodating the popular nominal<br />

input voltages of 3.3, 5, 12, 15, or 24 VDC and with output voltages of<br />

3.3, 5, 9, 12 or 15 VDC. The MEE1’s isolation allows the converter to be<br />

configured to provide an isolated negative rail in systems where only a<br />

positive rail exists. For more information, please click here.<br />

DRAM Reduces Power Use<br />

SK Hynix announced that it has introduced DDR3L-RS(Reduced Standby)<br />

DRAM for mobile solutions using its 20nm class technology. This product<br />

significantly reduces the standby power consumption. By using cuttingedge<br />

20nm class technology and efficiently managing standby current,<br />

this DDR3L-RS product reduces 70% of standby power compared to<br />

existing DDR3L DRAM while it maintains DDR3L performance. DDR3L<br />

DRAM which has recently gone mainstream works at 1.35V, while DDR3<br />

DRAM does at 1.5V. For more information, please click here.<br />

Visit www.eeweb.com<br />

9

O C T O B E R 2 2 - 2 5 , 2 0 1 2<br />

Join us this Fall! Hands-on Labs, Seminars, Meet the<br />

Experts, Demos, Partner Solutions and much more!<br />

For all things DevCon – including up-to-date course<br />

information, lodging and registration details – go to:<br />

Guest Speaker<br />

Dean Kamen<br />

Dean Kamen landed<br />

in the limelight with<br />

the Segway, but he<br />

has been innovating<br />

since high school,<br />

with more than 150<br />

patents under his belt. Recent projects<br />

include portable energy and<br />

water purification for the<br />

developing world.<br />

SESSION TRACKS<br />

Human Machine Interface<br />

Display Technologies<br />

System Design<br />

Motor Control<br />

Automotive<br />

Security<br />

Machine to Machine<br />

Computing Architectures<br />

Cloud Computing<br />

<strong>Analog</strong> & Power<br />

Development Tools<br />

Connectivity<br />

Operating Systems<br />

E n a b l i n g t h e S m a r t So c iety<br />

Hyatt yatt yatt Regency<br />

Regency<br />

Regency<br />

Orange County, CA<br />

REGISTER NOW!<br />

RenesasDevCon.com<br />

© 2012 Renesas Electronics America Inc. *Source: Gartner 2011 Worldwide Semiconductor Market Share Database, March 2012 results<br />

