The CES EduPack Eco Audit Tool ? A White Paper - MAELabs UCSD

The CES EduPack Eco Audit Tool ? A White Paper - MAELabs UCSD

The CES EduPack Eco Audit Tool ? A White Paper - MAELabs UCSD

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

5. Case studies<br />

An eco audit is a fast initial assessment. It identifies the<br />

phases of life – material, manufacture, transport and use<br />

– that carry the highest demand for energy or create the<br />

greatest burden of emissions. It points the finger, so to<br />

speak, identifying where the greatest gains might be<br />

made. Often, one phase of life is, in eco terms,<br />

overwhelmingly dominant, accounting for 60% or more<br />

of the energy and carbon totals. This difference is so<br />

large that the imprecision in the data and the<br />

ambiguities in the modeling, are not an issue; the<br />

dominance remains even when the most extreme values<br />

are used. It then makes sense to focus first on this<br />

dominant phase, since it is here that the potential<br />

innovative material choice to reduce energy and carbon<br />

are greatest. As we shall see later, material substitution<br />

has more complex aspects – there are trade-offs to be<br />

considered – but for now we focus on the simple audit.<br />

This section outlines case studies that bring out the<br />

strengths and weaknesses of the <strong>Eco</strong> <strong>Audit</strong> <strong>Tool</strong>. Its use<br />

is best illustrated by a case study of extreme simplicity –<br />

that of a PET drink bottle – since this allows the inputs<br />

and outputs to be shown in detail. <strong>The</strong> case studies that<br />

follow it are presented in less detail.<br />

Bottled water. One brand of bottled water is sold in 1<br />

liter PET bottles with polypropylene caps (similar to<br />

that in Figure 8). A bottle weighs 40 grams; the cap 1<br />

gram. Bottles and caps are molded, filled, transported<br />

550km from Evian in the French Alps to London,<br />

England, by 14 tonne truck, refrigerated for 2 days<br />

requiring 1 m 3 of refrigerated space at 4 o C and then<br />

sold. Table 1 shows the data entered in the <strong>Audit</strong> <strong>Tool</strong>.<br />

Figure 8. A 1 litre PET water bottle.<br />

<strong>The</strong> calculation is for 100 units.<br />

What has the tool done? For step 1 it retrieved from the<br />

database the energies and CO2 profiles of the materials<br />

and the processes 3 . What it found there are ranges for<br />

3 Data are drawn from the <strong>CES</strong> <strong>EduPack</strong> Level 2 or 3<br />

database, according to choice.<br />

the values. It created the (geometric) mean of the range,<br />

storing the values shown below:<br />

Material and primary<br />

manufacturing process<br />

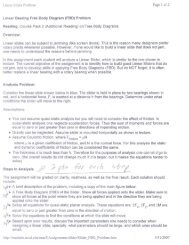

Table 1: <strong>The</strong> inputs<br />

Product name: PET bottle, bill of materials.<br />

Life: 1 year.<br />

Step 1: Materials and manufacture: 100 units<br />

Component<br />

name<br />

Material Process Mass<br />

(kg)<br />

Bottle, 100 units PET Molded 4<br />

Cap, 100 units PP Molded 0.1<br />

Dead weight (100<br />

liters of water)<br />

Step 2: Transport<br />

Stage name Transport<br />

type<br />

Transport of filled<br />

bottles<br />

Water 100<br />

Embodied<br />

energy<br />

(MJ/kg)<br />

Distance (km)<br />

14 tonne truck 550<br />

Step 3: Use phase: static mode – refrigeration i<br />

Energy input<br />

and output<br />

Electric to<br />

mechanical<br />

Power<br />

rating<br />

(kw)<br />

Step 4: Energy selected.<br />

Usage<br />

(hr / day)<br />

CO 2<br />

footprint<br />

(kg/kg)<br />

PET, material 84 2.3<br />

PP, material 95 2.7<br />

Polymer molding 6.8 0.53<br />

Usage<br />

(days /<br />

year)<br />

0.12 24 2<br />

i <strong>The</strong> energy requirements for refrigeration, based on A-rated<br />

appliances are 10.5 MJ/m 3 .day for refrigeration at 4 o C and<br />

13.5 MJ/m 3 .day for freezing at -5 o C. <strong>The</strong> use energy is chosen<br />

to give the value for refrigeration.<br />

It then multiplied these by the mass of each material,<br />

summing the results to give total energy and carbon.<br />

For step 2 it retrieved the energy and CO2 profile of the<br />

selected transport mode from a look-up table (see<br />

Appendix A), finding:<br />

© 2009 Granta Design Ltd. 7 MFA, 18/02/2009