Key Sponsors<br />

Hosted by the<br />

Number One<br />

MCU Supplier<br />

Worldwide *

For course descriptions,<br />

visit RenesasDevCon.com<br />

Meet the Experts<br />

Design Issues for Systems That Use<br />

LCD Panels<br />

M2M Development<br />

Development Ecosystem and<br />

Services<br />

Customer Feedback<br />

Expert Panel: The Auto Industry<br />

Speaks<br />

Expert Panel: The Future of Auto<br />

Software/System Development<br />

Model-based Development<br />

Simulation: Expert Insights into<br />

Modelling Microcontrollers<br />

Automotive<br />

Cost Effective HIL for Rapid Prototyping<br />

Virtual HIL test/ISO 2626 using<br />

Processor Models<br />

Introduction to Velocity Lab<br />

Infotainment & Instrumentation<br />

Solutions<br />

QuantiPhi for RL78: The Fastest<br />

Path from Idea to Implementation<br />

Simulation: Moving Development<br />

into the Virtual World<br />

Active Safety Solutions<br />

Graphic System Design Considerations<br />

Insights into MCU & Mixed Signal<br />

Design<br />

Automotive Quality/Failure Analysis<br />

Working with AUTOSAR<br />

Trends in Automotive Communication<br />

Improve a Product’s User Experience<br />

with Model-based UI Design<br />

Intelligent Power Devices<br />

Mastering Functional Safety and<br />

ISO 26262<br />

Advanced SOC for Telematics and<br />

Infotainment<br />

MICON Racing – Qualify using<br />

QuantiPhi for RL78<br />

Using Processor Models for Software<br />

Development and Validation<br />

HEV/EV Traction Motor Control Lab<br />

Computing Architecture<br />

Renesas Next-generation<br />

Microcontroller and Microprocessor<br />

Technology Roadmap<br />

Microcontroller Solutions Enabling<br />

a Greener Society<br />

The Core Difference: When the<br />

Core Matters<br />

RH850 & RL78: Introducing the Next<br />

Generation of Microcontollers for<br />

Automotive Applications<br />

Benchmarking using EEMBC<br />

Optimizing Performance of<br />

RX-based Applications<br />

Connectivity<br />

Industrial Ethernet<br />

Instant Connectivity for the<br />

“Internet of Things”<br />

PLM-1 Modem<br />

Renesas Connecting through<br />

802.15.4 Radio<br />

CMX TCP-IP<br />

LibUSB: Create a Solution Without<br />

the Class Struggle<br />

CAN In a Day:<br />

Using the RX CAN API<br />

IR and Bluetooth Connectivity<br />

Using the RL78<br />

Development Tools<br />

Getting Started with Renesas<br />

Development Tools<br />

Introduction to e2studio, The New<br />

Eclipse-based IDE from Renesas<br />

Getting the most out of the Renesas<br />

Demonstration Kits (RDKs)<br />

Trends in Embedded Software<br />

Development<br />

High-performance Compiler<br />

Solutions for Renesas MCUs<br />

Getting the Most Out of the GNU<br />

Toolchain<br />

Getting Started with e2studio, The New Eclipse-based IDE<br />

from Renesas<br />

Introduction to the RX Arduino<br />

Using Embedded Tools for I2C, SPI,<br />

and USB Debugging and Development<br />

on the Renesas RX63N RDK<br />

Seeing Inside your Target at<br />

Run-time with µC/Probe<br />

Advanced Debugging with<br />

the RX600<br />

Migration from HEW to Eclipse<br />

Migration from Cube Suite to Eclipse<br />

Using Software Building Blocks for<br />

Faster Time-to-market<br />

VectorCAST Tools:<br />

A Complete Test Environment for<br />

Safety-critical Applications<br />

Using a Renesas Code-generation<br />

Tool for RL78 Devices<br />

e2studio Advanced Topics<br />

Advanced Debugging on RX with<br />

IAR Embedded Workbench<br />

Security<br />

NFC Ecosystem and Solutions<br />

Hardware Roots of Trust –<br />

A Foundation for Security<br />

Security Solutions for the<br />

Automotive Industry<br />

Security Solutions Part 1: Javacard<br />

Applet Development Training<br />

Security Solutions Lab 2: Secure<br />

Host Firmware Upgrade using<br />

BoardID Secure Solution<br />

Human Machine<br />

Interface<br />

Audio Solutions on the RX MCU<br />

Family<br />

Capacitive Touch Based User<br />

Interfaces and Hardware-based<br />

Solutions<br />

Enhance Embedded Designs with<br />

Low-cost TFT LCD Solutions<br />

Embedded Vision:<br />

Creating “Machines that See”<br />

Driving E Ink Displays<br />

Direct-drive LCD<br />

Using Altia to Design a GUI and<br />

Deploy it on Renesas SH7269<br />

Extreme Makeover with the RX600:<br />

Adding Touch/Graphics to Your<br />

Product<br />

Direct-drive LCD Software<br />

Integration for the RX62N/RX63N<br />

Incorporating a Capacitive Touch<br />

Interface into Your Design<br />

Industrial Controls GUI Application<br />

Using emWin<br />

Display<br />

Flat Panel Displays:<br />

LCD Technologies and Trends<br />

Flat Panel Displays: Touch Panel<br />

Technologies and Integration<br />

Flat Panel Displays: Beyond the Basics<br />

Flat Panel Displays: How to Overcome<br />

High Ambient Light Conditions<br />

Flat Panel Displays:<br />

Exploring a 2D/3D Solution<br />

Flat Panel Displays:<br />

Advanced Technology Trends<br />

M2M and Cloud Solutions<br />

Energy-efficient Communications<br />

with Wi-Fi<br />

Adding Wi-Fi to Embedded<br />

Applications<br />

Wireless Connectivity for<br />

Embedded Systems<br />

M2M: How to Create Revenuegenerating<br />

Services and Applications<br />

Wireless Sensors<br />

Wireless Transceivers<br />

M2M: Cloud Connectivity with RX<br />

and Exosite<br />

Power<br />

IGBT vs. Mosfet:<br />

Which Device to Select?<br />

How to Make Your House Smarter<br />

Digital Power: Design and<br />

Architectural Trade-offs<br />

Increasing the Performance of PFC<br />

and LED Driver IC Applications<br />

Optical Isolation, SSR Switching,<br />

and Ambient Light Sensing<br />

in MCU-based Applications<br />

IGBTs for HEV/EV<br />

Register Today! Limited Space Available.<br />

RenesasDevCon.com<br />

Motor Control<br />

Power Factor Correction:<br />

Why and How?<br />

Sensorless Vector Control and<br />

Implementation: Why and How<br />

Know your Precise Position with<br />

RX600 MCUs<br />

Field-oriented Control Using a 16-bit<br />

Low-power MCU<br />

Operating Systems<br />

Using ThreadX and IAR Embedded<br />

Workbench on the RX Processor<br />

Introduction to RoweBots’<br />

Ultra Tiny Linux RTOS<br />

Embedding USB: Implementation<br />

Challenges and Limitations<br />

FreeRTOS Lecture<br />

Rapid Development on the Renesas<br />

RX63N RDK using µEZ ® and FreeRTOS<br />

Introduction to Python<br />

Software Development with an Open<br />

Source Real-time Operating System<br />

HTML5 HMI Development with QNX<br />

Developing Next-gen Automotive<br />

User Interface using EB GUIDE 5.3<br />

w/Windows Embedded Automotive<br />

7 and Renesas R-Car H1<br />

Getting Started with Micriµm’s<br />

µC/OS-III Kernel<br />

Embedding TCP/IP: Working<br />

Through uC/TCP-IP Usage<br />

Introduction to the .NET Micro<br />

Framework<br />

System Design<br />

Technologies<br />

Are all Batteries Created Equal?<br />

A/D Converter Fundamentals<br />

Designing Modern Medical Systems<br />

Digital Filtering on a MCU<br />

Infinite Runtime: Energy Harvesting<br />

with Renesas MCUs<br />

Moving from 8-bit to 32-bit MCUs<br />

Battery Management<br />

ADC Resolution: Myth and Reality<br />

Exploring the Safety Features of<br />

the RX210<br />

Low-power Design<br />

Increase the Dynamic Range and<br />

Precision of Digital Filters Using a FPU<br />

RL78 Project Configuration Tips<br />

RX Project Configuration Tips<br />

Sensor Fundamentals<br />

Extreme Low-power Design:<br />

Tools, Design Techniques and<br />

Implementation<br />

Creating Virtual EEPROM on<br />

Renesas MCUs<br />

Implementing Bootloaders on<br />

Renesas MCUs<br />

Designing Energy Harvesting<br />

Applications with the RL78<br />

Portable Instrumentation<br />

Applications with the RL78<br />

Embedded Systems Bootcamp

<strong>EEWeb</strong> PULSE<br />

Preparing Our N<br />

of Young Enginee<br />

Success<br />

Steve Darrough<br />

IXYS-ZILOG - VP of Marketing<br />

H ow can the engineering industry help the<br />

next generation of young engineers get prepared<br />

for their real-world careers in product design? As<br />

we teach the bright young minds of engineering,<br />

who may be already be experts in their own<br />

specializations, about the micro-elements of<br />

components and platform development, it is also<br />

crucial to help them understand the relationship<br />

between these specialized micro-elements and<br />

the total process of product design.<br />

12 28 <strong>EEWeb</strong> | | Electrical Engineering Community

TECH ARTICLE<br />

ext Generation<br />

rs For<br />

Visit www.eeweb.com<br />

13 29

<strong>EEWeb</strong> PULSE<br />

The general complexity of most technology naturally<br />

encourages engineers to specialize within their<br />

particular areas of system design. Because most<br />

technologies are so complex, it often takes a specialized<br />

team to work on the particular elements of a design.<br />

An example of this scenario is the hardware element,<br />

which can be segmented into areas such as power and<br />

control, and even further into more specialties of solar<br />

cells, motor control, and data management. Even in<br />

addition to these areas, there is a need for design of<br />

software applications, development environments, and<br />

other elements. All of these elements of a technology<br />

can be further segmented into functional areas such<br />

as wireless communication, code libraries, and often<br />

many other dependences. A young engineer may find it<br />

beneficial to specialize in one of these areas, and ignore<br />

the work of other areas entirely. However, in order to truly<br />

be successful, he still must have some understanding of<br />

the overall process of product development, as well as<br />

the ability to work with engineers and others involved in<br />

product development.<br />

When first entering the workplace, one of the<br />

challenges young engineers face is to be tasked with<br />

designing new systems; they quickly come up against<br />

many different types of challenges as to how they must<br />

manage their interactions given these dependencies.<br />

Typically, if one team is working on a power system or a<br />

communications transport block, this team may have a<br />

different perspective, knowledge set, or understanding<br />

(based on their area of focus) than that of another team<br />

involved in the development of a different aspect of the<br />

same product. Individual teams may witness that each<br />

of the other key teams has requirements or processes<br />

that are different in some ways than their own. This is<br />

why it is critical that new engineers develop a broad<br />

understanding of how the company’s groups are each<br />

working together toward completing a new product.<br />

Marketing, Sales, Engineering, Manufacturing, and<br />

Fulfillment — each have different SOPs and processes<br />

they follow in delivering their teams’ element of<br />

focus within the context of the final production result.<br />

Engineers should be taught about the importance of<br />

different areas of product development, and offered an<br />

overview of their function, preferably before entering<br />

the workforce, in order to avoid costly and ineffective<br />

mishaps.<br />

One of the ways to help young engineers develop a<br />

broader focus is to encourage the many fine engineering<br />

universities to educate their students early on about<br />

process. Learning about process is great training for the<br />

14 <strong>EEWeb</strong> | Electrical Engineering Community<br />

real world. However, the focus is often put on teaching<br />

engineers to be productive as quickly as possible,<br />

which may seem to benefit a company quickly, as young<br />

professional engineers hit the ground running and<br />

begin producing results quickly. However, even if these<br />

students are encouraged to begin rowing as fast and<br />

hard as they can, the results are empty unless they are<br />

rowing together with the group. Most of us engineers<br />

who are well into our careers have witnessed a wide<br />

variety of experiences and have learned to more-or-less<br />

row together, but for those just coming out of school,<br />

suddenly being asked to think about process and work<br />

with others (rather than simply focus on their one small<br />

specialty area) can be quite challenging.<br />

So what can we do about helping prepare and together<br />

proactively “invest” in the next generation of talented<br />

engineers coming into the workforce? I propose a few<br />

ideas – things we all can consider:<br />

• Don’t wait. Get involved now with educational<br />

platforms that are designed to hit the mark for students.<br />

• Offer up reference designs that are relative to today’s<br />

technology trends.<br />

Zilog Educatio

nal Platform<br />

• Promote special engineering programs that support<br />

the schools. Don’t just throw a few dollars at it; instead,<br />

get your senior engineers to participate to some extent<br />

in those programs.<br />

IXYS and Zilog currently administer an engineering<br />

program in the Philippines with 65 young engineers<br />

who are looking at entire system designs, and who are<br />

designing solutions as teams. Through this program,<br />

students build an understanding about “the entire<br />

process. “ The goal is to get students to understand<br />

that although engineering is a critical part of achieving<br />

optimum results, the process of product development<br />

works best when all aspects of a project are considered<br />

and there is interdependency between different<br />

groups. Students in the program learn that a singular,<br />

linear development process – as opposed to a parallel<br />

process involving interaction with multiple groups –<br />

may ultimately slow a project down (and possibly even<br />

cause critical areas and loss of key reasoning) and in<br />

the end can create new, larger, problems that will hinder<br />

the final result.<br />

These days, when Zilog hosts our “meet and greet”<br />

presentations to students, we first present a holistic<br />

TECH ARTICLE<br />

overview of our university program. The presentation<br />

begins by completely examining the developmental<br />

stage of product development and proceeds to examine<br />

the process all the way through to the launch of the<br />

product and even examines the customers will actually<br />

be buying the product or service. We next define<br />

the entire process and explain how each part of the<br />

organization works in tandem to achieve the best result<br />

of producing a competitive product. All departmental<br />

groups and/or stakeholders are identified as to their<br />

contributions so that the big picture is well-defined.<br />

To cement understanding as to why we’re focusing<br />

on these process points, we also share examples of<br />

missteps or areas in which past programs endured<br />

serious setbacks due to lack of understanding, lack of<br />

communication, and/or plain old sandbox politics.<br />

All of this is food for thought no matter your role, be<br />

it Senior Engineering Manager running your own<br />

development environment, or Executive Director<br />

determining how you will invest in the next generation<br />

of talented engineers. Helping new engineering hires<br />

come to understand the complete developmental<br />

lifecycle as it relates to producing real-world<br />

applications will likely improve the success of your own<br />

products and businesses. The most important resource<br />

in any company is its people. The better engineers,<br />

employers, and teachers understand a company’s<br />

systems and how much more can be accomplished by<br />

working in teams, the need for investment in a broad<br />

education will be clear. Hopefully one day we will see<br />

the results of such education manifest itself in both the<br />

acceleration of new designs and improved end results.<br />

About the Author<br />

Steve Darrough is Vice President of Marketing at<br />

IXYS- Zilog. Steve joined Zilog in 2008. Responsibilities<br />

include management of Zilog marketing presence<br />

from brand to product development and driving the<br />

strategic campaigns for demand creation and growth.<br />

Steve possesses more than twenty years of technical<br />

engineering and marketing management experience,<br />

leading branding and marketing programs. Prior to<br />

coming onboard with Zilog, Steve held marketing<br />

management and technical engineering roles at Intel<br />

Corporations for over 14 years where he had several<br />

teams driving new technologies directly relating to the<br />

current products initiatives, his teams drove worldwide<br />

programs in evangelizing new technologies and<br />

accelerate adoption. Steve has a Marketing Degree<br />

from the University of Oklahoma.<br />

Visit www.eeweb.com<br />

15

1.2A High Efficiency Buck-Boost Regulators<br />

ISL9110, ISL9112<br />

The ISL9110 and ISL9112 are highly-integrated Buck-Boost<br />

switching regulators that accept input voltages either above or<br />

below the regulated output voltage. Unlike other Buck-Boost<br />

regulators, these regulators automatically transition between<br />

operating modes without significant output disturbance.<br />

Both parts are capable of delivering up to 1.2A output current,<br />

and provide excellent efficiency due to their fully synchronous<br />

4-switch architecture. No-load quiescent current of only 35µA<br />

also optimizes efficiency under light-load conditions. Forced<br />

PWM and/or synchronization to an external clock may also be<br />

selected for noise sensitive applications.<br />

The ISL9110 is designed for standalone applications and<br />

supports 3.3V and 5V fixed output voltages or variable output<br />

voltages with an external resistor divider. Output voltages as low<br />

as 1V, or as high as 5.2V are supported using an external resistor<br />

divider.<br />

The ISL9112 supports a broader set of programmable features<br />

that may be accessed via an I 2 C bus interface. With a<br />

programmable output voltage range of 1.9V to 5V, the ISL9112<br />

is ideal for applications requiring dynamically changing supply<br />

voltages. A programmable slew rate can be selected to provide<br />

smooth transitions between output voltage settings.<br />

The ISL9110 and ISL9112 require only a single inductor and very<br />

few external components. Power supply solution size is<br />

minimized by a tiny 3mmx3mm package and a 2.5MHz<br />

switching frequency, which further reduces the size of external<br />

components.<br />

July 13, 2012<br />

FN7649.2<br />

VIN =<br />

1.8V TO 5.5V<br />

C1<br />

10µF<br />

STATUS<br />

OUTPUTS<br />

5<br />

8<br />

7<br />

ISL9110IRTNZ<br />

PVIN<br />

6<br />

VIN<br />

10<br />

MODE<br />

9<br />

EN<br />

BAT<br />

PG<br />

GND<br />

11<br />

VOUT<br />

VOUT =<br />

3.3V/1A<br />

1<br />

LX1<br />

L1<br />

2.2µH<br />

LX2<br />

FB<br />

12 C2<br />

10µF<br />

PGND<br />

3<br />

FIGURE 1. TYPICAL APPLICATION<br />

4<br />

2<br />

Features<br />

• Accepts Input Voltages Above or Below Regulated Output<br />

Voltage<br />

• Automatic and Seamless Transitions Between Buck and Boost<br />

Modes<br />

• Input Voltage Range: 1.8V to 5.5V<br />

• Output Current: Up to 1.2A<br />

• High Efficiency: Up to 95%<br />

• 35µA Quiescent Current Maximizes Light-load Efficiency<br />

• 2.5MHz Switching Frequency Minimizes External Component<br />

Size<br />

• Selectable Forced-PWM Mode and External Synchronization<br />

•I 2C Interface (ISL9112)<br />

• Fully Protected for Overcurrent, Over-temperature and<br />

Undervoltage<br />

• Small 3mmx3mm TDFN Package<br />

Applications<br />

• Regulated 3.3V from a Single Li-Ion Battery<br />

• Smart Phones and Tablet Computers<br />

• Handheld Devices<br />

• Point-of-Load Regulators<br />

Related Literature<br />

• See AN1648 “ISL9110IRTNEVAL1Z, ISL9110IRT7EVAL1Z,<br />

ISL9110IRTAEVAL1Z Evaluation Board User Guide”<br />

• See AN1647 “ISL9112IRTNEVAL1Z, ISL9112IRT7EVAL1Z<br />

EvaluationBoard User Guide”<br />

EFFICIENCY (%)<br />

100<br />

95<br />

90<br />

85<br />

80<br />

V IN = 3V<br />

V IN = 5V<br />

Get the Datasheet and Order Samples<br />

http://www.intersil.com<br />

V IN = 2.5V<br />

75<br />

VOUT = 3.3V<br />

70<br />

0.01 0.05 0.25 1.25<br />

IOUT (A)<br />

FIGURE 2. EFFICIENCY<br />

Intersil (and design) is a registered trademark of Intersil Americas Inc. Copyright Intersil Americas Inc. 2011, 2012<br />

All Rights Reserved. All other trademarks mentioned are the property of their respective owners.

<strong>EEWeb</strong> PULSE<br />

Homemade<br />

Tools Part 1<br />

Whether you’re a full-time engineer or a hobbyist, it’s<br />

important to recognize the value and potential of your<br />

tools. Even more useful than simply understanding<br />

the value and proper use of tools, however, is knowing<br />

how to build your own specialized tools, or ones that<br />

will work well for new, perhaps unforeseen tasks. It is<br />

also helpful to be able to build your own tools if you are<br />

working with limited resources. Homemade tools can<br />

be very valuable items, and knowing how to make your<br />

own tools can free you from many limitations.<br />

18 28 <strong>EEWeb</strong> | | Electrical Engineering Community<br />

In the first part of this miniseries, I will outline the<br />

process of designing and constructing a tool that will<br />

help me pursue a unique task- in this case, remote data<br />

logging. I hope to demonstrate that you can use off-theshelf<br />

kits to build your own specialized, and possibly<br />

more effective, tools.

Paul Clarke<br />

Electronics Design<br />

Engineer<br />

TECH ARTICLE<br />

Visit www.eeweb.com<br />

19 29

<strong>EEWeb</strong> PULSE<br />

The purpose of this exercise is to focus on the process<br />

of building new tools and reusing kits, rather than to<br />

focus on the particular product itself. The particular<br />

tool I am building is simply a vehicle with which I will<br />

demonstrate the process of building new tools.<br />

Figure 1: Magazine Hobby Project<br />

My aims are a little extreme for a data logger—what I<br />

want is a unit that can monitor analog and digital inputs,<br />

but the data that I gather must both be recorded locally<br />

and also available for downloading later. I’d also like to<br />

be able to do this remotely, and to be able to start and<br />

stop the logging at set time intervals. And — of course<br />

— all of this has to be done wirelessly.<br />

What I really need is a box that can be dropped anywhere<br />

– even a place where power is no available—that can<br />

carry out the local instrument recording. Because of<br />

these special requirements, I will need to build a tool of<br />

my own specifications.<br />

The exact number of inputs for my project does<br />

not matter because this is an example project, but<br />

considering how many inputs you need is a good place<br />

to start when building such a tool.<br />

20 <strong>EEWeb</strong> | Electrical Engineering Community<br />

After determining what your needs are, you should look<br />

for a cost-effective platform to build your tool on. For<br />

example, if you want to make your own multi-channel<br />

logic analyzer, you would probably want to consider an<br />

FPGA-based board. In my case, because analog inputs<br />

and data storage are both important, kits such as the<br />

Arduino, AVR, Microchip, and mbed boards jump to<br />

mind. All of these have analog inputs, free programming<br />

environments, available code to add on, and even welldocumented<br />

interfaces for storage devices like USB<br />

flash drives.<br />

Kits like the Microchip development boards tend to be<br />

focused on an application. Programming directly onto a<br />

micro can also be too time-consuming—it will take time<br />

to add libraries, debut, etc. For these reasons it’s easy<br />

to see that the mbed and Arduino platforms stand out<br />

as being quick and easy to work with, and since I want<br />

some storage, the mbed seems to be the best choice for<br />

this my example project. Not only does it have its local<br />

file system that can store data, but it can also be used in<br />

conjunction to an external USB Flash drive – it doesn’t

Figure 2: Mbed<br />

need any hardware besides a physical connector. The<br />

mbed is also quite fast, which should make grabbing<br />

values from the ADC and digital inputs fast too — how<br />

fast is yet to be seen.<br />

Next on my detail list is the need for wireless capability.<br />

There are, once again, lots of different wireless units<br />

available that run on various protocols. For example,<br />

I could use a network like WiFi, but I think this option<br />

would require too much overhead, so instead, a simple<br />

serial communication will work just fine. One of the<br />

most popular serial communication modules around is<br />

the Xbee.<br />

Figure 3: Xbee<br />

Xbee modules allow for complex mesh networks, or as<br />

my project requires, direct point to point. However, this<br />

also means that at the other end of the link, I will need<br />

TECH ARTICLE<br />

the same type of Xbee compatible device to talk to my<br />

computer – though that shouldn’t be a problem as Xbee<br />

compatible devices are easy to make or buy.<br />

My little project is coming together. In Part 2, I’ll take the<br />

next step of starting to build the hardware and outlining<br />

what else I will need as I proceed.<br />

About the Author<br />

Digital Electronics Engineer with strong software skills<br />

in assembly and C for embedded systems. At ebmpapst<br />

I’m developing embedded electronics for thermal<br />

management control solutions for the air movement<br />

industry. These controllers monitor environmental<br />

inputs like Temperature, Humidity and Pressure and<br />

then control the speed of our fans based on various<br />

profiles. Our controls also interface with other systems<br />

over RS232/485 or TCP/IP as well as a host of other user<br />

or control interfaces.<br />

Visit www.eeweb.com<br />

21